- DL manuals

- Vents

- Fan

- Fan

- Operation Manual

Vents Fan Operation Manual - Ххх-Х 80

ХХХ-Х 80

Outlet Fitting Diameter, mm

Position of supplementary inlet fitting for

ventilating one more room:

Unmarked - no supplementary inlet;

D - bottom inlet*;

L - left-side inlet*;

P - right-side inlet*.

* - with the outlet on top

ÕÕÕ - KV, KP or KVK.

5

Casing Type:

KV - in-the-wall, plastic casing;

KP - in-the-wall, fire-preventing casing;

KVK - in-the-wall, plastic casing

with a fire damper;

DELIVERY

PACKAGE

VN 80(Ê)/

VN-1 80 Ê

VNV-1 80

ÊV 80/

ÊP 80/

KVK 80

Fan System (complete), pcs

Fan Assembly, pcs

Casing, pcs.

Set of Fasteners, pcs.

Mounting Bracket, pcs.

Protective fiberboard plate, pcs.

Plastic screwdriver, pcs

(only for timer-equipped models)

Operation Manual, pcs

Packing Box, pcs.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

VNV-1 80 ÊV/

VNV-1 80 ÊP/

VNV-1 80 KVK

1

1

2

Conventional Designations of Casings

VN

VN

Summary of Fan

Page 1

Operation manual 2012 vn vn.

Page 2

Contents attention type codes delivery package purpose main technical specifications operating procedures electronics operation algorithm installation and setup electrical mains connection technical maintenance transportation and storage regulations manufacturer's warranty figures - external view an...

Page 3

3 attention! Disconnect the product from the power mains prior to all operations specific to connection, setup, maintenance and repair. Maintenance and installation shall only be performed by the personnel qualified for unassisted operations with electrical installations up to 1000 v familiar with t...

Page 4: Vn V-1 Х 80 Х Х Х

4 vn v-1 Х 80 Х Х Х vn - fan forced draught v - modification for concealed (in-the-wall) installation 1 - plastic front panel 2 - aluminium front panel 80 - outlet diameter in mm 3 air flow rate, m /h : unmarked - 60/100/150; a - 35/60; b - 35/100; c - 35/60/100; d - 60/100. Extra options: i - inter...

Page 5: Ххх-Х 80

ХХХ-Х 80 outlet fitting diameter, mm position of supplementary inlet fitting for ventilating one more room: unmarked - no supplementary inlet; d - bottom inlet*; l - left-side inlet*; p - right-side inlet*. * - with the outlet on top ÕÕÕ - kv, kp or kvk. 5 casing type: kv - in-the-wall, plastic casi...

Page 6

6 purpose the product is a centrifugal fan for exhaust ventilation of small and medium accomodation spaces heated in the winter season. The fan can be mounted on the ceiling or on a wall with the air exhaust directed into a ventilation shaft or a round duct of suitable diameter. Each fan model is de...

Page 7

7 operating procedures the fan is intended for connection to a 220...240 v 50 hz ac mains and allows continuous operation without disconnection from the power mains. The fans are suitable for operation at ambient temperatures ranging from +1°c to +45°c. The fan must be grounded. Protection class - i...

Page 8

8 i - with an interval switch: depending on the connection pattern the fan remains off or constantly operates at speed 1. From time to time as set by the user (from 30 minutes to 15 hours) the fan switches to maximum speed to operate for 10 minutes and then reverts to the initial state. On external ...

Page 9

9 installation and setup the fan can be mounted on the ceiling or on a wall with the air exhaust directed into a ventilation shaft or a round duct of suitable diameter. Examples of fan installations are given on fig. 12-22. Examples of in-the-wall fan mounting with a supplementary inlet fitting are ...

Page 10

10 3.7. Turn the fan and align the mounting holes in the casing and in the hinged fire damper then mark dowel hole centers (fig. 42); 3.8. Move the fan aside to access the markings, drill dowel holes and install the dowels (fig. 43); 3.9. Turn the fan and align the mounting holes in the casing and i...

Page 11

To install kp 80 casing: 6.1. Perform operations 5.1 and 5.2; 6.2. Arrange a recess in the shaft wall for the fan casing (fig. 21); 6.3. Connect an air duct to the fan outlet fitting; 6.4. Prior to casing installation make sure that the fire-retarding spring-loaded back valve in kp 80 casing to be i...

Page 12

12 electrical mains connection installation examples and various fan connection options are given on fig. 65...71 and on schematic diagrams 1-12. To connect the fan to the power mains: route the cables through the sealed lead-in in the rear part of the casing; strip 7-8 mm of cable ends of insulatio...

Page 13

13 technical maintenance the technical maintenance includes periodic filter replacement and cleaning of surfaces from accumulations of dust and dirt. The impeller wheels require thorough cleaning every 6 months. The filter must be replaced when dirty, but at least once every 6 months. To replace the...

Page 14

14 the manufacturer hereby warrants normal operation (service life) of the fan over the period of 60 months from the retail sale date provided observance of the transportation, storage, installation and operation regulations. Should any malfunctions occur in the fan operation through the manufacture...

Page 15

15 connection to the power mains with voltage in excess of the figures given in the user's operation manual; voltage surges in the power mains resulting in product failure; product repair by the user; product repair by a third party without manufacturer's permission; expiration of the product warran...

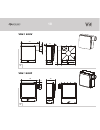

Page 16: Vn 80

16 2 1 235 215 vn 80 235 215 199 135 7 9 102 244 244 203 138 7 9 102 vn-1 80 vn vn.

Page 17: Vn 80 Ê

17 4 3 vn 80 Ê 244 215 8 0 7 5 138 204 215 244 135 201 8 0 7 5 235 235 vn-1 80 Ê vn vn.

Page 18: Vnv-1 80 Kp

18 271 109 102 80 156 265 320 56 vnv-1 80 kp vnv-1 80 kv 235 215 90 102 138 244 79 65 304 6 5 vn vn.

Page 19: Vnv-1 80

19 vnv-1 80 vnv-1 80 kvk 265 67 135 102 8 0 7 5 215 320 235 8 7 vn vn.

Page 20: Kv 80

20 kv 80 kp 80 kvk 80 10 9 11 vn vn.

Page 21

21 installation examples vn 80, vn-1 80 vn 80 Ê, vn-1 80 Ê 12 13 14 15 16 vn vn.

Page 22

22 installation examples vnv-1 80 kv, vnv-1 80 kvk 19 20 17 18 installation examples vnv-1 80 kp 21 22 vn vn.

Page 23

23 23 24 1 9 9 installation examples for fans with supplementary inlet fitting vn 80, vn-1 80 vn 80, vn-1 80 vn 80 Ê, vn-1 80 Ê vn 80, vn-1 80 vn 80 Ê, vn-1 80 Ê 75 7 5 25 27 26 28 75 2 7 5 7 5 75 2 7 5 75 90 90 90 90 vn 80, vn-1 80 vn 80 Ê, vn-1 80 Ê fan mounting examples relative to walls and ceil...

Page 24

30 29 vn-1 80 installation procedure 24 31 32 33 34 vn vn.

Page 25

Vn-80 installation procedure 35 36 25 37 vn-1 80 k installation procedure 38 39 vn vn.

Page 26

40 41 26 42 43 44 vn vn.

Page 27

27 vnv-1 80 kv vnv-1 80 kvk vnv-1 80 kp installation procedure 45 46 47 48 49 vn vn.

Page 28

28 protective fiberboard plate 50 51 52 53 54 55 vn vn.

Page 29

29 60 61 62 5 2 0 64 electrical mains connection 63 1 2 vn vn.

Page 30

Sample schematic of basic three-speed fan model connection - basic modification and modification c. 65 diagram 1 diagram 2 3 3 1 n l n 1 a s 2 2 el 3 3 1 n 2 s off 2 l n 1 off a el b a s a - fan b - distribution box el - lighting lamp s - external speed switch p3-1-300 (shown schematically). The fan...

Page 31

Sample schematic of basic two-speed fan model connection - modifications a, b and d. 66 el b a a - fan b - distribution box el - lighting lamp sw - two-position switch (shown schematically). S - external speed switch p2-1-300 (shown schematically). 1 n l n 1 a s 2 2 el 1 n s 2 off 2 l n off 1 a s(sw...

Page 32

Sample schematic of basic two-speed fan model connection - modifications a, b and d. Continued. 67 b a a - fan b - distribution box sw - two-position switch (shown schematically). Sw the fan constantly remains on operating at speed 1 or speed 2. The speed is selected with the help of switch sw. L n ...

Page 33

M l n s1 lt sb l n a el sample schematic of basic two-speed fan model connection (modifications a, b and d) with a timer (t), adjustable timer (tr) or interval switch (i). 68 a - fan b - distribution box el - lighting lamp s1 - lighting switch (shown schematically). S - base load mode switch (shown ...

Page 34

M lt n l n el s1 l sb a a m lt n l n el l s1 sample schematic of basic two-speed fan model connection (modifications a, b and d) with photoelectronic sensors (f). 69 el b a s1 a - fan b - distribution box el - lighting lamp s1 - lighting switch (shown schematically) s - base load mode switch (shown ...

Page 35

M lt n s1 l l n el a m lt n l l n a sb sample schematic of basic two-speed fan model connection (modifications a, b and d) with a humidity sensor (h). 70 el b a s1 a - fan b - distribution box el - lighting lamp s1 - lighting switch (shown schematically) s - base load mode switch (shown schematicall...

Page 36

Sample schematic of basic two-speed fan model connection (modifications a, b and d) with a humidity sensor (h). Continued. 71 el b a s1 a - fan b - distribution box el - lighting lamp s1 - lighting switch (shown schematically) s - base load mode switch (shown schematically). S the fan constantly ope...

Page 37

37 72 73 74 fan maintenance 75 vn vn.

Page 38

77 78 79 76 Í Ò Ò t 1 t 38 modification tr (fig. 76): Ò1 - turn-on delay time can be set from 0 to 150 seconds; Ò - turn-off delay can be set from 2 to 30 minutes. Modification i (fig. 77): Ò - interval timer can be set within the range from 30 minutes to 15 hours. Modification f (fig. 77): Ò - turn...

Page 39

Acceptance certificate acceptance inspector's stamp manufacturing date the manufacturer shall not be liable for any damage resulting from any misuse of or gross mechanic interference with the fan. The fan owner must follow the applicable instructions. ! Plastic casing kv 80 _______________________ f...

Page 40

Warranty card v22en-06 40 vn vn.