- DL manuals

- Vega

- Switch

- VEGAVIB 61

- Operating instructions manual

Vega VEGAVIB 61 Operating instructions manual

Summary of VEGAVIB 61

Page 1

Operating instructions vibrating level switch with tube extension for granuled bulk solids vegavib 63 namur document id: 31217.

Page 2: Contents

2 contents vegavib 63 • namur 31217-en-170315 contents 1 about this document 1.1 function ........................................................................................................................... 4 1.2 target group ......................................................................

Page 3

3 contents vegavib 63 • namur 31217-en-170315 safety instructions for ex areas takenoteoftheexspecificsafetyinstructionsforexapplications. These instructions are attached as documents to each instrument with ex approval and are part of the operating instructions manual. Editing status: 2017-03-06.

Page 4: 1 About This Document

4 1 about this document vegavib 63 • namur 31217-en-170315 1 about this document 1.1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instruc- tionsformaintenanceandfaultrectification.Pleasereadthisinforma- tion...

Page 5: 2 For Your Safety

5 2 for your safety vegavib 63 • namur 31217-en-170315 2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the required ...

Page 6

6 2 for your safety vegavib 63 • namur 31217-en-170315 2.5 safety label on the instrument the safety approval markings and safety tips on the device must be observed. 2.6 eu conformity thedevicefulfilsthelegalrequirementsoftheapplicableeuguide- lines.Byaffixingthecemarking,weconfirmsuccessfultesting...

Page 7: 3 Product Description

7 3 product description vegavib 63 • namur 31217-en-170315 3 product description 3.1 configuration the scope of delivery encompasses: • vegavib 63 point level switch • documentation – this operating instructions manual – safety manual "functional safety (sil)" (optional) – supplementary instructions...

Page 8

8 3 product description vegavib 63 • namur 31217-en-170315 youcanfindtheserialnumberontheinsideoftheinstrumentaswell as on the type label on the outside. 3.2 principle of operation vegavib 63 is a point level sensor with vibrating rod for level detec- tion. It is designed for industrial use in all a...

Page 9

9 3 product description vegavib 63 • namur 31217-en-170315 • mode switch to select the switching condition (reverse character- istics) • simulation key 3.4 storage and transport your instrument was protected by packaging during transport. Its capacity to handle normal loads during transport is assur...

Page 10: 4 Mounting

10 4 mounting vegavib 63 • namur 31217-en-170315 4 mounting 4.1 general instructions make sure that all parts of the instrument coming in direct contact with the process, especially the sensor element, process seal and processfitting,aresuitablefortheexistingprocessconditions,such as process pressur...

Page 11

11 4 mounting vegavib 63 • namur 31217-en-170315 warning: the housing must not be used to screw the instrument in! Applying tightening force can damage internal parts of the housing. Use the hexagon above the thread for screwing in. Metric threads in the case of instrument housings with metric threa...

Page 12

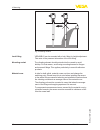

12 4 mounting vegavib 63 • namur 31217-en-170315 fig.3:inflowingmedium vegavib63canbemountedwithalockfittingforheightadjustment. Takenoteofthepressureinformationofthelockfitting. The vibrating element should protrude into the vessel to avoid buildup.Forthatreason,avoidusingmountingbossesforflanges a...

Page 13

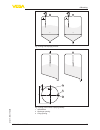

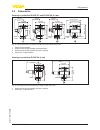

13 4 mounting vegavib 63 • namur 31217-en-170315 d d d 6 d 6 fig. 4: filling and emptying centred d d 6 1 2 3 fig. 5: filling in the centre, emptying laterally 1 vegavib 63 2 discharge opening 3 filling opening.

Page 14

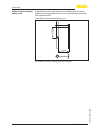

14 4 mounting vegavib 63 • namur 31217-en-170315 in applications such as grit chambers or settling basins for coarse sediments, the vibrating element must be protected against damage withasuitablebaffle. Thisbafflemustbemanufacturedbyyou. > 125 mm (> 5") > 120 mm (> 4.7") fig.6:baffleforprotectionag...

Page 15

15 5 connecting to power supply vegavib 63 • namur 31217-en-170315 5 connecting to power supply 5.1 preparing the connection always keep in mind the following safety instructions: warning: connect only in the complete absence of line voltage. • the electrical connection must only be carried out by t...

Page 16

16 5 connecting to power supply vegavib 63 • namur 31217-en-170315 3. Remove approx. 10 cm (4 in) of the cable mantle, strip approx. 1 cm (0.4 in) of insulation from the ends of the individual wires 4. Insert the cable into the sensor through the cable entry 5. Lift the opening levers of the termina...

Page 17

17 5 connecting to power supply vegavib 63 • namur 31217-en-170315 5 5 5 5 1 2 4 3 fig. 8: material versions, single chamber housing 1 plastic (not with ex d) 2 aluminium 3 stainless steel (not with ex d) 4 stainless steel, electropolished (not with ex d) 5 filter element for pressure compensation o...

Page 18

18 5 connecting to power supply vegavib 63 • namur 31217-en-170315 + - + - 1 2 3 4 3 2 1 fig. 10: wiring plan - external simulation key 1 namuramplifier 2 bridge 3 external simulation key 5.4 wiring plan - version ip 66/ip 68, 1 bar 1 2 fig. 11: wire assignment, connection cable 1 brown (+) and blue...

Page 19: 6 Setup

19 6 setup vegavib 63 • namur 31217-en-170315 6 setup 6.1 general information thefiguresinbracketsrefertothefollowingillustrations. Ontheelectronicsmoduleyouwillfindthefollowingdisplayand adjustment elements: • potentiometer for adjustment of the density range (1) • dil switch for mode adjustment - ...

Page 20

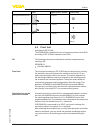

20 6 setup vegavib 63 • namur 31217-en-170315 the characteristics reversal can be carried out with the dil switch. You can choose between falling characteristic curve (switch position max.) and rising characteristic curve (switch position min.). This al- lows you to output the desired current. Modes...

Page 21

21 6 setup vegavib 63 • namur 31217-en-170315 level signal current - sensor control lamp rising characteristics min. ≥2.2ma rising characteristics min. ≤1.0ma fault any ≤1.0ma flashes 6.4 proof test according to iec 61508. Thevegavib63isqualifiedforuseinmeasuringchainsoflevelsil2 according to iec 61...

Page 22

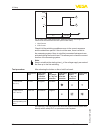

22 6 setup vegavib 63 • namur 31217-en-170315 > 2,2 i/ma 3 ±1 t/s 1 2 1,5 ±0,5 fig. 22: flow chart of the function test - switching function according to the covered and characteristics selection (see function table) 1 high current 2 low current check if all the switching conditions occur in the cor...

Page 23

23 7maintenanceandfaultrectification vegavib 63 • namur 31217-en-170315 7 maintenanceandfaultrectification 7.1 maintenance if the device is used properly, no special maintenance is required in normal operation. 7.2 rectify faults the operator of the system is responsible for taking suitable meas- ur...

Page 24

24 7maintenanceandfaultrectification vegavib 63 • namur 31217-en-170315 error reason rectification signallampflashesyellow error on the vibrating el- ement check if the vibrating element is damaged or extreme- ly corroded. Interference on the elec- tronics module exchanging the electronics module in...

Page 25

25 7maintenanceandfaultrectification vegavib 63 • namur 31217-en-170315 8. Compare the settings of the two electronics modules. Set the adjustment elements of the new electronics module to the same setting of the old one. Information: make sure that the housing is not rotated during the electronics ...

Page 26: 8 Dismount

26 8 dismount vegavib 63 • namur 31217-en-170315 8 dismount 8.1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of chapters "mounting" and "connecting to power s...

Page 27: 9 Supplement

27 9 supplement vegavib 63 • namur 31217-en-170315 9 supplement 9.1 technical data note for approved instruments the technical data in the respective safety instructions are valid for approved instruments (e.G. With exapproval).Thesedatacandifferfromthedatalistedherein,forexampleregardingtheprocess ...

Page 28

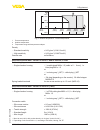

28 9 supplement vegavib 63 • namur 31217-en-170315 Ʋ aluminium/stainless steel housing max. 50 nm (36.88 lbf ft) output variable output two-wire namur output current consumption Ʋ falling characteristics (max.) ≥2.2mauncovered/≤1.0macovered Ʋ rising characteristics (min.) ≤1.0mauncovered/≥2.2macover...

Page 29

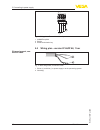

29 9 supplement vegavib 63 • namur 31217-en-170315 1 2 3 -50°c (-58°f) 50°c (122°f) 40°c (104°f) -40°c (-40°f) 80°c (176°f) 0°c (32°f) 100°c (212°f) 150°c (302°f) 200°c (392°f) 250°c (482°f) fig. 31: ambient temperature - process temperature 1 process temperature 2 ambient temperature 3 temperature ...

Page 30

30 9 supplement vegavib 63 • namur 31217-en-170315 Ʋ min. Bending radius 25 mm (0.984 in) with 25 °c (77 °f) Ʋ diameter approx. 8 mm (0.315 in) Ʋ colour - standard pe black Ʋ colour - standard pur blue Ʋ colour - ex-version blue adjustment elements mode switch Ʋ min. Rising characteristic curve (hig...

Page 31

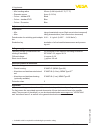

31 9 supplement vegavib 63 • namur 31217-en-170315 9.2 dimensions housing in protection ip 66/ip 67 and ip 66/ip 68; 0.2 bar 3 2 1 4 ~ 69 mm (2.72") ø 79 mm (3.11") 11 7 mm (4.61") m20x1,5/ ½ npt ~ 59 mm (2.32") ø 80 mm (3.15") 11 2 mm (4.41") m20x1,5/ ½ npt ~ 69 mm (2.72") ø 79 mm (3.03") 1 12 mm (...

Page 32

32 9 supplement vegavib 63 • namur 31217-en-170315 l 25 mm (0.98") g1 ø 16 mm (0.63") 20 mm (0.79") 125 mm (4.92") ø 29 mm (1.14") fig. 34: vegavib 63, threaded version g1 (din iso 228/1) l sensor length, see chapter "technical data".

Page 33

33 9 supplement vegavib 63 • namur 31217-en-170315 g1½ 33 mm (1.30") ø 16 mm (0.63") 22 mm (0.87") 125 mm (4.92") ø 29 mm (1.14") l fig. 35: vegavib 63, threaded version g1½ (din iso 228/1) l sensor length, see chapter "technical data".

Page 34

34 9 supplement vegavib 63 • namur 31217-en-170315 ø 34 mm (1.34") 178 mm (7.01") fig. 36: temperature adapter.

Page 35

35 9 supplement vegavib 63 • namur 31217-en-170315 9.3 industrial property rights vega product lines are global protected by industrial property rights. Further information see www.Vega.Com. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte. Nähere informationen unter www.V...

Page 36

Printing date: vega grieshaber kg am hohenstein 113 77761 schiltach germany 31217-en-170315 all statements concerning scope of delivery, application, practical use and operat- ing conditions of the sensors and processing systems correspond to the information available at the time of printing. Subjec...