- DL manuals

- Verine

- Indoor Fireplace

- Alpena

- Installation, Maintenance & User Instructions

Verine Alpena Installation, Maintenance & User Instructions

Alpena

COAL EFFECT BALANCED FLUE GAS FIRE

Installation, Maintenance & User Instructions

Hand these instructions to the user

Model No. NBFC**MN2, NBFC**RN2 & NBFC**EN2 are for use on Natural Gas

(G20) at a supply pressure of 20 mbar in G.B. / I.E.

Model No. NBFC**MP2 is for use on Propane Gas (G31) at a supply pressure

of 37 mbar in G.B. / I.E.

** denotes trim / fret or fascia variant

Summary of Alpena

Page 1

Alpena coal effect balanced flue gas fire installation, maintenance & user instructions hand these instructions to the user model no. Nbfc**mn2, nbfc**rn2 & nbfc**en2 are for use on natural gas (g20) at a supply pressure of 20 mbar in g.B. / i.E. Model no. Nbfc**mp2 is for use on propane gas (g31) a...

Page 2

Contents page section 1 information and requirements 1.0 appliance information 3 1.1 conditions of installation 4 1.2 fireplace surround & suitability 4 1.3 flue terminal position 5 1.4 shelf position 6 1.5 hearths 6 section 2 installation of fire 2.1 unpacking the fire 6 2.2 fireplace opening 7-8 2...

Page 3

Section 1 information and requirements 1.0 appliance information natural gas lpg main injector : (1 off) 1.65mm 1.20mm pilot type - s.I.T.140 series size 27 size 19 max. Gross heat input : 4.6kw 4.8kw min. Gross heat input : 3.2kw 3.4kw gas rate : 0.427 m3/hr 0.180 m3/hr cold pressure : 20.0+/-1.0 m...

Page 4

Installation requirements efficiency declaration the efficiency of this appliance has been measured as specified in bs en 613 : 2001 and the result is 85%. The gross calorific value of the fuel has been used for this efficiency calculation. The test data from which it has been calculated has been ce...

Page 5

1.3 flue terminal position the minimum acceptable dimensions from the flue terminal to obstructions and ventilation openings are shown below and listed in the table it is important that the position of the flue allows the free passage of air across it at all times. The minimum acceptable space from ...

Page 6

1.4 shelf position the fire may be fitted below a combustible shelf providing there is a minimum distance of 200mm above the top of the fire and the shelf does not project more than 150mm. If the shelf overhangs more than 150mm the distance between the fire and the shelf must be increased by 15mm fo...

Page 7

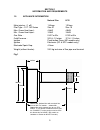

2.2 fire place opening 2.2.1 the front opening of the fire place must be between 410 and 420mm wide, and between 555 and 570mm high. If the opening exceeds these dimensions then a surround must be constructed from suitable non- combustible material to produce a suitable sized opening. Any surround m...

Page 8

2.2.3 note : when measuring length between firebox and the outer wall take into account the distance between the back of the firebox and the inner wall as this will vary between installations, dependent upon the fire surround rebate or cavity depth. (dimension “x” below - fig. 5). Fig. 5 2.2.4 the a...

Page 9

Fig. 6 2.4 preparation of the flue hole 2.4.1 mark the position of the centre of the flue on the inner wall. 2.4.2 cut hole for outer flue pipe. There are two possible methods to achieve this, either core drill or via hammer and chisel. 2.4.3 to core drill, proceed as follows :- drill a pilot hole t...

Page 10

2.5 installation of the gas supply 2.5.1 before installing the firebox, decide from which side or if a rear connection to the gas supply is required. Plan the pipe run to enter the firebox from the left, right or rear and connect to the inlet elbow. See below :- 2.5.2 if concealed pipe work is requi...

Page 11

2.6 preparation of the flue duct 2.6.1 place the firebox into the fire opening with fire surround correctly secured in the final position. From the outside of the house measure from the face of the outside wall to the rear panel of the firebox through the flue hole. Cut the flue duct to this size, u...

Page 12

2.7 securing of firebox to the opening 2.7.1 there is a choice of methods of fixing the firebox that are provided to enable the installer to deal with any type of installation. The preferred method of fixing the appliance is the cable fixing method, which is described in detail in the following sect...

Page 13

2.7.8 to improve access to tension the screws it may be advantageous to remove the control panel from the fire. To do this, remove the 4 off retaining screws and on mc models, remove the control valve retaining nut. 2.7.9 thread a tensioning screw over both of the cables and ensure that the tensioni...

Page 14

2.9 fitting the terminal guard 2.9.1 with the flue terminal in position, place the terminal guard over the top of the flue terminal and mark the position of the holes on the outer wall. 2.9.2 remove the terminal guard and drill the 4 off 6 mm holes. 2.9.3 insert the raw plugs into the drilled holes,...

Page 15

2.10 removing & refitting of the glass frame. 2.10.1 remove the 2 screws which hold the convection slot cover to the firebox, as shown below in fig 11 2.10.2 remove the burner heat shield by unscrewing the 2 off retaining screws as shown below in fig. 11 2.10.3 remove the 4 off m5 retaining nuts as ...

Page 16

Section 3 assembling fuel bed and commissioning 3.1 fitting the fuelbed 3.1.1 place the ceramic fibre support behind the burner as shown below in fig. 12 fig. 12 3.1.2 place the front right coal moulding onto the front coal support as shown below in fig. 13 fig. 13 16 right front coal moulding front...

Page 17

3.1.3 place the front left coal moulding onto the front coal support as shown below in fig. 14 fig. 14 3.1.4 place the upper right coal moulding as shown below in fig. 15. This moulding tucks under the front right coal moulding and is supported by the ceramic fibre support. Fig. 15 17 left front coa...

Page 18

3.1.5 place the upper left coal moulding as shown below in fig. 16. This moulding tucks under the front left coal moulding and is supported by the ceramic fibre support. Fig. 16 3.1.5 refit the glass frame as detailed in section 2.10, then light the appliance as detailed in section 3.2 / 3.3 to ensu...

Page 19

3.4 lighting the appliance - manual control variants important note : if the burner is extinguished for any reason you must ensure that you wait a full five minutes before attempting to re-light the fire. When turning the fire “off” please ensure that the control valve is turned to the “off” positio...

Page 20

3.5 fixing the infrared sensor in position - remote control models only 3.5.1 due to the different fascia’s that can be supplied with these fires, the infrared sensor is supplied from the factory attached to a self adhesive pad. This pad can therefore be attached to the hearth in a position to suit ...

Page 21

3.6 connecting the battery pack - remote control & electronic fire control models only. 3.6.1 to prevent un-necessary battery drain, the battery pack that is used to provide the remote and electronic control function for this product is disconnected at the factory. Prior to attempting to light the p...

Page 22

3.7 lighting the appliance - remote control models only 3.7.1 the remote control handset generates an infrared signal, which will be received by the sensor situated at the front right of your fire, behind the ashpan cover. This infrared signal requires direct line of sight from the handset to the se...

Page 23

3.8 lighting the appliance - electronic fire control models only 3.8.1 to light the fire using the electronic fire control, press the ignition button as indicated below in fig. 21. The fire will emit a “beep” sound, the buttons can now be released. After a few seconds an audible clicking can be hear...

Page 24

Section 4 maintenance servicing notes servicing should be carried out annually by a competent person such as a gas safe registered engineer. It is a condition of the verine guarantee schemes that this is carried out by a competent person i.E a gas safe registered engineer in accordance with these se...

Page 25

4.3 removing the control valve from the fire (manual control models only) 4.3.1 remove ash-pan, fret assembly / trim or fascia from the front of the fire. 4.3.2 isolate the gas supply, remove the glass frame as shown on in section 2.10 then remove the ceramics. Remove the 2 off fixing screws which h...

Page 26

4.5 removing the control board (remote & efc models) 4.5.1 remove ash-pan, fret assembly / trim or fascia from the front of the fire. 4.5.2 isolate the gas supply, disconnect the gas control valve to bulkhead pipe and pilot / thermcouple connections to the pilot. 4.5.3 pull controls sub assembly for...

Page 27

4.9 removing the efc trim switch 4.9.1 remove ash-pan, fret assembly / trim or fascia from the front of the fire. 4.9.2 isolate the gas supply, disconnect the gas control valve to bulkhead pipe and pilot / thermcouple connections to the pilot. Remove the fire from the opening. 4.9.3 pull controls su...

Page 28

Section five - user instructions 5.1 installation information conditions of installation it is the law that all gas appliances are installed only by a competent (e.G. Registered) installer, in accordance with the installation instructions and the gas safety (installation and use) regulations 1998. F...

Page 29

About your new verine alpena gas fire the verine alpena coal effect gas fire incorporates a unique and highly developed fuel bed which gives the realism of a loose coal layout combined with realistic flames and glow. The use of durable ceramic material in the construction of the fuelbed components e...

Page 30

5.2 operating the fire (manual control models) 5.2.1 the controls are located behind the ashpan cover which is situated behind the ashpan / fender. The controls, comprise a control valve to adjust the gas flow and a push button piezo igniter. To light the fire proceed as follows:- 5.2.2 depress the ...

Page 31

5.3 operating the fire (remote control models) 5.3.1 the remote control handset generates an infrared signal, which will be received by the sensor situated at the front right of your fire, behind the ashpan cover. This infrared signal requires direct line of sight from the handset to the sensor on t...

Page 32

5.4 lighting the appliance - electronic fire control models only 5.4.1 to light the fire using the electronic fire control, press the ignition button as indicated below in fig. 2. The fire will emit a “beep” sound, the buttons can now be released. After a few seconds an audible clicking can be heard...

Page 33

5.5 turning the product off in the unlikely event of a remote handset or electronic fire control malfunction. 5.5.1 in the unlikely event of the remote control handset malfunctioning (or if lost or broken) after the appliance has been turned on, the fire can be turned off via the emergency shut off ...

Page 34

5.7 removal / replacing the glass frame 5.7.1 remove the 2 screws which hold the convection slot cover to the firebox, as shown below in fig. 4 5.7.2 remove the burner heat shield by unscrewing the 2 off retaining screws as shown below in fig. 4 5.7.3 remove the 4 off retaining nuts as shown below i...

Page 35

5.8 removing / replacing the fuelbed 5.8.1 place the ceramic fibre support behind the burner as shown below in fig. 5 fig. 5 5.8.2 place the front right coal moulding onto the front coal support as shown below in fig. 6 fig. 6 right front coal moulding front coal support 35.

Page 36

5.8.3 place the front left coal moulding onto the front coal support as shown below in fig. 7 fig. 7 5.8.4 place the upper right coal moulding as shown below in fig. 8. This moulding tucks under the front right coal moulding and is supported by the ceramic fibre support. Fig. 8 left front coal mould...

Page 37

5.8.5 place the upper left coal moulding as shown below in fig. 9. This moulding tucks under the front left coal moulding and is supported by the ceramic fibre support. Fig. 9 5.8.6 refit the glass frame as detailed in section 5.7, then light the appliance as detailed in section 5.2 / 5.3 / 5.4 to e...

Page 38

5.9 user replaceable parts complete fuel-bed / ceramic set b-130100 l/h front ceramic b-130060 r/h front ceramic b-130070 l/h rear ceramic b-130080 r/h rear ceramic b-130090 due to our policy of continual improvement and development the exact accuracy of illustrations and descriptions contained in t...