- DL manuals

- VOKERA

- Boiler

- Vibe 20 A G.C. N 41-094-84

- User Instructions

VOKERA Vibe 20 A G.C. N 41-094-84 User Instructions

36

Users Instructions

Installation &

Servicing

Instructions

THESE INSTRUCTIONS

TO BE RETAINED

BY USER

Vokèra is a licensed member of the Benchmark scheme

which aims to improve the standards of installation and

commissioning of domestic hot water systems in the UK.

Vibe

High efficiency system boiler

Vibe 20 A G.C. N° 41-094-84

Vibe 25 A G.C. N° 41-094-85

Summary of Vibe 20 A G.C. N 41-094-84

Page 1

36 users instructions installation & servicing instructions these instructions to be retained by user vokèra is a licensed member of the benchmark scheme which aims to improve the standards of installation and commissioning of domestic hot water systems in the uk. Vibe high efficiency system boiler ...

Page 2

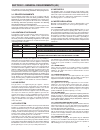

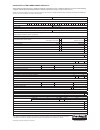

32 users instructions things you should know page 1.1 gas appliances 1 1.2 electrical supply 1 1.3 guarantee registration card 1 1.4 appliance log book (uk only) 1 1.5 how does it work? 1 1.6 dimensions 1 1.7 clearances required 1 1.8 frost protection system 1 1.9 appliance status indicators 1 getti...

Page 3: Users Instructions

1 users instructions 1.1 gas appliances gas safety (installations and use) regulations (uk). In the interests of your safety and that of others it is a legal requirement that all gas appliances are installed and correctly maintained by a competent person and in accordance with the latest regulations...

Page 4

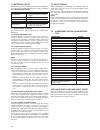

2 fig. 1 boiler status led green led boiler is working/responding to a heating/hot water request red led boiler has identified a fault and has failed-safe. Refer to instructions on how to reset yellow led service operation pressure gauge ensure the system pressure is set correctly (minimum 0.5-bar) ...

Page 5

3 2.1 before switching on before switching the appliance on, please familiarise yourself with: - how to isolate the appliance from the gas, water, and electricity supplies; - how to check and top-up – if necessary – the system water pressure; - the time clock or programmer (if fitted); - any externa...

Page 6

4 4.1 what if i suspect a gas leak if you suspect a gas leak, turn off the gas supply at the gas meter and contact your installer or local gas supplier. If you require further advice please contact your nearest vokèra office. 4.2 what if i have frequently to top-up the system if the system regularly...

Page 7

5 all installers are asked to follow the benchmark scheme by adhering to the code of practise, which can be obtained from www.Centralheating.Co.Uk. The vibe comprises a range of high-efficiency system boilers with outputs of 20kw and 25kw. These appliances – by design – incorporate electronic igniti...

Page 8

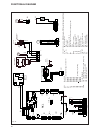

6 1.1 principle components • a fully integrated electronic control board featuring electronic temperature control, anti-cycle control, pump over-run, self- diagnostic fault indicator, full air/gas modulation • aluminium heat exchanger • electronic ignition with flame supervision • integral high-head...

Page 9

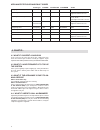

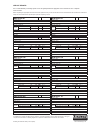

7 section 2 - technical data 2.1 central heating vibe 20a vibe 25a heat input (kw) 20.00 25.00 maximum heat output (kw) 60/80°c 19.50 24.45 minimum heat output (kw) 60/80°c 4.91 5.90 maximum heat output (kw) 30/50°c 20.84 26.23 minimum heat output (kw) 30/50°c 5.36 6.40 minimum working pressure 0.25...

Page 10

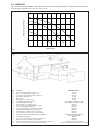

8 key location minimum distance a below an opening (window, air-brick, etc.) 300 mm b above an opening (window, air-brick, etc.) 300 mm c to the side of an opening (window, air-brick, etc.) 300 mm d below gutter, drain-pipe, etc. 25 mm e below eaves 25 mm f below balcony, car-port roof, etc. 25 mm g...

Page 11

9 section 3 - general requirements (uk) this appliance must be installed by a competent person in ac- cordance with the gas safety (installation & use) regulations. 3.1 related documents the installation of this boiler must be in accordance with the relevant requirements of the gas safety (installat...

Page 12

10 this appliance must be installed by a competent person in accordance with and defined by, the standard specification (domestic gas installations) declaration (i.S. 813). 3a.1 related documents the installation of this boiler must be in accordance with the relevant requirements of the local buildi...

Page 13

11 the terminal must be protected by a guard of durable material. The guard must be fitted centrally over the terminal. Refer to i.S. 813, when the terminal is 0.5 metres (or less) below plastic guttering or 1 metre (or less) below painted eaves. 3a.5 air supply the following notes are intended for ...

Page 14

12 fig. 10 4.1 delivery due to the weight of the appliance it may be necessary for two people to lift and attach the appliance to its mounting. The appliance is contained within a heavy-duty cardboard carton. Lay the carton on the floor with the writing the correct way up. 4.2 contents contained wit...

Page 15

13 fig.12 extending the flue connect the bend – supplied with the terminal kit – to the top of the boiler using clamp (supplied) see fig. 10. The additional bends & extensions have push-fit connections, care should be taken to ensure that the correct seal is made when assembling the flue system. Con...

Page 16

14 important the vertical flue terminal is 1.0 metre in length and cannot be cut; therefore it may be necessary to adjust the height of the appliance to suit or use a suitable extension. Connect the vertical flue assembly to the boiler flue spigot us - ing the 100mm clip, gasket & screws (supplied),...

Page 17

15 fig. 18 horizontal termination (fig. 20) the twin flue system must be converted to the dedicated con - centric flue kit for termination. • the horizontal terminal is supplied with a built-in converter box and cannot be shortened. • a 130mm hole is required for the passage of the concentric termin...

Page 18

16 4.6 connecting the gas and water the appliance is supplied with an accessory pack that includes service valves. The service valves are for welding. The accessory pack contains sealing washers’ etc, for use with the service valves. Note it will be necessary to hold the valve with one spanner whils...

Page 19

17 5.1 gas supply installation inspect the entire installation including the gas meter, test for tightness and purge. Refer to bs 6891 (i.S. 813 in roi) for specific instruction. 5.2 the heating system the appliance contains components that may become damaged or rendered inoperable by oils and/or de...

Page 20

18 6.1 general once the appliance has been serviced, the benchmark service record must be completed. For uk only: it is important that the benchmark service record is correctly completed and handed to the user. Failure to install and commission the appliance to the manufacturers instructions will in...

Page 21

19 fig. 26 fig. 27 fig. 28 a b c d e f i j fig. 29 fig. 30 m n fig. 31 o p k l g h g h appliance or removed component. Undertake a complete com - missioning check as detailed in section 5, after replacing any component. Always test for gas tightness if any gas carrying components have been removed o...

Page 22

20 6.14 flue fan & mixer (fig. 34-35) carry out component removal procedure as described in 6.4. Remove the air chamber front cover. Locate and remove the gas pipe locking pin ( a1 ) and swing/rotate the gas pipe away from the fan assembly ( b1 ), (if necessary unscrew the gas pipe from the gas valv...

Page 23

21 fig. 35 a1 b1 g1 m1 n1 o1 p1 j1 fig. 36 q1 s1 r1 fig. 38 fig. 37 w1 v1 u1 6.16 main heat exchanger (fig. 35) carry out component removal procedure as described in 6.4. Remove the air chamber front cover. Locate and remove the gas pipe locking pin ( a1 ) and swing/rotate the gas pipe away from the...

Page 24

22 7.1 checking appliance operation when carrying out any repairs or servicing to the appliance, the relevant commissioning procedure must be undertaken to ensure the continued safe operation of the appliance. Particular attention should be made to ensure gas tightness, water tight- ness and the ele...

Page 25

23 7.3 checking the co 2 and adjusting the gas valve the gas valve must be set-up or adjusted with the aid of a properly calibrated flue gas analyser. Isolate the appliance from the electrical supply and remove the appliance casing as described in 4.7.1. Set the flue gas analyser to read co 2 and in...

Page 26

24 7.9 component values & characteris- tics appliance status led and fault codes when the boiler detects a temporary fault condition, the ap- propriate led indication is shown. If/when the fault is final, the pump will perform a 60-second post circulation and red led will be illuminated. See table o...

Page 27

25 section 8 - wiring diagrams 8.1 external wiring external controls must to be added to the system and they must be connected to the appliance as shown in the following diagrams. For advice on controls that are not featured in this book, please contact vokera technical on 0844 3910999 8.1.1 externa...

Page 28

26 functional diagram cn1-cn15 connec tors - (cn4 unused – cn5 room thermostat (24 vdc ) s.W . Co 2 function button f .S. (1) flame sensor f1 fuse 3.15a t f external fuse 3.15a f m3 t ermina l strip for electrical connection high power p pump ope gas valve solenoids f hv fan power supply 230 v f lv ...

Page 29

27 9.1 related documents bs 5440 parts 1 & 2 flues & ventilation requirements bs 5449 part 1 forced circulation of hot water systems bs 5482 part 1 domestic butane & propane gas burners in permament dwellings bs 5546 installation of gas hot water supplies for domestic purposes bs 6798 installation o...

Page 30

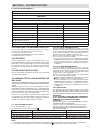

Commissioning: co and combustion ratio check set boiler to maximum rate in accordance with, section 7.3, set boiler to operate at maximum rate (full load condition). Allow sufficient time for combustion to stabilise. , insert analyser probe into air inlet sampling point. Is o2 ≥20.6% and co2 verify ...

Page 31: Www.Centralheating.Co.Uk

29 © heating and hotwater industry council (hhic) www.Centralheating.Co.Uk benchmark commissioning and servicing section it is a requirement that the boiler is installed and commissioned to the manufacturers instructions and the data fields on the commissioning checklist completed in full. To instig...

Page 32

30 *allinstallationsinenglandandwalesmustbenotifiedtolocalauthoritybuildingcontrol(labc)eitherdirectlyorthrougha competentpersonsscheme.Abuildingregulationscompliancecertificatewillthenbeissuedtothecustomer. Www.Centralheating.Co.Uk © heating and hotwater industry council (hhic) this commissioning c...

Page 33

31 *allinstallationsinenglandandwalesmustbenotifiedtolocalauthoritybuildingcontrol(labc)eitherdirectlyorthrougha competentpersonsscheme.Abuildingregulationscompliancecertificatewillthenbeissuedtothecustomer. ©heatingandhotwaterindustrycouncil(hhic) www.Centralheating.Co.Uk it is recommended that you...

Page 34

33 ✎.

Page 35

34.

Page 36

35 cod. 20085448 - 05/14 - ed.0 registered address: vokèra ltd borderlake house unit 7 riverside industrial estate london colney herts al2 1hg enquiries@vokera.Co.Uk www.Vokera.Co.Uk www.Vokera.Ie sales, general enquires t 0844 391 0999 f 0844 391 0998 vokèra ireland west court, callan co kilkenny t...