- DL manuals

- Vekso

- Bicycle Accessories

- CPU1001

- Technical Manual

Vekso CPU1001 Technical Manual

Summary of CPU1001

Page 1

Air compressor pump cpu1001 technical manual enriching urban life 10057001 v1.0 2013 01 28 en.

Page 2

Air cpu1001 2 table of contents table of contents .....................................................................................2 introduction .............................................................................................3 product overview .........................................

Page 3

Air cpu1001 3 introduction thank you for choosing a veksØ product from our range of urban cycling solutions. Air is an automatic air pump designed for use with bicycles. The pump fea- tures an electrical compressor to make filling bicycle tires with air simple and easy. The pump head accommodates th...

Page 4

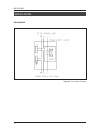

Air cpu1001 4 product overview no. Description 1 air pump system cabinet door 2 fuse box 3 pressure adjusting box 4 power supply switch 5 compressor system 6 front glass 7 led housing led pcb 8 pump handle and hose 9 hook for pump handle 10 cover for hose 11 control box 11 6 7 8 9 10 1 5 4 3 2 figur...

Page 5

Air cpu1001 5 safety information important: read these instructions before product installation and operation before product installation and operation, please read the following safety information and sections in this manual concerning operation and installation. In addition to addressing safety co...

Page 6

Air cpu1001 6 safety information to reduce risk of explosion or fire •serviceandoperatethisproductonlyinwellventilatedareas. •duringsprayingwithcombustibleliquidsriskofexplosionmayarise, particularly in closed rooms. •donotusethisproductinornearexplosiveatmospheresorwhere aerosol products are being ...

Page 7

Air cpu1001 7 operation general use before turning on the pump, ensure the fuse box (figure 1, item 2) and compressor switch (figure 3) are both in the on position. Turn on the pump by moving the power supply switch to the on position (figure 1, item 4). The pump is now ready for use. The pump is de...

Page 8

Air cpu1001 8 operation compressor the compressor will automatically stop when the preset maximum pressure is reached (stop pressure). The compressor will automatically start when pressure has dropped below the preset minimum pressure (start pressure). Safety warning: do not remove the protection co...

Page 9

Air cpu1001 9 operation adjustment of pressure switch the compressor stop pressure and start pressure is preset from the factory and it does not normally require adjustment. If it is necessary to change the preset settings, these instructions should be followed carefully. Attention: the compressor i...

Page 10

Air cpu1001 10 installation mounting installation of the pump is typically done by casting 4 x m10 threaded rods into a concrete foundation (figure 5). The threaded rods should protrude ap- proximately 75mm above the foundation. The distance between the mounting holes is 120mm x 420mm (figure 5). Th...

Page 11

Air cpu1001 11 installation electrical safety warning: incorrect electrical connection may result in electric shock. The electrical connection must be carried out in accordance with local electrical regulations and by qualified electricians. Attention: the installer must be careful to ensure that th...

Page 12

Air cpu1001 12 installation figure 8: connection diagram connection.

Page 13

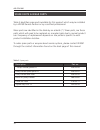

Air cpu1001 13 technical specification figure 9: other dimensions table 2: technical specification model model no. Cpu1001 materials and finish outer casing 3mm aluminium aluminium or powder coated front glass 3mm blue acrylic hose armoured steel hydraulic air line. Pump handle accomodates dunlop, s...

Page 14

Air cpu1001 14 technical specification table 2: technical specification compressor max pressure 8bar (factory setting 6bar) noise in app. 50db the compressor is oil free and drains automatically. The compressor automatically switches off if fault or vandalism causes the compressor to run continuousl...

Page 15

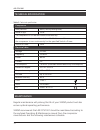

Air cpu1001 15 table 3: maintenance list maintenance list monthly semi annual annual check the pump handle and rubber gaskets for proper functioning. Replace gaskets if necessary. • the switch off time of the compressor is 5 minutes. Activate the pump handle valve for 5 minutes, and ensure the compr...

Page 16

Air cpu1001 16 spare parts & wear parts table 5 identifies spare parts available for this product which may be installed by a veksØ service partner or by a certified professional. Wear parts are identified in the table by an asterisk (*). Wear parts, are those parts which will need to be replaced on...

Page 17

Air cpu1001 17 terms & conditions of sale veksØ terms & conditions of sale are available on the veksØ website. This product has a 1-year warranty covering manufacturing defects. Warranty coverage does not include damage due to vandalism. Warranty coverage does not include replacement of wear parts s...

Page 20

Contact information & service support please contact us if you have questions about your veksØ product, require service support, would like to order replacement parts, or would like to enquire about other veksØ products and services. Nordensvej 2 7000 fredericia denmark tel +45 7921 2200 fax +45 792...