- DL manuals

- Vento

- Scooter

- Triton R4

- Service Maintenance Manual

Vento Triton R4 Service Maintenance Manual

Summary of Triton R4

Page 1

Vento motorcycles rev no.01/.Page 1 of 143 triton r4 service& maintenance manual.

Page 2

Vento motorcycles rev no.01/.Page 2 of 143.

Page 3

Vento motorcycles rev no.01/.Page 3 of 143 this service manual has been specially prepared to provide all the necessary information for the proper maintenance and servicing of vento triton r4 scooter. The triton r4 has many features such as: • v-belt drive automatic transmission • fan air-cooling sy...

Page 4

Vento motorcycles rev no.01/ page 4of 143.

Page 5

Vento motorcycles rev no.01/ page 5of 143 general information model identification…………………………………………….… 1-1 fuel and engine oil…………………………………………………. 1-1 break-in procedures……………………………………………… 1-1 precautions and general instructions……………………1-2 specifications …………………………………………………………1-3 contents 1111.

Page 6

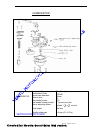

Vento motorcycles rev no.01/ page 6of 143 1-1 general information type & identification frame number frame number ○ 1 is engraving on the steel tube of frame as shown in figure. ○ 1 engine number engine number ○ is engraving on rear side crankcase as shown in figure. Both frame nuber and engine numb...

Page 7

Vento motorcycles rev no.01/ page 7of 143 1-2 general information precautions and general instructions general precautions: warning o proper service and repair procedures are important for the safety of the service mechanic and the reliability of the vehicle. O when two or more persons are working t...

Page 8

Vento motorcycles rev no.01/ page 8of 143 1-3 general information specifications dimensions over all length …….……… 1830mm over all width ……………… 695mm over all height……..……… 1160 mm wheel base ……………. 1295mm net weight…..……………… 92kg chassis front shock absorber……hydraulic rear shock absorber……spring, ...

Page 9

Vento motorcycles rev no.01/ page 9of 143 perodic maintenance and service periodic maintenance and service schedule------------------------------- 2- 1 service and adjustment procedures--------------------------------------------2- 2 storage battery---------------------------------------------------...

Page 10

Vento motorcycles rev no.01/ page 10of 143 2-1 periodic maintenance schedule the chart below lists the recommended intervals for all the required periodic service work necessary to keep the motorcycle operating at peak performance and economy. Mileages are expressed in terms of kilometer, miles and ...

Page 11

Vento motorcycles rev no.01/ page 11of 143 2-2 periodic maintenance procedure battery inspection and checking procedure storage battery inspect at initially 1000kms 630 miles 2 months and every 6000 kms 3780 miles 12 months • open the battery box cover from the foot rest. • disconnect negative termi...

Page 12

Vento motorcycles rev no.01/ page 12of 143 remove the battery from the motorcycle/scooter. Connect the battery on load tester ensuring red lead of tester to (+ve) and black lead to (-ve) terminal of battery. Check the terminal voltage of battery. It should be 12~14.5 volts. Press the push button on ...

Page 13

Vento motorcycles rev no.01/ page 13of 143 specific gravity the specific gravity of fully charged battery should be 1.220~1.240 use hydrometer to check each cell of battery. Warning remove negative terminal first, then positive terminal. If the battery is corroded by sulfur. Please exchange it. If t...

Page 14

Vento motorcycles rev no.01/ page 14of 143 2-3 periodic maintenance and adjustment procedure cylinder head nuts and exhaust pipe bolts tighten at initially 1000 km 630 miles or 2 moths and every 6000 km 3780 miles or 12 months if cylinder head nuts are not tightened to the specified torque, may resu...

Page 15

Vento motorcycles rev no.01/ page 15of 143 2-4 periodic maintenance and adjustment procedures spark plug neglecting the spark plug maintenance eventually leads to difficult starting and poor performance. If the spark plug is used for a long time, the electrode gradually burns away and carbon builds ...

Page 16

Vento motorcycles rev no.01/ page 16of 143 2-5 periodic maintenance and adjustment procedur e air cleaner : clean every 3000 kms 1890 miles replace every 12000 kms(1750 miles) if the air cleaner is clogged with dust, air intake resistance will be increased with a result decrease in power output and ...

Page 17

Vento motorcycles rev no.01/ page 17of 143 loosen locknut and adjust throttle cable play by turning adjuster in or out to obtain the following cable play. After adjusting the cable play tighten the locknut. Cable play 0.5-1.0mm 0.02.-0.040 inch engine idle speed adjust at initially 1000kms 630 miles...

Page 18

Vento motorcycles rev no.01/ page 18of 143 2-6 periodic maintenance procedure oil pump: inspect at initially 1000 kms 630 miles 2 months and every 6000 kms 3780 miles or 12 months there after. The oil pump to the engine feeds the engine oil. The amount of oil fed to it is regulated by engine speed a...

Page 19

Vento motorcycles rev no.01/ page 19of 143 2-7 periodic maintenance procedure gear oil: inspect at initially 1000 km 600 miles or 2 months and every 2000 km 1260 miles or 12 months thereafter. Inspect gear oil periodically as follows: remove the cover and hose. Remove the kick-start lever. Remove cl...

Page 20

Vento motorcycles rev no.01/ page 20of 143 2-8 periodic maintenance procedure brake pads (front brake) observing the limit can check the wear condition of brake pads line ○ 1 marked on the pad. When the wear exceeds the limit mark, replace the pads with new ones. Caution: replace the brake pad as a ...

Page 21

Vento motorcycles rev no.01/ page 21of 143 □ bleed air from the bleeder valve. Squeeze and release the brake lever several times in rapid succession. And squeeze the lever fully without releasing it. Loosen the bleeder valve by turning it a quarter of a turn so that the brake fluid runs into the rec...

Page 22

Vento motorcycles rev no.01/ page 22of 143 brake shoe wear: this vehicle is equipped with the brake lining limit indicator on the rear brake. Inspect brake lining limit as follows • first check if the brake system is properly adjusted. • when operating the brake, check to see that the tip of indicat...

Page 23

Vento motorcycles rev no.01/ page 23of 143 tire: inspect at initially 1000kms 630 miles 2 months and every 6000km 3780 miles 12 months thereafter tire pressure if the tire pressure is too high, the steering will be adversely affected and tire wear increased. Conversely, if tire pressure is too low, ...

Page 24

Vento motorcycles rev no.01/ page 24of 143 front fork: inspect &adjust at initially 1000 kms 630 miles 2 months and every 6000 km 3780 miles 12 months thereafter. Inspect the front shock absorber for oil leakage or other damage, and replace the defective parts, if necessary. Rear shock absorber: ins...

Page 25

Vento motorcycles rev no.01/ page 25of 143 10 14 14.

Page 26

Vento motorcycles rev no.01/ page 26of 143 compression pressure check the compression of the cylinder is a good indicator of its internal condition. The decision to overhaul the cylinder is often based on the results of a compression test. Periodic maintenance records kept at your dealership should ...

Page 27

Vento motorcycles rev no.01/ page 27of 143 automatic clutch inspection this vento triton r4 is equipped with an automatic clutch and variable ratio belt drive transmission. The engagement of the clutch is governed by engine rpm and centrifugal mechanism located in the clutch. To ensure proper perfor...

Page 28

Vento motorcycles rev no.01/ page 28of 143 chapter 3 engine contens engine components removal with the engine in place…………….. Engine removal and remounting ……………………………………. Engine removal……………………………………………………….. Engine remounting…………………………………………………… engine disassembly………………………………………………….. Engine compo...

Page 29

Vento motorcycles rev no.01/ page 29of 143 engine components removable with the engine in place the parts listed below can be removed and reinstalled without removing the engine from the frame. Engine left side • kick starter lever • clutch cover • kick starter shaft • kick driven gear • fixed drive...

Page 30

Vento motorcycles rev no.01/ page 30of 143 engine removal and reinstallation engine assy. • remove the muffler • remove cooling fan cover • remove cylinder cover • remove cooling fan • remove magneto nut with special tools. • remove magneto rotor and half circle key with special tools. • remove magn...

Page 31

Vento motorcycles rev no.01/ page 31of 143 • remove worm wheel and oil seal press board remove cylinder head and cylinder place a cloth stopper below the piston and remove the circlip with a plier. Remove the piston pin and piston. Remove the piston rings from the piston..

Page 32

Vento motorcycles rev no.01/ page 32of 143 remove the kick starter lever. Remove side cover. Remove movable ratchet wheel and clip.

Page 33

Vento motorcycles rev no.01/ page 33of 143 remove starting driven ratchet wheel by removing the nuts. Remove fan ○ 5 and v-belt ○ 6 . Disassemble the movable drive face ○ 7 . Remove electric gear press board, electric gear and super clutch. Remove starter motor.

Page 34

Vento motorcycles rev no.01/ page 34of 143 • remove the clutch housing with the special tool. • drain gear oil • remove rear axle nut • remove rear wheel • remove brake shoe ○ 5 and rear axle ○ 6 ..

Page 35

Vento motorcycles rev no.01/ page 35of 143 remove the rear brake cam lever ○ 1 indicator plate ○ 2 and camshaft ○ 3 . Remove spring ○ 4 remove cotter pin ○ 5 and shaft ○ 6 remove main stand ○ 7 • remove gear case cover • remove paper gasket ○ 1 and middle gear assy. ○ 2 • remove output gear assy. ○ ...

Page 36

Vento motorcycles rev no.01/ page 36of 143 • remove intake pipe • remove reed valve and paper gasket. Disassemble crankcase with special tools.

Page 37

Vento motorcycles rev no.01/ page 37of 143 remove crankcase with special tools remove crank shaft from crankcase. Remove crankshaft bearing with special tools..

Page 38

Vento motorcycles rev no.01/ page 38of 143 • loosen the clutch shoe nut with the special tool. • remove the nut while holding down clutch shoe assy. By both hands as shown in the illustration. Warning gradually back off the clutch shoe assy. Pressed down by hands to reduce the clutch sparing load. R...

Page 39

Vento motorcycles rev no.01/ page 39of 143 do not attempt to disassemble the clutch shoe assy. Otherwise the clutch shoe may be damaged. • remove the movable driven face seat with a thin bared screwdriver. • remove the pins ○ 4 , movable driven face ○ 5 and fixed driven face ○ 6 . • remove circlip ○...

Page 40

Vento motorcycles rev no.01/ page 40of 143 one. Remove the spacer remove the oil seal from the gear case cover with the special tool . Caution replace the removed oil seal with a new one. Remove the bearing with special tool . Caution replace the removed bearing with a new one. Removing the bearings...

Page 41

Vento motorcycles rev no.01/ page 41of 143 remove the bearing retainer. Remove oil seal with the special tools . Caution replace the removed oil seal with a new one. Remove the bearing with special tool . Caution replace removed bearing with a new one. Remove the drive shaft bearing ○ 1 and idle sha...

Page 42

Vento motorcycles rev no.01/ page 42of 143 remove the right crankshaft oil seal with special tool. Caution the removed oil seal should be replaced with a new one. Remove the the right crankshaft bearing with the special tool. Caution the removed bearing should be replace with a new one. Remove the l...

Page 43

Vento motorcycles rev no.01/ page 43of 143 the engine mounting bushings on a vise as shown in the illustrations. Engine components inspection and servicing bearing: clear bearing with solvent and lubricate with engine oil before inspection. Rotate the bearing inner race by finger to inspect for abno...

Page 44

Vento motorcycles rev no.01/ page 44of 143 oil seal: damage to the lip of the oil seal may result in leakage of the fuel-air mixture or oil. Inspect for damage and be sure to replace the damaged seal if found. Crankshaft: crankshaft run out: support the crankshaft with“v” blocks as shown, with the t...

Page 45

Vento motorcycles rev no. 01/ page 50 of 143 service limit 3.0mm(0.12in) instruments: 1. Dial gauge (1/100 mm) 2. V block and 3. Thickness gauge push the big end of the conrod to one side and measure the side clearance with the thickness gauge. Standard: 0.10~0.45 mm (0.004~0.018 in) service limit: ...

Page 46

Vento motorcycles rev no. 01/ page 51 of 143 clutch housing, for deep scratches or uneven wear or discoloration caused by burning. Measure the clutch housing inside diameter with inside calipers. Measure the diameter at several points to check for an out-of-round condition as well as wear. If any de...

Page 47

Vento motorcycles rev no. 01/ page 52 of 143 driving face spring inspection: measure the free distance of the driven face spring. If the length is shorter than the service limit, replace the spring with a new one . Service limit: 104.5mm (4.11 in) driven face pin and oil seal inspection: turn the dr...

Page 48

Vento motorcycles rev no. 01/ page 53 of 143 inspect the belt contacting surface of both driven faces for any scratches, wear and damage. Replace driven face with a new one if there is any abnormality..

Page 49

Vento motorcycles rev no. 01/ page 54 of 143 cylinder head distortion: de-carb the combustion chamber. Check the gasket surface of the cylinder head as shown in the illustration for distortion with a straightedge and thickness gauge, taking a clearance reading at several places. If the largest readi...

Page 50

Vento motorcycles rev no. 01/ page 55 of 143 after reworking the bore to an oversize, be sure to chamfer the edges of ports and smooth the chamfered edges with emery paper. To chamfer, use a scraper, taking care not to nick the wall surface. Note minor surface flaws on the cylinder wall due to seizu...

Page 51

Vento motorcycles rev no. 01/ page 56 of 143 standard service limit cylinder 4 40.005-40.020 mm 40.075 mm piston 39.94-39.955 mm 39.885 mm cylinder to piston 0.06-0.07 mm 0.120 mm de-carb: de-carb the piston and piston ring grooves, as illustration. After cleaning the grooves, fit the rings and rota...

Page 52

Vento motorcycles rev no. 01/ page 57 of 143 service limit 11.980mm(0.4717 in) piston rings: check each ring for end gap, reading the gap with a thickness gauge shown in the illustration. If the end gap is found to exceed the specified limit, indicated below, replace it with a new one. The end gap o...

Page 53

Vento motorcycles rev no. 01/ page 58 of 143 reed valve: check the clearance ○ a between reed valve and its seat and the dimension ○ b. If the clearance ○ a is noted to exceed 0.2mm, replace the reed valve assembly. The dimension ○ b is at least 1mm..

Page 54

Vento motorcycles rev no. 01/ page 59 of 143 engine reassembly: reassembly is generally performed in the reverse order of disassembly, but there are a number of reassembly steps that demand detailed explanation. These steps will be taken up for respective parts and components. Oil seals: fit the oil...

Page 55

Vento motorcycles rev no. 01/ page 60 of 143 engine mounting bearing pressing: using two steel tubes of appropriate size and a vise, press the mounting bushings ○ 1 and ○ 2 into the crankcase holes as shown in the illustration. Bushing crankcase crankcase bushing.

Page 56

Vento motorcycles rev no. 01/ page 61 of 143 crank shaft • decide the length between the webs refer the figure at right when assembling the crankshaft. Standard width between webs: 38±0.1mm(1.496±0.004in) • when mounting the crankshaft into.

Page 57

Vento motorcycles rev no. 01/ page 62 of 143 crankcase, it is necessary to pull its left end into the crankcase with the special tool. Caution: never fit the crankshaft into the the crankcase by driving it with a plastic hammer. Always use the special tool, otherwise crankshaft alignment accuracy wi...

Page 58

Vento motorcycles rev no. 01/ page 63 of 143 crankcase • wipe the crankcase mating surfaces with cleaning solvent. • apply specified liquid gasket evenly to the mating surface of the left half of the crankcase, and install the dowel pins. • install the two dowel pins • tighten the crankcase bolts se...

Page 59

Vento motorcycles rev 01/ page90 of 143 crankcase. • turn to position the cam where the punched mark ○ a on the end face is directed toward the axis of the rear axle shaft. • aligning the tang on the wear indicator plate with a cutaway on the rear brake cam serrated end; slide the indicator plate ov...

Page 60

Vento motorcycles rev 01/ page91 of 143 6~8n.M(0.6~0.8kgm) • install the brake shoes. • install the rear wheel.

Page 61

Vento motorcycles rev 01/ page92 of 143 transmission note: when using a new circlip, pay attention to the direction of the cir-clip between its two faces; one with sharp corners and the other with rounded corners. When installing, determine the direction of thrust being applied and position the cir-...

Page 62

Vento motorcycles rev 01/ page93 of 143 • assemble the idle shaft subassembly using the idle shaft ○ , cir-clip ○ and thrust washer ○ , and then install the subassembly on the gear case. • install the final driven gear ○ on the rear axle shaft using the cir-clip ○ . • install washer ○ , new gasket ○...

Page 63

Vento motorcycles rev 01/ page94 of 143 • insert the two dowel pins bushing ○ on the crankcase and install the starter idle gear cap ○ . • install the starter gear ○ over the left crankshaft end. • install the new o-ring ○ . Install the starter motor ○ . When tightening the attachment screws, secure...

Page 64

Vento motorcycles rev 01/ page95 of 143 movable driven and clutch.

Page 65

Vento motorcycles rev 01/ page96 of 143 install the bearing ○ in the fixed driven face ○ with the special tools. Install needle bearing ○.

Page 66

Vento motorcycles rev 01/ page97 of 143 install the bearing ○ with special tool install the spacer ○ and cir-clip ○ . • install the new oil seals ○ and ○ to the movable driven face with the special tool. • apply grease to the lip of oil seals and groove of inside of movable driven face. Note: when r...

Page 67

Vento motorcycles rev 01/ page98 of 143 • install the movable driven face seat ○ . • install the clutch shoe assembly ○ and nut ○ . • tighten the nut ○ to the specified torque with the special tool. Tightening torque 50-60 nm(4.0-6.0kg.M) • insert the v-belt between the driven faces as deep inside p...

Page 68

Vento motorcycles rev 01/ page99 of 143 movable drive • apply grease to all the sliding and rolling surfaces for six roller weights. For each weight, approximately 1.5g of grease should be used. • mount the three dampers ○ 1 on the movable drive plate ○ 2 and install it on the movable drive face. • ...

Page 69

Vento motorcycles rev 01/ page100 of 143 make sure that the movable drive plate is fully positioned inside, otherwise the rollers may come out. Insert the spacer ○ 4 . Position the movable drive face subassembly on the crankshaft as shown in illustration. Note thoroughly clean the belt contact to be...

Page 70

Vento motorcycles rev 01/ page101 of 143 driven faces ○ will move together smoothly without slip. • fill the final gearbox with engine oil up to the level hole. Oil capacity 100 ml tighten the oil level bolt to the specified torque. Tightening torque 9-15n.M (0.9~1.5 kg.M) kick starter.

Page 71

Vento motorcycles rev 01/ page102 of 143 apply grease on inside surface of the kick-starter shaft spacer. Position the kick-starter shaft return spring and hook the spring end ○ on the clutch cover boss ○ . Install the dowel pins ○ 1 . Install the new gaskets ○ 2 and ○ 3 ..

Page 72

Vento motorcycles rev 01/ page103 of 143 • fix the gasket to the clutch cover as shown in the illustration. Note: install the kick starter lever as shown in the illustration. Tightening torque 8~12n.M (0.8-1.2kg-m).

Page 73

Vento motorcycles rev 01/ page104 of 143 piston • install the piston rings on the piston. The first and the second ring. Note: position the ring so that the marking is on upside. • it is extremely important that, when the piston is fed into the cylinder, each ring in place should be so positioned as...

Page 74

Vento motorcycles rev 01/ page105 of 143 • tighten the cylinder head nut to the specification. Tightening torque 18-28nm (1.8~2.8 kim oil pump driven gear and oil pump • install right crankcase oil seal press board • apply grease to the oil pump driven gear and install into the crankcase. • install ...

Page 75

Vento motorcycles rev 01/ page106 of 143 reed valve install reed valve paper gasket. Install reed valve install oil hose intake pipe • install the gasket and intake pipe with reed valve to the crankcase. • install the clamps. • install the oil hose..

Page 76

Vento motorcycles rev 01/ page107 of 143 magneto degrease the tapered portion of the crankshaft and also the magneto rotor. Install the key. Install the stator and retainer and tighten with specified torque. Apply thread lock super “1322”to the rotor nut and tighten it to the specified torque with t...

Page 77

Vento motorcycles rev 01/ page108 of 143 • install the rotor ○ 1 and cooling fan ○ 2 . • install the magneto lead wire and starter motor lead wire correctly. • install the cooling fan cover ○ 3 . • tighten the screw ○ a and ○ b . • install fan guiding cover.

Page 78

Vento motorcycles rev 01/ page109 of 143 • install exhaust pipe screw ○ 4 and screw ○ 5 for tightening the muffler to their specified torque. Tightening orque: ○ 4 8~12n.M(0.8-1.2kg.M) ○ 5 18~28n.M(1.8-2.8kg.M) • lubricate brake cam shaft ○ a with special grease..

Page 79

Vento motorcycles rev 01/ page110 of 143 chaptor 4 fuel and lubrication system contents fuel switch………………………………………………. Carburetor………………………………………………. Oil pump …………………………………………………..

Page 80

Vento motorcycles rev 01/ page111 of 143 fuel switch when turning the starter motor, a negative pressure is generated in the combustion chamber. This negative pressure draws on the fuel tap diaphragm, (through a passage way in the carburetor intake pipe) and vacuum hose. Due to this, the negative pr...

Page 81

Vento motorcycles rev 01/ page112 of 143 carburetor carburetor carburetor type identification code throat tube diameter main jet size idle needle jet size fuel needle clamp position idle air adjusting screw float height throttle cable play side draught pz19jb 19mm 80 57.5 3 rd groove from top extrud...

Page 82

Vento motorcycles rev 01/ page113 of 143 carburetion proper carburetion is determined according to the results of various tests, mainly concerning engine power, fuel consumption and cooling effect of fuel on engine, and jet settings are made so as to satisfy and balance all of these conditions. Ther...

Page 83

Vento motorcycles rev 01/ page114 of 143 air –fuel system air-fuel flow circuit fuel is being supplied to the carburetor from fuel tank by controlled fuel cock assy. Air filter box is fitted on the left side of the motorcycle. Fuel gets atomized and mixes with clean air in right proportion in the ca...

Page 84

Vento motorcycles rev 01/ page115 of 143 air fuel mixture ratio • starting ------------------------------------------ 7~8: 1 • idling speed--------------------------------------- 10~12: 1 • slow speed -------------------------------------- 12~14: 1 • medium speed-------------------------------------...

Page 85

Vento motorcycles rev 01/ page116 of 143 carburettor circuits 1. Fuel intake circuit: from fuel tank fuel comes into float chamber of carburetor by controlled fuel cock assy . Separate vent is provided at lh side of carburetor body to maintain inside atmospheric pressure. When fuel starts filling th...

Page 86

Vento motorcycles rev 01/ page117 of 143 3 . Idling circuit: after starting operation choke is released, more air starts flowing thru the venturi. From slow jet fuel is sucked due to venturi effect. A separate passage from the air filter side is coming at the diffuser of the slow jet for the atomiza...

Page 87

Vento motorcycles rev 01/ page118 of 143 1. High speed circuit during acceleration the throttle valve (piston) is fully raised, more air is being supplied due to higher velocity. Hence pressure drops at the opening of throttle jet needle. Where as more fuel is sucked from the main jet due to tappern...

Page 88

Vento motorcycles rev 01/ page119 of 143 carburettor assembly disassembly procedure for carburettor cleaning: • remove the throttle valve from the accelerator cable by compressing the spring up from the seat in long slit. Remove the tip of the cable from the slot of the valve. • remove the jet needl...

Page 89

Vento motorcycles rev 01/ page120 of 143 carburettor tuning or adjustment procedure after installation the carburetor in the engine as per above said procedure, follow the following steps: 1 . Warming up the engine to the normal running temperature. 2. Adjust idling speed to 1800±100 rpm by throttle...

Page 90

Vento motorcycles rev 01/ page121 of 143 chapter 5 electrical system contetns • ignition system …………………………….. • charging and lighting system……….. • starter system……………………………….. • fuel gauge…………………………………….. • oil level check light and turn signal • indicator……………………………………….. • switchs ………………………………………...

Page 91

Vento motorcycles rev 01/ page122 of 143 ignition system the ignition system consists of a flywheel magneto, a cdi&ignition coil unit and a spark plug . ○ 1 as the rotor generates, an ac current is induced in the coil. Then current induced in the ○ a direction charges up the capacitor. ○ 2 as the ro...

Page 92

Vento motorcycles rev 01/ page123 of 143 note: the spark in the spark gap window should be strong and continuous, not intermittent, across a preset 8mm(0.32in) gap. Allow the spark to jump the test gap for at least five minutes continuously. To insure proper operation under the temperature of actual...

Page 93

Vento motorcycles rev 01/ page124 of 143 charging and lighting system the charging system uses the flywheel magneto shown in the figure. The charging and lighting coils are mounted on the magneto stator and generate ac as the flywheel rotor turns. Ac generated in the charging coil flows to the regul...

Page 94

Vento motorcycles.

Page 95

Vento motorcycles rev 01/ page 125 of 143 charging output checking: start the engine and keep it running at 5000 rpm with light switch turned on condition. Note: when making the test, be sure that the battery is fully charged condition. Digital tachometer: for measuring engine rpm specified charging...

Page 96

Vento motorcycles rev 01/ page 126 of 143 no-load performance disconnect the magneto lead wire coupler. Start the engine and keep it running at 5000 rpm. Using a multimeter, measure the ac voltage between the white and red tracer lead wire and ground. If the tester reading is as follows, magneto is ...

Page 97

Vento motorcycles rev 01/ page 127 of 143 starter system description the starter system is shown in the diagram below namely, the starter motor, relay, starter switch and battery. Depressing the starter button while squeezing the front or rear brake lever energizes the relay, causing the contact poi...

Page 98

Vento motorcycles rev 01/ page 128 of 143 starter motor removal and disassembly: remove the starter motor; disassemble the starter motor as shown in the illustration starter motor inspecition carbon brushes when the brushes are worn, the motor will be unable to produce sufficient torque, and the eng...

Page 99

Vento motorcycles rev 01/ page 129 of 143 armature coil using the multimeter, check the coil for open and ground by placing probe pins on each commutator segment and rotor core and on any two segments at various places. With the brushes lifted off the commutator surface. If the coil is found open-ci...

Page 100

Vento motorcycles rev 01/ page 130 of 143 fuel level gauge inspection of fuel level gauge the two different checks to be used for inspection of fuel level gauge. The first and simplest test will tell if the meter is operating but will not indicate the meters accuracy throughout the range. To perform...

Page 101

Vento motorcycles rev 01/ page 131 of 143 signal system: the same bulb is used for both oil levels check light and turn signal indicator light. The circuit diagram is shown below. When the oil level has fallen to a certain level (the remaining amount of oil has become approximately 160 ml, the oil l...

Page 102

Vento motorcycles rev 01/ page 132 of 143 switches battery specifications type designation yuasa/yb4l-b capacity 12v-4ah specific gravity (fully charged) needs charging 1.24~1.28 at 27 0 c below 1.220 initial charging fillng electrolyte remove the aluminum tape sealing the battery electrolyte filler...

Page 103

Vento motorcycles rev 01/ page 133 of 143 battery open the battery cap ○ 1 remove the electrolyte cap ○ . Note after filling the electrolyte completely, use the removed cap ○ as the sealed caps of battery-filler holes. Do not remove or pierce the sealed areas ○ of the electrolyte container. Insert t...

Page 104

Vento motorcycles rev 01/ page 134 of 143 after confirming that the electrolyte has entered into the battery completely, remove the electrolyte containers from the battery, wait for around 25 minuets. Insert the caps into the filler holes, pressing in firmly so that the top of the caps does not prot...

Page 105

Vento motorcycles rev 01/ page 135 of 143 chapter 6 chassis contents leg shield and frame side covers···················································· leg shield removal································································ leg shield remounting··········································...

Page 106

Vento motorcycles rev 01/ page 136 of 143 side cover removal 1. Remove seat and helmet box by opening seat and by opening of 4 nos bolts. 2. Open the screws ○ 2 , ○ 3 , ○ 4 , ○ 5 , ○ 6 , ○ 7 and remove decorating cap,rear carrier. ○ 5 3. Unlock fuel tank cap and remove it, open two tapping screws an...

Page 107

Vento motorcycles rev 01/ page 137 of 143 under cover removal 1. Open the screws as sequence of illustration. 2. Removing under cover by loosing the left and right tapping screws. . Under cover assembly 3 the assembly sequence is the reverse of disassembly. . Front cover removal 1 unscrew tapping sc...

Page 108

Vento motorcycles rev 01/ page 138 of 143 legshield removal 1. Remove power lock housing ○ 2 and open bolt ○ 1 . 3. Remove leg shield by opening the four bolts ○ 3 4. The assembly sequence is the reverse of disassembly..

Page 109

Vento motorcycles rev 01/ page 139 of 143 handle cover removal a) remove front handle cover ○ 2 by unscrewing the six tapping screws ○ 1 1. Remove master cylinder by removing the two bolts ○ 3.

Page 110

Vento motorcycles rev 01/ page 140 of 143 b) disconnect throttle cable ○ 3 and oil pump cable ○ 4 . C) remove rear brake cable adjusting nut ○ 5.

Page 111

Vento motorcycles rev 01/ page 141 of 143 handle cover removal 5. Remove all wiring couplers. 6 remove handle cover by unscrewing bolt ○ 6 7. The assembly sequence is reverse of removal sequence..

Page 112

Vento motorcycles rev 01/ page 142 of 143 front wheel 1. Front rim 2. Middle bushing 3. Oil seal 4. Coller bearing gb6201-2rs 5. Tire 6. Valve 7. Nut gb6817 8. Front shaft 9. Front wheel left bushing 10. Speedometer gear 11. Valve cap disassembly • remove the front brake caliper ○ 2 by removing the ...

Page 113

Vento motorcycles rev 01/ page 143 of 143 inspection and disassembly wheel bearing inspect the play of bearing inner ring by hand while mounted in the wheel. Rotate the inner race by hand to inspect if any abnormal noise occurs or rotating smoothly. Replace the bearing if abnormal remove the dust se...

Page 114

Vento motorcycles rev 01/ page 144 of 143 front wheel reassembly reassemble and remount the front wheel in the reverse order of removal, and also carry out the following steps: • install the wheel bearing with the special tools. Caution: install the wheel bearing for left side.. • install the brake ...

Page 115

Vento motorcycles rev 01/ page 145 of 143 front brake system brake pad replacement remove the calliper by removing the mounting bolts ○ 1 . Note: do not operate the front brake lever while dismounting the calliper. 1. Disc brake assy. 2. Disc brake handle lever 3. Tightening bolt 4. Nut m6 5. Master...

Page 116

Vento motorcycles rev 01/ page 146 of 143 brake pads removal caution: replace the brake pads as a set, otherwise braking performance will be adversely affected. Reassemble and remount the calliper. Caliper removal and disassembly remove the brake hose and collect the brake fluid in a suitable recept...

Page 117

Vento motorcycles rev 01/ page 147 of 143 caliper and disc inspection inspect the calliper cylinder bore wall or nicks, scratches or other damage. Check piston for damage and wear. Check carefully each rubber parts for damage and wear. Check the disc for wear with a micrometer. Its thickness can be ...

Page 118

Vento motorcycles rev 01/ page 148 of 143 brake caliper reassembly reassemble and remount the calliper in the reverse order of removal and disassembly, and also carry out the following steps. Caution: wash the calliper components with fresh brake fluid before reassembly. Never use cleaning solvent o...

Page 119

Vento motorcycles rev 01/ page 149 of 143 remove the dust boot. Remove the circlip with the special tool. • remove the piston/primary cup with return spring. Remove the reservoir cap and diaphragm. • drain brake fluid. Master cylinder inspection inspect the master cylinder bore for any scratches or ...

Page 120

Vento motorcycles rev 01/ page 150 of 143 master cylinder reassembly and ermounting reassemble and remount the master cylinder in the reverse order of removal and disassembly, and also carry out the following steps. Caution: wash the master cylinder components with fresh brake fluids before reassemb...

Page 121

Vento motorcycles rev 01/ page 151 of 143 steering stem and front suspension removal and disassembly • remove the handle cover • remove under decorating cover • remove leg shield • remove front wheel • disconnect the front and rear brake light switch lead wires ○ 1 . • remove the rear brake cable ○ ...

Page 122

Vento motorcycles rev 01/ page 152 of 143 • remove disc brake system by unscrewing tightening bolt. • remove handle by removing tightening bolt • unscrew locknut with special tool • remove front fork assy. By removing upper outer steel bowl note: keep the steering stem balls safely. • remove front f...

Page 123

Vento motorcycles rev 01/ page 153 of 143 inspection • check the removed parts for the following abnormalities. Bearing race wear and brinelling. Worn and damaged steel balls. Distortion of steering stem or handlebar. • check the suspension for damage.

Page 124

Vento motorcycles rev 01/ page 154 of 143 reassembly and remounting reassemble and remount the steering stem, handlebar and front fork in the reverse order of disassembly and removal, and also carry out the following steps. Install the right left suspension arms. Steel ball apply grease when install...

Page 125

Vento motorcycles rev 01/ page 155 of 143 • install handlebar and tighten the bolt to the specified torque. Torque :37-44n.M note: after performing the adjustment and installing the handlebar, rock the front wheel forward and backward to ensure that there is not play and that the procure is accompli...

Page 126

Vento motorcycles rev 01/ page 156 of 143 rear wheel and brake 1. 1. Tire 130/70-12 2. Rear rim assy. 3. Brake pad kit assy. 4. Brake pad kit spring 5. Rear brake tension 6. Rear indicator 7. Anti-dust cover 8. Rear brake camshaft 9. Bolt m6Χ30 10. Valve 11. Nut m16Χ1.5 12. Rear brake arm 13. Valve ...

Page 127

Vento motorcycles rev 01/ page 157 of 143 removal • place the scooter on level ground. • remove muffler. • remove rear small fender. • remove locknut and rear wheel. • remove brake shoes. Inspection rear rim measure inner diameter of rear rim hub with micrometer, if measured diameter exceeds 110.7mm...

Page 128

Vento motorcycles rev 01/ page 158 of 143 reassembly and remounting reassemble and remount the rear wheel and brake in the reverse of removal, and also carry out the following steps: • turn the punched mark ○ 1 on the camshaft to the rear axle shaft side. • install the protrusion ○ 2 of indicator pl...

Page 129

Vento motorcycles rev 01/ page 159 of 143 servicing inforamtion troubleshooting battery vehicle wiring diagram wire, cable and brake hose routing special tools thread parts tightening torque service data contents.

Page 130

Vento motorcycles rev 01/ page 160 of 143 trouble shooting engine complaint symptom and possible causes remedy engine does not start, or is hard to start. Compression too low 1. Excessively worn cylinder or piston rings. 2. Stiff piston ring in place. 3. Gas leaks from the joint in crankcase, cylind...

Page 131

Vento motorcycles rev 01/ page 161 of 143 complaint symptom and possible causes remedy engine runs poorly in high-speed range. 1. Excessively worn cylinder or piston rings. 2. Stiff piston ring in place. 3. Spark plug gaps to narrow. 4. Ignition not advanced sufficiently due to poorly working cdi & ...

Page 132

Vento motorcycles rev 01/ page 162 of 143 complaint symptom and possible causes remedy medium- or high-speed trouble. 1. Main jet or main air jet is clogged. 2. Needle jet is clogged. 3. Fuel level is improperly set. 4. Throttle valve is not operating properly. 5. Fuel filter is clogged. Check and c...

Page 133

Vento motorcycles rev 01/ page 163 of 143 battery complaint symptom and possible causes remedy battery runs down quickly. 1. The charging method is not correct. 2. Cell plates have lost much of their active material as a result of over-charging. 3. A short-circuit condition exists within the battery...

Page 134

Vento motorcycles rev 01/ page 164 of 143 wobbly front wheel. 1. Distorted wheel rim. 2. Worn front wheel bearings. 3. Defective or incorrect tire. 4. Loose nut on axle. 5. Loose nuts on the rear shock. 6. Worn engine mounting bushing. 7. Loose nuts or bolts for engine mounting. Replace. Replace. Re...

Page 135

Vento motorcycles rev 01/ page 165 of 143 noisy front suspension. 1. Not enough grease. 2. Loose nuts on suspension. Refill. Retighten. Wobbly rear wheel. 1. Distorted wheel rim. 2. Defective or incorrect tire. 3. Loose nuts on the rear shock absorber. 4. Worn engine mounting bushing. 5. Loose nuts ...

Page 136

Vento motorcycles rev 01/ page 166 of 143 wire, cable and brake hose routing.

Page 137

Vento motorcycles rev 01/ page 167 of 143.

Page 138

Vento motorcycles rev 01/ page 168 of 143.

Page 139

Vento motorcycles rev 01/ page 169 of 143 ignition coil starting relay cdi horn power switch.

Page 140

Vento motorcycles rev 01/ page 170 of 143 special tools listed below for removal and reinstallation no. Tool number description 1 2 3 4 5 6 7 8 9 10 t01 t02 t03 t04 t05 t06 t07 t08 t10 t 11 “t”shape of sleeve sleeve tools 7mm,8mm,10mm,12mm,13mm flywheel remover sleeve (18mm,24mm) screw remover cylin...

Page 141

Vento motorcycles rev 01/ page 171 of 143 ○ ○ ○ ○ ○ ○ ○ 10

Page 142

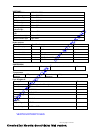

Vento motorcycles rev 01/ page 172 of 143 tightenting torque o f screw thread parts engine item n m cylinder guide cover tapping screw 1-4 fan guide cover lock bolt 10-12 cylinder cover locknut 15-18 spark plug 15-18 inlet pipe lock bolt 10-12 cooling fan impeller lock screw 10-12 flywheel lock bolt...

Page 143

Vento motorcycles rev 01/ page 173 of 143 servicing data cylinder+piston+piston ring description standard tolerance mm( in) piston to cylinder clearance 0.06-0.07 (0.0024-0.0028) 0.120 (0.0047) cylinder bore 40.005-40.020 (1.5750-1.5756) 40.075 (1.5778) piston diameter 39.94-39.955 (1.5724-1.5746) 3...

Page 144

Vento motorcycles rev 01/ page 174 of 143 clutch description standard mm(in) limit mm(in) clutch wheel inner diameter 112.00-112.15(4.410-4.415) 112.5(4.429) clutch shoe thickness 1.8(0.071) 1.2(0.005) clutch engagement 3000±300r/min clutch closedown 6000±300r/min transmission system (gear ratio) de...

Page 145

Vento motorcycles rev 01/ page 175 of 143 wattage description specification headlight high beam/ 12v 35w/35w dipped headlight 12v 35w taillight 12v 21w/5w front turn light 12v 10w rear turn light 12v 10w turning signal indicator light 12v 3w high beam indicator light 12v 1.7 w meter indicator light ...

Page 146

Vento motorcycles rev 01/ page 176 of 143.