- DL manuals

- VOKERA

- Boiler

- RAIN 24

- Installation And Servicing Instructions

VOKERA RAIN 24 Installation And Servicing Instructions

Summary of RAIN 24

Page 1

Installation installation installation installation installation & servicing & servicing & servicing & servicing & servicing instructions instructions instructions instructions instructions these instructions to be retained by user 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi.

Page 2

Contents design principles and operating sequence page 1.1 principle components 2 1.2 mode of operation 2 1.3 safety devices 2 technical data page 2.1 central heating 3 2.2 gas pressure 3 2.3 expansion vessel 3 2.4 dimensions 3 2.5 clearances 3 2.6 connections 3 2.7 electrical 3 2.8 flue details 3 2...

Page 3

1 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi introduction fig.1/1a general layout 1 safety valve 2 hydraulic manifold 3 pressure switch 4 pump 5 auto air vent (aav) 6 main heat exchanger 7 high limit thermostat 8 primary ntc sensor 9 differential pressure switch 10 flue outlet 11 flue gas analysis...

Page 4

2 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi section 1 design principles and operating sequence fig. 2 1.1 principle components ● a fully integrated electronic control board fea- turing electronic temperature control, anti-cy- cle control, pump over-run, self-diagnostic fault indicator, continuous...

Page 5

3 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi section 2 technical data ref. Condition 15 °c , 1013,25 mbar, dry gas note: l.P.G. Data refer to section 10 2.1 central heating heat input (kw) 26.3 30.5 heat output (max) 24.0 27.6 heat output (min) 9.4 10.5 minimum working pressure 0.5 bar maximum wor...

Page 6

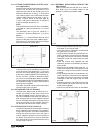

4 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi 2.10 pump duty fig. 3 shows the flow-rate available - after allowing for pressure loss through the appli- ance - against system pressure loss. When using this graph apply only the pressure loss of the system. The graph is based on a 20 ºc temperature di...

Page 7

5 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi this appliance must be installed by a competent person in accordance with and defined by, the standard specification (domestic gas installa- tions) declaration (i.S. 813). 3a.1 related documents the installation of this boiler must be in accord- ance wi...

Page 8

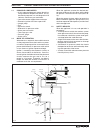

6 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi 3a.6.7 low pressure sealed system an alternative method of filling the system would be from an independent make-up vessel or tank mounted in a position at least 1-metre above the highest point in the system and at least 5-metres above the boiler (see fi...

Page 9

7 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi section 4 installation fig. 7 external installation internal installation fig. 7a rain bi boiler 4.1 delivery due to the weight of the appliance it may be necessary for two people to lift and attach the appliance to its mounting. The appliance is contai...

Page 10

8 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi should this application be preferred, it’s recom- mended that any openings on the top of the enclosure are sealed with a suitable silicone seal- ant in order to minimise the ingress or rainwater. The use of the enclosure allows the installation pipework...

Page 11

9 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi 4.5.1.1 fitting the horizontal flue kit (enclo- sure applications) determine the route of the flue pipe and carefully measure the distance from the centre of the appliance flue outlet to the outside face of the enclosure (dimension ‘x’ see fig. 7). Ensu...

Page 12

10 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi 4.5.2 concentric vertical flue the rain/rain bi appliance can be used with the standard 60/100mm concentric vertical terminal. For further details on vertical terminations, please contact the vokera technical help-line. 4.5.3 vokera twin flue applicati...

Page 13

11 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi live and neutral) to their corresponding terminals on the terminal strip. Ensure that the earth wire is left slightly longer that the others, this will pre- vent strain on the earth wire should the cable become taut. Do not remove the link do not remov...

Page 14

12 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi isolate the appliance from the electrical supply and attach a suitable manometer to the gas valve outlet test nipple (see fig. 11). Light the boiler as described in 5.6 and compare the reading on the manometer with the value described in section 2. If ...

Page 15

13 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi section 6 servicing instructions 6.1 general to ensure the continued safe and efficient opera- tion of the appliance, it is recommended that it is checked and serviced at regular intervals. The frequency of servicing will depend upon the particular ins...

Page 16

14 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi 7.1 checking appliance operation when carrying out any repairs or servicing to the appliance, the relevant commissioning proce- dure must be undertaken to ensure the continued safe operation of the appliance. Particular atten- tion should be made to en...

Page 17

15 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi notes the timer delay can be de-activated by the inser- tion of a ‘jumper’ on the pcb at jp2 (fig.14) or by isolating the appliance from the electrical supply for 30 seconds. When the request for heating and/or hot water has been satisfied, the applian...

Page 18

16 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi symptom possible causes no ignition check external wiring check external controls no hot water check external controls no central heating check external controls frequency faults/status on every 6-secs at stand-by with no faults flashing 8-times a seco...

Page 19

17 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi if tests on the isolator also reveal reversed polar- ity or a supply fault, consult the local electricity supplier for advice. 7.7.5 resistance to earth check isolate the appliance from the electrical supply, and using a suitable multi-meter carry out ...

Page 20

18 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi section 8 wiring diagrams 8.1 external wiring the appliance comes with a factory fitted link (fig. 16) to allow basic operation of the boiler via the mode selector switch. If external controls are to be added to the system, they must be connected to th...

Page 21

19 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi functional diagram note: l-n-e connection is advisable fig. 17.

Page 22

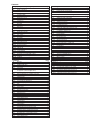

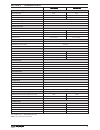

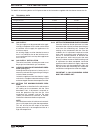

20 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi section 9 exploded diagrams pos. Description 24 28 24 bi 28 bi 10 support 10025348 10025348 10025348 10025348 12 quick primer pressure gauge 10024664 10024664 10024664 10024664 15 wiring junctions 01005313 01005313 01005313 01005313 18 cover 10024677 1...

Page 23

21 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi pos. Description 24 28 24 bi 28 bi 3 pressure switch 2044 2044 2044 2044 7 heating by-pass valve 1552 1552 1552 1552 9 heating distrib. Manifold 10021821 10021821 10021821 10021821 22 safety valve 2907 2907 2907 2907 27 heating cock 1789 1789 1789 1789...

Page 24

22 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi pos. Description 24 28 24 bi 28 bi 1 expansion vessel 10024662 10024662 10024662 10024662 2 flexible pipe 10025188 10025188 10025188 10025188 3 up 15-50 ao pump 10020437 10020437 10020437 10020437 4 automatic air vent bottle 0439 0439 0439 0439 7 pipe ...

Page 25

23 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi pos. Description 24 28 24 bi 28 bi 1 roomsealed chamber 10024669 10024745 10024669 10024745 2 air box clip 0442 0442 0442 0442 3 main burner injector manifold 10025271 10024742 10025271 10024742 4 burner 10025270 10026102 10025270 10026102 5 spark-sens...

Page 26

24 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi pos. Description 24 28 24 bi 28 bi 2 back insulating panel 2230 2230 2230 2230 3 lateral insulating panel 2231 2231 2231 2231 4 front insulating panel 2232 2232 2232 2232 10 fan 10020793 10023907 10020793 10023907 12 fan connection 10021972 10021972 10...

Page 27

25 24/28/bi 24/28/bi 24/28/bi 24/28/bi 24/28/bi section 10 l.P.G. Instructions 10.2 gas supply the gas supply must be connected to the appli- ance by a competent lpg installer and must be of sufficient size to supply the appliance at its maximum output. An existing supply must be checked to ensure t...

Page 28

Cod. 10027715 - 39/05 - ed. 1 energizing home heating vokèra ltd. 4 th floor, catherine house, boundary way, hemel hempstead, herts, hp2 7rp email: enquiries@vokera.Co.Uk web: www.Vokera.Co.Uk sales, technical advice, general enquiries - tel: 0870 333 0520 fax: 01442 281403 after sales service - tel...