- DL manuals

- Vega

- Laser Level

- VEGAPULS 62 standpipeversion

- Operating Instructions Manual

Vega VEGAPULS 62 standpipeversion Operating Instructions Manual

Summary of VEGAPULS 62 standpipeversion

Page 1

Operating instructions vegapuls 62 standpipe version foundation fieldbus document id: 36510 radar.

Page 2: Contents

Contents 1 about this document 1.1 function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 symbolism used. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2 for your safety 2.1 authorised...

Page 3

8.2 communicator 375, 475 . . . . . . . . . . . . . . . . . . . . . . 34 9 diagnosis, asset management and service 9.1 maintaining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 9.2 measured value and event memory . . . . . . . . . . . . . . 35 9.3 asset management function . . . ....

Page 4: About This Document

1 about this document 1 .1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instructions for maintenance and fault rectification. Please read this information before putting the instrument into operation and keep...

Page 5: For Your Safety

2 for your safety 2 .1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the required personal protective equipment must always be worn. 2 ....

Page 6

Depending on the instrument version, the emitting frequencies are in the c or k band range. The low emitting frequencies are far below the internationally approved limit values. When used correctly, there is no danger to health. 2 .5 ce conformity the device fulfills the legal requirements of the app...

Page 7

L the device must be non-sensitive to interfering immissions, including those that may cause undesirable operating conditions. Modifications not expressly approved by the manufacturer will lead to expiry of the operating licence according to fcc/ic. The instrument is in conformity with rss-210 of the...

Page 8: Product Description

3 product description 3 .1 structure the type label contains the most important data for identification and use of the instrument: 2 1 13 14 15 16 12 11 5 3 6 4 7 8 9 10 fig. 1: structure of the type label (example) 1 instrument type 2 product code 3 approvals 4 power supply and signal output, electr...

Page 9

This operating instructions manual applies to the following instrument versions: l hardware from 2.1.1 l software from 4.4.0 the instrument is available in two different electronics versions. Each version can be identified via the product code on the type label as well as on the electronics. L standar...

Page 10

The antenna of the radar sensor emits short radar pulses with a duration of approx. 1 ns. These pulses are reflected by the product and received by the antenna as echoes. The running time of the radar pulses from emission to reception is proportional to the distance and hence to the level. The determ...

Page 11

The interface adapter vegaconnect enables the connection of communication-capable instruments to the usb interface of a pc. For parameter adjustment of these instruments, an adjustment software such as pactware with vega-dtm is required. You can find further information in the operating instructions ...

Page 12: Mounting

4 mounting 4 .1 general instructions with instruments with threaded process fitting, suitable tools must be applied for tightening the hexagon. Warning: the housing must not be used to screw the instrument in! Applying tightening force can damage internal parts of the housing. Use the recommended cab...

Page 13

5 connecting to the bus system 5 .1 preparing the connection always keep in mind the following safety instructions: l connect only in the complete absence of line voltage l if voltage surges are expected, install overvoltage arresters the instrument requires a operating voltage of 9 … 32 v dc. Opera...

Page 14

5 .2 connect the voltage supply and signal output are connected via the spring- loaded terminals in the housing. The connection to the indicating and adjustment module or to the interface adapter is carried out via contact pins in the housing. Proceed as follows: 1 unscrew the housing cover 2 if an ...

Page 15

9 tighten the compression nut of the cable entry. The seal ring must completely encircle the cable 10 screw the housing cover back on the electrical connection is finished. Information: the terminal block is pluggable and can be removed from the electronics. To do this, lift the terminal block with a...

Page 16

5 .4 wiring plan, double chamber housing 5 0 1 0 1 + 6 7 8 bus 2 3 1 2 ( ) (-) 1 1 fig. 4: electronics compartment, double chamber housing 1 internal connection to the connection compartment 2 contact pins for the indicating and adjustment module or interface adapter 3 simulation switch ("on" = mode...

Page 17

1 bus usb status test sim-card 1 2 + ( ) (-) fig. 6: cconnection of the voltage supply of the radio module 1 voltage supply you can find detailed information for connection in the supplementary instructions "plicsmobile gsm/gprs radio module". 5 .5 wiring plan with double chamber housing ex d 5 0 1 0...

Page 18

+ bus 2 1 2 ( ) (-) 1 fig. 8: connection compartment, double chamber housing ex d 1 voltage supply, signal output 2 ground terminal for connection of the cable screen 3 4 1 2 fig. 9: top view of the plug connector 1 pin 1 2 pin 2 3 pin 3 4 pin 4 contact pin colour connection cable in the sensor term...

Page 19

5 .6 wiring plan - version ip 66/ip 68, 1 bar 1 2 fig. 10: wire assignment fix-connected connection cable 1 brown (+) and blue (-) to power supply or to the processing system 2 shielding 5 .7 switch-on phase after vegapuls 62 is connected to the bus system, the instrument carries out a self-test for ...

Page 20: Module

6 set up with the indicating and adjustment module 6 .1 insert indicating and adjustment module the indicating and adjustment module can be inserted into the sensor and removed any time. Four positions displaced by 90° can be selected. It is not necessary to interrupt the power supply. Proceed as fo...

Page 21

1 2 fig. 12: insertion of the indicating and adjustment module with double chamber housing 1 in the electronics compartment 2 in the connection compartment (with ex d version not possible) note: if you intend to retrofit the instrument with an indicating and adjustment module for continuous measured ...

Page 22

6 .2 adjustment system 1 2 fig. 13: indicating and adjustment elements 1 lc display 2 adjustment keys l [ok] key: - move to the menu overview - confirm selected menu - edit parameter - save value l [->] key: - presentation change measured value - select list entry - select editing position l [+] key:...

Page 23

6 .3 parameter adjustment through the parameter adjustment the instrument is adapted to the application conditions. The parameter adjustment is carried out via an adjustment menu. The main menu is divided into five sections with the following functions: setup: settings, e.G., for measurement loop nam...

Page 24

Through this selection, the sensor is adapted perfectly to the product and measurement reliability, particularly in products with poor reflective properties, is considerably increased. Enter the requested parameters via the appropriate keys, save your settings with [ok] and jump to the next menu item...

Page 25

4 enter the suitable distance value in m for the empty vessel (e.G. Distance from the sensor to the vessel bottom) corresponding to the percentage value. 5 save settings with [ok] and move with [esc] and [->] to the max. Adjustment. Proceed as follows: 1 select with [->] the menu item max. Adjustmen...

Page 26

The "echo curve" shows the signal strength of the echoes over the measuring range in db. The signal strength enables an evaluation of the quality of the measurement. The "false signal suppression" displays the saved false echoes (see menu "additional settings") of the empty vessel with signal streng...

Page 27

The following circumstances cause interfering reflections and can influence the measurement: l high sockets l vessel installations such as struts l agitators l buildup or welded joints on vessel walls note: a false signal suppression detects, marks and saves these false signals so that they are no lon...

Page 28

Note: check the distance to the product surface, because if an incorrect (too large) value is entered, the existing level will be saved as false signal. The filling level would then no longer be detectable in this area. If a false signal suppression is already created in the sensor, then the followin...

Page 29

Caution: note the following if the instrument with corresponding approval is used as part of an overfill protection system according to whg: if a linearisation curve is selected, the measuring signal is no longer compulsorily linear proportional to the level. This must be taken into consideration by ...

Page 30

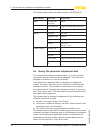

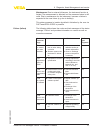

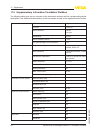

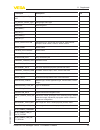

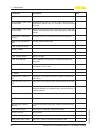

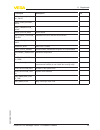

The following table shows the default values of vegapuls 62: menu section menu item default value setup measurement loop name sensor min. Adjustment length of the standpipe ex factory damping 0.0 s display language like order displayed value distance display unit m(d) scaling 0.00 %, 0 l 100.00 %, 1...

Page 31

Vegapuls 62 standpipe version • foundation fieldbus 31 6 set up with the indicating and adjustment module 36510 -en -120301.

Page 32: Setup With Pactware

7 setup with pactware 7 .1 connect the pc 3 1 2 fig. 14: connection of the pc directly to the sensor via the interface adapter 1 usb cable to the pc 2 interface adapter vegaconnect 4 3 sensor information: the interface adapter vegaconnect 3 or additional previous versions are not suitable for connec...

Page 33

Further setup steps are described in the operating instructions manual "dtm c ollection/pactware" attached to each dtm collection and which can also be downloaded from the internet. Detailed descriptions are available in the online help of pactware and the dtms. Fig. 15: example of a dtm view all de...

Page 34

8 set up with other systems 8 .1 dd adjustment programs device descriptions as enhanced device description (edd) are available for dd adjustment programs such as, for example, ams™ and pdm. A free-of-charge download of these files is available via internet. Move via www.Vega.Com and "downloads" to "s...

Page 35

9 diagnosis, asset management and service 9 .1 maintaining if the device is used correctly, no maintenance is required in normal operation. 9 .2 measured value and event memory the instrument has several memories which are available for diagnosis purposes. The data remain even with voltage interrupt...

Page 36

Further echo curves: up to 10 echo curves can be stored in a ring buffer in this memory section. Additional echo curves are stored via: l pc with pactware/dtm l control system with edd 9 .3 asset management function the instrument features self-monitoring and diagnosis according to ne 107 and vdi/vde...

Page 37

Maintenance: due to external influences, the instrument function is limited. The measurement is affected, but the measured value is still valid. Plan in maintenance for the instrument because a failure is expected in the near future (e.G. Due to buildup). This status message is inactive by default. Ac...

Page 38

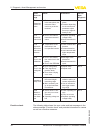

Code text mes- sage cause rectification pa dev- spec diagnosis f 105 determine measured value l the instrument is still in the start phase, the measured value could not yet be de- termined l wait for the warm-up phase l duration depending on the version and parameter adjust- ment up to approxi- matel...

Page 39

Code text mes- sage cause rectification c 700 simulation l simulation active l finish simulation l wait for the automatic end after 60 mins. The following table shows the error codes and text messages in the status message "out of specification" and provides information on causes as well as corrective...

Page 40

Code text mes- sage cause rectification m 503 reliability too low l the echot/noise ratio is the small for a reliable measu- rement l check installation and pro- cess conditions l clean the antenna l change polarisation direc- tion l use instrument with higher sensitivity m 504 error on an device int...

Page 41

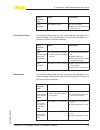

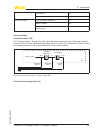

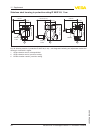

The images in column "error pattern" show the actual level with a broken line and the level displayed by the sensor as a continuous line. 1 2 l e ve l time 0 fig. 17: the broken line 1 shows the real level, the continuous line 2 shows the level displayed by the sensor instructions: l wherever the se...

Page 42

Measurement error during filling fault description error pattern cause rectification 3. Measured value re- mains in the bottom section during filling level time 0 l the tank floor echo is larger than the product echo, e.G. With products with ε r .5 oil- based, solvents l application parameter "me- dium"...

Page 43

Since we offer this service worldwide, the support is in english language. The service is free-of-charge, only the standard telephone costs will be charge. 9 .5 exchanging the electronics module if the electronics module is defective, it can be replaced by the user. In ex applications only one instru...

Page 44

L connecting the sensor to voltage supply and via the interface adapter to the pc l start pactware and go via the menu "project" to the vega project assistant l select "usb", "create new project" and "set instrument online" l activate the project assistant with "start"; the connection to the sensor ...

Page 45: Dismounting

10 dismounting 10 .1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in re...

Page 46: Supplement

11 supplement 11 .1 technical data general data 316l corresponds to 1.4404 or 1.4435 materials, wetted parts - process fitting 316l, hastelloy c22 - process seal on site (instruments with thread: klingersil c-4400 is attached) - antenna impedance cone ptfe, pp, peek, ceramic (99.7 % al 2 o 3 ) - seal...

Page 47

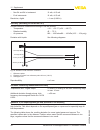

The measured quantity is the distance between process fitting of the sensor and product surface. The reference plane is the seal surface on the hexagon or the lower side of the flange. 3 4 2 1 fig. 24: data of the input variable 1 reference plane 2 measured variable, max. Measuring range 3 antenna len...

Page 48

- non-ex and ex ia instrument 10 ma, ±0.5 ma - ex d instruments 16 ma, ±0.5 ma resolution, digital > 1 mm (0.039 in) accuracy (according to din en 60770-1) process reference conditions according to din en 61298-1 - temperature +18 … +30 °c (+64 … +86 °f) - relative humidity 45 … 75 % - air pressure ...

Page 49

Gas phase temperature pressure 1 bar/ 14 .5 psig 10 bar/ 145 psig 50 bar/ 725 psig 100 bar/ 1450 psig 200 bar/ 2900 psig air 20 °c/68 °f 0.00 % 0.22 % 1.2 % 2.4 % 4.9 % 200 °c/392 °f -0.01 % 0.13 % 0.74 % 1.5 % 3.0 % 400 °c/752 °f -0.02 % 0.08 % 0.52 % 1.1 % 2.1 % hydrogen 20 °c/68 °f -0.01 % 0.10 %...

Page 50

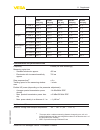

Process conditions for the process conditions, please also note the specifications on the type label. The lower value always applies. Seal antenna impedance co- ne process temperature (measured on the process fitting) fkm (shs fpm 70c3 glt) pffe -40 … +200 °c (-40 … +392 °f) ffkm (kalrez 6375) pffe -2...

Page 51

L 1 x closing cap ½ npt, 1 x blind stopper ½ npt , 1 x blind stopper m16 x 1.5 or optionally 6) 1 x plug m12 x 1 for external indicating and adjustment unit or: l 1 x plug (depending on the version), 1 x blind stopper m20 x 1.5; 1 x blind stopper m16 x 1.5 or optionally 7) 1 x plug m12 x 1 for exter...

Page 52

Adjustment elements 4 keys protection rating - unassembled ip 20 - mounted into the sensor without cover ip 40 materials - housing abs - inspection window polyester foil integrated clock date format day.Month.Year time format 12 h/24 h time zone ex factory cet measurement electronics temerature reso...

Page 53

Protection class ii approvals instruments with approvals can have different technical data depending on the version. That's why the associated approval documents have to be noted with these instruments. They are part of the delivery or can be downloaded under www.Vega.Com via "vega t ools" and "seria...

Page 54

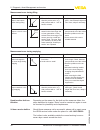

11 .2 supplementary information foundation fieldbus the following table gives you an overview of the instrument versions and the corresponding device descriptions, the electrical characteristics of the bus system as well as the applied function blocks. Revisions data dd-revision rev_01 cff-file 0101...

Page 55

Performance no function blocks instantiable no general information las (link active scheduler) yes master capable yes number of vcrs (virtual communication relationships) 24 function blocks transducer block (tb) the transducer block "analog input (ai)" takes the original measured value (secondary va...

Page 56

The function block "analog input (ai)" takes the original measured value selected by a channel number and makes it available to additional function blocks on its output. Fig. 27: schematic presentation function block analog input (ai) function block discret input (di) the function block "discret inp...

Page 57

The function block "pid control " is a key component for various tasks in the process automation and is used universally. Pid blocks can be cascaded if this is necessary or requested due to different time constants with the primary and secondary process measurement. Fig. 29: schematic presentation fu...

Page 58

The function block "output splitter" generates two control outputs out of one input. Each output is a linear image of a part of the input. A retrograde calculation function is realised by using the linear imaging function inversely. A cascading of several output splitters is supported by an integrat...

Page 59

The function block "signal characterizer" has two channels the outputs of which are not in linear relation with the respective input. The non-linear relation is defined by a look-up table with individually selectable x/y-pairs. The respective input signal is imaged on the corresponding output, hence ...

Page 60

The function block "integrator" integrates a continuous input signal over the time and sums the results of an impulse input block. It is used as a totalizer up to a reset or as a subtotalizer up to a reference point at which the integrated and accumulated value is compared with the default values. W...

Page 61

The function block "input selector" offers selection possibilities for up to four inputs and generates an output signal according to the selection criteria. Typical input signals are ai blocks. Selection possibilities are maximum, minimum, mean value, average value and first useful signal. Through par...

Page 62

L fourth order polynomial based on pv fig. 34: schematic presentation function block arithmetic parameter list the following table gives you an overview of the parameters used. Ff desciptor description unit primary_value primary_value (linearized value). This is the process value after min/max adjus...

Page 63

Ff desciptor description unit secondary_value_2_- type secondary value 2 type fill_height_value_type filling height value type diagnosis aitb diagnosis diag_mask_1 diag_out_1 diag_mask_2 diag_out_2 device_identification manufacturer id, device type, bus type id, measurement principle, serial number,...

Page 64

Ff desciptor description unit false_signal_cmd_sta- te busy, last command, errorcode false_signal_cmd_con- figuration 1 amplitude safety of the 0 % curve, safety of the false signal suppression, position of the 0 % and 100 % curve in near and far range false_signal_cmd_con- figuration 2 gradient of ...

Page 65

Ff desciptor description unit user_min_max_physi- cal_value min.-/max.- distance values, date reset_peak_physical_- value reset_linearization_- curve device_status_ascii device status echo_curve_plicscom_- request parameters as curve selection and resolution echo_curve_plicscom_- limits parameters a...

Page 66

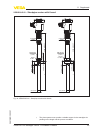

11 .3 dimensions the following dimensional drawings represent only an extract of the possible versions. Detailed dimensional drawings can be downloaded on www.Vega.Com under "d ownloads" and "drawings". Plastic housing ~ 69 mm (2.72") ø 79 mm (3.03") 1 1 2 mm (4 .4 1 ") m20x1,5/ ½ npt ~ 84 mm (3.31"...

Page 67

Aluminium housing in protection rating ip 66/ip 68, 1 bar 1 2 0 mm (4 .7 2 ") ~ 105 mm (4.13") 1 16 m m (4.57 ") ~ 150 mm (5.91") ø 84 mm (3.31") ø 84 mm (3.31") m20x1,5/ ½ npt m16x1,5 2 m20x1,5 m20x1,5 1 fig. 37: housing versions in protection ip 66/ip 68 (1 bar) - with integrated indicating and ad...

Page 68

Stainless steel housing in protection rating ip 66/ip 68, 1 bar 1 17 m m (4.61 ") ~ 103 mm (4.06") ø 77 mm (3.03") 1 20 m m (4. 7 2 ") ~ 105 mm (4.13") ø 84 mm (3.31") ~ 93 mm (3.66") ø 80 mm (3.15") 1 12 m m (4.41 ") m20x1,5/ ½ npt m20x1,5 3 m20x1,5/ ½ npt m16x1,5 2 1 fig. 39: housing versions in p...

Page 69

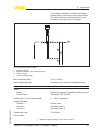

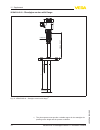

Vegapuls 62 - standpipe version with thread ø 21,3 mm (0.84") ø 21,3 mm (0.84") ø 39,5 mm (1.56") ø 39,5 mm (1.56") 2 2 4 mm (8 .8 2 ") 1 6 mm (0 .6 3 ") 3 2 mm (1 .2 6 ") 3 2 mm (1 .2 6 ") ø 3 ,5 mm (0 .1 4 ") 2 0 mm (0 .7 9 ") 2 2 mm (0 .8 7 ") 2 2 4 mm (8 .8 2 ") sw 46 mm (1.81") sw 32 mm (1.26")...

Page 70

Vegapuls 62 - standpipe version with flange ø 39,5 mm (1.56") ø 21,3 mm (0.84") 2 0 3 mm (7 .9 9 ") 3 3 mm (1 .3 0 ") l fig. 41: vegapuls 62 - standpipe version with flange 10 ) 10) the plant operator must provide a suitable support for the standpipe de- pending on the length and the process condition...

Page 71

11 .4 industrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com . Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrecht...

Page 72: Index

Index a accessory - external indicating and adjustment unit 11 - external radio unit 11 - flanges 11 - indicating and adjustment module 10 - interface adapter 11 - protective cap 11 adjustment 24 - max. Adjustment 25 - min. Adjustment 24 adjustment system 22 c cable entry 13 connection procedure 14 ...

Page 73

Vegapuls 62 standpipe version • foundation fieldbus 73 index 36510 -en -120301.

Page 74

74 vegapuls 62 standpipe version • foundation fieldbus index 36510 -en -120301.

Page 75

Vegapuls 62 standpipe version • foundation fieldbus 75 index 36510 -en -120301.

Page 76

Vega grieshaber kg am hohenstein 113 77761 schiltach germany phone +49 7836 50-0 fax +49 7836 50-201 e-mail: info.De@vega.Com www.Vega.Com printing date: iso 9001 all statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems co...