- DL manuals

- Volkswagen

- Engine

- 1.9 tdi

- Owner's Manual

Volkswagen 1.9 tdi Owner's Manual

Summary of 1.9 tdi

Page 1

1.9-liter tdi engine with pump injection (pumpe düse) design and function self-study program course number 841303.

Page 2

Volkswagen of america, inc. Service training printed in u.S.A. Printed 10/2003 course number 841303 ©2003 volkswagen of america, inc. All rights reserved. All information contained in this manual is based on the latest information available at the time of printing and is subject to the copyright and...

Page 3: Table of Contents

I table of contents the self-study program provides you with information regarding designs and functions. The self-study program is not a repair manual. For maintenance and repair work, always refer to the current technical literature. Important/note! New! Introduction .................................

Page 5: Introduction

Introduction 1 1.9-liter tdi engine with pump injection system the demands on the modern diesel engine for increased performance and fuel economy, and reduced exhaust emissions and noise levels are growing constantly. Good fuel and air mixture preparation is a key factor in meeting these requirement...

Page 6: Engine – Mechanics

Engine – mechanics 2 development of the 1.9-liter tdi engine with pump injection system the new 100 bhp (74 kw) 1.9-liter tdi engine with pump injection system was developed from the existing 109 bhp (81 kw) 1.9-liter tdi engine with a distributor injection pump and no intermediate shaft. The pump i...

Page 7: Engine – Mechanics

Speed (rpm) 3 engine – mechanics technical data – 1.9-liter tdi engine with pump injection system • engine code bew • type four-cylinder in-line engine with two valves per cylinder • displacement 115.7 cu in (1,896 cm 3 ) • bore 3.13 in (79.5 mm) • stroke 3.76 in (95.5 mm) • compression ratio 19.0 :...

Page 8: Engine – Mechanics

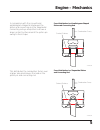

4 engine – mechanics trapezoidal piston and connecting rod to accommodate the higher combustion pressures in the 1.9-liter tdi engine with pump injection system than are encountered in the base engine, the piston hub and the connecting rod eye are trapezoidal in shape. Ssp209/007.

Page 9: Engine – Mechanics

5 engine – mechanics this distributes the combustion forces over a larger area and relieves the load on the piston pin and connecting rod. In comparison with the conventional parallelogram-shaped link between the piston and connecting rod, the trapezoidal connecting rod eye and piston hub have a lar...

Page 10: Engine – Mechanics

Toothed belt drive high pump forces are required to generate high injection pressures of up to 27,846 psi (192,000 kpa / 1,920 bar). These forces subject the components of the toothed belt drive to high loads. To relieve the load on the toothed belt, several modifications have been made. • a vibrati...

Page 11: Engine – Mechanics

Function during the injection cycle, the high pumping forces exert a heavy load on the toothed belt. The camshaft timing belt gear is slowed down by the pumping forces. At the same time, the combustion process speeds up the crankshaft timing belt gear. The toothed belt is stretched and the pitch is ...

Page 12: Fuel Supply

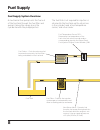

8 fuel supply fuel supply system overview a mechanical fuel pump sucks the fuel out of the fuel tank through the fuel filter and pumps it along the supply line in the cylinder head to the pump/injectors. Fuel cooler – cools the returning fuel to prevent excessively hot fuel from being routed back to...

Page 13: Fuel Supply

9 fuel supply ssp209/018 fuel return line pressure limiting valve – keeps the pressure in the fuel return line at 14.5 psi (100 kpa / 1 bar). This maintains a force equilibrium at the pump/ injector solenoid valve needle. Strainer – collects vapor bubbles in the fuel supply line. These vapor bubbles...

Page 14: Fuel Supply

There is a fitting on the fuel pump for connecting pressure gauge vas 5187 to check the fuel pressure in the supply line. Please refer to the repair manual for instructions. Fuel supply 10 fuel pump the fuel pump is located directly behind the vacuum pump at the cylinder head. It moves the fuel from...

Page 15: Fuel Supply

11 fuel supply the fuel pump is a blocking vane-cell pump. The blocking vanes are pressed against the pump rotor by spring pressure. This design enables the fuel pump to deliver fuel even at low engine speeds. The fuel ducting system within the pump is designed so that the rotor always remains wette...

Page 16: Fuel Supply

12 function the fuel pump operates by taking fuel in as the pump chamber volume increases and pushing the fuel out under pressure as the chamber volume is reduced. The fuel is drawn into two chambers and pumped out from two chambers. The intake and delivery chambers are separated from one another by...

Page 17: Fuel Supply

13 fuel supply distributor pipe a distributor pipe is integrated in the fuel supply line in the cylinder head. It distributes the fuel evenly to the pump/injectors at a uniform temperature. In the supply line, the fuel moves through the center of the distributor pipe toward cylinder 1 at the far end...

Page 18: Fuel Supply

14 fuel supply fuel cooling circuit the heated fuel returning from the pump/ injectors flows through the fuel cooler and its heat transfers to the coolant in the fuel cooling circuit that also flows through the fuel cooler. The auxiliary water cooler reduces the temperature of the coolant in the fue...

Page 19: Pump Injection System

15 pump injection system pump/injectors a pump/injector is, as the name implies, a pressure-generating pump combined with a solenoid valve control unit (valves for pump/ injectors, cylinders 1 through 4, n240, n241, n242, and n243) and an injector. Each cylinder of the engine has its own pump/inject...

Page 20: Pump Injection System

16 pump injection system the pump/injectors are installed directly in the cylinder head. Ssp209/086 ssp209/087 they are attached to the cylinder head by individual clamping blocks. It is important to ensure that the pump/injectors are positioned correctly when they are installed. Refer to the repair...

Page 21: Pump Injection System

17 pump injection system design ssp209/023 roller-type rocker arm o-ring o-ring o-ring heat- insulating seal cylinder head injector needle injector needle damping element injector spring fuel supply line retraction piston fuel return line high-pressure chamber pump/injector solenoid valve solenoid v...

Page 22: Pump Injection System

18 pump injection system drive mechanism the camshaft has four additional cams for driving the pump/injectors. They activate the pump/injector pump pistons with roller-type rocker arms. Valve cam ssp209/015 injection cam (hidden by rocker arm roller) roller-type rocker arm.

Page 23: Pump Injection System

19 pump injection system the gradual slope of the cam trailing edge allows the pump piston to move up relatively slowly and evenly. Fuel flows into the pump/injector high-pressure chamber free of air bubbles. The injection cam has a steep leading edge and a gradual slope to the trailing edge. As a r...

Page 24: Pump Injection System

20 pump injection system mixture formation and combustion requirements good mixture formation is a vital factor to ensure efficient combustion. Accordingly, fuel must be injected in the correct quantity at the right time and at high pressure. Even minimal deviations can lead to higher levels of poll...

Page 25: Pump Injection System

21 pump injection system injection cycle high-pressure chamber fills during the filling phase, the pump piston moves upward under the force of the piston spring and thus increases the volume of the high-pressure chamber. The pump/injector solenoid valve is not activated. The solenoid valve needle is...

Page 26: Pump Injection System

22 pump injection system pre-injection phase starts the injection cam pushes the pump piston down via the roller-type rocker arm. This displaces some of the fuel from the high-pressure chamber back into the fuel supply line. The diesel direct fuel injection engine control module j248 initiates the i...

Page 27: Pump Injection System

23 pump injection system injector needle damping during the pre-injection phase, the stroke of the injector needle is dampened by a hydraulic cushion. As a result, it is possible to meter the injection quantity exactly. As soon as the damping piston plunges into the bore in the injector housing, the...

Page 28: Pump Injection System

24 pump injection system pre-injection phase ends the pre-injection phase ends immediately after the injector needle opens. The rising pressure causes the retraction piston to move downward, thus increasing the volume of the high-pressure chamber. The pressure drops momentarily as a result, and the ...

Page 29: Pump Injection System

25 pump injection system main injection phase starts the pressure in the high-pressure chamber rises again shortly after the injector needle closes. The pump/injector solenoid valve remains closed and the pump piston moves downward. At approximately 4,351 psi (30,000 kpa / 300 bar), the fuel pressur...

Page 30: Pump Injection System

26 pump injection system main injection phase ends the injection cycle ends when the diesel direct fuel injection engine control module j248 stops activating the pump/injector solenoid valve. The solenoid valve spring opens the solenoid valve needle, and the fuel displaced by the pump piston can ent...

Page 31: Pump Injection System

27 pump/injector fuel return the fuel return line in the pump/injector has the following functions: • cool the pump/injector by flushing fuel from the fuel supply line through the pump/injector ducts into the fuel return line. • discharge leaking fuel at the pump piston. • separate vapor bubbles fro...

Page 32: Engine Management

Engine management 28 1.9-liter tdi engine edc 16 system overview sensors diesel direct fuel injection engine control module j248 16-pin connector (diagnosis connection) t16 abs control module with edl/asr/esp j104 drivetrain can data bus barometric pressure sensor f96 additional signals • road speed...

Page 33: Engine Management

Engine management 29 ssp209/053 actuators additional signals • coolant auxiliary heater • engine speed • cooling fan run-on • air conditioner compressor cut-off • fuel consumption signal relay for pump, fuel cooling j445 pump for fuel cooler v166 change-over valve for intake manifold flap n239 waste...

Page 34: Engine Management

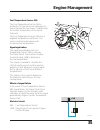

30 sensors camshaft position sensor g40 the camshaft position sensor g40 is a hall-effect sensor. It is attached to the toothed-belt guard below the camshaft gear. It scans seven teeth on the camshaft sensor wheel attached to the camshaft gear. Signal application the diesel direct fuel injection eng...

Page 35: Engine Management

Engine management 31 cylinder recognition when starting the engine when starting the engine, the diesel direct fuel injection engine control module j248 must determine which cylinder is in the compression stroke in order to activate the correct pump/injector valve. To achieve this, it evaluates the ...

Page 36: Engine Management

Engine management 32 function each time a tooth passes the camshaft position sensor g40, a hall-effect voltage is induced and transmitted to the diesel direct fuel injection engine control module j248. Because the teeth are spaced at different distances apart, the induced voltage occurs at different...

Page 37: Engine Management

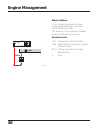

33 engine management engine speed sensor g28 the engine speed sensor g28 is an inductive sensor. It is attached to the cylinder block. Ssp209/056 j248 ssp209/085 engine speed sensor wheel the engine speed sensor g28 scans a 60-2-2 sensor wheel attached to the crankshaft. This means that the sensor w...

Page 38: Engine Management

34 engine management quick-start function to allow the engine to be started quickly, the diesel direct fuel injection engine control module j248 evaluates the signals generated by the camshaft position sensor g40 and the engine speed sensor g28. The diesel direct fuel injection engine control module...

Page 39: Engine Management

35 engine management fuel temperature sensor g81 the fuel temperature sensor g81 is located in the fuel return line between the fuel pump and the fuel cooler. It determines the current temperature of the fuel at that point. The fuel temperature sensor g81 has a negative temperature coefficient. The ...

Page 40: Engine Management

36 mass air flow sensor g70 the mass air flow sensor g70 with reverse flow recognition is located in the intake pipe. It determines the intake air mass. The opening and closing actions of the valve produce reverse flows in the induced air mass in the intake pipe. The mass air flow sensor g70 recogni...

Page 41: Engine Management

37 engine management ssp209/60 engine coolant temperature sensor g62 the engine coolant temperature sensor g62 is located at the coolant connection on the cylinder head. It sends information about the current coolant temperature to the diesel direct fuel injection engine control module j248. Signal ...

Page 42: Engine Management

38 accelerator pedal sensors the accelerator pedal sensors are integrated into a single housing and connected to the pedal by mechanical linkage. • throttle position sensor g79 • kick down switch f8 • closed throttle position switch f60 signal application the diesel direct fuel injection engine cont...

Page 43: Engine Management

39 engine management ssp209/045 intake manifold sensors the intake manifold sensors are integrated into a single module and installed in the intake pipe. • manifold absolute pressure sensor g71 • intake air temperature sensor g72 manifold absolute pressure sensor g71 signal application the manifold ...

Page 44: Engine Management

40 engine management barometric pressure sensor f96 the barometric pressure sensor f96 is located inside the diesel direct fuel injection engine control module j248. Signal application the barometric pressure sensor f96 sends the current ambient air pressure to the diesel direct fuel injection engin...

Page 45: Engine Management

41 engine management brake pedal sensors the brake pedal sensors are integrated into a single module that is mounted on the brake pedal bracket. • brake light switch f • brake pedal switch f47 signal application both switches supply the diesel direct fuel injection engine control module j248 with th...

Page 46: Engine Management

42 engine management cruise control switch the signal generated by the cruise control switch tells the diesel direct fuel injection engine control module j248 that the cruise control system has been activated. Three-phase ac generator terminal df the signal supplied by generator terminal df indicate...

Page 47: Engine Management

43 engine management actuators pump/injector solenoid valves the 1.9-liter tdi engine with the new pump injection system uses four pump/injector solenoid valves: • valve for pump/injector, cylinder 1 n240 • valve for pump/injector, cylinder 2 n241 • valve for pump/injector, cylinder 3 n242 • valve f...

Page 48: Engine Management

44 effects of failure if a pump/injector solenoid valve fails, the engine will not run smoothly and performance will be reduced. The pump/injector solenoid valve has a dual safety function. If the valve stays open, pressure cannot build up in the pump/injector. If the valve stays closed, the high-pr...

Page 49: Engine Management

45 engine management pump/injector solenoid valve monitoring the diesel direct fuel injection engine control module j248 monitors the electrical current that actuates the solenoid valves at the pump/injectors. This provides feedback to the diesel direct fuel injection engine control module j248 of t...

Page 50: Engine Management

46 engine management the actual moment at which the pump/ injector solenoid valve closes (bip) is used by the diesel direct fuel injection engine control module j248 to calculate the point of actuation for the next injection period. If the actual bip deviates from the mapped details stored in the di...

Page 51: Engine Management

47 engine management change-over valve for intake manifold flap n239 the change-over valve for intake manifold flap n239 is located in the engine compartment, in the vicinity of the mass air flow sensor g70. It switches the vacuum for actuating the intake manifold flap in the intake pipe. This stops...

Page 52: Engine Management

48 engine management effects of failure if the change-over valve for intake manifold flap n239 fails, the intake manifold flap stays open. The tendency of the engine to shudder when switched off will increase. Electrical circuit j217 transmission control module j248 diesel direct fuel injection engi...

Page 53: Engine Management

49 engine management relay for pump, fuel cooling j445 the relay for pump, fuel cooling j445 is located on the engine control module mounting bracket. It is activated by the diesel direct fuel injection engine control module j248 at a fuel temperature of 158 °f (70°c) and switches the working curren...

Page 54: Engine Management

50 engine management wastegate bypass regulator valve n75 the engine has a variable turbine geometry for optimally adapting the charge pressure to the actual driving conditions. To regulate the charge pressure, the vacuum in the vacuum unit for turbocharger vane adjustment is set depending on the pu...

Page 55: Engine Management

51 engine management ssp209/075 egr vacuum regulator solenoid valve n18 the egr vacuum regulator solenoid valve n18 enables the exhaust gas recirculation system to mix a portion of the exhaust gases with the fresh air supplied to the engine. This lowers the combustion temperature and reduces the for...

Page 56: Engine Management

52 additional output signals engine management engine speed this signal provides information on engine speed for the tachometer in the instrument cluster. Cooling fan run-on the run-on period of the cooling fan is controlled according to a characteristic curve stored in the diesel direct fuel inject...

Page 57: Glow Plug System

53 glow plug system glow plug system the glow plug system makes it easier to start the engine at low outside temperatures. It is activated by the diesel direct fuel injection engine control module j248 at coolant temperatures below 48 °f (9°c). The glow plug relay j52 is activated by the diesel dire...

Page 58: Functional Diagram

54 functional diagram edc 16 functional diagram for 1.9-liter tdi engine components e45 cruise control switch f brake light switch f8 kick down switch f36 clutch vacuum vent valve switch f47 brake pedal switch f60 closed throttle position switch g28 engine speed sensor g40 camshaft position sensor g...

Page 59

55 functional diagram ssp209/080 30 15 31 31 3 1 b d g j 317 s s s s n239 n75 n18 q7 q7 j360 a/+ g70 f60/f8 g79 g28 g81 f f47 e45 g62 f36 j52 a/+ q6 g72 c s g71 s s s n240 n241 n242 n243 s g40 e f v166 j445 j359 a in out j248 h k l m n o m.

Page 60: Service

56 service self-diagnosis the following functions can be read out using the vehicle diagnosis, test and information system vas 5051: 01 interrogate control unit version 02 interrogate fault memory 03 actuator diagnosis 04 basic adjustment 05 erase fault memory 06 end of output 07 encode control unit...

Page 61: Service

57 service pump/injector adjustment after installing a pump/injector, the minimum clearance between the base of the high-pressure chamber and the pump piston must be adjusted at the pump/ injector adjusting screw. This adjustment prevents the pump piston from knocking against the base of the high- p...

Page 62: Service

58 service special tools marking plate t 10008 holds the hydraulic toothed belt tensioner in place when installing and removing the toothed belt. Crankshaft sealing ring assembly fixture t 10053 guide sleeve and compression sleeve for installing the crankshaft sealing ring. Camshaft gear puller t 10...

Page 63: Service

59 service socket insert t 10054 pump/injector clamping block fastener installation. Pressure gauge vas 5187 fuel pressure measurement at the supply line to the fuel pump. Shackle t 10059 this shackle is used to remove and install the engine in the passat. The engine is moved into position using thi...

Page 64: Notes

60 notes.

Page 65: Knowledge Assessment

61 knowledge assessment an on-line knowledge assessment (exam) is available for this self-study program. The knowledge assessment may or may not be required for certification. You can find this knowledge assessment at: www.Vwwebsource.Com from the vwwebsource.Com homepage, do the following: – click ...

Page 67

Volkswagen of america, inc. 3800 hamlin road auburn hills, mi 48326 printed in u.S.A. October 2003.