- DL manuals

- Vent-Axia

- Ventilation Hood

- LoWatt HR204

- User, installation & servicing instructions

Vent-Axia LoWatt HR204 User, installation & servicing instructions

Summary of LoWatt HR204

Page 1

Please leave these instructions with the user whole house ventilation system with heat recovery user, installation & servicing instructions lowatt hr204 abc.

Page 2

2 contents section page 1.0 safety and guidance notes 2.0 user information 3.0 general layout 4.0 technical data 5.0 appliance operation 6.0 installation requirements 7.0 installation 8.0 wiring diagrams 9.0 commissioning 10.0 maintenance 11.0 changing components 12.0 fault finding 13.0 short parts ...

Page 3

3 1.0 safety and guidance notes 1. Do not install this product in areas where the following may be present or occur: -excessive oil or a grease laden atmosphere. -corrosive or flammable gases, liquids or vapours. -ambient temperatures higher than 40°c or less than 5°c. -possible obstructions which w...

Page 4

4 2.0 user information read the instructions fully before installing or using the appliance. This appliance must be installed in accordance with the manufacturer's instructions and the regulations in force. The lowatt hr204 is a mechanical ventilation with heat recovery (mvhr) unit. The unit provide...

Page 5

5 3.0 general layout lowatt hr 204 exhaust out to atmosphere fresh air in from atmosphere n l 1 2 1 2 3 4 5 6 7 8 normal boost 1 2 3 4 5 4 5 6 on front up hot stale air extracted in from wet rooms warmed fresh air supplied out to dry rooms 1 2 8 10 9 11 15 6 7 14 4 13 5 12 fig. 2 3 1. Heat exchanger...

Page 6

6 4.0 technical data dimensions (mm) height width depth minimum clearances (mm) both sides above casing below casing front for servicing front in operation lift weight (kg) power consumption @ 0pa (watts) suitable for Ø100mm circular ducts. Suitable for Ø15mm pipe. 220-240v ~ 50hz 3 amps 3.15 amps e...

Page 7

7 4.0 technical data 412 552 mounting brackets side view Ø 98 100 280 285 4 lower fixing hole e x h a u s t o u t f re s h a ir in h o t s ta le a ir i n w a rm a ir o u t air flow system clean air stale air front view fig. 6 flow rate vs pressure chart fig. 5 the unit has six speeds. One of the low...

Page 8

8 5.0 appliance operation on normal running the fans run at the speed set during commissioning (speed 1, 2, 3, 4 or 5). If the external controls call for boost operation the fans automatically run at the boost speed & increase the air movement of both exhaust & inlet air. Optional extras. External c...

Page 9

9 6.0 installation requirements 6.1 location and site requirements all dimensions in mm total required (including clearances) height - 692 width - 562 depth - 530 minimum top clearance for servicing 200 minimum side clearance 5 minimum side clearance 5 minimum bottom clearance 100 minimum front clea...

Page 10

10 6.0 installation requirements 6.2 general 1. The lowatt hr204 has a choice of 5 normal speed settings and 3 boost speed settings. The performance curve chart (section 4, fig.5) gives the ventilation rates at each fan speed setting compared to the pressure drop of the system. 2. The transmission o...

Page 11

11 6.0 installation requirements n l 1 2 1 2 3 4 5 6 7 8 normal boost 1 2 3 4 5 4 5 6 on remove bottom cover panel to access the fan speed settings & condensate connection. The condensate outlets are marked on the wall template. Wall template mains lead cable clamp & grommet for mains lead fuse fit ...

Page 12

N l 1 2 1 2 3 4 5 6 7 8 normal boost 1 2 3 4 5 4 5 6 on front up 12 ex ha us t o ut fr es h a ir in ho t s t a e l air in w arm a ir o ut example of a possible understairs installation place unit on its back & remove front cover remove electrical cover plate (3 screws) ground floor stair case mark p...

Page 13

N l 1 2 1 2 3 4 5 6 7 8 normal boost 1 2 3 4 5 4 5 6 on front up 13 7.3 fitting the lowatt hr204 1. Offer the unit to the wall and engage the keyhole slots over the screws previously fitted. 2. Make sure the unit is level and tighten the top screws before engaging the final screw. 7.4 making the con...

Page 14

N l 1 2 1 2 3 4 5 6 7 8 normal boost 1 2 3 4 5 4 5 6 on front up 14 7.0 installation 7.5 making the duct connections 1. The unit has four duct connections suitable for 100mm round ducting. 1. Exhaust outlet to outside 2. Air inlet from outside 3. Stale air inlet from dwelling 4. Fresh air outlet to ...

Page 15

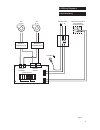

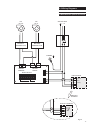

15 8.0 wiring diagrams fig. 13 lowatt hr204 wiring manual normal /boost switch nbsw or pull switch pcsw common boost normal l fan (air out) fan (air in) speed select 1 2 l n 1 2 3 4 5 6 7 8 normal boost 1 2 3 4 5 4 5 6 on motor control a b motor supply a b 220-240v 50hz motor b control p.C.B motor a...

Page 16

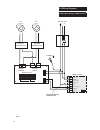

L fan (air out) fan (air in) speed select 1 2 l n 1 2 3 4 5 6 7 8 normal boost 1 2 3 4 5 4 5 6 on motor control a b motor supply a b 220-240v 50hz motor b control p.C.B motor a control p.C.B chassis n 16 8.0 wiring diagrams fig. 14 lowatt hr204 wiring & cmsm controller cmsm controller l n l live in ...

Page 17

17 hs6 humidistat 0 2 1 common boost ordinary n l lowatt hr204 with optional humidistats 8.0 wiring diagrams 1 2 fig. 15 l fan (air out) fan (air in) speed select 1 2 l n 1 2 3 4 5 6 7 8 normal boost 1 2 3 4 5 4 5 6 on motor control a b motor supply a b 220-240v 50hz motor b control p.C.B motor a co...

Page 18

18 9.2 balancing the system it is important that a suitable anemometer is used to balance the system to give the required ventilation rates to each room. 1. Set the appliance running on normal speed. 2. Make a preliminary adjustment of all the duct inlet and outlet louvres. Note: the supply air term...

Page 19

N l 1 2 1 2 3 4 5 6 7 8 normal boost 1 2 3 4 5 4 5 6 on front up wiring service 19 10.0 maintenance important: before servicing ensure that the appliance is isolated from the electrical supply. After isolating from the electrical supply, allow one minute for the fans to stop rotating before servicin...

Page 20: 1 3

N l 1 2 1 2 3 4 5 6 7 8 normal boost 1 2 3 4 5 4 5 6 on front up n l 1 2 1 2 3 4 5 6 7 8 normal boost 1 2 3 4 5 4 5 6 on 20 11.0 changing components 11.3 speed select & motor control pcbs 1. Remove the front cover by releasing the two screws and lifting the cover up and forwards. 2. Remove the botto...

Page 21

21 11.4 extract fan and input fan 1. Lift off the front cover by releasing the two screws and lifting upwards. 2. Remove the pcb chassis by following the instructions in 11.3. Disconnect the motor lead. 3. Slacken the two rear fan bracket screws. 4. Remove the two front fan bracket screws and remove...

Page 22

22 12.0 fault finding start yes no check mains supply. Is there mains voltage across terminals a1 & a2? Yes no investigate cause and rectify fault is the fuse on the speed select pcb o.K? Replace speed no is there low voltage between b1 and b2? Yes no check external control wiring. Reconnect wires t...

Page 23

23 replace fan (section 11.4) yes re-align fan either fan rotate when powered? Replace speed select pcb. No no no are fans free to rotate? Is the fan fouling on inlet ring? Yes note no yes did this solve the problem? Yes does swap the problem fan's connection to the drive pcb with the other fan's dr...

Page 24

24 13.0 short parts list 1 2 3 4 5 6 10 7 8 12 n rm o al boo st 11 fr o t n up fig. 21 key no. Spares part no. Description 1 436373 dc motor/impeller assembly 436374 motor drive pcb 372735 inlet duct filter 372736 heat exchanger 372737 heat exchanger seals (4 off) 372739 outer door/cover assembly op...