Installation instructions and user guide vb0188 pro301 heat recovery ventilator v enmar v entilation i nc ., 550 l emire b lvd ., d rummondville , q c . C anada j2c 7w9 www . Venmar . Ca * this product earned the energy star ® by meeting strict energy efficiency guidelines set by natural resources c...

First, we want to congratulate you on your purchase of this excellent unit which will allow you and your family to enjoy clean and healthy air throughout your home for years to come! Please take note that this manual uses the following symbols to emphasize particular information: identifies an instr...

T able of c ontents 3 1. T ypical i nstallations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.1 f ully d ucted s ystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 c entral d raw p oint . . . ...

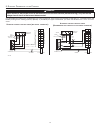

4 1. T ypical i nstallations use the following illustrations as guidelines to help you decide on how the unit will be installed. All the units should be hung from the joists. In every case, bathroom fans and a range hood could be used to exhaust stale air. However, please note that an optional bathr...

5 2. D imensions 11¼” 17 7 / 16 ” 37 7 / 16 ” 35 7 / 8 ” 31” 11 7 / 8 ” vk0081a 3. I nstallation 3.1 i nspect the c ontent of the b ox • inspect the inside of the unit for damage. Ensure that blower assembly, heat recovery core, core filters, insulation, dampers, etc. Are all intact, then reinstall ...

6 3. I nstallation ( cont ’ d ) 3.3 l ocating the unit choose an appropriate location for the unit. • within an area of the house where the ambient temperature is kept between 10°c (50°f) and 40°c (104°f) . • away from living areas (dining room, living room, bedroom), if possible. • so as to provide...

7 3.5 i nstalling n on -i nsulated d ucts and d iffusers ( cont ’ d ) 3.5.1 f ully d ucted s ystem ( as illustrated in s ection 1.1) ( cont ’ d ) h ow to connect the flexible ducts to the diffusers once the diffusers location is determined, cut out 5¼” diameter hole. Run one end of the flexible duct...

8 3.5 i nstalling n on -i nsulated d ucts and d iffusers ( cont ’ d ) fresh air distribution ductwork (return side connection) same as for central draw point, described in step 3.5.2 3.5.3 s implified i nstallation ( as illustrated in s ection 1.3) stale air exhaust ductwork (return side connection)...

9 3. I nstallation ( cont ’ d ) 3.6 i nstalling i nsulated f lexible d ucts ( cont ’ d ) choose an appropriate location for installing the exterior ports: • there must be a minimum distance of 6’ (1.8 m) between the hoods to avoid cross-contamination • there must be a minimum distance of 18” (457 mm...

10 3. I nstallation ( cont ’ d ) 3.9 c onnecting the d rain cut two sections of plastic tubing, approximately 12” long, and connect each one to both inner drain fittings located under the unit as shown. Join these both sections to the “t” junction and main tube as shown, to prevent the unit from dra...

11 4. C ontrols this unit is equipped with an integrated defrost control located under the electrical compartment of the unit. Plug the unit. 4.1 b ooting s equence the unit booting sequence is similar to a personnal computer boot sequence. Each time the unit is plugged after being unplugged, or aft...

12 4. C ontrols ( cont ’ d ) always disconnect the unit before making any connections. Failure in disconnecting power could result in electric shock or damage of the wall control or electronic module inside the unit. Warning ! Failure to comply with the following can cause erratic operation of the u...

4. C ontrols ( cont ’ d ) 13 4.4 w all c ontrol ( s ) c onnection to the u nit ve0275 once the control(s) connection have been made, insert the terminal connector in the electrical compartment interface. Plug the unit. 4.5 l ite -t ouch pro u se intermittent max min vc0124 l-t when power is applied ...

5. E lectric c onnection to the f urnace never connect a 120-volt ac circuit to the terminals of the furnace interlock (standard wiring). Only use the low voltage class 2 circuit of the furnace blower control. Warning ! On some electronic thermostats, energizing the “r” and “g” terminals at the furn...

6. W iring d iagram 15 • risk of electric shocks. Before performing any maintenance or servicing, always disconnect the unit from its power source. • this product is equipped with an overload protection (fuse). A blown fuse indicates an overload or a short-circuit situation. If the fuse blows, unplu...

16 7. M aintenance risk of electric shock. Before performing any maintenance, always turn off and disconnect the unit from its power source. Warning ! 7.1 e very t hree m onths vd0005 turn the unit off and unplug it. Using a phillips or a robertson screwdriver, loosen both door screws ( a ). Note: t...

7. M aintenance ( cont ’ d ) 17 7.2 a nnual m aintenance repeat steps to and continue with the following steps: allow the heat recovery core to soak for 3 hours in a solution of warm water and mild soap (dishwashing liquid). Rinse carefully, drain off water, and reinstall with its filters as well as...

18 9. T roubleshooting if the unit does not work properly, reset the unit by unplugging it for one minute and then replug it. If it is still not working properly, refer to table below. Problems you should try this 1 unit does not work. • see if the unit is plugged in. • check if the upper left port ...