- DL manuals

- Ventus

- Control Unit

- VS 10-75 CG OPTIMA

- Operation and maintenance manual

Ventus VS 10-75 CG OPTIMA Operation and maintenance manual

Summary of VS 10-75 CG OPTIMA

Page 1

Compact control gear for supply and supply-exhaust air handling units vs 10-75 cg optima vs 40-150 cg optima sup vs 40-150 cg optima sup-exh operation and maintenance manual en dtr-cg optima – ver.2.0 (05.2012).

Page 2

Www.Vtsgroup.Com control boxes vs 10-75 cg optima; vs 40-150 cg optima sup; vs 40-150 cg optima sup-exh are designed according to the following european standards: en 60335-1; en 60439-1; en 60439-3; en 50082-1; en 50081-1 en.

Page 3

En vts reserves the right to implement changes without prior notice user’s manual 1 table of content user’s manual ................................................................................................ 3 1. Description of controls ..............................................................

Page 4

En vts reserves the right to implement changes without prior notice user’s manual 2 settings dx cooler ................................................................................................................................................ 20 settings recovery ..........................

Page 5: User’S Manual

En vts reserves the right to implement changes without prior notice user’s manual 3 user’s manual 1. Description of controls introduction application: protection and control of supply and supply-exhaust air handling units equipped with: ○ two fan sets with frequency converters ○ two air dampers ○ co...

Page 6

En vts reserves the right to implement changes without prior notice user’s manual 4 2. Green – comm – to indicate the state of modbus master communication line a. Off – no communication, hmi optima not connected b. Blinking – in case of stable communication ! 1. All control boxes of the vs…cg optima...

Page 7

En vts reserves the right to implement changes without prior notice user’s manual 5 ! Parameters available in the lcd window depends on a ahu type and the control application. Hence in ahus not equipped with heater, options related to the heating module will not be visible. System start-up ! Operati...

Page 8

En vts reserves the right to implement changes without prior notice user’s manual 6 2. Application basics main menu structure unit state – indicates the current state of the air handling unit and the control system ▪ stop – normal stop of the unit ▪ running – normal operation of the unit with ventil...

Page 9

En vts reserves the right to implement changes without prior notice user’s manual 7 en / pl / ru – jump to language selection change password – allows entering specific password to protect the controller from unintended access v.2.1 20-04-12 – application identifier vs-optima – controller type ident...

Page 10

En vts reserves the right to implement changes without prior notice user’s manual 8 hmi com speed / rs485m com speed – settings for communication speed between the hmi and the controller. First parameter refers to hmi speed, the other refers to the controller. Note! The speed settings must match eac...

Page 11

En vts reserves the right to implement changes without prior notice user’s manual 9 calendar annual inside the “annual” menu there are visible all previously stored programs and also the link to “new program” editor. Entering new program allows for setting: ▪ date and time “from” ▪ date and time...

Page 12

En vts reserves the right to implement changes without prior notice user’s manual 10 calendar example intended scheme of operation for the office: 1. Daily: a. Normal working hours: 7 – 15 – work in “comfort” conditions b. Overtime: 15 – 17 – work in “comfort” conditions, but save energy c. Office e...

Page 13

En vts reserves the right to implement changes without prior notice user’s manual 11 time to 07:00.00 operation mode standby temp. Setting 18°c save programming steps 3/4/5 – do the settings for daily operation calendar daily new program time from: 07:00.00 time to: 15:00.00 operation mode: stag...

Page 14

En vts reserves the right to implement changes without prior notice user’s manual 12 parameters dampers state of the intake / outlet dampers ▪ closed ▪ opened dampers closed parameters fans state of the fans fans status – indicates which fans are currently running ▪ stop – none ▪ supply – on...

Page 15

En vts reserves the right to implement changes without prior notice user’s manual 13 parameters dx cooler status state of the dx cooler ▪ off ▪ on note! Cooler status could be affected not only by operation mode of the unit. Safe operation of the dx cooler requires some minimal working / resting...

Page 16

En vts reserves the right to implement changes without prior notice user’s manual 14 parameters recovery rate readout of control signal for the rotary heat regenerator or plate cross-flow recuperator, range 0..100% recovery rate 0% parameters rotary regen. state of the rotary heat regenerato...

Page 17

En vts reserves the right to implement changes without prior notice user’s manual 15 ▪ heating – standby enabled only for heating (unit starts when the room gets too cold) ▪ cooling – standby enabled only for cooling (unit starts when the room gets too warm) ▪ heating/cooling – standby enabled for b...

Page 18

En vts reserves the right to implement changes without prior notice user’s manual 16 settings temp. Regulator supply t max – setting for the upper limit of supply air temperature ▪ low limit: 20°c ▪ high limit: 50°c ▪ default: 40°c supply t min – setting for the lower limit of supply air tempera...

Page 19

En vts reserves the right to implement changes without prior notice user’s manual 17 k p / t i – settings for frost protection pi regulator ▪ k p – gain for the regulator ▪ t i – integral factor for the regulator ▪ default: k p =5 / t i =10s settings fans pressure delay – time to check the fan p...

Page 20

En vts reserves the right to implement changes without prior notice user’s manual 18 note! Between the points of max and min t.Out the valve position is calculated with linear characteristics. For example at half the range, the valve will be 50% opened. Initial heating / preheating time – setting fo...

Page 21

En vts reserves the right to implement changes without prior notice user’s manual 19 tbwtr setpoint - setting for the desired temperature of the backwater from the heater. If unit stopped, regulator keeps exactly the setpoint. If unit running, tbwtr setpoint is considered as lower limit of backwater...

Page 22

En vts reserves the right to implement changes without prior notice user’s manual 20 pump protection / stoppage period – setting of the resting time for the pump ▪ low limit: 1day ▪ high limit: 30days ▪ default: 7days pump protection / run time – setting of the operation time for the pump ▪ low limi...

Page 23

En vts reserves the right to implement changes without prior notice user’s manual 21 k p frost prot. / t i frost prot. – settings for frost protection pi regulator ▪ k p – gain for the regulator ▪ t i – integral factor for the regulator ▪ default: k p =5 / t i =10s t i frost prot. 10s settings mix...

Page 24: Advanced Manual

En vts reserves the right to implement changes without prior notice advanced manual 22 advanced manual 6. Service menu service menu contains the most fundamental settings, necessary for proper configuration and safe startup of the unit. Moreover, some service–oriented functions are available here ...

Page 25

En vts reserves the right to implement changes without prior notice advanced manual 23 ▪ s6 (aux) – external start/stop signal, no voltage free contact note! Di1 input mode setting are available only in n… applications where hardware input di1 is a configurable resource. As the functions of hardware...

Page 26

En vts reserves the right to implement changes without prior notice advanced manual 24 rrg fc / ... – the same settings for frequency converter of the rotary energy regenerator response timeout – setting for max waiting for a slave to respond. If the time was exceeded, the error will be detected. It...

Page 27

En vts reserves the right to implement changes without prior notice advanced manual 25 service menu output forcing relay outputs – overwriting the actual states of hardware digital outputs ▪ rel1 – none / force off / force on ▪ rel2 – none / force off / force on ▪ rel3 – none / force off / force...

Page 28

En vts reserves the right to implement changes without prior notice advanced manual 26 note! Mind the proper addressing of the frequency converters, which is crucial for correct operation of the unit. Note! The ls frequency converters can be restored to factory configuration by setting the parameter...

Page 29

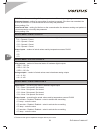

En vts reserves the right to implement changes without prior notice advanced manual 27 note! Each blocking alarm needs to be acknowledged separately. Holding the [ok] button affects only the alarm, that is currently displayed on the hmi. List of self release alarms alarm name description input contr...

Page 30

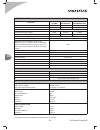

En vts reserves the right to implement changes without prior notice advanced manual 28 9. Technical data parameter vs10-75 cg optima vs 40-150 cg optima sup vs 40-150 cg optima sup-exh weight 6,5 7,0 7,5 dimensions w x h x d 240x300x130 240x400x130 240x400x130 electrical supply system tn rated power...

Page 31

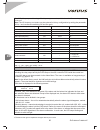

En vts reserves the right to implement changes without prior notice advanced manual 29 relay ouputs max. Switching voltage min. Switching voltage rated current in ac1 / dc1 class min. Current rated long term load 250vac 5vdc 8a 10ma 8a 10. Cabling connect power leads of the control box and frequency...

Page 32

En vts reserves the right to implement changes without prior notice advanced manual 30 name of element / connection point symbol wire type section [mm 2 ] cooling device start input e1 [2] 2x0,75 refrigerating unit start input – i stage e2.1 [2] 2x0,75 cooling device analog control signal (valve) y2...

Page 33

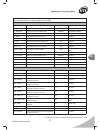

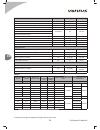

En vts reserves the right to implement changes without prior notice advanced manual 31 table b p 0,55kw 0,75kw 1,1kw 1,5kw 2,2kw 3kw 4kw 5,5kw 7,5 11 kw l1 l2 l3 l1 l2 l3 l1 l2 l3 l1 l2 l3 l1 l2 l3 l1 l2 l3 l1 l2 l3 l1 l2 l3 l1 l2 l3 l1 l2 l3 0,55 19 0,75 19 19 1,1 22 25 1,5 22 25 25 2,2 25 28 28 31...

Page 34

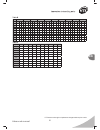

En vts reserves the right to implement changes without prior notice advanced manual 32 11. Electric diagrams optima.

Page 35

En vts reserves the right to implement changes without prior notice advanced manual 33 vs 40-150 cg optima sup-exh.

Page 36

En vts reserves the right to implement changes without prior notice advanced manual 34 67 8 10 9 1 2345 q1 1l1 1l1 1l2 1l2 1l3 1l3 pe n l1 l2 l3 1l1 1l2 1l3 2m1 3~ 2u1 1 2 3 4 5 6 2f1m n n pe pepepe t1 24v 230v 1 n 2 n1 xg0 xg gnd 24v a c xg0 gnd c ok hmi - 216 complex alarm comm el-piast vs 40-150 ...