- DL manuals

- VOKERA

- Heater

- Syntesi e

- Installation & Servicing Instructions Manual

VOKERA Syntesi e Installation & Servicing Instructions Manual

Summary of Syntesi e

Page 1

Supplied by www.Heating spares.Co tel. 0161 620 6677 installation & servicing instructions these instructions to be retained by user.

Page 2

Supplied by www.Heating spares.Co tel. 0161 620 6677 contents design principles and operating sequence page 1.1 principle components 2 1.2 mode of operation (at reset) 2 1.3 mode of operation (heating) 2 1.4 mode of operation (dhw) 2 1.5 safety devices 2 1.6 optional accessories 2 technical data pag...

Page 3

Supplied by www.Heating spares.Co tel. 0161 620 6677 1 the syntesi range of appliances is comprised of 3 models of high-efficiency combination boiler with outputs to heating & dhw of 24, 28, & 34kw respectively. Each appliance – by design – incorporates electronic ignition, circulating pump, expansi...

Page 4

Supplied by www.Heating spares.Co tel. 0161 620 6677 2 1.1 principle components ● a fully integrated electronic control board featuring electronic temperature control, anti- cycle control, pump over-run, self-diagnostic fault indicator, full air/gas modulation. ● low-water-content, copper heat excha...

Page 5

Supplied by www.Heating spares.Co tel. 0161 620 6677 3 section 2 technical data 2.1 central heating syntesi 25 syntesi 29 syntesi 35 heat input 25.0 kw 29.0 kw 35.0 kw max heat output 60/80 ° c (return & flow temp.) 24.1 kw 28.0 kw 33.9 kw max heat output 30/50 ° c (return & flow temp.) 25.9 kw 29.7...

Page 6

Supplied by www.Heating spares.Co tel. 0161 620 6677 4 2.11 pump duty fig. 3 shows the flow-rate available – af- ter allowing for pressure loss through the appliance – for system requirements. When using this graph, apply only the pressure loss of the system. The graph is based on a 20 ° c temperatu...

Page 7

Supplied by www.Heating spares.Co tel. 0161 620 6677 5 section 3 general requirements (uk) this appliance must be installed by a competent person in accordance with the gas safety (installation & use) regulations. 3.1 related documents the installation of this boiler must be in accordance with the r...

Page 8

Supplied by www.Heating spares.Co tel. 0161 620 6677 6 3.6 water circulation detailed recommendations are given in bs 5449 part 1 and bs 6798. The following notes are for general guidance only. 3.6.1 pipework it is recommended that copper tubing to bs 2871 part 1 is used in conjunction with soldered...

Page 9

Supplied by www.Heating spares.Co tel. 0161 620 6677 7 3.10 timber framed buildings if the appliance is to be fitted in a timber framed building, it should be fitted in accordance with the institute of gas engineers publication (ige/up/ 7) ‘guide for gas installations in timber frame buildings’. 3.1...

Page 10

Supplied by www.Heating spares.Co tel. 0161 620 6677 8 3a.6.1 pipework it is recommended that copper tubing be used in conjunction with soldered capillary joints. Where possible pipes should have a gradient to ensure air is carried naturally to air release points and that water flows naturally to dr...

Page 11

Supplied by www.Heating spares.Co tel. 0161 620 6677 9 section 4 installation 4.1 delivery due to the weight of the appliance it may be necessary for two people to lift and attach the appliance to its mounting. The appliance is contained within a heavy-duty cardboard carton. Lay the carton on the fl...

Page 12

Supplied by www.Heating spares.Co tel. 0161 620 6677 10 horizontal flue terminals and accessories part no. Description min-max length 0225720 horizontal flue kit for use 1000mm with add. Bends & extensions 0225755 telescopic extension 350mm – 500mm 0225740 0.5m extension 500mm 0225745 1.0m extension...

Page 13

Supplied by www.Heating spares.Co tel. 0161 620 6677 11 4.5.2 concentric vertical flue the appliance can be used with either the vokera condensing 60/100mm concentric flue system or the optional 80/125mm concentric flue system. Note these instructions relate only to the vokera condensing 60/100mm co...

Page 14

Supplied by www.Heating spares.Co tel. 0161 620 6677 12 bend reduction in maximum flue length for each bend 45 ° bend 1.0 metre 90 ° bend 1.0 metre reduction for bends part no. Description length 0225805 horizontal flue terminal 1.0 metre 0225810 vertical flue terminal 1.0 metre 359 twin adapter kit...

Page 15

Supplied by www.Heating spares.Co tel. 0161 620 6677 13 4.5.3.2 horizontal termination (see fig. 12) the twin flue system must be converted to the dedicated concentric flue kit for termination. ● the horizontal terminal is supplied with a built- in converter box and cannot be shortened. ● a 130mm ho...

Page 16

Supplied by www.Heating spares.Co tel. 0161 620 6677 14 4.6 connecting the gas and water the appliance is supplied with a fixing jig that includes service valves (fig. 14). The service valves are of the compression type. The accessories pack contains sealing washers etc, for use with the service val...

Page 17

Supplied by www.Heating spares.Co tel. 0161 620 6677 15 connect a discharge pipe to the fixing jig connection and tighten. The discharge pipe must have a continuous fall away from the appliance to outside and allow any water to drain away thereby eliminating the possibility of freezing. The discharg...

Page 18

Supplied by www.Heating spares.Co tel. 0161 620 6677 16 do not remove the link wire (between ta & spare) unless additional external controls are to be fitted (see section 8). 4.7.4 connecting the vokera time clock (part no. 201 & 202) the appliance is supplied with a clock connector plug that is con...

Page 19

Supplied by www.Heating spares.Co tel. 0161 620 6677 17 5.1 gas supply installation inspect the entire installation including the gas meter, test for soundness and purge. Refer to bs 6891 for specific instruction. 5.2 the heating system the appliance contains components that may become damaged or re...

Page 20

Supplied by www.Heating spares.Co tel. 0161 620 6677 18 5.8 final flushing of the heating system the system shall be flushed in accordance with bs 7593. If a cleanser is to be used, it shall be from a reputable manufacturer* and shall be administered in strict accordance with the manufacturers instr...

Page 21

Supplied by www.Heating spares.Co tel. 0161 620 6677 19 6.1 general to ensure the continued safe and efficient operation of the appliance, it is recommended that it is checked and serviced at regular intervals. To ensure correct and safe operation of the appliance, it is essential that any worn or f...

Page 22

Supplied by www.Heating spares.Co tel. 0161 620 6677 20 6.9 pressure gauge (see fig. 23) carry out component removal procedure as described in 6.4. Remove pressure gauge locking screw (1), located on pump base, and withdraw the pressure gauge pipe (2), locate the spring tabs on the pressure gauge bo...

Page 23

Supplied by www.Heating spares.Co tel. 0161 620 6677 21 6.11 high limit thermostat (see fig. 25) carry out component removal procedure as described in 6.4. Unclip and remove the air chamber cover. Pull off electrical connections from the high limit thermostat (2), slacken and remove retaining screws...

Page 24

Supplied by www.Heating spares.Co tel. 0161 620 6677 22 6.14 integral time switch (if fitted) carry out component removal procedure as described in 6.4. Locate and remove the terminal cover and securing screws (2), locate and remove the time clock retaining screws, remove time clock. Disconnect wiri...

Page 25

Supplied by www.Heating spares.Co tel. 0161 620 6677 23 fig. 30 6.16 flue fan (see fig. 28 & 30) carry out component removal procedure as described in 6.4. Fig. 28: unclip and remove the air chamber cover, gently pull the cover towards you before lifting and disengaging (2). Locate and remove the si...

Page 26

Supplied by www.Heating spares.Co tel. 0161 620 6677 24 6.18 air pressure switch (see fig. 30) carry out component removal procedure as described in 6.4. Fig. 28: unclip and remove the air chamber cover, gently pull the cover towards you before lifting and disengaging (2). Fig. 30: locate and remove...

Page 27

Supplied by www.Heating spares.Co tel. 0161 620 6677 25 fig. 37 fig. 38 fig. 36 6.24 secondary thermistor (see fig. 36) carry out component removal procedure as described i 6.4. Pull back the protective cover from the thermistor and disconnect the electrical plug. Using a 13mm spanner slacken and re...

Page 28

Supplied by www.Heating spares.Co tel. 0161 620 6677 26 fig. 39 fig. 41 fig. 43 6.28 latent heat collector fig’s. 40 & 41 carry out component removal procedure as described in 6.4. Remove the flue hood and fan assembly as detailed in 6.16. Disconnect the condense sensor wire from the sensor. Fig. 40...

Page 29

Supplied by www.Heating spares.Co tel. 0161 620 6677 27 section 7 checks, adjustments and fault finding 7.1 checking appliance operation when carrying out any repairs or servicing to the appliance, the relevant commissioning procedure must be undertaken to ensure the continued safe operation of the ...

Page 30

Supplied by www.Heating spares.Co tel. 0161 620 6677 28 the temperature at the primary thermistor has dropped 6 ° c below the set-point. Notes the timer delay can be de-activated by the insertion of a ‘jumper’ on the pcb or by isolating the appliance from the electrical supply for 30 seconds. Any dh...

Page 31

Supplied by www.Heating spares.Co tel. 0161 620 6677 29 fault code possible causes 01 gas supply problem gas line requires purging reversed polarity broken, internal flue joint 02 flow/return valves closed stuck pump 03 debris in flue system debris in flue venturi 04 insufficient water pressure air ...

Page 32

Supplied by www.Heating spares.Co tel. 0161 620 6677 30 or a supply fault, consult the local electricity supplier for advice. 7.7.5 resistance to earth check isolate the appliance from the electrical supply, and using a suitable multi-meter carry out a resistance test. Connect test leads between the...

Page 33

Supplied by www.Heating spares.Co tel. 0161 620 6677 31 mains on fan replace fan replace wiring or connections mains on pump replace pump a2 a is there 0 vdc between terminals m5.5 & m5.6 on pcb check &/or replace wiring and connections mains on fan connector m12.1 & m12.2 replace control board main...

Page 34

Supplied by www.Heating spares.Co tel. 0161 620 6677 32 check wiring and connections, high limit thermostat or pcb is there 24 vdc between terminals m5.3 and m3.3 on pcb is there 24 vdc between terminals m5.3 on pcb & white wire on high limit thermostat is there 24 vdc between terminals m5.3 on pcb ...

Page 35

Supplied by www.Heating spares.Co tel. 0161 620 6677 33 a2 replace control board fuse ok check fuses f1 and f2 on connection board recheck supply fuse & connectors to boiler terminals is red led flashing replace the bicoulored led assembly mains present between m16.L & m16.N on control board restart...

Page 36

Supplied by www.Heating spares.Co tel. 0161 620 6677 34 does burner light check boiler startup: test a turn on tap turn mode selector switch to dhw. Dhw stat at max. Start test b : check control in dhw mode turn dhw thermostat at min. Do burner and fan switch off is water flow temperature >40 ˚c wai...

Page 37

Supplied by www.Heating spares.Co tel. 0161 620 6677 35 check boiler startup test a does burner light make a link between pin m16.Ta and m16.Ta on control board switch on boiler and select mode to winter c/h thermostat at max. Start test c: check control in c/h mode check &/or replace 3 way valve is...

Page 38

Supplied by www.Heating spares.Co tel. 0161 620 6677 36 0 vdc on boiler flow switch check water flow switch ok is there a voltage > 0.5 vdc between terminals m3.11 & m3.10 on pcb is there 0 vdc between terminals m5.3 & m5.4 on pcb is there main between terminals m14.1 & m14.2 on pcb a replace sensin...

Page 39

Supplied by www.Heating spares.Co tel. 0161 620 6677 37 a4 replace control board check dhw ntc sensor or connection fault code showing 03 do the boiler flow switch operate does the flow switch pin operate check and/or replace the diaphragm. Check the correct water dp check the water circuit. Check i...

Page 40

Supplied by www.Heating spares.Co tel. 0161 620 6677 38 replace control board remove jumper is timer jumper on jp9 wait 3 min. Restart the test do burner and fan switch on is water flow temperature >80 ˚c wait water flow temperature replace control board replace control board remove jumper is timer ...

Page 41

Supplied by www.Heating spares.Co tel. 0161 620 6677 39 section 8 wiring diagrams 8.1 external wiring the appliance comes with a factory fitted link to allow basic operation of the boiler via the mode selector switch. If external controls are to be added to the system, they must be connected to the ...

Page 42

Supplied by www.Heating spares.Co tel. 0161 620 6677 40 appliance wired to basic voltage-free time clock fig. 49 basic wiring with link between ta & ta (no controls fitted) appliance wired to programmable room thermostat appliance wired to basic voltage-free time clock and room thermostat red-b lac ...

Page 43

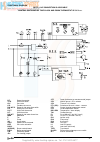

Supplied by www.Heating spares.Co tel. 0161 620 6677 41 functional diagram note: l-n-e connection is advisable control switching of time clock and room thermostat is 230 v.A.C. R.T. Room thermostat ts h heat time switch g.V. Gas valve c.S. Condensate sensor d.H.W.F.S. Domestic hot water flow switch ...

Page 44

Supplied by www.Heating spares.Co tel. 0161 620 6677 42 note: l-n-e connection is advisable control switching of time clock and room thermostat is 230 v.A.C. Wiring diagram syntesi 25 syntesi 35 syntesi 29.

Page 45

Supplied by www.Heating spares.Co tel. 0161 620 6677 43 section 9 exploded diagrams 90 31 16 17 18 20 48 38 26 39 40 12 49 50 43 51 326 226 362 19 1 52 53 400 401 402 pos. Description 25 29 35 1 frame r01005288 r01005289 r01005290 12 quick primer pressure gauge r1857 r1857 r1857 16 2a fuse r8968 r89...

Page 46

Supplied by www.Heating spares.Co tel. 0161 620 6677 44 24 201 26 40 7 201 201 2 292 4 202 285 22 277 31 3 41 292 1 9 37 248 200 10 17 202 16 19 18 353 366 353 366 351 328 351 328 351 328 365 28 27 64 61 35 30 34 62 11 400 401.

Page 47

Supplied by www.Heating spares.Co tel. 0161 620 6677 45 pos. Description 25 29 35 1 domestic water heat exchanger r8036 r8037 r10024627 2 connection r9807 r9807 r9807 3 pressure switch r2044 r2044 r2044 4 non return valve r2908 r2908 r2908 7 by-pass valve r2047 r2047 r1552 9 heating manifold r100204...

Page 48

Supplied by www.Heating spares.Co tel. 0161 620 6677 46 pos. Description 25 29 35 1 expansion vessel r2204 r2204 r2573 2 flexible pipe r2164 r2164 r2164 3 circulation pump r10020437 r10020437 r10020438 4 pump cable r1845 r1845 r1845 5 automatic air vent bottle r0439 r0439 r0439 6 pipe r10023195 r100...

Page 49

Supplied by www.Heating spares.Co tel. 0161 620 6677 47 pos. Description 25 29 35 1 air box bottom r10024449 r10024385 r10024516 2 ambidx air box side r10024166 r10024166 r2059 3 air box clip r0442 r0442 r0442 4 ng burner r10023168 r10022980 r10023834 4 lpg burner r10023169 r10025053 r10024626 5 spa...

Page 50

Supplied by www.Heating spares.Co tel. 0161 620 6677 48 pos. Description 25 29 35 1 combustion chamber assembly r6027 r6028 r10020514 2 combustion chamber back panel r5270 r5316 r10020518 3 combustion chamber lateral panel r5271 r5271 r5271 4 combustion chamber front panel r5269 r5315 r10020517 7 ho...

Page 51

Supplied by www.Heating spares.Co tel. 0161 620 6677 49 section 10 lpg instructions 10.3 converting the appliance gas type to convert the appliance to another gas type it is necessary to change the burner injectors and adjust the gas pressures. It is also necessary to ensure the jumper tag at jp8 is...

Page 52: Energizing Home Heating

Supplied by www.Heating spares.Co tel. 0161 620 6677 cod. 10024509 - 46/03 - ed. 2 vokèra ltd. 4 th floor, catherine house, boundary way, hemel hempstead, herts, hp2 7rp email: enquiries@vokera.Co.Uk web: www.Vokera.Co.Uk sales, technical advice, general enquiries - tel: 0870 333 0520 fax: 01442 281...