- DL manuals

- Verine

- Indoor Fireplace

- NRDC**MN2

- Installation, Maintenance & User Instructions

Verine NRDC**MN2 Installation, Maintenance & User Instructions

Important Note

This manual is only suitable for Verine Quasar MK2 models that are to be installed in

GB / IE. If in the future the product is to be installed in any other country detailed as

appropriate for the gas type and supply pressure on the rating plate then the

manufacturer (BFM Europe Ltd.) must be contacted to obtain a set of instructions that

are translated into the language of the country of destination, and reflect the differing

legislative installation criteria for that country.

Quasar MK2

INSET RADIANT FUEL EFFECT GAS FIRE

Installation, Maintenance & User Instructions

Hand these instructions to the user

Model No’s NRDC**MN2, NRDC**SN2, NRDC**TN2 & NRDC**RN2 are

for use on Natural Gas (G20) at a supply pressure of 20 mbar in G.B.

/ I.E.

Model No’s NRDC**MP2 is for use on Propane Gas (G31) at a supply

pressure of 37 mbar in G.B. / I.E.

** denotes variant of trim / fascia where applicable

Summary of NRDC**MN2

Page 1

Important note this manual is only suitable for verine quasar mk2 models that are to be installed in gb / ie. If in the future the product is to be installed in any other country detailed as appropriate for the gas type and supply pressure on the rating plate then the manufacturer (bfm europe ltd.) ...

Page 2

Contents section 1 information and requirements page 1.0 appliance information 3-4 1.1 conditions of installation 5 1.2 flue and chimney suitability 5 1.3 fireplace / surround suitability 6 1.4 shelf position 6 1.5 chimney inspection 6 1.6 fire place opening / catchment space 7-8 1.7 fitting to meta...

Page 3

Section 1 information and requirements 1.0 appliance information model nrdc**mn2 (mc) nrdc**mp2 (mc) nrdc**sn2 (sc) nrdc**rn2 (rc) nrdc**tn2 (efc) gas type g20 g31 main injectors (2 off) size 260 size 85 pilot type copreci copreci 21100 / 141 (mc) 21100 / 264 (mc) 21100 / 162 (sc & rc) max. Gross he...

Page 4

Installation requirements 1.1 conditions of installation it is the law that all gas appliances are installed only by a gas safe registered installer, in accordance with these installation instructions and the gas safety (installation and use) regulations 1998 as amended. Failure to install appliance...

Page 5

1.3 fireplace / surround suitability the fire must only be installed on a hearth it must not be installed directly onto carpet or other combustible floor materials. The fire is suitable for fitting to non-combustible fire place surrounds and proprietary fire place surrounds with a temperature rating...

Page 6

There must be no leakage of smoke through the structure of the chimney during or after the smoke pellet test and it is important to check inside upstairs rooms adjacent to the chimney / flue. Check the chimney pot / terminal and general condition of the brickwork or masonry. If the chimney or flue i...

Page 7

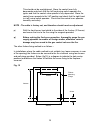

Table a - installation depth requirements for a verine quasar mk2 gas fire being installed into a brick built chimney, requiring 12.0 litres of debris collection volume (fig. 2) when installing this product into a builders opening / brick-built chimney, the depth required is a minimum of 170mm (150m...

Page 8

1.7 fitting to pre-fabricated twin wall metal flue boxes the appliance may be fitted to twin wall metal flue boxes conforming to the constructional requirements of bs 715 / bs en 1856-2, (for example the selkirk lfe 175 box). The box must have a minimum flue diameter of 175mm internal and minimum in...

Page 9

1.10 spillage monitoring system this appliance is fitted with an atmosphere sensing spillage monitoring system in the form of an oxygen sensing pilot. This is designed to shut the fire off in the event of a partial or complete blockage of the flue causing a build up of combus- tion products in the r...

Page 10

Section 2 installation of fire 2.1 unpacking the fire carefully lift the fire out of the carton. Remove the loose item packaging carefully from the front of the appliance. Check the contents as listed :- packing check list - all models 1 off fire box / burner assembly 1 off boxed ceramic base, front...

Page 11

For manual control models proceed as follows :- a) remove the trim / fret. Remove the burner heat shield from the front of the fire box to allow access to the burner. See fig. 3 below. Fig. 3 b) ensure that the hearth is protected from damage and carefully lift the fire box into the fire opening, th...

Page 12

For slide control models proceed as follows: d) remove the trim / fret. Remove the burner heat shield from the front of the fire box to allow access to the burner. See fig. 5 below. Fig. 5 e) ensure that the hearth is protected from damage and carefully lift the fire box into the fire opening, then ...

Page 13

Fig. 6 g) unscrew the burner assembly fixing screws at either side of the firebox, and the two fixing screws at the base of the fire (see fig. 7 below). Carefully pull the base of the burner forwards from the fuel-bed support panel. The burner can now be removed from the appliance. Fig. 7 13.

Page 14

For remote control / electronic fire control models proceed as follows: a) remove the trim. Remove the burner heat shield from the front of the fire box to allow access to the burner. See fig. 8 below. Fig. 8 b) ensure that the hearth is protected from damage and carefully lift the fire box into the...

Page 15

Continue for all models whilst the fire box is still in position, decide which side the gas supply is to enter the fire from. If concealed pipe work is required plan the pipe run to enter the fire box through one of the openings in the sides of the fire box below the fuelbed support panel and connec...

Page 16: Please Note :-

Important : sealing of the gas unused gas pipe inlet apertures in line with current gas safe regulations, it is imperative that the gas supply inlet apertures that are not utilised during the installation are sealed with the foil tape as supplied. Failure to seal these inlet apertures could lead to ...

Page 17

The preferred method of fixing which is suitable for almost all situations is the cable fixing method which is described in the following section in detail. The fire may be secured using the cable method as described below, or alterna- tively, in installations where the cable method is not suitable ...

Page 18

K) thread a tensioning screw over each of the cables and ensure that the tensioning nut is screwed fully up against the hexagon shoulder of the tensioning screw (this provides maximum travel for the tensioning nut). L) fit a screwed nipple on to each of the cables and pull hand tight up against the ...

Page 19

This should not be overtightened. Move the control lever fully downwards and check that the left hand micro-switch operates the igniter and that the control valve spindle is fully depressed. Move the control lever upwards to the “off” position and check that the right hand (cut-off) micro-switch ope...

Page 20

2.3 gas tightness and inlet pressure (manual control models) a) remove the pressure test point screw from the inlet elbow and fit a manometer. B) turn on the main gas supply and carry out a gas tightness test. C) depress the control knob and turn anti-clockwise to the position marked pilot. Hold in ...

Page 21

Section 3 assembling fuel bed and commissioning 3.1 assembling the ceramics and fuel bed - coal models a) place the ribbed ceramic fuelbed base on top of the fuelbed support and pull fully forwards to the burner. Make sure that the fuelbed base is located centrally in the fire box. Ensure that the f...

Page 22

C) fit three of the large sized square coals onto the front ceramic rail, and two of the random shaped coals as shown below ensuring that they are evenly spaced. Use the recess’s in the front ceramic rail as a guide for placement. (see fig. 18 below) fig. 18 d) select two of the large square coals t...

Page 23

E) select two of the oblong coals and one of the square coals and arrange along the rear of the fuelbed, using the ribs in the rear of the fuelbed as a guide for placement. (see fig. 20 below) fig. 20 f) select the two small coals and position to fill the gaps at each end of the third row of coals, ...

Page 24

G) select the remaining two oblong coals, one random coal and one square coal and position along the rear edge of the fuelbed, see fig. 22 below. Fig. 22 the exact position and fit of the coals may be finely adjusted to give the most pleasing and random appearance. Warning : use only the coals suppl...

Page 25

3.2 assembling the ceramics and fuel bed - pebble models a) place the ribbed ceramic fuelbed base on top of the fuelbed support and pull fully forwards to the burner. Make sure that the fuelbed base is located centrally in the fire box. Ensure that the fuelbed base fit fully down onto the fuel bed s...

Page 26

C) pick pebbles a to e and arrange along the the front rail, ensuring that they are evenly spaced. Use the recess’s in the front ceramic rail as a guide for placement. (see fig. 25 below) fig. 25 d) select pebbles f to i and arrange behind the front row of pebbles, ensuring that flame paths as indic...

Page 27

E) select pebbles k, l & m and arrange along the rear of the fuelbed, using the ribs in the rear of the fuelbed as a guide for placement. (see fig. 27 below) fig. 27 f) select the two small pebbles (j & n) and position to fill the gaps at each end of the third row of pebbles, as shown. Above in fig....

Page 28

3.3 fixing the infrared sensor in position (rc models only) a) due to the different fascia’s that can be supplied with these fires, the infrared sensor is supplied from the factory attached to a self adhesive pad. This pad can therefore be attached to the hearth in a position to suit the form of the...

Page 29

3.4 connecting the battery pack (rc & efc models) a) to prevent un-necessary battery drain, the battery pack that is used to provide the remote control or trim switch function for this product is disconnected at the factory. Prior to attempting to light the product, can the installer please ensure t...

Page 30

3.7 lighting the appliance (manual control models) a) turn on the gas isolation tap. B) depress the control knob and turn anti-clockwise to the position marked pilot. Hold in the control knob for a few seconds to purge the pipe work. C) continue to hold-in the control knob and press the igniter butt...

Page 31

D) the gas control can be moved from the high to low position to give the desired heat output. E) to turn the fire off, fully raise the control lever to the off position. Warning : if the fire goes out for any reason or is turned off and it isnecessary to re-light the fire it is important to allow t...

Page 32

3.9 lighting the appliance (remote control models) a) the remote control handset generates an infrared signal, which will be received by the sensor situated at the front right of your fire, behind the ashpan cover. This infrared signal requires direct line of sight from the handset to the sensor on ...

Page 33

3.10 lighting the appliance - (electronic fire control models). A) to light the fire using the electronic fire control, press the ignition button as indicated below in fig. 32. The fire will emit a “beep” sound, the buttons can now be released. After a few seconds an audible clicking can be heard an...

Page 34

3.11 checking for clearance of combustion products a) close all doors and windows in the room. B) light the fire and allow to run for approximately 5 minutes on high position. C) after approximately 5 minutes hold a smoke match just inside and below the centre of the lower front edge of the top of t...

Page 35

Section 4 maintenance servicing notes servicing should be carried out annually by a competent person such as a gas safe registered engineer. The service should include visually checking the chimney and fire opening for accumulations of debris and a smoke test to check for a positive up-draught in th...

Page 36

4.3 removing the control tap from the fire. 4.3.1 remove the burner assembly as in section 4.1. 4.3.2 pull the control knob off the control tap spindle. 4.3.3 loosen and remove the three gas pipe retaining nuts from the control tap and release the ends of the gas pipes from the control tap body. Loo...

Page 37

Location. Remove all of the loose coals / pebbles and front ceramic rail. Unscrew the two pozi-drive fixing screws which secure the burner heat shield and remove it from the fire. 4.5.3 isolate the gas supply and remove the inlet pipe from the appliance inlet elbow. To allow burner removal, the cont...

Page 38

4.7 replacing the battery 4.7.1 unscrew battery retaining cap situated at the front right of the fire and remove the battery 4.7.2 replace in the reverse order using a 1.5v aa alkaline battery. 4.8 removing the oxy-pilot assembly note: because this appliance is fitted with an atmosphere sensing ‘oxy...

Page 39

4.9.2 hold the hexagonal control lever cable locking bush with a spanner and unscrew the locking screw using a 2mm allen key to release the cable from the control lever. The control cable can now be removed from the cable guide tubes. 4.9.3 to fit the replacement cable, thread the end of the new cab...

Page 40

Remote / efc models – for diagrams refer to section 2 4.10 removing the burner assembly from the fire. 4.10.1 prepare work area (lay down dust sheets etc.) 4.10.2 lift the fender and ash pan cover of the way and put them in a safe location. Remove the loose coals from the fuel bed and front ceramic ...

Page 41

4.12.3 re-connect to the wiring loom. 4.12.4 replace in reverse order and carry out a gas tightness test. Fret information to enable customers to choose their own style of fret these fires are now available without frets. In order to maintain the efficient and safe operation of the fire it is import...

Page 42

Section five - user instructions 5.1 installation information conditions of installation it is the law that all gas appliances are installed only by a competent (e.G. Registered) installer, in accordance with the installation instructions and the gas safety (installation and use) regulations 1998. F...

Page 43

About your new verine quasar mk2 gas fire the verine quasar mk2 coal effect gas fire incorporates a unique and highly developed fuel bed which gives the realism of a loose coal layout combined with realistic flames and glow. The use of durable ceramic material in the construction of the fuelbed comp...

Page 44

5.2 operating the fire (manual control models) the controls are located behind the ashpan cover which is situated behind the ashpan / fender. The controls, comprise a control valve to adjust the gas flow and a push button piezo igniter. To light the fire proceed as follows:- a) depress the control k...

Page 45

5.3 operating the fire (slide control models) the controls comprise a control lever, to turn the fire on and off and adjust the gas rate. The control lever is located at the top right hand side of the fire. Depressing the control lever fully operates the igniter and lights the pilot flame and igniti...

Page 46

5.4 operating the fire using the remote control a) the remote control handset generates an infrared signal, which will be received by the sensor situated at the front right of your fire, behind the ashpan cover. This infrared signal requires direct line of sight from the handset to the sensor on the...

Page 47

5.5 lighting the appliance - electronic fire control models only a) to light the fire using the electronic fire control, press the ignition button as indicated below in fig. 2. The fire will emit a “beep” sound, the buttons can now be released. After a few seconds an audible clicking can be heard an...

Page 48

5.6 turning the product off in the unlikely event of a remote handset or efc trim switch malfunction. A) in the unlikely event of the remote control handset or efc trim switch malfunctioning (or if lost or broken) after the appliance has been turned on, the fire can be turned off via the emergency s...

Page 49

Replacing the battery (slide control models only) ensure the fire is cool before replacing batteries unscrew battery retaining cap situated at the front right of the fire and remove battery. Replace in the reverse order using a 1.5v aa alkaline battery. It is important that only an alkaline battery ...

Page 50

5.7 assembling fuel bed & ceramics - coal models a) place the ribbed ceramic fuelbed base on top of the fuelbed support and pull fully forwards to the burner. Make sure that the fuelbed base is located centrally in the fire box. Ensure that the fuelbed base fit fully down onto the fuel bed support a...

Page 51

C) fit three of the large sized square coals onto the front ceramic rail, and two of the random shaped coals as shown below ensuring that they are evenly spaced. Use the recess’s in the front ceramic rail as a guide for placement. (see fig. 6 below) fig. 6 d) select two of the large square coals two...

Page 52

E) select two of the oblong coals and one of the square coals and arrange along the rear of the fuelbed, using the ribs in the rear of the fuelbed as a guide for placement. (see fig. 8 below) fig. 8 f) select the two small coals and position to fill the gaps at each end of the third row of coals, as...

Page 53

G) select the remaining four coals and position along the rear edge of the fuelbed (see fig. 10 below) fig. 10 the exact position and fit of the coals may be finely adjusted to give the most pleasing and random appearance. Warning : use only the coals supplied with the fire. When replacing the coals...

Page 54

5.8 assembling the ceramics and fuel bed - pebble models a) place the ribbed ceramic fuelbed base on top of the fuelbed support and pull fully forwards to the burner. Make sure that the fuelbed base is located centrally in the fire box. Ensure that the fuelbed base fit fully down onto the fuel bed s...

Page 55

C) pick pebbles a to e and arrange along the the front rail, ensuring that they are evenly spaced. Use the recess’s in the front ceramic rail as a guide for placement. (see fig. 13 below) fig. 13 d) select pebbles f to i and arrange behind the front row of pebbles, ensuring that flame paths as indic...

Page 56

E) select pebbles k, l & m and arrange along the rear of the fuelbed, using the ribs in the rear of the fuelbed as a guide for placement. (see fig. 15) fig. 15 f) select the two small pebbles (j & n) and position to fill the gaps at each end of the third row of pebbles, as shown above in fig. 14 the...

Page 57

User replaceable parts the only user replaceable parts on this fire are the fuelbed components and coals which may be replaced as described in the above section. Replacement of any other parts must be carried out by a competent person such as a gas safe registered gas installer. The part numbers of ...