Summary of V400

Page 1

Installation manual swing gate automation.

Page 2

Centurion systems has been manufacturing automatic gate systems since 1987, and is committed to providing reliable, cost effective solutions in the field of access automation. Centurion strives to give service and backup second to none. Our engineers are available to give sales support, installation...

Page 3

Page 3 table of contents table of contents important safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 general description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4: Warnings For The Installer

Important safety instructions important safety instructions page 4 to ensure the safety of people, it is important that you read all the following instructions. Incorrect installation or incorrect use of the product could cause serious harm to people. The installer, being either professional or diy,...

Page 5: Lightning Protection

Page 5 the vector operator has been designed to safely and cost-effectively automate a wide variety of swing gates, from single light domestic swing gates to heavy industrial double swing gates. The fail-safe and fully redundant position and collision detection system has been designed and tested to...

Page 6: Overall Dimensions

Page 6 overall dimensions 1400mm extended 1400mm extended 1000mm retracted 1000mm retracted 400mm stroke 400mm stroke model v400 100 95mm all dimensions shown in millimetres model v500 1600mm extended 1600mm extended 1100mm retracted 1100mm retracted 100 95mm all dimensions shown in millimetres 500m...

Page 7: Operator V400/v500

Power configurations: extention/retraction (no load): max. Output force: max. Operations (day): max. Number of continuous operations: standby operations: standby period: ½ day 1 day 2 days typical gate opening/ closing time: operating temp. Range: housing protection: mass of operator: operator strok...

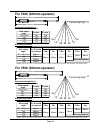

Page 8: Allowable Gate Mass

Page 8 allowable gate mass maximum allowable gate mass for v400 operator: gate swing angle up to up to up to up to up to up to 1.5m 2m 2.5m 3m(#1) 3.5m(#1) 4m(#1) 90° 500kg 500kg 500kg 360kg 260kg 200kg 100° 500kg 500kg 388kg 160kg 190kg 150kg 110° 500kg 306kg 198kg 130kg 120° 180kg 100kg 65kg (#1 -...

Page 9: (Vec40000V2 & Vec50000V2)

Item description qty. Part no. 1 vector gate operator 1 1050m00000 2 wall bracket (standard) 1 1050m20000 3 wall bracket pin 1 domcen0069 4 gate bracket 1 1050m27000 5 gate bracket pin 1 1050m05000 6 origin body 1 1050m0161m 7 gate operator keys 1 gtkeytg01 8 gate warning decal 2 labelgate1 9 cap sc...

Page 10

Page 10 control box including charger & controller (domestic) veccad00v2 / (light industrial) veccad01v2 figure 3 o ptional accessories continued. Item description qty. Part no. 1 wall adaptor plate 2 1050m34000 2 m10x20 countersunk screw 2 b123201025 3 m10 hexnuts 2 n120110000 4 vector wall adaptor...

Page 11

Item description qty. Part no. 1 wall bracket (high security) 1 1050m3000d 2 padlock 2 m-pltri263 4 vector high security kit packing leaflet 1 doc1050d05 high security kit (optional) vechsk00v1 page 11 1 2 3 item description qty. Part no. 1 vector securing plate (short) 1 1050m3200d 2 vector securin...

Page 12

Page 12 item description qty. Part no. 1 gate bracket spreader plate 1 1050m03500 2 m6x12 countersunk screw 2 b123206010 3 m6 hexnuts 2 n1202060ss 4 vector gate adaptor kit packing leflet 1 doc1050d07 gate adaptor kit (optional) vecgak00v1 1 2 3 4 item description qty. Part no. 1 piston guard 1 1050...

Page 13

Required tools & equipment required tools & equipment figure 4 required tools and equipm ent spanner 17m m , 15m m preferably socket set screw drivers 6m m philips 3.5 flat crim ping tool and pin lugs pliers side cutters ham m er 2 x g-clam ps electric drilling m achine m easuring tape hacksaw angle...

Page 14: Strength Of The Pillar

Site considerations site considerations page 14 in order to ensure a reliable and durable installation thought should be given to: strength of the pillar for reliable operation it is important to ensure that the way the operator is secured to the wall takes into account the strength of the pillar, t...

Page 15: The Mechano Kit

Page 15 strength of the gate and gate bracket the gate adaptor kit both strengthens the connection to the gate, and also allows for more flexibility when mounting the bracket to the gate: the mechano kit this kit is useful when fitting vectors to existing installations, and also makes adjustments ea...

Page 16

Figure 5 m inim um installation requirem ents install the gate operator only if: 1. It will not pose a hazard to the public. 2. There is sufficient clearance to a roadway and/or public thoroughfares. 3. The installation will meet all municipal and/or local authority requirements once completed. 4. T...

Page 17

Cabling requirements cabling requirements figure 6 cabling requirem ents page 17 1. 220v ac mains cable via mains isolator or switch (3 core lne 0,5mm²)*, optional keypad (if required, 3 core 2 or 0,5mm multi-stranded). Low voltage 16v ac battery charger 6. Optional infrared beams or safety edge 2 s...

Page 18

1. Determine gate opening angle and direction of operator (inward or outward). Alternatively the swing angle can be deter- mined more accurately with the process detailed on page 37. 120° 100° 110° 90° 80° 70° 60° open closed e l g n a g n i w s e t a m i t s e 2. Determine a suitable height for the...

Page 19

4. Secure the bracket to the wall with the most appropriate means. See page 14 for site considerations. 5. Fit the gate bracket to the operator. 1 or 2 turns 6. Fit the motor end of the operator to the wall bracket. 7. Open the gate fully and temporarily clamp the gate bracket to the gate. Determine...

Page 20: Fasten Gate Bracket to Gate

Or or 8. Unlock the operator and swing the gate closed. 9. Remove the pin and the operator from the bracket, check that there are at least one or two turns of the actuator before it is fully extended. 10. Secure the gate bracket using the most appropriate means. 11. Fit operator, wall bracket pins a...

Page 21: Adjust Origin Clamp

Or 13.Unlock the operator and open the gate fully 14. Slide the origin clamp along the actuator tube, right up to the operator. Secure in place with an allen key tighten properly. 15. Attach warning decals to the gate as shown. 2 1 adjust origin clamp (nb - not required for outward swinging gates) p...

Page 22: Inward Swing Gate Setup

Figure 7 position inward o pening g ates page 22 operator installation operator installation b a inward swing gate setup b a for gates opening 90° or less: for gates opening m ore than 90°: ensure thatthe gate doesnotexceed the gatem assspeci fi cati onsonpage8. Forbestsecurity (butsl oweroperati on...

Page 23: For V400 (400Mm Operator)

Alternative positions a and b must each be greater than gate swing a+b should up to up to up to up to up to up to angle not exceed 1.5m 2m 2.5m 3m 3.5m 4m 60° - 90° or less 465mm 100° 400mm 110° 340mm 120° 285mm recommended positions (only for a 2.5m gate or shorter) a value b value 90° or less 220 ...

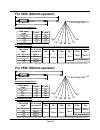

Page 24: Outward Swing Gate Setup

Outward swing gate setup b a make up bracket to suit for gates opening 90° or less: b a make up bracket to suit for gates opening m ore than 90°: figure 8 position o utward o pening g ates page 24 ensure thatthe gate doesnotexceed the gatem assspeci fi cati onsonpage8. Outward openi ng swi ng gates ...

Page 25: For V400 (400Mm Operator)

Page 25 alternative positions a and b must each be greater than gate swing a+b should up to up to up to up to up to up to angle not exceed 1.5m 2m 2.5m 3m 3.5m 4m 60° - 90° or less 465mm 100° 400mm 110° 340mm 120° 285mm recommended positions (only for a 2.5m gate or shorter) a value b value 90° or l...

Page 26: Secure Control Box to Wall

Electrical set-up electrical set-up warning 1. Always check that the isolator in the mains supply to the gate is in the off position, before doing any work. 2. Ensure that all low voltage systems (less than 42.4v) are suitably protected from damage, by disconnecting all sources of power such as char...

Page 27: Setting The Limits

Page 27 light light batt + batt - mtr m+ mtr m - mtr s+ mtr s - com frx lit led com aux 12v com saf sol 4. Check that the charger and battery are connected to the controller. Ensure the battery polarity is correct. 5. Switch on the mains supply (via isolator). 6. Ensure that both the controller and ...

Page 28

Figure 10 provides the full menu of features that can be setup on the system. Explanation of each feature is provided in the section “controller features”. When setting up the vector system via the lcd display, all the steps that have to be followed are clearly provided via the display. It is only n...

Page 29

Menu navigation map menu navigation map page 29 figure 10 part a of “m enu navigation m ap” setting limits: 1 safety: 2 autoclose: 3 modes of operation: 4 run profile: 5 ir beams: 6 setup wizard mtrm collision force: 2.1 mtrs collision force: 2.2 collision count: 2.3 autoclose status: 3.1 autoclose ...

Page 30

Page 30 figure 10 part b of “m enu navigation m ap” pedestrian open position: 7.1 pedestrian autoclose time: 7.2 pedestrian pre-open delay: 7.3 pedestrian pre-close delay: 7.4 lock enabled status: 8.1 lock type: 8.2 release time: 8.3 pre-release time: 8.4 lock location: 8.5 lock drive (ac/dc): 8.6 c...

Page 31

Page 31 § refer to table 1 on page 39 for schedule of factory defaults for each feature described below. Controller features controller features safety (collision force) - menu 2 mtrm/s collision force if the gate is obstructed, the internal collision circuitry will activate. The response of the sys...

Page 32

Page 32 3 4.

Page 33

If “short stop” is correctly set, pcm will cut off when gates reach closed position, in line line of gates when closed m gate closes slightly behind s gate (leaf delay) s gate closes first mechanical lip 1 * m gate continues to close “short stop” * s gate stops slightly before closed position 2 * * ...

Page 34

Page 34 5 inside closing beam o utside closing beam typic a l c lo sin g b ea m in sta llatio n g ates w ill not close.

Page 35

Page 35 outside closing beam inside closing beam opening beam irbo = irbc (com bi ne i nsi de cl osi ng beam wi th openi ng beam = save on one beam ) intruder breaks beam while loitering at gate = = al arm adj ustab l e beam brok en ti m e = = al arm + + intrud er bl ocks beam.

Page 36

Page 36 7 8 6.

Page 37

Page 37 9.

Page 38

Page 38 10

Page 39

Factory defaults schedule factory defaults schedule page 39 table 1 factory d efaults schedule parameter description unit min default max south african standard profile auto-close enabled auto-close time mode of operation motor m opening force pcm enabled leaf delay enabled motor m closing force pcm...

Page 40

Page 40 parameter description unit min default max ped open distance gate lock enabled pirac enabled irb ambush alarm enabled irbo starts wire-less** courtesy light time diagnostic screen enabled remote menu locked gate lock type saf common enabled irb ambush alarm hold-off time irbc starts wire-les...

Page 41

Page 41 description of terminal functions description of terminal functions.

Page 42

Page 42.

Page 43: During Normal Operation

Page 43 led indicator lights led indicator lights the controller is fitted with diagnostic lights (leds) that assist with the set-up and maintenance of the gate. Table 2 provides a description and purpose of the indicator lights. Refer to figure 11 below for location. During normal operation on off ...

Page 44: Fuse Protection

Charger and pillar light connections charger and pillar light connections page 44 the following protection fuses are provided on the system: fuse protection item main controller motor circuit - fuse per channel light circuit auxiliary supply charger mains input type automotive fuse (25x7) 5x20mm ele...

Page 45

Use this procedure to accurately determine the gate opening angle: determine gate swing angle determine gate swing angle use gate sw ing angle of 90 degrees 100 degrees 110 degrees 120 degrees 60 degrees 70 degrees 80 degrees 1 351mm 1 474mm 1 587mm 1 687mm 1 000mm value z from ... 1 075mm 1 218mm 1...

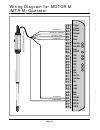

Page 46

Figure 13 w iring d iagram for m otor m master slave black black red red blue blue purple purple black black red red blue blue purple purple s sens1 s sens2 m sens1 m sens2 light light batt + batt - mtr m+ mtr m - mtr s+ mtr s - sens+ sens- safe cls safe opn com lck/stp trg ped com frx lit led com a...

Page 47

Figure 14 w iring d iagram for m otor s 15 15 15 15 ssens1 ssens2 msens1 msense2 sens+ sens- safclo safope com lck/stp trg ped com frx lit led com aux12v comsaf sol light light batt+ bat- mtrm+ mtr— mtrs+ mtrs- black black red red blue blue purple purple purple purple blue blue s sens1 s sens2 m sen...

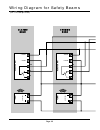

Page 48

Com nc no o pen in g b ea m +12v/24v com nc no irb receiver - 12v/24v 12v or 24v irb tx c lo sin g b ea m +12v/24v irb receiver - 12v/24v 12v or 24v irb tx wiring diagram for safety beams wiring diagram for safety beams (for ce compliance) (for ce compliance) page 48.

Page 49

Page 49 s sens1 s sens2 m sens1 m sens2 light light batt + batt - mtr m+ mtr m - mtr s+ mtr s - sens+ sens- safe cls safe opn com lck/stp trg ped com frx lit led com aux 12v safe com sol.

Page 50

Wiring diagram for other inputs wiring diagram for other inputs neg +12v/24v com nc no radio receiver remote control circuitry neg +12v com nc no loop loop detector free exit circuitry holiday lockout keyswitch (normally closed) pillar light pushbutton (normally open) pedestrian keyswitch (normally ...

Page 51

Page 51 solenoid or strike lock s sens1 s sens2 m sens1 m sens2 light light batt + batt - mtr m+ mtr m - mtr s+ mtr s - sens+ sens- safe cls safe opn com lck/stp trg ped com frx lit led com aux 12v safe com sol.

Page 52

Page 52 wind speeds for which operator will still operate the gate (for v400 or v500 operators) for a 25% covered gate: (palisades, etc.) x 1.8m high value of gate lengths: a or b dimension up to up to up to up to up to up to once installed. #1 1.5m 2m 2.5m 3m(#2) 3.5m(#2) 4m(#2) 100mm 94km/h 66km/h...

Page 53

Page 53 installation handover installation handover once the installation has been successfully completed and tested, it is important for the installer to explain the operation and safety requirements of the system. Never assume the user knows how to safely operate an automated gate. Even if the use...

Page 54

Sharecall 0860-centurion (sharecall number applicable when dialed from within south africa only) (omit (0) when dialing from outside south africa) or visit www.Centsys.Co.Za for details of your nearest agent for technical support, contact: south a frican b ranches and r egional d istributors: o ther...