- DL manuals

- VOKERA

- Boiler

- Easi-Heat Plus 25C

- User instructions

VOKERA Easi-Heat Plus 25C User instructions

Users Instructions

Installation &

Servicing

Instructions

THESE INSTRUCTIONS

TO BE RETAINED

BY USER

Vokèra is a licensed member of the Benchmark scheme

which aims to improve the standards of installation and

commissioning of domestic hot water systems in the UK.

Easi-Heat Plus C

High efficiency combi boiler

Easi-Heat Plus 25C G.C. N° 47-364-29

Easi-Heat Plus 29C G.C. N° 47-364-30

Summary of Easi-Heat Plus 25C

Page 1

Users instructions installation & servicing instructions these instructions to be retained by user vokèra is a licensed member of the benchmark scheme which aims to improve the standards of installation and commissioning of domestic hot water systems in the uk. Easi-heat plus c high efficiency combi...

Page 2

Users instructions 1. Things you should know ............................................1 1.1 gas appliances ................................................................1 1.2 electrical supply ..........................................................1 1.3 guarantee registration card .............

Page 3: Users Instructions

1 users instructions 1.1 gas appliances gas safety (installations and use) regulations (uk). In the interests of your safety and that of others it is a legal requirement that all gas appliances are installed and correctly maintained by a competent person and in accordance with the latest regulations...

Page 4

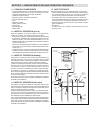

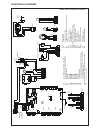

2 fig. 1 boiler status led green led boiler is working/responding to a heating/hot water request red led boiler has identified a fault and has failed-safe. Refer to instructions on how to reset yellow led dhw pre-heat function working/service operation dhw temperature selector move the selector cloc...

Page 5

3 2.1 before switching on before switching the appliance on, please familiarise yourself with: - how to isolate the appliance from the gas, water, and electricity supplies; - how to check and top-up – if necessary – the system water pressure; - the time clock or programmer (if fitted); - any externa...

Page 6

4 4.1 what if i suspect a gas leak if you suspect a gas leak, turn off the gas supply at the gas meter and contact your installer or local gas supplier. If you require further advice please contact your nearest vokèra office. 4.2 what if i have frequently to top-up the system if the system regularly...

Page 7

5 all installers are asked to follow the benchmark scheme by adhering to the code of practise, which can be obtained from www.Centralheating.Co.Uk. The easi-heat plus c comprises a range of high-efficiency combination boilers with outputs to dhw of 25kw and 29kw respectively. These appliances – by d...

Page 8

6 1.1 principle components • a fully integrated electronic control board featuring electronic temperature control, anti-cycle control, pump over-run, self- diagnostic fault indicator, full air/gas modulation. • aluminium heat exchanger. • electronic ignition with flame supervision. • integral high-h...

Page 9

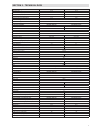

7 2.1 central heating easi-heat plus 25c easi-heat plus 29c heat input (kw) 20.00 25.00 maximum heat output (kw) 60/80°c 19.50 24.45 minimum heat output (kw) 60/80°c 4.91 5.90 maximum heat output (kw) 30/50°c 20.84 26.23 minimum heat output (kw) 30/50°c 5.36 6.40 minimum working pressure 0.25-0.45 b...

Page 10

8 seasonal space heating energy efficiency class a water heating energy efficiency class a parameter symbol value unit parameter symbol value unit rated heat output prated 20 kw seasonal space heating energy efficiency ηs 93 % for boiler space heaters and boiler combination heaters: useful heat outp...

Page 11

9 fig. 6 2.12 pump duty fig. 6 shows the flow-rate available – after allowing for pressure loss through the ap- pliance – for system requirements. When using this graph, apply only the pressure loss of the system. The graph is based on a 20 o c temperature differential. Fig. 7 flow rate (l/h) residu...

Page 12

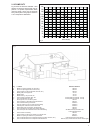

10 section 3 - general requirements (uk) this appliance must be installed by a competent person in ac- cordance with the gas safety (installation & use) regulations. 3.1 related documents the installation of this boiler must be in accordance with the relevant requirements of the gas safety (installa...

Page 13

11 this appliance must be installed by a competent person in accordance with and defined by, the standard specification (domestic gas installations) declaration (i.S. 813). 3a.1 related documents the installation of this boiler must be in accordance with the relevant requirements of the local buildi...

Page 14

12 the terminal must be protected by a guard of durable material. The guard must be fitted centrally over the terminal. Refer to i.S. 813, when the terminal is 0.5 metres (or less) below plastic guttering or 1 metre (or less) below painted eaves. 3a.5 air supply the following notes are intended for ...

Page 15

13 4.1 delivery due to the weight of the appliance it may be necessary for two people to lift and attach the appliance to its mounting. The appliance is contained within a heavy-duty cardboard carton. Lay the carton on the floor with the writing the correct way up. 4.2 contents contained within the ...

Page 16

14 extending the flue connect the bend – supplied with the terminal kit – to the top of the boiler using clamp (supplied) see fig. 11. The additional bends & extensions have push-fit connections, care should be taken to ensure that the correct seal is made when assembling the flue system. Connect th...

Page 17

15 note when cutting an extension to the required length, you must ensure that the excess is cut from the plain end of the exten- sion. Remove any burrs, and check that any seals are located properly. You must ensure that the entire flue system is properly sup- ported and connected. 4.6 connecting t...

Page 18

16 fig. 17 a fig. 18 5.1 gas supply installation inspect the entire installation including the gas meter, test for tightness and purge. Refer to bs 6891 (i.S. 813 in roi) for specific instruction. 5.2 the heating system the appliance contains components that may become damaged or rendered inoperable...

Page 19

17 5.8 final flushing of the heating system the system shall be flushed in accordance with bs 7593 (i.S. 813 roi). Should a cleanser be used, it must be suitable for aluminium heat exchangers. It shall be from a reputable manu- facturer and shall be administered in strict accordance with the manufac...

Page 20

18 the flame side of the burner is made of state-of-the-art material. Being fragile: - be particularly careful when handling, mounting or disman- tling the bur ner and adjacent components (e.G. Electrodes, insulation panelling etc.) - avoid direct contact with any cleaning appliance (e.G. Brushes, a...

Page 21

19 6.10 return thermistor (fig. 4 - pos. 21) carry out component removal procedure as described in 6.4. Unclip and remove the air chamber front cover. Unclip the re- turn thermistor from the return inlet pipe. Disconnect thermistor electrical plug. Replace in the reverse order. 6.11 printed circuit ...

Page 22

20 fig. 29 fig. 30 q1 t1 s1 r1 fig. 32 fig. 31 u1 a1 b1 m1 n1 o1 p1 j1 w1 v1 6.16 main heat exchanger (fig. 29) carry out component removal procedure as described in 6.4. Remove the air chamber front cover. Locate and remove the gas pipe locking pin ( a1 ) and swing/rotate the gas pipe away from the...

Page 23

21 fig. 35 fig. 34 y1 fig. 33 z1 a2 a3 a4 b2 c2 d2 e2 f2 g2 h2 k2 6.20 flue collector removal (fig. 33) carry out component removal procedure as described in 6.4. Remove the air chamber front cover. Remove the heat exchang- er as per 6.16. Locate and remove the screw ( y1 ) that secures the flue gas...

Page 24

22 7.1 checking appliance operation when carrying out any repairs or servicing to the appliance, the relevant commissioning procedure must be undertaken to ensure the continued safe operation of the appliance. Particular attention should be made to ensure gas tightness, water tight- ness and the ele...

Page 25

23 fig. 37 7.3.1 co 2 function settings locate the co button (see 7.3) select the main selector switch in position . Co 2 functions action on the button led status combustion analysis mode press once = burner running at maximum heating yellow led blinking gas valve maximun setting press twice = burn...

Page 26

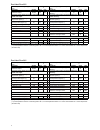

24 7.9 component values & characteristics appliance status led and fault codes when the boiler detects a temporary fault condition, the appro- priate led indication is shown. If/when the fault is final, the pump will perform a 60-second post circulation and the red led will be illuminated. See table...

Page 27

25 8.1 external wiring the appliance comes supplied with a time clock to allow opera- tion of the boiler via the mode selector switch. If external controls are to be added to the system, they must be connected to the appliance as shown in the following diagrams. For advice on controls that are not f...

Page 28

26 functional diagram fig. 41 note: l-n-e connection is advisable akl main pcb with vis medium integrated p1 selector switch and heating potentiometer p2 dhw potentiometer p3 unused p4 unused jp1 unused jp2 unused jp3 unused jp4 unused jp5 unused jp6 unused jp7 unused jp8 closed - unused led led 1 (...

Page 29

27 9.1 related documents section 9 - lpg instructions 9.6 checking the co 2 and adjusting the gas valve the gas valve must be set-up or adjusted with the aid of a properly calibrated flue gas analyser. Isolate the appliance from the electrical supply and remove the appliance casing as described in 4...

Page 30

Commissioning: co and combustion ratio check set boiler to maximum rate in accordance with, section 7.3, set boiler to operate at maximum rate (full load condition). Allow sufficient time for combustion to stabilise. , insert analyser probe into air inlet sampling point. Is o2 ≥ 20.6% and co2 verify...

Page 31: Www.Centralheating.Co.Uk

© heating and hotwater industry council (hhic) www.Centralheating.Co.Uk benchmark commissioning and servicing section it is a requirement that the boiler is installed and commissioned to the manufacturers instructions and the data fields on the commissioning checklist completed in full. To instigate...

Page 32

*allinstallationsinenglandandwalesmustbenotifiedtolocalauthoritybuildingcontrol(labc)eitherdirectlyorthrougha competentpersonsscheme.Abuildingregulationscompliancecertificatewillthenbeissuedtothecustomer. Www.Centralheating.Co.Uk ©heatingandhotwaterindustrycouncil(hhic) this commissioning checklist ...

Page 33

*allinstallationsinenglandandwalesmustbenotifiedtolocalauthoritybuildingcontrol(labc)eitherdirectlyorthrougha competentpersonsscheme.Abuildingregulationscompliancecertificatewillthenbeissuedtothecustomer. ©heatingandhotwaterindustrycouncil(hhic) www.Centralheating.Co.Uk it is recommended that your h...

Page 36

Cod. 201 17173 - 04/16 - ed. 1 registered address: vokèra ltd borderlake house unit 7 riverside industrial estate london colney herts al2 1hg enquiries@vokera.Co.Uk www.Vokera.Co.Uk www.Vokera.Ie sales, general enquires t 0844 391 0999 f 0844 391 0998 vokèra ireland west court, callan co kilkenny t ...