- DL manuals

- Vega

- Touch Panel

- VEGADIS 62

- Operating Instructions Manual

Vega VEGADIS 62 Operating Instructions Manual

Summary of VEGADIS 62

Page 1

Operating instructions vegadis 62 document id: 36469 indication and adjustment.

Page 2: Contents

Contents 1 about this document 1.1 function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 symbolism used. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2 for your safety 2.1 authorised...

Page 3

9 dismounting 9.1 dismounting steps . . . . . . . . . . . . . . . . . . . . . . . . . . 42 9.2 disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 10 s upplement 10.1 technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 10.2 hart communication . . . ....

Page 4: About This Document

1 about this document 1 .1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instructions for maintenance and fault rectification. Please read this information before putting the instrument into operation and keep...

Page 5: For Your Safety

2 for your safety 2 .1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the required personal protective equipment must always be worn. 2 ....

Page 6

2 .5 ce conformity the device fulfills the legal requirements of the applicable ec guidelines. By affixing the ce marking, we confirm successful testing of the product. You can find the conformity certificate in the download section under www.Vega.Com. 2 .6 fulfillment of namur recommendations the device f...

Page 7: Product Description

3 product description 3 .1 structure the indicating and adjustment unit vegadis 62 consists of a housing with a terminal insert as well as an integrated indicating and adjustment module. Dependent on the order specification, a mounting adapter for wall, carrier rail or tube mounting belongs to the ho...

Page 8

The scope of delivery encompasses: l indicating and adjustment unit l documentation - this operating instructions manual - ex-specific "safety instructions" (with ex versions) - if necessary, further certificates 3 .2 principle of operation the vegadis 62 is an external indicating and adjustment unit ...

Page 9

L radar and ultrasonic sensors l sensors with guided microwave l capacitive probes l pressure transmitter l previous instrument versions (replacement for vegadis 12) the operation of respective sensors from other manufacturers is also possible. The vegadis 62 acts like a hart handheld with limited f...

Page 10

Transport must be carried out under consideration of the notes on the transport packaging. Nonobservance of these instructions can cause damage to the device. The delivery must be checked for completeness and possible transit damage immediately at receipt. Ascertained transit damage or concealed def...

Page 11: Mounting

4 mounting 4 .1 general instructions use the recommended cables (see chapter "connecting to power supply") and tighten the cable gland. You can give your instrument additional protection against moisture penetration by leading the connection cable downward in front of the cable entry. Rain and conde...

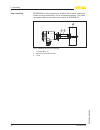

Page 12

Vegadis 62 for tube mounting is supplied with a meas. Instrument holder and four screws m5 x 12 as mounting accessory. The meas. Instrument holder is mounted to the socket of vegadis 62. 1 3 2 fig. 5: vegadis 62 for tube mounting 1 4 screws m5 x 12 2 measuring instrument holder 3 tube tube mounting ...

Page 13

5 connecting to power supply 5 .1 preparing the connection always keep in mind the following safety instructions: l connect only in the complete absence of line voltage l if voltage surges are expected, install overvoltage arresters power supply and current signal are carried on the same two-wire ca...

Page 14

If potential equalisation currents are expected, the connection on the processing side must be made via a ceramic capacitor (e. G. 1 nf, 1500 v). The low frequency potential equalisation currents are thus suppressed, but the protective effect against high frequency interfer- ence signals remains. War...

Page 15

2 remove the indicating and adjustment module by turning it slightly to the left fig. 6: dismounting of the indicating and adjustment module 3 loosen compression nut of the cable glands 4 remove approx. 10 cm (4 in) of the signal cable mantle, strip approx. 1 cm (0.4 in) insulation from the ends of ...

Page 16

5 insert the cable into the sensor through the cable entry fig. 7: connection steps 5 and 6 6 insert the wire ends into the terminals according to the wiring plan note: solid cores as well as flexible cores with cable end sleeves are inserted directly into the terminal openings. In case of flexible co...

Page 17

5 .3 wiring plan 1 2 + ( ) (-) 3 4 + ( ) (-) 1 2 3 fig. 8: wiring plan vegadis 62 1 to the sensor 2 for power supply 3 coupling for the connection cable to the indicating and adjustment module 5 .4 connection hart standard the following illustrations show in a simplified way the use of vegadis 62 in ...

Page 18

1 2 + ( ) (-) 3 4 + ( ) (-) 1 2 4 3 fig. 10: connection of vegadis 62 with low impedance power supply 1 sensor 2 vegadis 62 3 hart resistor > 150 Ω 4 voltage supply/processing 5 .5 connection hart multidrop the following illustrations show in a simplified way the use of vegadis 62 in conjunction with...

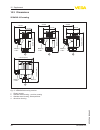

Page 19

~ = 1 2 4 3 fig. 11: installation example with one vegadis 62 per sensor in a multidrop system 1 sensor 2 vegadis 62 3 hart resistance > 150 Ω (necessary with low impedance power supply) 4 voltage supply/processing ~ = 1 2 4 3 fig. 12: installation example with one vegadis 62 for several sensors in ...

Page 20

1 2 + ( ) (-) 3 4 + ( ) (-) 1 2 4 3 fig. 13: connection of vegadis 62 with low impedance power supply 1 sensor 2 vegadis 62 3 hart resistor > 150 Ω 4 voltage supply/processing 5 .6 connection signal conditioning instruments the following illustrations show the simplified connection of vegadis 62 to a...

Page 21

Hence terminals 1 and 2 on the vegadis 62 must be closed with a bridge. 1 2 + ( ) (-) 3 4 + ( ) (-) 1 2 3 fig. 15: bridge on terminals 1 and 2 on the vegadis 62 1 bridge 2 vegadis 62 3 signal conditioning instrument 5 .7 switch-on phase during the start-up process, the vegadis 62 tries automatically...

Page 22: Set Parameters

6 set parameters 6 .1 adjustment system 1 2 3 4 5 fig. 16: indicating and adjustment elements 1 status information (hart mode, unit lock, warning or error information) 2 unit and information line 3 digital measured value indication 4 bar graph for quasianalogue measured value indication 5 adjustment...

Page 23

By pushng the [ok] key, the parameter adjustment mode will be started. The parameter adjustment is carried out via an adjustment menu. The same menu window is opened from which the parameter adjustment mode is quit during the last parameter adjustment. Single points in the menu can be selected with ...

Page 24

A flashing heart symbol is displayed as long as a hart communi- cation takes place for the first time and the instrument is hence set to the hart mode. The heart symbol is displayed permanently if the hart communication is finished and the digital indication is configured according to the measuring rang...

Page 25

L pressure: bar, mbar, psi, hpa, kpa, mpa, mmh2o, mh2o, inhg l temperature: °c, °f, k l electrical variables: v, ma, ohm l user-specific unit: user the previously listed units can be initially edited. A storing in the vegadis 62 is however only possible if the unit is supported by the sensor. Note: a...

Page 26

Adjustment of the measuring range final value of the connected transmitter (for example 4 bar at a measuring range of -1 … 5 bar) 3) the measuring range endpoint is initially adopted by the sensor when starting with connected sensor. Thereafter, the measuring range endpoint of the sensor can be chang...

Page 27

In this menu item, the actual measured value is accepted as min. Adjustment for the sensor 6) this is a zero adjustment to which 0 % of the current output are assigned. The value accepted hier, shifts the measuring range end! The difference between measuring range begin and end however remains. In th...

Page 28

The units % and ma are not available in multidrop operation because in this case the loop current is fixed. Adjustment range: mbar, bar, psi, hpa, kpa, mpa, mmh2o, mh2o, mhg, mm, cm, m, in, ft, %, °c, °f, k, v, ma, ohm, user durcby activating the unit locking, the set indication unit is locked agains...

Page 29

From this menu item you jump to the alarm configuration by pushing ok. Switching on or switching off the alarm function. If an adjusted alarm limit is exceeded or decreased, the warning symbol is displayed in the indication and the measured value begins to flash. Adjustment range: off/on setting the val...

Page 30

From this menu item you jump to the min./max. Value storage by pushing "[ok]". Function to delete the memory. By pushing the ok key twice, the memories will be deleted. Activation of the min./max. Value indication. If the min./max. Value indication is switched on, the indication switches over cyclic...

Page 31

Adjustment of the display contrast adjustment range: 0 … 4 with a reset, all settings of the digital indication will be reset to the default values. For activating the reset, the "ok" key must be pushed once. After pushing the "ok" key for a second time, the indication will be completely faded out a...

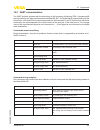

Page 32

Menu section menu item default value indication range decimal point 0.000 filter 0 alarm - alarm on/off off min. Alarm 4.000 max. Alarm 20.000 min./max. Value memory - delete min./max. Del min./max. On/off off configuration language eng contrast 2 reset - user unit user min. Failure mes- sage 3.6 max. Fa...

Page 33

Setting the current value that triggers the max. Failure message when it is reached or exceeded. The max. Failure message is shown in the display with 5 overlines ( ¯ ¯ ¯ ¯ ¯ ) and the message "ausmax" (or "outmax" ). Adjustment range: 20.1 … 21.5 the number of the firmware used is displayed. This me...

Page 34

This menu item is available from software 2.10. It enables the early logout after entering the password. Configuration/logout 34 vegadis 62 6 set parameters 36469 -en -120329.

Page 35: Set Up Sensors

7 set up sensors 7 .1 adjust the sensor the min./max. Adjustment of the connected sensor is carried out via the menu "measurement", menu items "unit", "measuring range begin", "measuring range end" and if necessary "measuring range decimal point". The entered values are taken over when storing into ...

Page 36

2 select in the menu "measurement", menu item "unit" the unit "user" . 3 enter in the menu "measurement", menu item "mb begin" the initial value of the requested scaling. 4 enter in the menu "measurement", menu end "mb begin" the final value of the requested scaling. 5 enter in the menu "measurement"...

Page 37

Note: the menu items used for the adjustment are also used for entering the scaling data. We thus recommend writing down the scaling data for plant documentation or for a possible later correction of the adjust- ment. 7 .3 correct sensor adjustment for a correction of the sensor adjustment, the hart...

Page 38

38 vegadis 62 7 set up sensors 36469 -en -120329.

Page 39: Diagnosis And Service

8 diagnosis and service 8 .1 maintenance if the device is used correctly, no maintenance is required in normal operation. 8 .2 error messages hart communication errors are signalled with numerical codes 1 - 7. An error message is sent if a transaction was not successful after multiple attempts. An e...

Page 40

8 .3 remove interferences the operator of the system is responsible for taking suitable measures to rectify faults. Connect a handmultimeter in the suitable measuring range according to the wiring plan. The following table describes possible errors in the current signal and helps to remove them: err...

Page 41

You can download a return form (23 kb) from our homepage at www. Vega.Com under: "downloads - forms and certificates - repair form". By doing this you help us carry out the repair quickly and without having to call back for needed information. L print and fill out one form per instrument l clean the i...

Page 42: Dismounting

9 dismounting 9 .1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in reve...

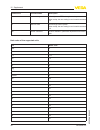

Page 43: Supplement

10 supplement 10 .1 technical data general data 316l corresponds to 1.4404 or 1.4435, 316ti corresponds to 1.4571 materials - housing plastic pbt, alu die-casting, 316l - inspection window in housing cover for indicating and adjustment module polycarbonate (ul-746-c listed) - ground terminal 316ti/3...

Page 44

Adjustment elements 4 keys protection rating - unassembled ip 20 - mounted into vegadis 62 without cover ip 40 materials - housing abs - inspection window polyester foil ambient conditions ambient temperature -20 … +70 °c (-4 … +158 °f) storage and transport temperature -40 … +80 °c (-40 … +176 °f) ...

Page 45

10 .2 hart communication the hart protocol operates with the technology of the frequency shift keying (fsk = frequency shift keying) based on the data communication standard bell 202. The digital signal is generated out of the frequencies 1200 and 2200 hz representing each the bit information 1 and ...

Page 46

Command no. Command name description 37 set lower range value min. Adjustment/zero through control system after receipt, the new scaling is read out with command 15 44 write pv units unit through control system after receipt, the new scaling is read out with command 15 156 service command control ca...

Page 47

Vegadis 62 47 10 supplement 36469 - en -120329.

Page 48

10 .3 dimensions vegadis 62 housing 1 2 3 4 123 mm (4.84") 128 mm (5.04") 112 mm (4.41") 125 mm (4.92") ~ 69 mm (2.72") ø 77 mm (3.03") ~ 69 mm (2.72") ~ 59 mm (2.32") ~ 116 mm (4.57") ø 77 mm (3.03") ø 80 mm (3.15") ø 84 mm (3.31") m20x1,5 m20x1,5/ ½ npt m20x1,5/ ½ npt m20x1,5/ ½ npt m20x1,5/ ½ npt...

Page 49

Mounting adapter vegadis 62 5mm ( 13 / 64 ") 16mm ( 5 / 8 ") 84mm (3 5 / 16 ") 70mm (2 3 / 4 ") r32mm (1 17 / 64 ") m6 67mm (2 41 / 64 ") ~ 111mm (4 31 / 8 ") 3mm ( 1 / 8 ") 11mm ( 7 / 16 ") 60mm (2 23 / 64 ") 1 2 3 fig. 18: mounting adapter vegadis 62 1 mounting plate for wall mounting 2 clip for c...

Page 50

10 .4 industrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com . Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrecht...

Page 51: Index

Index a adjustment 35 adjustment correction 37 alarm configuration 29 application area 8 c cable entry 13 check signal 40 connection cable 13 connection procedure 14 connection technology 14 contrast 31 d damping 27 decimal point indication 28 digital filter display 28 disposal 42 e error messages 39 ...

Page 52

Vega grieshaber kg am hohenstein 113 77761 schiltach germany phone +49 7836 50-0 fax +49 7836 50-201 e-mail: info.De@vega.Com www.Vega.Com printing date: iso 9001 all statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems co...