- DL manuals

- Volare

- Scooter

- Marcopolo

- Owner's Manual

Volare Marcopolo Owner's Manual

Summary of Marcopolo

Page 1

1.

Page 2

2.

Page 3

3 contents contents ............................................................................................... 3 introduction ...................................................................................... 5 warranty term .....................................................................

Page 4

4 daily inspection .................................................................................. 70 important recommendations for driver ...................................... 71 economical driving ......................................................................... 73 instruction for brea...

Page 5

5 introduction congratulations! You have just acquired a top quality product designed and built especially to serve you. This manual has been prepared to provide you with the information and instructions that are necessary for the proper operation and maintence of your vehicle, and also to present t...

Page 6

6.

Page 7

7 warranty term 1. Volare warranty term 1.1. Marcopolo s.A. – volare division provides a warranty for its products that, in normal service or operation, got material, workmanship or assembly defects within the periods and kilometerage specified in this warranty term. 2. Validity period 2.1. The vola...

Page 8

8 3.4. The warranty applies to the necessary repairs or replacement of components with proved material, assembly or workmanship defects. Under no circumstances shall the product be replaced. 3.5. Any event that is not foreseen in this term shall be submitted to the manufacture’s analysis and decisio...

Page 9

9 • if any of the inspections is not performed, it automatically cancels the product warranty. 5. Warranty limitations 5.1. Defected parts or components replaced under warranty become the property of marcopolo s.A. – volare division. 5.2. The warranty attends to possible material, workmanship and as...

Page 10

10 5.9. From this warranty are excluded expenses related to the following items of maintenance: • steering alignment and wheel balancing; • junctions in general, addition of water to the radiator and fan belts; • air filtration elements, lubricant oil and air conditioner; • oils, greases and solutio...

Page 11

11 of 12 (twelve) months or 100 000 (hundred thousand) kilometers. 5.17. Decoloration or alteration of the painting because of an inadequate use or normal or accidental wear of the product are excluded from the warranty. 5.18. Only the volare representatives are authorized to render service under wa...

Page 12

12 7.4. Marcopolo s.A. – volare division recommends consumers of its products that, for obtaining a full warranty, they should consult a volare representatives and the owner’s manual with respect to the correct and adequate operation of this product. 7.5. The figures given in this manual are merely ...

Page 13

13 inspection check lists to preserve the right to the vehicle’s warranty, it is obligatory to perform periodic inspections at the volare representatives in the specified intervals. The check of the maintenance char t execution is made by vir tue of the authentification by the executive representati...

Page 14

14 14.

Page 15

15 15 record of technical delivery delivery date mileage (km) volare representative’s code volare representative’s stamp record of technical delivery - copy to be sent to the manufacturer label: mileage (km): volare model: chassis no.: engine no: owner: address: no.: district: zip code: telephone: c...

Page 16

16.

Page 17

17 17 record of technical delivery delivery date mileage (km) volare representative’s code volare representative’s stamp record of technical delivery - customer copy label: mileage (km): volare model: chassis no.: engine no: owner: address: no.: district: zip code: telephone: city: state: e-mail: de...

Page 18

18.

Page 19

19 19 19 5,000 km overhaul delivery date mileage (km) volare representative’s code volare representative’s stamp 5,000 km overhaul - free-of-charge labour - copy to be sent to the manufacturer label: mileage (km): volare model: chassis no.: engine no: owner: address: no.: district: zip code: telepho...

Page 20

20

Page 21

21 21 21 15,000 km overhaul delivery date mileage (km) volare representative’s code volare representative’s stamp 15,000 km overhaul - free-of-charge labour - copy to be sent to the manufacturer label: mileage (km): volare model: chassis no.: engine no: owner: address: no.: district: zip code: telep...

Page 22

22.

Page 23

23 technical delivery instructions technical delivery instructions the technical delivery is primarily intended for giving to the volare owner the following orientations and for checking the items indicated in the check list. 1 . General basic orientations 1.1 warranty term (warranty term, validity ...

Page 24

24 2.8 traction (differential gear – oil and antifriction replacement); 2.9 brake system (compressor, brake shoe lining and/or pads, air reservoir and dry air filter); 2.10 suspension (springs and stabilizing rods); 2.11 steering system (hydraulic oil reservoir, steering rod and toe-in); 2.12 front ...

Page 25

25 4.11 cooling system – water indicator; 5. Orientations on the execution 5.1 driver’s, second driver’s and passenger seats (adjustments) and safety belts; 5.2 internal and external lighting; 5.3 air inlet and emergency exit; 5.4 heating system and air conditioner; 5.5 rear-view mirrors; 5.6 door(s...

Page 26

26 external facing and filaments: check fixation, shrinkage and singeing. Internal facing and filaments: check fixation, shrinkage and singeing. Seat assembly: check per formance, belts, gaps and cleanness. External mirrors: check fixation and adjustment. Front grille: check alignment and the mechan...

Page 27

27 preventive periodic maintenance chart volare w8 and w9 notes – models volare w8 and w9 the notes given below cover the lubrication and maintenance points that should be exactly fulfilled according to the preventive maintenance chart. 1- the components must be lubricated at every 10 000 km and/or ...

Page 28

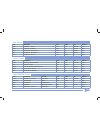

28 preventive maintenance chart - volare w8 and w9 description vol ume lu brica t ion 5.000 km 10.000 km 15.000 km 20.000 km 25.000 km 30.000 km 35.000 km 40.000 km 45.000 km 50.000 km 55.000 km 60.000 km 65.000 km 90.000 km 95.000 km 100.000 km 105.000 km 110.000 km 115.000 km 120.000 km 70.000 km ...

Page 29

29 intake system air filter replace primary element replace when the restriction warning light starts glowing on the panel replace secondary element at every 5th replacement of the primary element or anually (depending on what occurs first) check / inspect air filter, tubes and hoses air cooler air ...

Page 30

30 traction diferential gear check level and fill up change oil 4 litres chart 1 check for leakage rear wheel bearings lubricate with grease re-tighten the wheels nuts re-tighten the cover screws crankcase universal joints lubricate with grease chart 1 gearbox gearbox change oil - fso 4405 5,3 litre...

Page 31

31 suspension re-tighten the fixing brackets of the springs and stabilizing rods check degree of the bushing wear re-tighten the screws and nuts fixing the springs and stabilizing rods steering system steering hydraulic sector and hydraulic oil reservoir check level and fil up 1,7 litres chart 1 re-...

Page 32

32 trust the lubrications and re-tightening service only in a volare represen- tative. The torque of the main screws and nuts are indicated in the re-tightening chart. As the screws, nuts, clamps and connections not indicated in the re-tightening chart, it must be re-tighted each 6 months. Important...

Page 33

33 lubrication chart items to be lubricated lubricant (type) assembling 5.000 km 10.000 km 15.000 km 20.000 km 25.000 km 30.000 km 35.000 km 40.000 km 45.000 km 50.000 km 55.000 km 60.000 km 65.000 km 70.000 km 75.000 km 80.000 km 85.000 km 90.000 km 95.000 km 100.000 km 105.000 km 110.000 km 115.00...

Page 34

34 note: requiring any information about your volare, always mention the chassis number (inform the last six numbers). Chassis beam the chassis number is situated on the right side of the beam, the front-axle direction, behind the air filter. It comprises a number of arabic figures and letters that ...

Page 35

35 v.I.N. Numbers – sequential production number v.I.N. - vehicle identification number 9 3 p x x x x x x x x x x x x x x wmi ds vis manufacturer construction technical information plant/factory/serial number 1. On the structure 1.1. On the column of the hood. To reach it: open the hood and check on...

Page 36

36 engine the engine identification depends on the engine model. The engine identification number is situated on the upper part of the engine. To see it, open the hood as showed in the photo. Gearbox rear axle air conditioner the air conditioner’s serial number is situated on the air condenser or al...

Page 37

37 commands, controls and maintenance volare panel 04 05 02 02 06 automatic gearbox 02 10 07 08 11 09 01 03 12 12 12 13 panel identification 01 panel indicators 08 air conditioner 02 control switches 09 electric switchboard 03 starting switch 10 multifunctional switch 04 parking brake 11 selector sw...

Page 38

38 optical warning indicators 1- turning lights when the turning light is switched on, the green light indicates, in the form of intermittent signal, that this command is activated. The improper operation of this light indicates that the system is in trouble. Stop and find out the cause. 2 - total a...

Page 39

39 if this red light of the brake indicator starts glowing when the vehicle is in motion, park your car in a safe place and find out the reason of the pressure drop. Note: when the starting switch is set in position 3, this warning light starts glowing, but it should stop glowing right after the set...

Page 40

40 “cooling system”. Important: check the hoses and radiator for the leakage and splits regularly. 17 – oil temperature light (automatic gearbox) it indicates that the clutch oil is at abnormal temperature what, in this manner, may cause any abnormality in the system. Stop the vehicle immediately an...

Page 41

41 note: when set the starting switch in position 3, this warning light starts glowing, but it must stop glowing right after returning the switch in position 2 (contact). 21 - air conditioner light this light star ts glowing at the moment when the vehicle air conditioner is activated. 22 – tachomete...

Page 42

42 when its hand is in the red band, light 16 starts glowing, indicating that the vehicle should be fuelled as soon as possible. Note: see item “fuel tank capacity”. To activate the fuel indicator, it is necessary to set the starting switch in position 2. 25 - engine water temperature warning light ...

Page 43

43 panel switches panel switches symbols fog lamp low beam headlamp route sign light defroster (anti-fog) rotating light blower/exhauster alert flickering lamp air conditioner driver stop optical gage heating fridge steps/gangway lightening maintenance light night light (passenger compartment) nest ...

Page 44

44 switches operation position 1 – on position 1, the swithes will be off; position 2 – on position 2, the switches will be partially activated, that is, in this stage the functions will be restricted to one of the phases; position 3 – on position 3, the switches will be fully activated, that is, th...

Page 45

45 starting switch starting switch has three positions: 1- switched off 2- switched-on circuit 3- engine starting systematic use of the engine brake saves the service brake, ensuring its full efficiency in case of emergencies. To activate and disactivate the engine brake, just switch on the interrup...

Page 46

46 air diffusers on the panel the air diffusers are situated on the panel. They are activated by means of the ventilation switch and ensure airflow to the driver´s seat through their flaps. Air conditioner functions set-point increment switch* set-point decrement switch* * set-point: desired tempera...

Page 47

47 air diffusers – volare w8 and w9 equipped with air conditioner in the models volare w8 and w9 there is the defroster with air conditioner for the driver. It is situated on the panel and provides air directing to the driver and his auxiliary. Activation 1- switch on the vehicle air conditioner sys...

Page 48

48 sound system radio and cd player the radio and/or cd player, when required, are installed on the panel. For adequate operation of the radio, check the perfect fixing of the ground cable of the antenna, fixed on the first front ceiling light. Note: see also the electric diagram at the end of the m...

Page 49

49 set the volume of the device in 60% capacity and adjust the sound volume by means of the selector switch. This procedure will prevent from acoustical distortions in the ambient medium. Important: avoid starting the engine with this device switched on. Note: when the microphone is activated, it wi...

Page 50

50 attention: before replacing a fuse, turn off the switch of such a circuit. A burn-out fuse can be visually identified by its internal broken filament. The fuse should be replaced only after you find out why it has burned out (overcharge, shor t circuit, etc). Replace it with an original one of eq...

Page 51

51 moving the switch this movement activates the blinkers, high-beam headlights and headlight twinkling. 1- headlight twinkling 2- high-beam light 3- right blinker 4- left blinker button and the switching arm moving 5- pressing this button, the horn is activated. 6- moving the switching arm in direc...

Page 52

52 the parking brake is located in the left side of the driver, in the dashboard. To activate the parking brake, push the lever up until the end of the course, and for deactivate it, return the lever to the initial position. Commands and controls steering wheel the volare steering system is hydrauli...

Page 53

53 accelerator pedal operating the pedal sends an electric signal to the control module that adjusts dispensing of the fuel sent to the injectors and, therefore, acceleration. Important: • avoid abrupt variation and unnecessary rotation of the engine. • starting the engine, do not activate the accel...

Page 54

54 fire extinguisher read the instructions displayed on the fire extinguisher, as they can vary depending on the manufacturer. The fire extinguisher will function satisfactory if the manometer hand is above or within the green band (operating band). Replace the fire extinguisher or its load every 12...

Page 55

55 seat belts correctly-buckled seat belts keep their occupants in the correct position and significantly reduce the kinetic energy. The passengers wearing their seat belts correctly benefit greatly, as they allow the kinetic energy to be absorbed in an optimized manner. Passenger compartment seats ...

Page 56

56 to remove three-point seat belt press the red button on the buckle to release the tongue through the effect of a spring. Shor ten it with your hands to its initial position so that the automatic retractor may pull in the seat belt more easily. Two-point automatic seat belts the locks in this type...

Page 57

57 individual panel natural air inlet equipped with two natural air inlets for air renewal in the passenger compartment, located on the ceiling, they provide constant air renewal in the interior of the vehicle. Keep the diffusers open and close them only when it is cold. Ceiling air inlet, external ...

Page 58

58 emergency exit emergency mechanism to open it: 1- open the exit at its total-open position; 2- break the safety seal; 3- draw the lever (3) away by forcing the cover upwards. Seal reposition the seal of the assembly contains the information concerning its operation. We recommend that you check th...

Page 59

59 heating system detail of the heating system on the panel heating system valves booster hot air cool air cool air convector hot air radiator air diffusers left side convector right side convector radiator expansion tank engine hot water engine hot water valve valve defroster bus body front importa...

Page 60

60 rear-view mirrors the vehicle is equipped with two external articulated mirrors (on the left and right sides) and one internal rear-view mirror (on the internal lining – near the driver) facing the passenger compartment. Internal rear-view mirrors, front and rear external mirrors note: the image ...

Page 61

61 door emergency valve: 1- pull the valve to release the circuit pressure; 2- push the door with both hands. Important: to return the door in operation, press the valve again, but make sure that the internal operation valve, on the panel, is in the open position. Note: always keep the air reservoir...

Page 62

62 front hatch and maintenance lamp bus body painting painting conservation for cleaning use only neutral soap. Avoid washing in the sun and when the sheeting is hot. Do not use solvents or similar products. Do not put the washing roles directly on the vehicle when it is very dirty. Before it, appli...

Page 63

63 basic colors color identification code pattern line producer white royal white i - 88 fiat 0816 flat salcomix basf green java green - 97 vw 984 5050 flat salcomix basf yellow citrino yellow - 88 ford 7434 1040 flat salcomix basf blue miró blue dc - 95 gm 9440 4174 flat salcomix basf silver andean...

Page 64

64 safety measures on washing the vehicle if the vehicle is washed with agressive agents, such as fuel, oil, etc, avoid contact of these agents with the control module, sensors and the electronic motor actuators. When washing, take a special care to avoid damaging of the painting. Use, therefore, a ...

Page 65

65 polishing of the painting the polishing becomes necessary when the painting is in bad condition. It is difficult to shine it using the washing only. The application of a silicone-based polishing agent, besides providing a satisfactory shine, forms a protecting wax coating on the painting surface....

Page 66

66 polyester tissues washing procedures description cleaning product how to use produtct grease benzene rub until the stain disappears solvent detergent 1/20 wash the residues with a sponge emulsifier ammonia 1/3 apply slightly neutralizer vinegar 1/3 apply slightly odour eliminator oils benzene rub...

Page 67

67 towing hook when the vehicle is down or damaged and you need to tow it, do as follows: 2- never exceed 40 km/h during towing procedure. 3- if possible, keep the engine running during this procedure to ensure the correct lubrication of the gearbox and keep the hydraulic steering running and the br...

Page 68

68 general instruction general safety regulations driving a vehicle is a big responsibility, since any minor lack of attention or lack of maintenance may lead to serious damages that range from a simple incident to more serious accidents, putting at risk the lives of the driver, passengers and pedes...

Page 69

69 conama important precautions (conama – national council for inviroment) 1- levels of fumes emissions the operating characteristics of the vehicle are estimated by testing the oil-fuel specified in the resolution of the conama 10/89 and cnp 01/90 that limits sulphur content and defines other fuel ...

Page 70

70 free acceleration fumes index • restriction of air admission caused by clogged filter or obstr uction in the intake. • exhaust contrapressure caused by obstr uction in the exhaust duct. • irregular electroinjectors opening pressure caused by incorrect adjustment, obstr uction of the injection hol...

Page 71

71 important: check the tightening and state of the electrical connections of the engine sensors. I) check if all the the vehicle’s instruments and controls are functioning well; j) check if all the headlights, taillights, back-up light, blinkers, etc. Are functioning well; k) drain the water of the...

Page 72

72 11- do not start your vehicle motion until the pressure in the brake system reaches 9.0 bar, in the both reservoirs (red hand and white hand of the manometer). 12- accustom youself to observe the panel indicators showing the engine temperature, oil pressue, etc. Frequently. 13- do not hold the st...

Page 73

73 economical driving fuel consumption is connected with a number of factors which make it impossible to establish consuming parameters for a vehicle. In general, fuel consumption depends on a variety of parameters. Vehicle type influence on fuel consumption is related to tyre size, to ratio transmi...

Page 74

74 e) do not overload the vehicle and/or its engine. The maximum load may be imposed on the engine, however, do not let it continue long. Overload may be stated when, pressing the accelerating pedal, the engine does not react with increasing rotations. F) do not hezitate in reducing gears on ascents...

Page 75

75 forcing the engine and transmission, provoke a premature wear of the coupling clutch. 2- do not rest your foot on the clutch pedal. Such procedure causes wear of the bearing the clutch collar. 3- never use the clutch to slowdown the vehicle on ascents. 4- avoid abrupt accelerations, especially wh...

Page 76

76 engine stoppage a) after the vehicle stoppage, reduce the engine rotations using the lower gear; b) let it operating during 1 minute before switching it off. Parking the vehicle a) reduce the vehicle speed; b) look for a safe place permitted for parking; c) declutch the gearbox and immobilize the...

Page 77

77 and lubrications generally should be performed most frequently possible than prescribed in the preventive maintenance chart. • always when oil level check and drainage plugs are removed, is is recommended to use adequated keys in order to avoid damage of the plugs, the same in case of the ring ga...

Page 78

78 precautions concerning the alternator operation • the alternator may function only if it is connected to the voltage regulator and the battery, in order to avoid damages of the current rectifiers and voltage regulator. • battery, connected with inversion of poles, provokes immediate destruction o...

Page 79

79 prevention and cares with electronic components to avoid damages to the electronic components in the electric system, do not disconnect the battery with the operating engine. Never start the engine while the battery is disconnected. When chargin it, turn off the vehicle’s battery. First disconnec...

Page 80

80 engine electromotor mwm management the volare is equipped with an electronic diagnosis system that makes it possible to inform eventual problems in the engine by means of glowing lamps on the panel. If the diagnosis lamp starts glowing, the motor may start loosing capacity (motor autoprotection a...

Page 81

81 orientation chart for vehicles w8 and w9 state of the lamp reaction of the vehicle risk that may be caused by the failure what is to be done in this case gravity level switched off normal - - - switched on reaction: no loss of capacity of the motor risk to the vehicle controlability c o n t i n u...

Page 82

82 engine oil level check procedure: a) remove the gage rod (1) and clean it with a clean cloth; b) insert back the gage rod until the stop piece. Remove it again and check the level. The level should be between the min and max marks on the gage rod; c) if the lubricating oil level is at the minimum...

Page 83

83 important: a- primary element (5) must not be cleaned. Replace it everytime when the warning light on the panel (1) starts glowing. B- do not remove, unless necessary, the filter element because this procedure interfers with the sealing quality and also contribute to the penetration of impurities...

Page 84

84 2- new primary filter element installation procedure: d) first push carefully the open side of the primary element (5) until it settles on the bottom of the frame; e) install the cover (3). Note: the air filter discharge valve should stay downward. Important: push the cover till the end and ensur...

Page 85

85 air filter discharge valve the discharge valve of the air filter is located on the air filter base. To clean the cube, press the discharge valve shaking down the dust and smut accumulated in its inner part. Periodically check if the gap of the discharge valve is not obstructed. Fuel system fuel s...

Page 86

86 change of the fuel filter elements use this procedure to replace the input filter (1) and filter (2). Procedure for the fuel filters change: a) clean the external part of the head of the filter to be replaced; b) remove the base (a) turning it counterclockwise. Note: the filter (2) does not featu...

Page 87

87 stop immediately to avoid its or high-pressure pump damaging. • try to find out the causes or require assistence of a volare representative. • it does not need to drain the filter (2). Change it according to the preventive maintenance chart. Attention: the injection system failures, caused by fue...

Page 88

88 high-pressure pump its function in the system is to provide fuel in the exact quantity under high pressure for the distributing tubes (common rail). The high-pressure pump is a high-pressure component. Its adjustment or eventual repairs should be performed by special personnel. Electroinjectors t...

Page 89

89 cooling system radiator cleaning of the radiator it is very important to keep the water radiator and intercooler (1) grilles always clean. Abstruction damages seriously these components performance, resulting in superheating and loss of engine capacity. Operating in very dusty conditions, perform...

Page 90

90 1 max min and added with anticorrosion agent. This protects from formation of incrustations that, as the time goes on, form a layer around the grille, complicating the warm dissipation and leading to a bad performance of the engine. Cooling liquid level check the cooling liquid is comprised of a ...

Page 91

91 water + additive agent from the cooling system and add the following mixture: 50% of water + 50% of additive agent havoline xlc. Attention: do not remove the cooling system cap when the engine temperature is over 90º c; the system steam may cause severe burn injuries. If it is absolutely necessar...

Page 92

92 fluid level in the clutch reservoir the reservoir with the clutch fluid is located in the panel. To reache it, open the panel upper cover plate, above the steering wheel. Note: when the clutch fluid level is below the normal, the lamp (2) will start glowing on the panel of instruments. Every 5 00...

Page 93

93 • activating a gear, do not exert force in any other direction except for the normal course; • changing gears, release totally the accelerator pedal. Double activation of the clutch pedal or accelerations are unnecessary. These procedures only enhance the fuel consumption and cause premature wear...

Page 94

94 procedures for gear changing in the automatic gearbox press the lever button to set it in any position. Never proceed with changing gears without pressing it. R - to change gears from 1, 2, d, od to the r gear, or vice versa, completely stop the vehicle. Move the pare (stop) lever in position (n)...

Page 95

95 • take care, start the engine only with the gear in selected n position; • do not change gears from n to d or from n to r when the vehicle is moving forward. Perform the change without pressing the accelerator pedal. Engine starting and stoppage. Certainly, you already know the safety meusures an...

Page 96

96 c) switch off all the vehicle’s electric accessories that are not required to be switched on. D) activate the starting switch, setting it in position 3 – starting. Vehicle starting and parking. Starting the vehicle perform the engine starting, 1 minute later (if the engine is cold, according to t...

Page 97

97 safety measures to be taken when the light (1) starts glowing, it indicates operation errors: operate the gearbox as it was described above. When the light (2) starts glowing, you should immediately require the allison assistance. If the light (3) starts glowing – an excessive temperature – stop ...

Page 98

98 filter and oil change oil and filter change should be carried out at the volare representative or at the allison. After the first 8 000 km and before every 160 000 km or 48 months, depending on what occurs first. In severe conditions, change them every 80 000 km or 24 months, depending on what oc...

Page 99

99 b) after every oil change and before putting the vehicle into normal operation, drive without load and at a limited speed of 40 km/h, from 5 to 10 minutes, or 2 to 3 km to ensure that all the ports are properly filled with lubricating oil. Pneumatic suspension inspect visually the serface of the ...

Page 100

100 note: do not perform modifications on the ends of the valve rods of the pneumatic suspension leve. When necessary, contact a volare representative. Hydraulic steering system the steering sytem comprises one steering sector with incorporated cylinder, one oil pump and one reservoir. The reservoir...

Page 101

101 meusure d 2 1 meusure t t - d = 1 a 2 mm c) release the fixing nuts of the wheel and lift it by means of the jack until it is free under the ground; d) remove the nuts and the wheel carefully, preventing the screw thread from damage; e) take the spare wheel. F) every time when a wheel is removed...

Page 102

102 edges and oxidation. Lubricate the screws thread with a thin layer of grease. Install the wheel and tighten the nuts hard. In double wheels, make sure that the tyre valves are in diametrically opposite positions. Firstly, mount the wheels with four equidistant nuts. Important recommendation conc...

Page 103

103 deformations or other damages. Check the pressure only with cold tyres, because in hot tyres, the pressure increases naturally. Changing tyres for longer tyres durabiity, it is necessary to perform the change every 5 000 km. See some types of tyres changing. All the crankcase cross-arms on the r...

Page 104

104 important: • manouvering the vehicle, avoid making it stopped; • perform balancing with warm tyres; spare wheel the position of the spare wheel varies in accordance with a volare model. Models volare w8 and w9 on the right side of the vehicle, near the side hatch. To remove the spare wheel, turn...

Page 105

105 factor, continuous use of the brake that operates under attrition and high temperatures, may wear out some of its components. To keep the system correctly adjusted and conserved is fundamental to ensure secure braking in emergency situations. Besides inspections within the planned periods, it is...

Page 106

106 service brake when auxiliary compressed air connections are needed (inflator, brake engine, horn, cleaning gun and others), connect only to the joint number 24 on the four-way valve. Otherwise, the vehicle may be immobilized because of lack of advertence. Periodically or always, when the vehicle...

Page 107

107 c) disactivate the parking brake; d) inspect the brake lining throuth the inspection openings situated on the brake support plates; e) turn the adjusting pin until the shoe lining blocks the drum; f) turn the adjusting pin in the opposite direction until two or three clicks (1/6 to ¼ turn of the...

Page 108

108 brake diagram 1- pedal valve 2- dual manometer 3- parking brake valve 4- interrupter 5- 4-way valve 6- dry air reservoir 7- rear chamber - spring brake 8- front chamber 9- front chamber 10- air compressor 11- pressure regulator 12- drain valve 13- humid air reservoir 14- 2-way valve 15- rapid di...

Page 109

109 specifications 1- general dimensions model volare a6 a8 comm.Urb. Esc./ exec. Vip school w8 and w9 commuter urban w8 and w9 exec. Vip w8 and w9 vehicle’s total length and distance between axles 6.535 / 5.750 (ee *3.350) 6.535 / 6.700 / 7.385 (ee 3.350 / 3.750) model w8: 8.085 and 8.235 (ee 4.200...

Page 110

110 3 – electric system model volare w8 and w9 system 24 v baterry - voltage 24 v battery - corrent 02 x 70 ah 4- engine model volare w8 and w9 model acteon 4.12 tce brand mwm number of cylinders 4 in line capacity 4.800 cm³ compression ratio 16,8 :1 rated load capacity – according to nbr iso 1585 1...

Page 111

111 6- cooling system modelvolare w8 and w9 water radiator heat dissipation area 3.127 cm² compensating reservoir type pressurized capacity 4 litres cooling liquid water 90% additive agent 10% havoline xli green total capacity of the system 20 litres 5- feed system model volare w8 and w9 fuel tank c...

Page 112

112 8 b - automatic gearbox - automatic transmition model volare w8 and w9 brand allison model lct 2100 terminal ( yoke) series 1480 8 a - manual transmission - gearbox model volare w8 and w9 brand eaton model fso 4405 c gear number 05 forward and 01 reverse reduction ratio first gear 5,762:1 second...

Page 113

113 9 - crankcase model volare w8 and w9 universal joints type crosspieces series 1480 10- traction axle model volare w8 and w9 brand model meritor ms 13113 8 b - automatic gearbox - automatic transmission, continued reduction ratio first gear 3,10:1 second gear 1,81:1 third gear 1,41:1 fourth gear ...

Page 114

114 11- front axle model volare w8 and w9 reinforced prolonged model meritor mfs 07 trademark/model vigia i 12- front suspension model volare w8 and w9 type interconnected parabolic spring and telescopic shock absorber amortecedores double-action spring width 70 mm assembly height right 78 mm left 8...

Page 115

115 13- rear suspension model volare w8 and w9 type interconnected simi-eliptic spring and telescopic shock absorber shock absorbers double-action springs number of plates/width first stage 80 mm second stage assembly height right 118 mm left 118 mm 14- wheels model volare w8 and w9 model 6.00 x 17,...

Page 116

116 17- steering system modelo volare w8 and w9 model zf servocom 8090 number of turns 5 oil atf tipo a capacity 1,7 litres 18- service brake model volare w8 and w9 type drum / “s cam” pneumatic 19- parking brake model volare w8 and w9 type brake spring 24” mode of funcitoning modulator valve actuat...

Page 117

117 20 – engine brake description mode of functioning electropneumatic actuation exhaust pipe 20 a - instruments (when bus is equipped with a manual gearbox) model volare w8 and w9 tachograph reference vdo mtco 1390 type electronic register capacity weekly – opt. Daily speed warning 80 km/h 20 b - i...

Page 118

118 lubrication chart - chart 1 description lubricant (type) nomenclature engine oil sae 15w 40 api ch-4/ci-4 traction axle oil sae 85w 140 api gl5 ep hydraulic steering system oil atf tipo a gearbox fso 4405 c oil sae 80/90 api gl 3/4 automatic gearbox - series 2100 oil castrol transynd fluid for h...

Page 119

119 lubricant chart - chart 2 lubricant (type) nomenclature oil sae 90w 140 api gl5 ep grease calcium or lithium-based greas powder graphite for systems requiring dry lubrication recomended brands: texaco: morfack mp2 (lithium-based) ipiranga: isa-fax (calcium based) ipiranga: isa-cassi 2 (calcium b...

Page 120

120 audio and video electric diagram basic captions connector central electric mother card ground structure ground ( ) ) antenna relay r3 12v inverter selector module selector module relay r3 antenna converter 12/24v relay r3 12v inverter rela y r3 relay r3 selector module selector module.

Page 121

121 audio and video electric diagram antenna converter 12/24v rela y r1 rela y fuse f3 amplifier selector module drivers radio antenna antenna selecting p anel ba t t ery positive pole front right side rear right side front lef t side rear lef t side front right side rear right side front lef t side...

Page 122

122 pneumatic command of the door door emergency activation valve air output adjustment in the piston sedan door activation piston door activation valve button (left side of the panel) door activation external valve.

Page 123

123 reservoir panel open and close valve front grille open and close valve emission valve door piston 1 1 2 2 3 2 air tubes color item color function 1 blue open 2 green close 3 red pressure.

Page 124

124 description owner’s manual code: 10055903 preparation volare technical assistance edition september/2008 group:02 publishing translation viacheslav yakovlev.