- DL manuals

- Vega

- Measuring Instruments

- VEGAMIP 61

- Operating instructions manual

Vega VEGAMIP 61 Operating instructions manual

Summary of VEGAMIP 61

Page 1

Operating instructions vegamip r61 receiving unit - transistor document id: 40694 radar.

Page 2: Contents

Contents 1 about this document 1.1 function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 symbolism used. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2 for your safety 2.1 authorised...

Page 3

Safety instructions for ex areas please note the ex-specific safety information for installation and operation in ex areas. These safety instructions are part of the operating instructions manual and come with the ex-approved instruments. Editing status: 2012-02-14 vegamip r 61 • - transistor 3 conte...

Page 4: About This Document

1 about this document 1 .1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instructions for maintenance and fault rectification. Please read this information before putting the instrument into operation and keep...

Page 5: For Your Safety

2 for your safety 2 .1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the required personal protective equipment must always be worn. 2 ....

Page 6

The emitting frequencies of the sensors depend on the model, but are all in the k band range. The low transmitting power lies far below the internationally permitted limit value. When the instrument is used correctly, it presents no danger to human health. It may be operated without restriction outs...

Page 7

2 .8 environmental instructions protection of the environment is one of our most important duties. That is why we have introduced an environment management system with the goal of continuously improving company environmental protection. The environment management system is certified according to din ...

Page 8: Product Description

3 product description 3 .1 structure the type label contains the most important data for identification and use of the instrument: l article number l serial number l technical data l article numbers, documentation with the serial number, you can access the delivery data of the instrument via www.Vega...

Page 9

Vegamip 61 can also be used for detection of vehicles and ships or for material recognition on conveyor belts. It works even under extremely difficult conditions: different grain sizes, contamination, extreme filling noise, high temperatures, strong dust generation and abrasive products are all no probl...

Page 10

Several antenna versions are available for different applications. 1 2 3 5 4 fig. 2: antenna versions 1 threaded version - internal horn antenna with ptfe cover 2 plastic encapsulated antenna with pp cover 3 horn antenna/316l 4 vegamip 61 with angled antenna extension 5 encapsulated horn antenna with...

Page 11

Up to the time of installation, the packages must be left closed and stored according to the orientation and storage markings on the outside. Unless otherwise indicated, the packages must be stored only under the following conditions: l not in the open l dry and dust free l not exposed to corrosive ...

Page 12

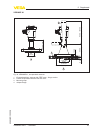

With high process temperatures exceeding 80 °c, you have to use a mounting adapter for the emitting and the receiving unit. The mounting adapter can only be used with the threaded version (internal horn antenna with ptfe cover). Fig. 3: vegamip 61 with high temperature mounting adapter mounting adap...

Page 13: Mounting

4 mounting 4 .1 general instructions with instruments with threaded process fitting, suitable tools must be applied for tightening the hexagon. Warning: the housing must not be used to screw the instrument in! Applying tightening force can damage internal parts of the housing. Make sure that all part...

Page 14

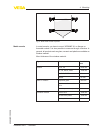

The vegamip 61 requires a minimum product strength to detect different products. Dependent on the medium there will be a respective product thickness. The properties of the medium are also dependent on the granulation size, the bulk density and the moisture content. Some exemplary reference values fo...

Page 15

Fig. 5: bulk solids vessel of plastic in metal vessels, you have to mount vegamip 61 on flanges or threaded sockets. It is also possible to measure through a window. In general, all products such as glass, ceramic and plastic are suitable as window material. Max. Thickness of the window material: typ...

Page 16

A c b fig. 6: installation in front of a vessel window a window of non-conductive material, for example, glass, plastic, etc. B mounting with condensation on the inner wall of the vessel c inspection glass fitting in general, the same as for metal vessels applies to concrete vessels due to the steel ...

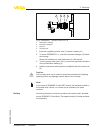

Page 17

1 2 3 4 fig. 8: vegamip 61 - threaded version g1½ a 1 polarisation marking 2 instrument hexagon 3 locknut 4 process seal 1 insert the supplied process seal (1) before screwing it in 2 to screw vegamip 61 in, use the instrument hexagon (3) below the housing. Screw the instrument in and hand-screw it ...

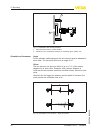

Page 18

2 1 fig. 9: front flush installation 1 unfavourable installation - bulk solid can settle in front of the sensor 2 correct front flush installation if a front-flush installation is not possible, you can fill long sockets with a plastic or ceramic cylinder to avoid build up of bulk solids and dust deposit...

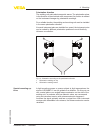

Page 19

2 1 2 2 1 1 fig. 10: front flush installation 1 plastic or ceramic material 2 fixing screw (if technically possible) in very abrasive products, vegamip 61 should be installed with a mounting adapter or in front of a suitable window. In this case, you have to use a window material which is appropriate...

Page 20

1 2 fig. 11: installation with vessel vibrations 1 anti vibration blocks or rubber buffers 2 window of non-conductive material, for example, glass, plastic, etc. Angle for an optimum switching signal, the two sensors must be adapted to each other. The accuracy must be in a range of ±5°. Offset the two...

Page 21

Polarisation direction the emitting unit emits electromagnetic waves. The polarisation plane is the direction of the electrical wave component. Its position is marked on the instrument hexagon by polarisation markings. For a reliable function, the emitting and receiving unit must be installed in the...

Page 22

45° 1 2 fig. 14: possibilities for signal deflection 1 metal plate for signal deflection of the microwave signal 2 bent antenna extension 22 vegamip r 61 • - transistor 4 mounting 40694 -en -120228.

Page 23

5 connecting to power supply 5 .1 preparing the connection always keep in mind the following safety instructions: l connect only in the complete absence of line voltage l if voltage surges are expected, install overvoltage arresters connect the operating voltage according to the following diagrams. ...

Page 24

4 insert the cable into the sensor through the cable entry fig. 15: connection steps 4 and 5 5 insert the wire ends into the terminals according to the wiring plan information: solid cores as well as flexible cores with cable end sleeves are inserted directly into the terminal openings. In case of fle...

Page 25

5 .3 wiring plan, single chamber housing we recommend connecting vegamip 61 in such a way that the switching circuit is open when there is a level signal, line break or failure (safe condition). The terminals 1 and 5 as well as 2 and 8 are internally connected. Hence pnp or npn action can be selecte...

Page 26

1 u h fig. 18: wiring plan receiving unit - vegamip 61 (receiver) - floating 1 voltage supply u h auxiliary voltage connection - floating 26 vegamip r 61 • - transistor 5 connecting to power supply 40694 -en -120228.

Page 27: Setup

6 setup 6 .1 adjustment elements the figures in brackets refer to the following illustration. 6 7 9 8 4 5 1 2 3 1 (-) ( ) 5 6 7 8 2 + (-) ( ) + 5 6 7 8 fig. 19: electronics module mp6x s receiver unit - transistor output 1 mode switch for selecting the switching behaviour (min./max.) 2 control lamp (...

Page 28

With the mode adjustment (min./max.) you can change the switching condition of the transistor output. You can set the required mode according to the "function chart" (max. - max. Detection or overflow protection, min. - min. Detection or dry run protection). With these keys (7 and 8) you can adjust t...

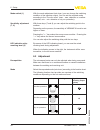

Page 29

Level switching status signal lamp - switching output (yellow) mode min. Dry run protection open failure of the supply voltage (max./min. Mode) any open malfunction any open red failure led lights depending on the switching function your output should carry out, you can determine the switching direc...

Page 30

Press the respective key until the indication is within the led indication strip. This means one or two leds on the led indication strip will light up. C b a 2 3 1 1 1 fig. 28: indication board 1 indication (led indication board) 2 more sensitive - key to the left 3 less sensitive - key to the right...

Page 31

Fig. 29: led indication strip - setting for products with good signal damping if there is strong buildup during operation, adjustment with buildup is recommended. A short period of operation is probably sufficient to create buildup, or buildup can be created artifically or imitated. In applications wit...

Page 32

By means of the led indicating board, you can adjust the switching delay. Push the two keys (7) and (8) simultaneously for approximately 2 s until the led indication flashes. With the two keys you can select the requested switching delay according to the following illustration. The switching delay ca...

Page 33

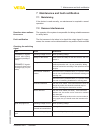

7 maintenance and fault rectification 7 .1 maintaining if the device is used correctly, no maintenance is required in normal operation. 7 .2 remove interferences the operator of the system is responsible for taking suitable measures to rectify faults. The first measure to be taken is to check the outp...

Page 34

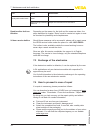

Error cause rectification instrument switches fre- quently with certain levels wave movements in the vessel adjust or increase switching delay effects through interfering reflections adjust the instrument more insensitive depending on the reason for the fault and the measures taken, the steps described...

Page 35: Dismounting

8 dismounting 8 .1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in reve...

Page 36: Supplement

9 supplement 9 .1 technical data general data material 316l corresponds to 1.4404 or 1.4435 materials, wetted parts - process fitting - thread 316l - process fitting - flange 316l antenna instrument seal cover or wetted materials threaded version - internal horn antenna with ptfe cover fkm (a+p 70.16.-...

Page 37

Frequency range k band, 24.085 ghz (ism band) measuring range 0.1 … 100 m (0.33 … 328 ft) beam angle 1) - threaded version - internal horn antenna (ptfe cover) 20° - plastic encapsulated antenna with pp cover 10° - horn antenna (316l) - ø 40 mm (1.575 in) 22° - horn antenna (316l) - ø 48 mm (1.89 in...

Page 38

- vegamip 61, horn antenna/316l -1 … 40 bar/-100 … 4000 kpa (-14.5 … 580 psig) - vegamip 61, encapsulated horn anten- na with ptfe cover -1 … 16 bar/-100 … 1600 kpa (-14.5 … 232 psig) - vegamip 61 with mounting adapter unpressurized (ip 67) process temperature (thread or flange tem- perature) - vegam...

Page 39

That's why the associated approval documents have to be noted with these instruments. They are part of the delivery or can be downloaded under www.Vega.Com via "vega t ools" and "serial number search" as well as via "downloads" and "approvals". Vegamip r 61 • - transistor 39 9 supplement 40694 - en ...

Page 40

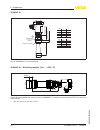

9 .2 dimensions vegamip 61 - housing versions ~ 69 mm (2 23 / 32 ") ø 77 mm (3 1 / 32 ") 1 1 2 mm (4 1 3 / 3 2 ") m20x1,5/ ½ npt ~ 69 mm (2 23 / 32 ") ø 77 mm (3 1 / 32 ") 1 1 7 mm (4 3 9 / 6 4 ") m20x1,5/ ½ npt ~ 116 mm (4 9 / 16 ") ø 84 mm (3 5 / 16 ") 1 1 6 mm (4 9 / 1 6 ") m20x1,5 m20x1,5/ ½ npt...

Page 41

Vegamip 61 2 1 4 3 1 5 mm (0 .5 9 ") 9 8 mm (3 .8 6 ") 1 7 0 mm / 3 0 0 mm (6 .6 9 ") / (1 1 .8 1 ") 1 9 mm (0 .7 5 ") ø 75 mm (2.95") ø 115 mm (4.53") 9 9 ,5 mm (3 .9 2 ") ø 44 mm (1.73") fig. 34: vegamip 61, encapsulated antennas 1 encapsulated horn antenna with ptfe cover - flange version 2 plasti...

Page 42

Vegamip 61 mm inch 3 8 mm (1 .5 0 ") 2 2 mm (0 .8 7 ") sw 46 mm (1.81") 8.50" 16.93" 3.94" ø1.58" ø1.89" ø2.95" ø3.74" 4.72" x y 100 ø40 120 ø48 216 ø75 430 ø95 1½" 2" 3" 4" x y 1½" 2" 3" 4" x y g1½a / 1½ npt 1 fig. 35: vegamip 61, horn antenna/316l vegamip 61 - mounting adapter (-40 … +450 °c) 24 m...

Page 43

9 .3 industrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com . Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte...

Page 44: Index

Index a abrasion 19 accessory - flanges 11 - protective cap 11 adjustment 28 application area 8 b bending 21 buildup 17 c cable 23 cable screening 23 e electronics module 11, 34 emitting unit 9 encapsulated antennas 41 f fault rectification 33 filling opening 14 functional principle 10 h horn antenna...

Page 45

Vegamip r 61 • - transistor 45 index 40694 - en -120228.

Page 46

46 vegamip r 61 • - transistor index 40694 -en -120228.

Page 47

Vegamip r 61 • - transistor 47 index 40694 - en -120228.

Page 48

Vega grieshaber kg am hohenstein 113 77761 schiltach germany phone +49 7836 50-0 fax +49 7836 50-201 e-mail: info.De@vega.Com www.Vega.Com printing date: iso 9001 all statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems co...