- DL manuals

- Vega

- Controller

- plicscom

- Operating Instructions Manual

Vega plicscom Operating Instructions Manual

Summary of plicscom

Page 1

Operating instructions indicating and adjustment module plicscom.

Page 2: Contents

Contents 1 about this document 1.1 function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 target group . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 symbolism used . . . . . . . . . . . . . . . . . . . . . . . 4 2 for your safety 2.1 authorised personnel. . . . . . . . ...

Page 3

7 dismounting 7.1 dismounting steps . . . . . . . . . . . . . . . . . . . . . . 34 7.2 disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 8 supplement 8.1 technical data. . . . . . . . . . . . . . . . . . . . . . . . . 35 8.2 dimensions . . . . . . . . . . . . . . . . . . . . . . ...

Page 4: 1 About This Document

1 about this document 1.1 function this operating instructions manual has all the information you need for quick setup and safe operation. Please read this manual before you start setup. 1.2 target group this operating instructions manual is directed to trained, qualified personnel. The contents of t...

Page 5: 2 For Your Safety

2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the operator. For safety and warranty reasons, any internal work on the instruments must be carried out only by personnel a...

Page 6

The parameter adjustment of the basic sensor functions is independent of the software version. The range of available functions depends on the respective software version of the individual components. You can view all software histories on our website www.Vega. Com. Make use of this advantage and ge...

Page 7: 3 Product Description

3 product description 3.1 configuration the scope of delivery encompasses: l indicating and adjustment module l documentation - this operating instructions manual - supplementary instructions manual "heating for indi- cating and adjustment module" (optional) the indicating and adjustment module is eq...

Page 8

1 2 fig. 2: rear of the indicating/adjustment module 1 integrated seal ring 2 gold plated contact paths 3.2 principle of operation the indicating and adjustment module is used for measured value indication, adjustment, and diagnostics for the following vega plics ® sensors: l vegapuls series 60 l ve...

Page 9

For instruments with national approvals such as e.G. According to fm and csa, this function only available at a later date. The optional heating requires its own power supply. You can find further details in the supplementary instructions manual "heating for indicating and adjustment module". 3.3 ope...

Page 10: 4 Mounting

4 mounting 4.1 mounting steps plicscom can be mounted or dismounted at any time. It is not necessary to interrupt the power supply. To mount, proceed as follows: 1 unscrew the housing cover 2 place plicscom in the required position to the electronics information: four different positions are possible...

Page 11: 5 Setup

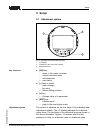

5 setup 5.1 adjustment system 1.1 2 3 1 fig. 4: indicating and adjustment elements 1 lc display 2 indication of the menu item number 3 adjustment keys l [ok] key: - move to the menu overview - confirm selected menu - edit parameter - save value l [->] key to select: - menu change - list entry - selec...

Page 12

Indication is triggered. Any values not confirmed with [ok] will not be saved. 5.2 overview continuously measuring sensors for level and pressure have various functions. Hence they can be adapted in an optimum way to the respective application. The functions are structured in a clear menu form (see s...

Page 13

▶ basic adjustment 1 indication diagnostics service info menu section, basic adjustment to damp process-dependent measured value fluctuations, you have to set an integration time of 0 … 999 s in this menu item. Depending on the sensor type, the factory setting is 0 s or 1 s. Damping 0 s in this menu ...

Page 14

If a linearisation curve is selected, the measuring signal is no longer compulsorily linear proportional to the level. This must be taken into consideration by the user, particularly when adjusting the switching point on the level switch. In the menu item "sensor-tag" you can edit a twelve-digit mea...

Page 15

Menu section, diagnostics min. And max. Measured values are saved in the sensor. The values are displayed in the menu item "peak values". L min. And max. Distance in m(d): radar, guided microwave, ultrasonic sensors l min. And max. Pressure: pressure transmitter 1) l min. And max. Temperature: ultra...

Page 16

With ultrasonic and radar sensors, the "false echo curve" represents the saved false echoes (see menu "service") of the empty vessel with signal strength in "db" over the measuring range. With all plics ® sensors, up to 3000 measured values (depending on the sensor) are recorded when starting a "tre...

Page 17

Echo curve menu section, service in this menu item you simulate a user-defined level or pressure value via the current output. This allows you to test the signal path, e.G. Through connected indicating instruments or the input card of the control system. The following simulation variables are availab...

Page 18

- reset the values modified with the indicating and adjustment module to the sensor-specific basic setting l factory setting - as basic adjustment, but also reset of special parameters to the default values 2) l peak values measured value and temperature 3) - reset of the min./max. Values of pressure,...

Page 19

L pycckuu l japanese l chinese language deutsch with this function l load parameter adjustment data from the sensor into the indicating and adjustment module l write parameter adjustment data from the indicating and adjustment module into the sensor the data are permanently saved in an eeprom memory...

Page 20

In this menu item, the pin is activated/deactivated perma- nently. Entering a 4-digit pin protects the sensor data against unauthorized access and unintentional modifications. If the pin is activated permanently, it can be deactivated temporarily (i.E. For approx. 60 min.) in any menu item. The instr...

Page 21

Sensor characteristics display now? 5.4 functions - 4 … 20 ma/hart the 4 … 20 ma/hart special functions are briefly described in this paragraph. The respective range of functions of the indicating and adjustment module is determined by the sensor and the sensor software revision. In the menu item "di...

Page 22

L with pressure, displayed value "pressure" or "height" means: presentation of the measured value in the selected adjustment unit, e.G. Bar or m. Displayed value scaled ▼ anzeigeeinheit volumen ▼ l ▼ scaling 0 % = 0.0 l 100 % = 100.0 l menu section, service in the menu item "current output" you dete...

Page 23

Current output output mode: 4-20 ma ▼ failure mode: 22 ma ▼ min. Current 3.8 ma ▼ certain sensors are suitable for use according to iec 61508. For this use, you have to activate the menu item "sil". This influences the following menu items: l menu items "current output" in "failure mode", "hold value...

Page 24

Menu section, basic adjustment level and pressure sensors operate as slaves on the profibus pa. To be identified as a bus participant, each sensor must have a unique address. Each instrument is delivered with address 126. With this address, it can at first be connected to an existing bus. However, the ...

Page 25

L sv1 (secondary value 1): pressure or height value before adjustment l sv2 (secondary value 2): percentage value after the adjustment l pv (primary value): linearised percentage value l pa-out (value after passing the function block): pa output l temperature in the menu item "display" you can define...

Page 26

The following displayed values are available in "out-scale unit": l pressure (only with pressure transmitters) l height l mass l flow l volume l others (no unit, %, ma) in the menu item "pv-out-scale", the requested numerical value with decimal point is entered for 0 % and 100 % of the measured valu...

Page 27

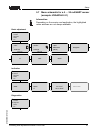

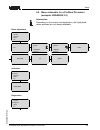

5.7 menu schematic for a 4 … 20 ma/hart sensor (example: vegapuls 61) information: depending on the version and application, the highlighted menu windows are not always available. Basic adjustment 1 ▶ basic adjustment indication diagnostics service info 1.1 min. Adjustment 0.00 % = 10,000 m(d) 8,000...

Page 28

3.1 pointer distance min.: 0.234 m(d) distance max.: 5.385 m(d) 3.2 meas. Reliability 8 db sensor status ok 3.3 curve selection echo curve 3.4 echo curve presentation of the echo curve service 4 basic adjustment indication diagnostics ▶ service info 4.1 gating out of false signals jetzt ändern? 4.2 ...

Page 29

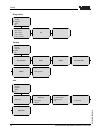

5.8 menu schematic for a profibus pa sensor (example: vegaflex 61) information: depending on the version and application, the highlighted menu windows are not always available. Basic adjustment 1 ▶ basic adjustment indication diagnostics service info 1.1 sensor address 000 1.2 min. Adjustment 0.00 % ...

Page 30

3.1 pointer distance min: 0.580 m(d) dist. Max: 16.785 m(d) 3.2 sensor status ok 3.3 curve selection echo curve 3.4 echo curve presentation of the echo curve service 4 basic adjustment indication diagnostics ▶ service info 4.1 sensor 5.00 m rod 4.2 application liquid standard (dk ≥2) 4.3 gating out ...

Page 31

5.9 menu schematic for a foundation fieldbus sensor (example: vegabar 52) information: menu schematic for a foundation fieldbus sensor (example: vegabar 52) depending on the version and application, the highlighted menu windows are not always available. Basic adjustment 1 ▶ basic adjustment indicati...

Page 32

Diagnostics 3 basic adjustment indication ▶ diagnostics service info 3.1 pointer tmin.: -12.5 °c tmax.: +85.5 °c p-min.: -0.58 bar p-max.: 16.765 bar 3.2 sensor status ok 3.3 trend recording service 4 basic adjustment indication diagnostics ▶ service info 4.1 simulation start simulation? 4.2 reset r...

Page 33

6 maintenance and fault rectification 6.1 maintenance when used as directed in normal condition, the indicating and adjustment module is maintenance-free. 6.2 instrument repair if a repair is necessary, please proceed as follows: you can download a return form (23 kb) in the internet from our homepag...

Page 34: 7 Dismounting

7 dismounting 7.1 dismounting steps warning: before dismounting, be aware of dangerous process con- ditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in rev...

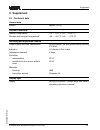

Page 35: 8 Supplement

8 supplement 8.1 technical data general data weight approx. 150 g ambient conditions ambient temperature -15 … +70 °c (+5 … +158 °f) storage and transport temperature -40 … +80 °c (-40 … +176 °f) indicating and adjustment module power supply and data transmission through sensor via gold-plated slidi...

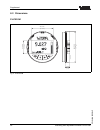

Page 36

8.2 dimensions plicscom 27,6mm (1 3 / 32 ") ø66,3mm (2 39 / 64 ") 45,1mm (1 25 / 32 ") 9,7mm ( 3 / 8 ") fig. 5: plicscom supplement 36 indicating and adjustment module plicscom 27835 -en -070123.

Page 37

8.3 industrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com. Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte. ...

Page 38

Supplement 38 indicating and adjustment module plicscom 27835 -en -070123.

Page 39

Supplement indicating and adjustment module plicscom 39 27835 -en -070123.

Page 40

Vega grieshaber kg am hohenstein 113 77761 schiltach germany phone +49 7836 50-0 fax +49 7836 50-201 e-mail: info@de.Vega.Com www.Vega.Com iso 9001 all statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems correspond to the...