- DL manuals

- Vega

- Transmitter

- VEGABAR 14

- Operating Instructions Manual

Vega VEGABAR 14 Operating Instructions Manual

Summary of VEGABAR 14

Page 1

Operating instructions vegabar 14 d ocument id: 22441 p rocess pressure.

Page 2: Contents

Contents 1 about this document 1.1 f unction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 t arget group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 s ymbolism used. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2 for your safety 2.1 a uthor...

Page 3

9.2 d imensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 supplementary documentation information: s upplementary documents appropriate to the ordered version come with the delivery. You can find them listed in chapter "product description". Instructions manuals for accessories...

Page 4: About This Document

1 about this document 1 .1 function t his operating instructions manual provides all the information you need for mounting, connection and setup as well as important instructions for maintenance and fault rectification. Please read this information before putting the instrument into operation and kee...

Page 5: For Your Safety

2 for your safety 2 .1 authorised personnel a ll operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. D uring work on and with the device the required personal protective equipment must always be worn. 2...

Page 6

2 .5 safety label on the instrument t he safety approval markings and safety tips on the device must be observed. 2 .6 ce conformity t his device fulfills the legal requirements of the applicable ec guidelines. By attaching the ce mark, vega provides a confirmation of successful testing. You can find t...

Page 7: Product Description

3 product description 3 .1 structure t he scope of delivery encompasses: l vegabar 14 process pressure transmitter l depending on the version, with plug connector, direct cable outlet or plug connector with connection cable l d ocumentation - this operating instructions manual - e x-specific "safety ...

Page 8

T he sensor element is the certec ® measuring cell with rugged ceramic diaphragm. The process pressure causes a capacitance change in the measuring cell via the ceramic diaphragm. This change is converted into an appropriate output signal and outputted as measured value. T wo-wire electronics 4 … 20...

Page 9: Mounting

4 mounting 4 .1 general instructions m ake sure that all parts of the instrument exposed to the process, in particular the sensor element, process seal and process fitting, are suitable for the existing process conditions. These include above all the process pressure, process temperature as well as t...

Page 10

Fig. 2: installation of vegabar 14 10 vegabar 14 4 m ounting 22441 -en -111006.

Page 11

5 connecting to power supply 5 .1 preparing the connection a lways keep in mind the following safety instructions: l c onnect only in the complete absence of line voltage l i f voltage surges are expected, install overvoltage arresters tip: w e recommend vega overvoltage arrester Üsb 62-36g.X. I n h...

Page 12

Warning: w ithin galvanic plants as well as vessels with cathodic corrosion protection there are considerable potential differences. Considerably equalisation currents can be caused via the cable scrren when the screen is earthed on both ends. To avoid this, the cable screen must only connected to gr...

Page 13

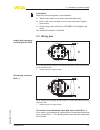

2 3 1 4 fig. 4: connection to the screw terminals 1 cable gland 2 plug housing 3 plug insert 4 plug seal 7 s nap the plug insert into the plug housing and insert the sensor seal 8 p lug the plug insert with seal to vegabar 14 and tighten the screw t he electrical connection is finished. P roceed as f...

Page 14

4 3 2 1 3 2 1 fig. 5: loosen the plug insert 1 plug insert 2 strain relief 3 cable gland 4 plug housing 5 r emove approx. 5 cm of the cable mantle, strip approx. 1 cm insulation from the individual wires 6 l ead the cable through the cable gland into the plug housing 7 c onnect the wire ends to the ...

Page 15

Information: n ote the correct arrangement, see illustration 9 t ighten the screws on the strain relief and cable entry 10 h ook in the cover and push onto the plug connection, tighten cover screw 11 p lug the plug insert with seal to vegabar 14 and tighten the screw t he electrical connection is fin...

Page 16

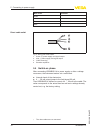

Wire colour connector b rown 1 w hite 2 b lue 3 b lack 4 4 1 2 2 3 fig. 9: wiring plan cable outlet 1 ) 1 brown (+) power supply and signal output 2 blue (-) power supply and signal output 3 cable screening 4 breather capillaries 5 .4 switch-on phase a fter connecting vegabar 14 to power supply or a...

Page 17: Set Up

6 set up 6 .1 setup steps a fter mounting and electrical connection, vegabar 14 is ready for operation. Vegabar 14 delivers a current of 4 … 20 ma corresponding to the actual process pressure. F urther settings are not necessary. Vegabar 14 17 6 s et up 22441 - en -111006.

Page 18

7 maintenance and fault rectification 7 .1 maintenance i f the instrument is used properly, no special maintenance is required in normal operation. 7 .2 remove interferences t he operator of the system is responsible for taking suitable measures to rectify faults. Vegabar 14 offers maximum reliability...

Page 19

? C urrent signal 22 ma l electronics module or measuring cell defective à exchange the instrument or send it in for repair i n ex applications, the regulations for the wiring of intrinsically safe circuits must be observed. D epending on the reason for the fault and the measures taken, the steps de...

Page 20: Dismounting

8 dismounting 8 .1 dismounting steps warning: b efore dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. T ake note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in re...

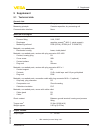

Page 21: Supplement

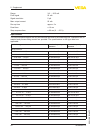

9 supplement 9 .1 technical data general data p arameter, pressure g auge pressure, absolute pressure, vacuum m easuring principle c eramic-capacitive, dry measuring cell c ommunication interface n one materials and weights m aterials, wetted parts - p rocess fitting 316l, pvdf - d iaphragm sapphire ...

Page 22

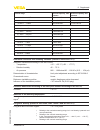

R ange 3.8 … 20.5 ma f ault signal 22 ma s ignal resolution 5 µa m ax. Output current 22 ma r un-up time approx. 2 s d ead time ≤ 10 ms s tep response time ≤ 20 ms (0 … 63 %) input variable t he overload specifications are only an overview and refer to the measuring cell. Limitations due to material ...

Page 23

Nominal range overload capacity, max. Pressure overload capacity, min. Pressure -1 … 25 bar/-1 … 2.5 mpa 130 bar/13 mpa -1 bar/-100 kpa -1 … 40 bar/-1 … 4 mpa 200 bar/20 mpa -1 bar/-100 kpa -1 … 60 bar/-1 … 6 mpa 200 bar/20 mpa -1 bar/-100 kpa a bsolute pressure 0 … 1 bar/0 … 100 kpa 35 bar/3500 kpa...

Page 24

Ambient conditions a mbient temperature - v ersion with plug connector -20 … +85 °c (-4 … +185 °f) - v ersion with cable outlet -20 … +60 °c (-4 … +140 °f) s torage and transport temperature - v ersion with plug connector -40 … +100 °c (-40 … +212 °f) - v ersion with cable outlet -40 … +60 °c (-40 …...

Page 25

1000 500 750 250 8 14 12 10 16 18 20 22 24 26 28 30 Ω v 2 1 3 fig. 10: voltage diagram 1 voltage limit 2 operating voltage 3 max. Load electrical protective measures p rotection rating 8) - w ith plug m12 x 1 or according to iso 4400 ip 65 - with direct cable outlet ip 67 p rotection class iii o ver...

Page 26

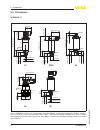

9 .2 dimensions vegabar 14 gv 151 mm (5 15 / 16 ") 34 mm (1 11 / 32 ") 23 mm ( 29 / 32 ") 3 mm ( 1 / 8 ") 49,5 mm (1 61 / 64 ") 36 mm (1 27 / 64 ") ø 38 mm (1 1 / 2 ") ø 3 mm ( 1 / 8 ") ø 6 mm ( 1 / 4 ") sw27 g½a 38 mm (1 1 / 2 ") 25 mm ( 63 / 64 ") 124 mm (4 7 / 8 ") 31 mm (1 7 / 32 ") 20 mm ( 25 /...

Page 27

9 .3 industrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com . Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte...

Page 28

Iso 9001 a ll statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems correspond to the information avail- able at the time of printing. © vega g rieshaber kg, schiltach/germany 2011 s ubject to change without prior notice 22...