- DL manuals

- Vega

- Transmitter

- VEGAWELL 52

- Operating instructions manual

Vega VEGAWELL 52 Operating instructions manual

Summary of VEGAWELL 52

Page 1

Operating instructions submersible pressure transmitter with ceramic measuring cell vegawell 52 4 … 20 ma document id: 35401.

Page 2: Contents

2 contents vegawell 52 • 4 … 20 ma 35401-en-171005 contents 1 about this document ............................................................................................................... 4 1.1 function ..............................................................................................

Page 3

3 contents vegawell 52 • 4 … 20 ma 35401-en-171005 safety instructions for ex areas take note of the ex specific safety instructions for ex applications. These instructions are attached as documents to each instrument with ex approval and are part of the operating instructions manual. Editing status...

Page 4: 1 About This Document

4 1 about this document vegawell 52 • 4 … 20 ma 35401-en-171005 1 about this document 1.1 function this operating instructions manual provides all the information you need for mounting, connection and setup of the instrument. Further- more there are important instructions for maintenance, fault rect...

Page 5: 2 For Your Safety

5 2 for your safety vegawell 52 • 4 … 20 ma 35401-en-171005 2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the requ...

Page 6

6 2 for your safety vegawell 52 • 4 … 20 ma 35401-en-171005 trary conversions or modifications are explicitly forbidden. For safety reasons, only the accessory specified by the manufacturer must be used. To avoid any danger, the safety approval markings and safety tips on the device must also be obs...

Page 7

7 2 for your safety vegawell 52 • 4 … 20 ma 35401-en-171005 • chapter " packaging, transport and storage " • chapter " disposal ".

Page 8: 3 Product Description

8 3 product description vegawell 52 • 4 … 20 ma 35401-en-171005 3 product description 3.1 configuration the scope of delivery encompasses: • vegawell 52 pressure transmitter with suspension cable • documentation – this operating instructions manual – test certificate – supplementary instructions " s...

Page 9

9 3 product description vegawell 52 • 4 … 20 ma 35401-en-171005 1 2 3 4 5 7 8 9 10 11 12 13 14 6 fig. 2: structure type label vegawell 52 (example) 1 instrument type 2 product code 3 approvals 4 process temperature 5 signal output/operating voltage 6 materials transmitter/measuring cell/measuring ce...

Page 10

10 3 product description vegawell 52 • 4 … 20 ma 35401-en-171005 tance change in the measuring cell via the ceramic diaphragm. This change is converted into an appropriate output signal. As a standard feature, the certec ® measuring cell is equipped with a lateral, recessed seal. Instruments with do...

Page 11

11 3 product description vegawell 52 • 4 … 20 ma 35401-en-171005 up to the time of installation, the packages must be left closed and stored according to the orientation and storage markings on the outside. Unless otherwise indicated, the packages must be stored only under the following conditions: ...

Page 12: 4 Mounting

12 4 mounting vegawell 52 • 4 … 20 ma 35401-en-171005 4 mounting 4.1 general instructions make sure that all parts of the instrument coming in direct contact with the process, especially the sensor element, process seal and process fitting, are suitable for the existing process conditions, such as p...

Page 13

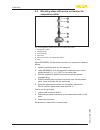

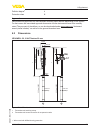

13 4 mounting vegawell 52 • 4 … 20 ma 35401-en-171005 fig. 5: mounting example: vegawell 52 in an open basin with breather hous- ing vegabox 03 4.2 mounting steps with straining clamp 2 3 1 fig. 6: straining clamp 1 suspension cable 2 suspension opening 3 clamping jaws mount vegawell 52 with straini...

Page 14

14 4 mounting vegawell 52 • 4 … 20 ma 35401-en-171005 4.3 mounting steps with screw connection for suspension cable 1 2 3 4 5 6 fig. 7: configuration, screw connection of suspension cable 1 suspension cable 2 sealing screw 3 cone bushing 4 seal cone 5 screw connection for suspension cable 6 seal mou...

Page 15

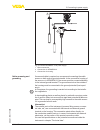

15 4 mounting vegawell 52 • 4 … 20 ma 35401-en-171005 4.4 mounting steps with threaded connection or housing 2 3 1 fig. 8: plastic housing 1 housing 2 seal 3 thread mount vegawell 52 as follows: 1. Weld the welded socket g1½ a or 1½ npt to the vessel top 2. Shift transmitter through the mounting bos...

Page 16

16 5 connecting to power supply vegawell 52 • 4 … 20 ma 35401-en-171005 5 connecting to power supply 5.1 preparing the connection generally connect the instrument only in the complete absence of line voltage. The instrument is equipped with an integrated overvoltage protection. For additional protec...

Page 17

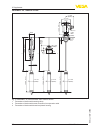

17 5 connecting to power supply vegawell 52 • 4 … 20 ma 35401-en-171005 1 2 3 fig. 9: connect vegawell 52 to power supply 1 direct connection 2 connection via vegabox 03 3 connection via housing if screened cable is required, we recommend connecting the cable screen on both ends to ground potential....

Page 18

18 5 connecting to power supply vegawell 52 • 4 … 20 ma 35401-en-171005 5.2 connection procedure proceed as follows: 1. Wire the suspension cable up to the connection compartment 2) 2. Connect the wire ends to the screw terminals according to the wiring plan connect the vegawell 52 according to the ...

Page 19

19 5 connecting to power supply vegawell 52 • 4 … 20 ma 35401-en-171005 1 2 4 5 3 6 1 2 fig. 12: wiring plan housing 1 to power supply or processing system 1 3 2 sensor 1 2 + ( ) (-) power supply 3 4 + ( ) (-) fig. 13: wiring plan vegawell 52 for 4 … 20 ma sensors 1 to the sensor 2 terminal for conn...

Page 20

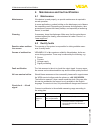

20 6 maintenance and fault rectification vegawell 52 • 4 … 20 ma 35401-en-171005 6 maintenance and fault rectification 6.1 maintenance if the device is used properly, no special maintenance is required in normal operation. In some applications, product buildup on the diaphragm can influence the meas...

Page 21

21 6 maintenance and fault rectification vegawell 52 • 4 … 20 ma 35401-en-171005 error code cause rectification 4 … 20 ma signal miss- ing wrong connection to voltage supply – check connection according to chapter " connection steps " and if necessary, correct according to chapter " wiring plan " no...

Page 22

22 6 maintenance and fault rectification vegawell 52 • 4 … 20 ma 35401-en-171005 1 2 fig. 14: step 4 1 sw 46 2 sw 22 4. Pull the suspension cable out of the screwed socket, remove the pressure screw, cone sleeve and seal cone from the cable 5. Remove the filter adapter from the capillary line 4 3 2 ...

Page 23

23 6 maintenance and fault rectification vegawell 52 • 4 … 20 ma 35401-en-171005 8. Shift the seal screw, cone sleeve and seal cone to the suspension cable and insert the cable into the screwed socket, insert the wire ends through the cable entry into the mounting plate the work steps are finished. ...

Page 24: 7 Dismount

24 7 dismount vegawell 52 • 4 … 20 ma 35401-en-171005 7 dismount 7.1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel or pipeline, high temperatures, cor- rosive or toxic products etc. Take note of chapters " mounting " and "...

Page 25: 8 Supplement

25 8 supplement vegawell 52 • 4 … 20 ma 35401-en-171005 8 supplement 8.1 technical data note for approved instruments the technical data in the respective safety instructions are valid for approved instruments (e.G. With ex approval). These data can differ from the data listed herein, for example re...

Page 26

26 8 supplement vegawell 52 • 4 … 20 ma 35401-en-171005 weight approx. Ʋ basic weight 0.8 kg (1.764 lbs) Ʋ suspension cable 0.1 kg/m (0.07 lbs/ft) Ʋ straining clamp 0.2 kg (0.441 lbs) Ʋ screw connection for suspension cable 0.4 kg (0.882 lbs) Ʋ plastic housing 0.8 kg (1.764 lbs) Ʋ stainless steel ho...

Page 27

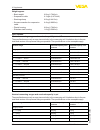

27 8 supplement vegawell 52 • 4 … 20 ma 35401-en-171005 nominal range overload capacity, max. Pressure overload capacity, min. Pressure 0 … 35 psig 700 psig -15 psig 0 … 70 psig 950 psig -15 psig 0 … 150 psig 1300 psig -15 psig 0 … 350 psig 1900 psig -15 psig 0 … 900 psig 2900 psig -15 psig absolute...

Page 28

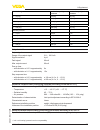

28 8 supplement vegawell 52 • 4 … 20 ma 35401-en-171005 deviation with version Ʋ turn down 1 : 1 up to 5 : 1 Ʋ turn down up to 10 : 1 deviation with version Ʋ turn down 1 : 1 up to 5 : 1 Ʋ turn down up to 10 : 1 influence of the medium or ambient temperature specifications refer to the set span. Tur...

Page 29

29 8 supplement vegawell 52 • 4 … 20 ma 35401-en-171005 Ʋ f kl : deviation ambient conditions ambient temperature Ʋ suspension cable pe -40 … +60 °c (-40 … +140 °f) Ʋ suspension cable pur, fep -40 … +80 °c (-40 … +176 °f) storage and transport temperature -40 … +80 °c (-40 … +176 °f) process conditi...

Page 30

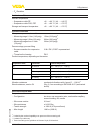

30 8 supplement vegawell 52 • 4 … 20 ma 35401-en-171005 Ʋ min. Bending radius 25 mm (at 25 °c/77 °f) Ʋ diameter approx. 8 mm (0.315 in) Ʋ cable extraction force ≥ 650 n (146.1 lbf) Ʋ colour (non-ex/ex) - pe black/blue Ʋ colour (non-ex/ex) - pur, fep blue/blue cable entry housing 1 x cable gland m20 ...

Page 31

31 8 supplement vegawell 52 • 4 … 20 ma 35401-en-171005 pollution degree 9) 4 protection class iii approvals instruments with approvals can have different technical specifications depending on the version. For that reason the associated approval documents of these instruments have to be carefully no...

Page 32

32 8 supplement vegawell 52 • 4 … 20 ma 35401-en-171005 vegawell 52, titanium 33 mm 22 mm (0.87") g1 ½a/ npt1 ½ 316 l ~ 69 mm (2.72") ø 77 mm (3.03") 112 mm (4.41") m20x1,5/ ½ npt 3 2 1 sw 30 mm (1.18") g1½ a 175 mm (6.89") l l l ø 33 mm (1.30") 210 mm (8.27") 38,5 mm (1.52") 14 mm (0.55") ø 8 mm (0...

Page 33

33 8 supplement vegawell 52 • 4 … 20 ma 35401-en-171005 vegawell 52, duplex (1.4462)/pvdf sw46 (1.81") l 22 mm (0.87") g1 ½a/ npt1 ½ 316 l ~ 69 mm (2.72") ø 77 mm (3.03") 112 mm (4.41") m20x1,5/ ½ npt 5 2 3 4 1 sw 30 mm (1.18") g1½ a l ø 32 mm (1.26") 206 mm (8.11") / 208 mm (8.19") ø 32 mm (1.26") ...

Page 34

34 8 supplement vegawell 52 • 4 … 20 ma 35401-en-171005 vegawell 52, duplex (1.4462) threaded fitting 234 mm (9.21") l l 20 mm (0.79") 74 mm (2.91") ø 32 mm (1.26") ø 40 mm (1.58") sw 27 mm (1.06") ø 32 mm (1.26") 230 mm (9.06") ø 8 mm (0.32") ø 22 mm (0.87") ø 8 mm (0.32") g½ sw 41 mm (1.61") g1 g¼...

Page 35

35 8 supplement vegawell 52 • 4 … 20 ma 35401-en-171005 8.3 industrial property rights vega product lines are global protected by industrial property rights. Further information see www.Vega.Com. Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind we...

Page 36: Index

36 index vegawell 52 • 4 … 20 ma 35401-en-171005 index a accessories – breather housing 11 – measuring instrument holder 11 – mounting bracket 11 application area 9 c cable screening 17 connection – directly 18 – via housing 19 – via vegabox 03 18 – via vegadis 82 19 f functional principle 9 i insta...

Page 37

37 notes vegawell 52 • 4 … 20 ma 35401-en-171005.

Page 38

38 notes vegawell 52 • 4 … 20 ma 35401-en-171005.

Page 39

39 notes vegawell 52 • 4 … 20 ma 35401-en-171005.

Page 40

Printing date: vega grieshaber kg am hohenstein 113 77761 schiltach germany 35401-en-171005 all statements concerning scope of delivery, application, practical use and operat- ing conditions of the sensors and processing systems correspond to the information available at the time of printing. Subjec...