- DL manuals

- Verine

- Gas Heater

- Fontana HE NPHL**RN

- Installation, Maintenance & User Instructions

Verine Fontana HE NPHL**RN Installation, Maintenance & User Instructions

Summary of Fontana HE NPHL**RN

Page 1

Fontana he model no. Nphl**rn high efficiency log effect room heater installation, maintenance & user instructions hand these instructions to the user model no. Nphl**rn is for use on natural gas (g20) at a supply pressure of 20 mbar in g.B. / i.E. ** denotes trim & colour variant.

Page 2

Contents page section 1 information and requirements 1.0 appliance information 3 1.1 conditions of installation 4 1.2 flue & chimney suitability 4 1.3 shelf position 5 1.4 hearths 5 1.5 installation to plastered wall surfaces 5 section 2 installation of fire 2.1 unpacking the combustion chamber 6 2....

Page 3

Section 1 information and requirements 1.0 appliance information main injector : (1 off) stereomatic injector cat 82 – size 380 (ng) pilot type : copreci ods 21100 / 162 (sit rc system) copreci ods 21100 / 141 (mertik maxitrol rc system) max. Gross heat input : 5.4 kw min. Gross heat input : 3.0 kw ...

Page 4

Installation requirements 1.1 conditions of installation it is the law that all gas appliances are installed only by a gas safe registered installer, in accordance with these installation instructions and the gas safety (installation and use) regulations 1998 as amended. Failure to install appliance...

Page 5

1.3 shelf position the fire may be fitted below a combustible shelf providing there is a minimum distance of 300mm above the top of the fire and the shelf does not project more than 150mm. If the shelf overhangs more than 150mm the distance between the fire and the shelf must be increased by 15mm fo...

Page 6

Section 2 installation of fire 2.1 unpacking the combustion chamber carefully lift the combustion chamber out of the carton. Remove the loose item packaging carefully from the pack. Check the contents as listed :- do not under any circumstances use this appliance if the glass panel is broken or not ...

Page 7

2.2 preparation of the combustion chamber opening (into studded wall) using a 125mm flue liner. All combustible parts of the studwork must be set at the distances as shown below in fig. 4 & 5. For installation into such applications a flue box with 125mm flue pipe adaptor is available to purchase as...

Page 8

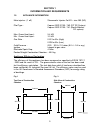

2.3 preparation of the combustion chamber opening (into existing chimney breast) an opening should be constructed to the following dimensions in the existing chimney breast. See fig. 6 below fig. 6 note : please ensure that access holes are cut into either the sides or area above the lintel to allow...

Page 9

Fig. 7 the opening needs to be sufficient to accomodate the combustion chamber. To support the wall above the opening, a suitable lintel must be inserted across the top of the opening. The lintel could be either pre-cast concrete or steel - catnic cn52 or cn 46 could be used, depending upon the inne...

Page 10

10 2.4 securing the fire to the opening a) the combustion chamber must be secured to the opening via the four off screw and rawlplugs provided. Fig. 8 & 9 below shows the hole centres in the mounting flanges of the combustion chamber. Fig. 8 b) do not secure the combustion chamber into the opening a...

Page 11

2.5 installation of the gas supply (into studded wall or existing chimney breast) before installing the combustion chamber, decide from which side or if a rear connection to the gas supply is required. Plan the pipe run to enter the below the firebox from the left, right or rear and connect to the i...

Page 12

2.6 fitting of the efficiency baffle. A) the product is supplied with an efficiency baffle to improve the efficiency of the product when installed into class 1 flues, of minimum diameter 175mm / 7” or brick built 225mm x 225mm chimneys. The minimum effective height of all flues must be 3 metres or a...

Page 13

2.8 removing / re-fitting the glass frame assembly a) the glass frame is held in position by hooking the top flange over the combustion chamber opening at the top as shown in fig. 14 below. Fig. 14 b) the assembly is then secured to the bottom of the combustion chamber by the two hinge clamp bracket...

Page 14

Section 3 installation of fire 3.1 fitting the fuel-bed logset a) the gravel material should then be first layed around the base of the combustion chamber as shown below in fig. 16, leaving the rear section as shown to allow the fitting of log “a” fig. 16 b) place the largest log “a” centrally onto ...

Page 15

C) fit log “b” into position on left hand side of the fuel-bed base log “a”as shown below in fig. 18, using the groove in log “a” as a guide for placement. Fig. 18 d) fit log “c” into position on left hand side of the fuel-bed base log “a”as shown below in fig. 19, using the groove in log “a” as a g...

Page 16

D) fit log “d” into position on left hand side of the fuel-bed base log “a”as shown below in fig. 20, using the groove in log “a” as a guide for placement. Fig. 20 e) fit log “e” into position at centre of the fuel-bed base log “a”as shown below in fig. 21, using the groove in the centre of log “a” ...

Page 17

F) fit log “f” into position at right hand side of centre of the fuel-bed base log “a”as shown below in fig. 22, using the groove in log “a” as a guide for placement. Fig. 22 g) fit log “g” into position at right hand side of the fuel-bed base log “a”as shown below in fig. 23, using the raised secti...

Page 18

Warning : use only the logs supplied with the fire. When replacing the logs remove the old logs and discard them. Fit a complete set of logs of the correct type. Do not fit additional logs or any logs other than a genuine replacement set. This appliance uses fuel effect pieces containing refractory ...

Page 19

3.3 removal & re-fitting of the trim assembly a) the trim is supplied in 3 pieces, the rear panel, the front panel and the stainless steel trim insert. Fix the rear panel to the wall with via the 4 screw holes with screws / rawlplugs. Note : the flange of the rear panel must locate onto the base of ...

Page 20

3.4 lighting the appliance before attempting to light the appliance, please determine which remote control system the product is fitted with. To determine this, check the handset designs as shown below and follow the instructions on the proceeding pages as necessary. 3.4.1 if fitted with the s.I.T. ...

Page 21

3.4.3 lighting the appliance - s.I.T. Acs2t remote control important : if the burner is extinguished for any reason you must ensure that you wait a full five minutes before attempting to re-light the fire. The product is controlled by the remote handset supplied with the fire. Ensure the 3 off aaa b...

Page 22

Fig. 28 c) to turn the fire off, press and hold the “on” / “off” button, this will extinguish all flames including the pilot. D) if is recommended that the handset is placed into locked mode when not in use. To lock the handset, press and hold the “mode” button for a minimum of 5 seconds. To unlock ...

Page 23

3.4.5 operation of the fire in “automatic” mode a) firstly turn the handset on and light the fire by pressing and holding the “on” / “off” button on the remote handset for a minimum of 2 seconds as shown in fig. 3, section 3.4.4 a), fig. 27 b) press the “thermostatic” button on the handset below as ...

Page 24

3.4.6 operation of the fire in “programme function” mode a) the handset is pre-programmed with ten off alternative settings to give various options of timed, automatic useage. Please see table below for the details of these 10 off pre-set functions. B) to set the handset in “programme function” mode...

Page 25

3.4.7 low battery signal a) when the batteries in the handset needs replacing, a small battery symbol will appear on the handset. B) remove the cover on the rear of the handset and replace the 3 off aaa batteries as necessary. 3.4.8 to set the time on the remote handset a) simultanelously press the ...

Page 26

3.5 lighting the appliance - mertik maxitrol gv60 remote control important : if the burner is extinguished for any reason you must ensure that you wait a full five minutes before attempting to re-light the fire. The product is controlled by the remote handset supplied with the fire. Ensure the 9v ba...

Page 27

C) with the product in “manual” mode the fire can now be switched between high rate heat input and low rate heat input by pressing the “down” arrow on the handset. To reduce the flame height of the main burner incrementally, press the arrow momentarily. To reduce the heat input directly down to the ...

Page 28

3.5.2 operation of the fire in “temperature” mode a) in order to change the mode of operation from “manual” to “temperature”, press the “set” button, the fire will then change to either “day temp” (fig. 34) mode or “night temp” mode (fig 35). To alternate between the 2, press the “set” button. The d...

Page 29

3.5.3 operation of the fire in “timer” mode a) in order to change the mode of operation from “manual” to “timer”, press the “set” button, the fire will then alternate between the settings until the “timer” mode is displayed. Note : the “set” button allows you to alternate between all modes of operat...

Page 30

3.5.4 low battery signal a) when the battery in the handset needs replacing, “batt” will be displayed on the handset. B) remove the cover on the rear of the handset and replace the 9v battery as necessary. 3.5.5 to set the time on the remote handset a) simultanelously press the “up” (large flame) ar...

Page 31

3.7 checking for clearance of combustion products a) close all doors and windows in the room. B) light the fire and allow to run for approximately 5 minutes on high position. C) after approximately 5 minutes hold a smoke match just inside and below the centre of the lower front edge of the top of th...

Page 32

Section 4 maintenance servicing notes servicing should be carried out annually by a competent person such as a gas safe registered engineer. It is a condition of verine fires guarantee schemes that this is carried out by a competent person i.E a gas safe registered engineer in accordance with these ...

Page 33

4.2.5 remove the 2 off fixing screws which hold the valve to its mounting bracket and lift the valve and its mounting plate away from the combustion chamber. 4.2.6 swap the valve (and reciever / control board on the sit equipped models) mounting plate onto the new valve and replace the fixings holdi...

Page 34

4.6 replacing the batteries in the handset 4.6.1 remove and re-fit the new 9v battery by removing the cover on the back of the handset on the mertik maxitrol handset or 3 off aaa batteries on the sit unit. Parts shortlist sit control valve b-106790 ods pilot (mertik) b-38930 sit handset b-129150 ods...

Page 35

Section five - user instructions 5.1 installation information conditions of installation it is the law that all gas appliances are installed only by a competent (e.G. Gas safe registered) installer, in accordance with the installation instructions and the gas safety (installation and use) regulation...

Page 36

5.2 about your new fontana he room heater the verine fontana high efficiency log effect room heater incorporates a unique and highly developed fuel bed which gives the realism of a loose log layout combined with realistic flames and glow. The use of durable hard ceramic material in the construction ...

Page 37

5.3 spillage monitoring system this appliance is fitted with a spillage monitoring system which shuts down the fire if the evacuation of combustion products from the fire is affected by a partially or fully blocked flue pipe. If this system operates the fire will go out. If this occurs, leave the fi...

Page 38

5.4 lighting the appliance before attempting to light the appliance, please determine which remote control system the product is fitted with. To determine this, check the handset designs as shown below and follow the instructions on the proceeding pages as necessary. 5.4.1 if fitted with the s.I.T. ...

Page 39

5.4.3 lighting the appliance - s.I.T. Acs2t remote control important : if the burner is extinguished for any reason you must ensure that you wait a full five minutes before attempting to re-light the fire. The product is controlled by the remote handset supplied with the fire. Ensure the 3 off aaa b...

Page 40

Fig. 4 c) to turn the fire off, press and hold the “on” / “off” button, this will extinguish all flames including the pilot. D) if is recommended that the handset is placed into locked mode when not in use. To lock the handset, press and hold the “mode” button for a minimum of 5 seconds. To unlock t...

Page 41

5.4.5 operation of the fire in “automatic” mode a) firstly turn the handset on and light the fire by pressing and holding the “on” / “off” button on the remote handset for a minimum of 2 seconds as shown in fig. 3, section 5.4.4 b) press the “thermostatic” button on the handset below as shown in fig...

Page 42

5.4.6 operation of the fire in “programme function” mode a) the handset is pre-programmed with ten off alternative settings to give various options of timed, automatic useage. Please see table below for the details of these 10 off pre-set functions. B) to set the handset in “programme function” mode...

Page 43

5.4.7 low battery signal a) when the batteries in the handset needs replacing, a small battery symbol will appear on the handset. B) remove the cover on the rear of the handset and replace the 3 off aaa batteries as necessary. 5.4.8 to set the time on the remote handset a) simultanelously press the ...

Page 44

5.5 lighting the appliance - mertik maxitrol gv60 remote control important : if the burner is extinguished for any reason you must ensure that you wait a full five minutes before attempting to re-light the fire. The product is controlled by the remote handset supplied with the fire. Ensure the 9v ba...

Page 45

C) with the product in “manual” mode the fire can now be switched between high rate heat input and low rate heat input by pressing the “down” arrow on the handset. To reduce the flame height of the main burner incrementally, press the arrow momentarily. To reduce the heat input directly down to the ...

Page 46

5.5.2 operation of the fire in “temperature” mode a) in order to change the mode of operation from “manual” to “temperature”, press the “set” button, the fire will then change to either “day temp” (fig. 10) mode or “night temp” mode (fig 11). To alternate between the 2, press the “set” button. The d...

Page 47

5.5.3 operation of the fire in “timer” mode a) in order to change the mode of operation from “manual” to “timer”, press the “set” button, the fire will then alternate between the settings until the “timer” mode is displayed. Note : the “set” button allows you to alternate between all modes of operat...

Page 48

5.5.4 low battery signal a) when the battery in the handset needs replacing, “batt” will be displayed on the handset. B) remove the cover on the rear of the handset and replace the 9v battery as necessary. 5.5.5 to set the time on the remote handset a) simultanelously press the “up” (large flame) ar...

Page 49

5.6 cleaning warning : before attempting any cleaning operation ensure that the fire has been allowed to fully cool. 5.6.1 cleaning the trim and painted metal parts the extruded aluminimum trim that is supplied for use with this product must be gently cleaned with a damp cloth only. Abrasive cleaner...

Page 50

5.7 removal & re-fitting the fuel-bed logset a) the gravel material should then be first layed around the base of the combustion chamber as shown below in fig. 14, leaving the rear section as shown to allow the fitting of log “a” fig. 14 b) place the largest log “a” centrally onto the fuel-bed suppo...

Page 51

C) fit log “b” into position on left hand side of the fuel-bed base log “a”as shown below in fig. 16, using the groove in log “a” as a guide for placement. Fig. 16 d) fit log “c” into position on left hand side of the fuel-bed base log “a”as shown below in fig. 17, using the groove in log “a” as a g...

Page 52

D) fit log “d” into position on left hand side of the fuel-bed base log “a”as shown below in fig. 18, using the groove in log “a” as a guide for placement. Fig. 18 e) fit log “e” into position at centre of the fuel-bed base log “a”as shown below in fig. 19, using the groove in the centre of log “a” ...

Page 53

F) fit log “f” into position at right hand side of centre of the fuel-bed base log “a”as shown below in fig. 22, using the groove in log “a” as a guide for placement. Fig. 22 g) fit log “g” into position at right hand side of the fuel-bed base log “a”as shown below in fig. 23, using the raised secti...

Page 54

Important note having fitted the gravel material in the base of the combustion chamber, ensure that none of it is on the burner flame strip or in the pilot assembly. If material is observed visually on these components, remove the fuel-bed logset, remove the gravel material from the burner and or pi...

Page 55

5.8 removing / re-fitting the glass frame assembly a) the glass frame is held in position by hooking the top flange over the combustion chamber opening at the top as shown in fig. 20 below. Fig. 20 b) the assembly is then secured to the bottom of the combustion chamber by the two hinge clamp bracket...

Page 56: Attempting To Remove It.

5.9 removal & re-fitting of the trim assembly a) the trim is supplied in 3 pieces, the rear panel, the front panel and the stainless steel trim insert. Fix the rear panel to the wall with via the 4 screw holes with screws / rawlplugs. Note : the flange of the rear panel must locate onto the base of ...

Page 57

5.10 user replaceable parts the only user replaceable parts on this fire are the fuelbed / log form, and the handset / ultrasonic receiver batteries, which may be replaced as described in the below. Replacement of any other parts must be carried out by a competent person such as a gas safe registere...