- DL manuals

- Vega

- Switch

- vegacap 62

- Operating Instructions Manual

Vega vegacap 62 Operating Instructions Manual

Summary of vegacap 62

Page 1

O perating i nstructions vegacap 62 with two - wire output.

Page 2: Ontents

C ontents 1 a bout this document 1 . 1 f unction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1 . 2 t arget group . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1 . 3 s ymbolism used . . . . . . . . . . . . . . . . . . . . . . . 4 2 f or your safety 2 . 1 a uthorised personnel ...

Page 3

8 d ismounting 8 . 1 d ismounting procedure . . . . . . . . . . . . . . . . . . 26 8 . 2 d isposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 9 s upplement 9 . 1 t echnical data . . . . . . . . . . . . . . . . . . . . . . . . . 27 9 . 2 d imensions . . . . . . . . . . . . . . . . ....

Page 4: Bout This Document

1 a bout this document 1 . 1 f unction t his operating instructions manual has all the information you need for quick setup and safe operation . P lease read this manual before you start setup . 1 . 2 t arget group t his operating instructions manual is directed to trained , quali fi ed personnel . T...

Page 5: Or Your Safety

2 f or your safety 2 . 1 a uthorised personnel a ll operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the operator . F or safety and warranty reasons , any internal work on the instruments must be carried out only by per...

Page 6

2 . 6 s afety information for e x areas p lease note the e x - speci fi c safety information for installation and operation in e x areas . T hese safety instructions are part of the operating instructions manual and come with the e x - approved instruments . 2 . 7 m anufacturer declaration i n confor...

Page 7

L m ount the instrument in such a position that the sensor cannot touch the vessel wall or vessel installations . K eep the in fl uences of product movements in the vessel in mind . L t he surface temperature on the housing must not exceed the ingnition temperature of the concerned explosive atmosphe...

Page 8: Roduct Description

3 p roduct description 3 . 1 c on fi guration t he scope of delivery encompasses : l vegacap 62 level sensor l d ocumentation - this operating instructions manual - e x speci fi c safety instructions ( with e x versions ), if necessary further certi fi cates vegacap 62 consists of the following compone...

Page 9

T he level switch can also be used in non - conductive liquids such as e . G . Oil . T ypical applications are over fi ll and dry run protection . T he capacitive measuring principle places no special require - ments on installation . H ence , many di ff erent applications can be equipped with vegacap...

Page 10

3 . 3 a djustment t he probe can be adapted to the dielectric constant of the product directly on the electronics module . A switching command can be triggered when the probe is covered or laid bare . O n the electronics module you will fi nd the following indicating and adjustment elements : l s ign...

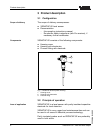

Page 11: Ounting

4 m ounting 4 . 1 g eneral instructions i n general , vegacap 62 can be mounted in any position . T he instrument must be mounted in such a way that the probe is at the height of the requested switching point . W ith screwed versions , the housing must not be used for screwing in ! T ightening can c...

Page 12

4 . 2 m ounting information d ue to agitators , vibrations or similar , the level switch can be subjected to strong lateral forces . F or this reason , do not use an overly long probe for vegacap 62 , but check if you can mount a short level switch on the side of the vessel in horizontal position . ...

Page 13

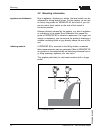

T he probe should protrude into the vessel to avoid buildup . F or that reason , avoid using mounting bosses for fl anges and screwed fi ttings . T his applies particularly to use with adhesive products . I n silos with bulk solids , material cones can form which change the switching point . P lease k...

Page 14

D d 6 1 2 3 f ig . 6 : f illing in the center , emptying laterally 1 vegacap 62 2 e mptying opening 3 f illing opening 14 vegacap 62 - with two - wire output m ounting 30007 - en - 060222.

Page 15: Onnecting To Power Supply

5 c onnecting to power supply 5 . 1 p reparing the connection a lways observe the following safety instructions : l c onnect only in the complete absence of line voltage i n hazardous areas you should take note of the appropriate regulations , conformity and type approval certi fi cates of the sensor...

Page 16

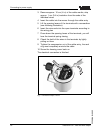

3 r emove approx . 10 cm ( 4 in ) of the cable mantle , strip approx . 1 cm ( 0 . 4 in ) insulation from the ends of the individual wires 4 i nsert the cable into the sensor through the cable entry 5 l ift the opening levers of the terminals with a screwdriver ( see following illustration ) 6 i nser...

Page 17

5 . 3 w iring plans , single chamber housing 1 4 4 4 2 3 f ig . 8 : m aterial versions , single chamber housing 1 p lastic ( not with dust - e x ) 2 a luminium 3 s tainless steel 4 f ilter element for pressure compensation or blind stopper with version ip 66 / ip 68 , 1 bar 4 1 2 3 f ig . 9 : e lect...

Page 18

T he wiring example is applicable for all suitable signal conditioning instruments . T ake note of the operating instructions manual of the signal conditioning instrument . S uitable signal conditioning instru - ments are listed in the " t echnical data " . 1 f ig . 10 : w iring plan 1 v oltage supp...

Page 19

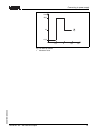

10 i/ma 20,5 1,5 3 4,5 t/s 1 f ig . 12 : s tart - up reaction 1 m easured value vegacap 62 - with two - wire output 19 c onnecting to power supply 30007 - en - 060222.

Page 20: Et Up

6 s et up 6 . 1 g eneral t he numbers in brackets refer to the following illustrations . O n the electronics module you will fi nd the following indicating and adjustment elements : l dil switch for measuring range selection l c ontrol lamp n ote : a s a rule , always set the mode with the mode switc...

Page 21

N ote : s crew the housing cover tightly to the point where the inspection glass is above the control lamp ( led ). T o adjust vegacap 62 , fi rst of all remove the housing cover . W ith the potentiometer on the signal conditioning instrument and the meas . Range selection switch ( 1 ) on vegacap 62 ...

Page 22: fi

7 m aintenance and fault recti fi cation 7 . 1 m aintenance w hen used as directed in normal operation , vegacap 62 is completely maintenance - free . 7 . 2 f ault recti fi cation vegacap 62 o ff ers maximum reliability . N evertheless faults can occur during operation . T hese may be caused by the fol...

Page 23

L u nfavourable installation location à m ount the instrument at a location in the vessel where no dead zones or mounds can form . à c heck if the probe is covered by buildup on the socket . L w rong mode selected on the signal conditioning instrument à s et the correct mode on the mode switch of th...

Page 24

2 1 f ig . 14 : l oosen the screws 1 e lectronics module 2 s crews ( 2 pcs .) 6 r emove the old oscillator 7 c ompare the new oscillator with the old one . T he type label of the oscillator must correspond to that of the old oscillator . T his applies particularly to instruments used in hazardous ar...

Page 25

7 . 4 i nstrument repair i f a repair is necessary , please proceed as follows : f rom our homepage in the i nternet www . Vega . Com , you can download a return form ( 23 kb ) under : “ d ownloads – f orms and c erti fi cates – r epair form ” b y doing this you help us carry out the repair quickly a...

Page 26: Ismounting

8 d ismounting 8 . 1 d ismounting procedure w arning : b efore dismounting , be aware of dangerous process con - ditions such as e . G . Pressure in the vessel , high temperatures , corrosive or toxic products etc . T ake note of chapters " m ounting " and " c onnecting to power supply " and carry o...

Page 27: Upplement

9 s upplement 9 . 1 t echnical data g eneral data m aterial 316 l corresponds to 1 . 4404 or 1 . 4435 m aterial wetted parts - p rocess fi tting - t hread 316 l - p rocess fi tting - f lange 316 l - p rocess seal k lingersil c - 4400 - insulation ( partly insulated ) ptfe - p robe ( rod ptfe partly in...

Page 28

A mbient conditions a mbient temperature on the housing - 40 … + 80 ° c (- 40 … + 176 ° f ) s torage and transport temperature - 40 … + 80 ° c (- 40 … + 176 ° f ) p rocess conditions p rocess pressure - 1 … 64 bar /- 100 … 6400 k p a (- 14 . 5 … 928 psi ) p rocess temperature vegacap 62 of 316 l - 5...

Page 29

S pring - loaded terminals for wire cross section up to 1 . 5 mm ² ( 0 . 0023 in ² ) e lectromechanical data - version ip 66 / ip 68 , 1 bar c able entry - s ingle chamber housing l 1 x ip 68 cable entry m 20 x 1 . 5 ; 1 x blind stopper m 20 x 1 . 5 or : l 1 x closing cap ½ npt , 1 x blind plug ½ np...

Page 30

E lectrical protective measures p rotection - p lastic housing ip 66 / ip 67 - a lu and stainless steel standard ip 66 / ip 68 ( 0 . 2 bar ) 2 ) - a lu and stainless housing , optionally available ip 66 / ip 68 ( 1 bar ) o vervoltage category iii p rotection class ii a pprovals ( option ) 3 ) atex i...

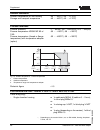

Page 31

9 . 2 d imensions h ousing versions in protection ip 66 / ip 67 and ip 66 / ip 68 ; 0 . 2 bar ø77mm (3 1 / 32 ") 112mm (4 13 / 32 ") 69mm (2 23 / 32 ") ø77mm (3 1 / 32 ") 69mm (2 23 / 32 ") 117mm (4 39 / 64 ") 116mm (4 9 / 16 ") ø84mm (3 5 / 16 ") 116mm (4 9 / 16 ") m20x1,5 m20x1,5/ ½ npt m20x1,5/ ½...

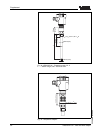

Page 32

ø16mm ( 5 / 8 ") 100mm (3 15 / 16 ") 12mm ( 15 / 32 ") l g 3 / 4 a, g 1 a, g 1 1 / 2 a 56 mm (2 1 / 4 ") 22 2 1 / 4 " f ig . 18 : vegacap 62 - t hreaded version g 1 a l = s ensor length , see " t echnical data " 73mm (2 7 / 8 ") ø 40mm (1 37 / 64 ") f ig . 19 : t emperature adapter s upplement 32 ve...

Page 33

S upplement vegacap 62 - with two - wire output 33 30007 - en - 060222.

Page 34

9 . 3 i ndustrial property rights vega product lines are global protected by industrial property rights . F urther information see http :// www . Vega . Com . O nly in u . S . A .: f urther information see patent label at the sensor housing . Vega p roduktfamilien sind weltweit gesch ü tzt durch gew...

Page 35

S upplement vegacap 62 - with two - wire output 35 30007 - en - 060222.

Page 36

Vega g rieshaber kg a m h ohenstein 113 77761 s chiltach g ermany p hone + 49 7836 50 - 0 f ax + 49 7836 50 - 201 e - mail : info @ de . Vega . Com www . Vega . Com iso 9001 a ll statements concerning scope of delivery , application , practical use and operating conditions of the sensors and process...