- DL manuals

- Volkswagen

- Automobile

- 1995 Passat Gasoline

- Repair Manual

Volkswagen 1995 Passat Gasoline Repair Manual

Summary of 1995 Passat Gasoline

Page 3

Suspension, wheels, brakes, steering 00 - general, technical data suspension, wheels, brakes, steering technical data steering brakes wheels, tires 40 - front suspension front wheel suspension, shafts and axle front suspension, servicing (base suspension) sub-frame, stabilizer bar and control arm (b...

Page 4

Rear axle, servicing (four wheel drive vehicles) rear drive shafts, servicing reworking cap nut in side member (four wheel drive vehicles) suspension strut, disassembling and assembling (four wheel drive vehicles) wheel bearings, servicing - disc brakes (four wheel drive vehicles) 44 - wheels, tires...

Page 5

Front brakes, servicing (teves/ate) brake pads, removing and installing rear wheel brakes, servicing (drum brakes) brake shoe adjustment, releasing rear wheel brakes, servicing brake shoes, removing and installing parking brake, adjusting (drum brakes) rear wheel brakes, servicing (disc brakes) girl...

Page 6

48 - steering steering assembly overview: steering column, column tube, steering wheel and airbag steering wheel airbag unit, removing and installing airbag steering wheel, removing and installing airbag spiral spring, removing and installing column tube for height adjustable steering wheel, removin...

Page 7

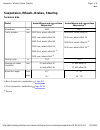

00-1 suspension, wheels, brakes, steering technical data model sedan/wagon and syncro base suspension 1) sedan/wagon and syncro base suspension 2) wheelbase mm 2625 2625 track, unladen mm 1479 front, wheel offset 38 1422 rear, wheel offset 38 1485 front, wheel offset 35 1428 rear, wheel offset 35 14...

Page 8

00-2 steering model sedan/wagon and syncro suspension version base suspension plus suspension steering gear power assisted steering gear power assisted steering gear steering wheel turns from lock to lock 3.33 3.14 overall steering ratio 17.5:1 16.4:1 wheel alignment specifications page 44-2 page 2 ...

Page 9

00-3 brakes model sedan/wagon output kw (hp) 55 (75) brake master cylinder mm dia. 22.2 (vehicles with abs: 23.81) brake servo dia. In inches 10 front brake caliper, piston diameter mm 54 front brake disc mm dia. 256 front brake disc, thickness mm 13 pad thickness mm 14 rear brake drum mm dia. 230 w...

Page 10

00-4 model sedan/wagon output kw (hp) 85 (115) 128 (172) brake master cylinder mm dia. 23.81 brake servo dia. In inches 10 front brake caliper dia. Mm 54 front brake disc mm dia. 256 288 front brake thickness mm 20 13 pad thickness mm 11 14 rear brake caliper dia. Mm 38 rear brake disc mm dia. 226 r...

Page 11

00-5 model passat syncro output kw (hp) 85 (115) 128 (172) brake master cylinder mm dia. 23.81 brake servo dia. In inches 10 front brake caliper dia. Mm 54 front brake disc mm dia. 256 288 front brake disc thickness mm 20 25 pad thickness mm 11 14 rear brake caliper dia. Mm 38 rear brake disc mm dia...

Page 12

00-6 wheels, tires engine output (kw) model tire size 1) wheel offset hole pattern 55 gas 55, 66 - diesel sedan/wagon 185/65 r 14 86 s 195/60 r 14 86 s 205/50 r 15 86 s 185/65 r 14 85 q (m+s) 195/60 r 14 85 q (m+s) 205/50 r 15 85 q (m+s) 6 j x 14 6 j x 14 6 j x 15 6 j x 14 6 j x 14 6 j x 15 38 38 38...

Page 13

00-7 engine output (kw) model tire size 1) wheel offset hole pattern 85 kw sedan/wagon 185/65 r 14 86 h 195/60 r 14 86 h 205/50 r 15 86 h 185/65 r 14 85 q (m+s) 195/60 r 14 85 q (m+s) 205/50 r 15 85 q (m+s) 6 j x 14 6 j x 14 6 j x 15 6 j x 14 6 j x 14 6 j x 15 38 38 35 38 38 35 4-hole 85 kw sedan/wa...

Page 14

00-8 engine output (kw) model tire size 1) wheel offset hole pattern 85 kw sedan/wagon syncro 185/65 r 14 86 h 195/60 r 14 86 h 205/50 r 15 86 h 185/65 r 14 86 q (m+s) 195/60 r 14 86 q (m+s) 205/50 r 15 86 q (m+s) 6 j x 14 6 j x 14 6 j x 15 6 j x 14 6 j x 14 6 j x 15 38 38 35 38 38 35 4-hole 85 kw s...

Page 15: Front Wheel

40-1 front wheel suspension, shafts and axle front suspension, servicing (base suspension) i - removing and installing subframe, stabilizer bar and control arm (base suspension) page 40-2 ii - removing and installing wheel bearings, suspension strut and drive shaft (base suspension) page 40-14 the b...

Page 16

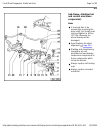

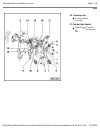

40-2 sub-frame, stabilizer bar and control arm (base suspension) note: if a vehicle has to be moved after removing the drive shaft, first install outer joint and tighten to 50 nm (37 ft lb) otherwise the wheel bearing will be damaged. Specifications for wheel alignment page 44-2 . Welding and straig...

Page 17

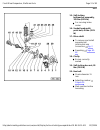

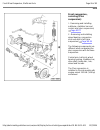

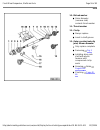

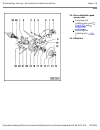

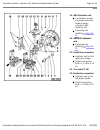

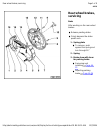

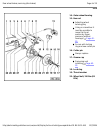

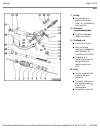

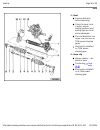

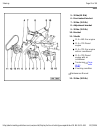

40-3 1 - hex bolt, 35 nm (26 ft lb) 2 - ball joint checking page 40- 10 check rubber boot for damage and if necessary, replace ball joint mark installation position. If replaced set to center of elongated hole and check toe elongated holes are not for camber adjustment. Failure to observe this instr...

Page 18

40-4 6 - control arm rear mounting installation position fig. 3 pressing out and in fig. 4 7 - hex bolt m 12 x 1.5 x 82 50 nm (37 ft lb) and turn 90 further 8 - hex bolt m 12 x 1.5 x 65 70 nm (52 ft lb) and turn 90 further 9 - hex bolt m 12 x 1.5 x 78 70 nm (52 ft lb) and turn 90 further 10 - contro...

Page 19

40-5 repair manual, engine mechanical, repair group 10 12 - connecting link mounting conical side toward control arm 13 - washer collar faces away from mounting 14 - self-locking hex nut, 25 nm (18 ft lb) 15 - sub-frame removing and installing with assemblies installed: supporting assemblies fig. 5 ...

Page 20

40-6 16 - hex bolt, 65 nm (48 ft lb) 17 - stabilizer bar mounting 18 - stabilizer bar 19 - stabilizer bar clamp 20 - hex bolt, 25 nm (18 ft lb) to secure stabilizer bar 21 - vibration damper note installation position, large part must protrude from sub-frame 22 - self-locking hex nut, 25 nm (18 ft l...

Page 21

40-7 fig. 1 front control arm mounting, pressing out note: before pressing in, coat with acid-free lubricant, e.G. Soft soap. Fig. 2 front control arm mounting, pressing in page 7 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=got...

Page 22

40-8 one of the embossed arrows points toward the recess in the control arm and the kidney shaped opening (arrow a) faces towards center of vehicle. Fig. 3 control arm rear mounting, installation position note: if bonded rubber bushing is tight because of corrosion, cut rubber out, saw through steel...

Page 23

40-9 fig. 5 supporting engine/transmission assembly with 10-222 a and legs 10-222 a/1 page 9 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.40.1.

Page 24

40-10 ball joint, checking (base and plus suspension) checking axial clearance checking radial play - forcibly pull ball joint down and press up again. Note: - press lower part of wheel outward and inward. There must be no perceptible or visual "play" during either test. Observe ball joint during ch...

Page 25

40-11 reworking cap nut in side member (base and plus suspension) if the threads of the cap nut in the side member are damaged, the thread must either be retapped or the cap nut must be drilled out. When drilling out proceed as follows. - support engine/transmission assembly with 10- 222 a and legs ...

Page 26

40-12 bolt/washer assemblies for sub-frame securing point thread bolt part no. Front sub-frame m12 x 1.5 m12 x 1.5 x 95 10.9 n 101 612.01 1) rear sub-frame m12 x 1.5 m12 x 1.5 x 95 10.9 n 101 612.01 sub-frame bracket m10 m10 x 38 10.9 n 019 541.1 engine front cross-member to side member m10 m10 x 75...

Page 27

40-13 note: tightening torque remains unchanged. 1 - bolt/washer 2 - cap nut 3 - side member 4 - sub-frame 5 - bonded rubber mounting/control arm page 13 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su0...

Page 28

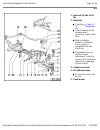

40-14 wheel bearing, suspension strut and drive shaft, removing and installing (base running gear) note: if a vehicle has to be moved after removing the drive shaft, first install outer joint and tighten to 50 nm (37 ft lb) otherwise the wheel bearing will be damaged. Welding and straightening opera...

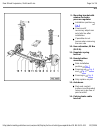

Page 29

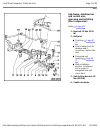

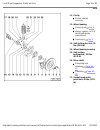

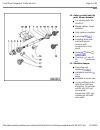

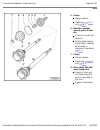

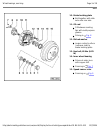

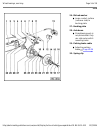

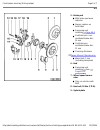

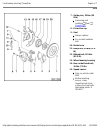

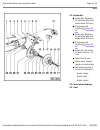

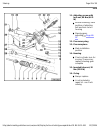

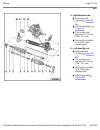

40-15 repair manual, suspension, wheels, brakes, steering, repair group 00 1 - self-locking nut, 265 nm (195 ft lb) only loosen and tighten with the vehicle standing on its wheels (danger of accident) any paint residue and/or corrosion on the thread of the outer joint must be removed before the nut ...

Page 30

40-16 6 - speed sensor rotor only on vehicles with abs 7 - hex bolt, 10 nm (7 ft lb) 8 - splash plate 9 - circlip ensure correctly seated 10 - wheel bearing pressing out fig. 6 replace, as it is destroyed during pressing out pressing in fig. 7 11 - self-locking hex nut, 35 nm (26 ft lb) 12 - wheel b...

Page 31

40-17 15 - self-locking bolt/washer assembly, 125 nm (92 ft lb) for securing brake carrier 16 - socket head multi- point bolt, 45 nm (33 ft lb) 17 - drive shaft to remove and install separate ball joint/control arm connection fig. 2 repairing page 40- 46 18 - circlip ensure correctly seated 19 - sel...

Page 32

40-18 21 - self-locking hex nut, 60 nm (44 ft lb) loosening and tightening fig. 1 22 - stop 23 - suspension strut bearing 24 - suspension strut removing and installing fig. 1 and fig. 2 disassembling and assembling page 40-23 25 - bracket 26 - hex bolt 27 - tie rod removing and installing page 48- 7...

Page 33

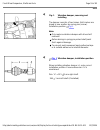

40-19 fig. 1 suspension strut to body, loosening and tightening note: camber must be adjusted each time joint is loosened. Fig. 2 wheel bearing housing/suspension strut joint, separating page 19 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/dis...

Page 34

40-20 to take drive shaft out, remove bolts (arrows). Note: first mark installation position. Fig. 3 ball joint/control arm connection, separating fig. 4 hub, pressing out of wheel bearing housing page 20 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/s...

Page 35

40-21 only use puller with leg clamp e.G. Kukko 204-2 (commercial type). Fig. 5 bearing race, pulling out of hub fig. 6 wheel bearing, pressing out of wheel bearing housing page 21 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=go...

Page 36

40-22 fig. 7 wheel bearing, pressing into wheel bearing housing fig. 8 hub, pressing into wheel bearing housing page 22 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.40.1.

Page 37

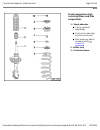

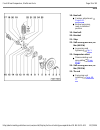

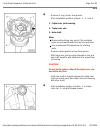

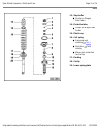

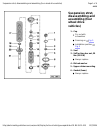

40-23 front suspension strut, servicing (base and plus suspension) 1 - shock absorber can be replaced individually check shock absorber for leaks and noises after replacing, adjust camber and toe page 44-1 2 - buffer stop 3 - protective sleeve page 23 of 82 front wheel suspension, shafts and axle 12...

Page 38

40-24 4 - coil spring removing and installing fig. 2 observe color coding outer surface of spring must not be damaged is slightly curved 5 - spring plate 6 - axial bearing 7 - hex nut, 60 nm (44 ft lb) loosening and tightening fig. 2 8 - suspension strut mounting 9 - stop 10 - self-locking hex nut, ...

Page 39

40-25 fig. 1 hex nut, loosening and tightening fig. 2 spring, removing and installing page 25 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.40.1.

Page 40

40-26 front suspension, servicing (plus suspension) i - removing and installing subframe, stabilizer bar and control arm (plus suspension) page 40-27 ii - removing and installing wheel bearing, suspension strut and drive shaft (plus suspension) page 40-36 the following components are different when ...

Page 41

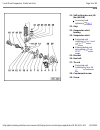

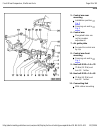

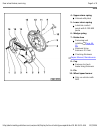

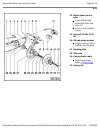

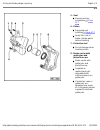

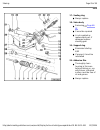

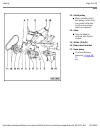

40-27 sub-frame, stabilizer bar and control arm, removing and installing (plus suspension) notes page 40-2 1 - hex bolt, 35 nm (26 ft lb) 2 - ball joint checking page 40- 10 check rubber boot for damage and if necessary, replace ball joint removing and installing page 40- 33 mark installation positi...

Page 42

40-28 5 - control arm rear mounting installation position fig. 2 pressing out and in fig. 3 6 - control arm elongated holes are not for camber adjustment! 7 - air guide plate secured to control arm by clip 8 - control arm front mounting pressing out and in fig. 1 9 - hex bolt m 12 x 1.5 x 78 70 nm (...

Page 43

40-29 12 - mounting for connecting link conical side towards control arm 13 - washer collar faces away from mounting 14 - self-locking hex nut, 25 nm (18 ft lb) 15 - hex bolt m 12 x 1.5 x 82 50 nm (37 ft lb) and turn 90 further 16 - 25 nm (18 ft lb) 17 - hex bolt, 25 nm (18 ft lb) to secure stabiliz...

Page 44

40-30 repair manual, engine mechanical, repair group 10 20 - vibration damper not installed on vehicles with vr 6 engine 21 - sub-frame removing and installing with assemblies installed: supporting assemblies fig. 4 remove sub-frame from below with control arm but without steering gear using transmi...

Page 45

40-31 note: before pressing in, coat with lubricant, e.G. Soft soap. Fig. 1 control arm front mounting, pressing out and in one of the embossed arrows points toward the recess in the control arm and the kidney shaped opening -arrow -a- in mounting faces towards center of vehicle. Fig. 2 control arm ...

Page 46

40-32 fig. 3 control arm rear mounting, pressing out and in fig. 4 engine/transmission assembly, supporting with 10-222 a and 10-222 a/3 page 32 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.40.1.

Page 47

40-33 ball joint, removing and installing (plus running gear) removing - loosen 12-point nut with vehicle standing on its wheels. - disconnect drive shaft at transmission drive flange. - remove bolts -arrow -a-. - loosen bolt -arrow -b-. - separate connection between ball joint/control arm. (first m...

Page 48

40-34 note: installing - install ball joint splitter as shown in illustration and press out ball joint. 1 - splitter. Matra v 176 place transmission jack vag 1383/a, or equivalent, underneath (danger of accident through falling parts when pressing out the ball joint). Protect ball joint threads by t...

Page 49

40-35 note: make sure that the boot is not damaged or twisted. Tightening torques ball joint to wheel bearing housing: 45 nm (33 ft lb) ball joint to control arm: 35 nm (26 ft lb) 1 - box insert (commercial type, 19 mm af) 2 - crowfoot insert (commercial type, 19 mm af) page 35 of 82 front wheel sus...

Page 50

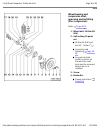

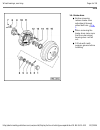

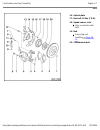

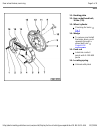

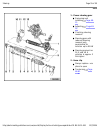

40-36 wheel bearing and suspension strut, removing and installing (plus suspension) notes page 40-14 1 - wheel bolt, 110 nm (81 ft lb) 2 - self-locking 12-point nut 90 nm (66 ft lb) and turn 45 further ( 1 / 8 ) loosening and tightening page 40- 44 any paint residue and/or corrosion on thread of the...

Page 51

40-37 5 - brake caliper do not loosen brake hose when working on front suspension hang up with wire or similar replacing brake pads page 46-6 6 - countersunk screw 7 - hub pressing out fig. 2 pressing in fig. 6 pulling off inner race fig. 3 8 - speed sensor rotor only for vehicles with abs 9 - hex b...

Page 52

40-38 11 - circlip ensure seated correctly 12 - wheel bearing pressing out fig. 4 always replace, as it is destroyed during pressing out pressing in fig. 5 13 - self-locking hex nut, 35 nm (26 ft lb) 14 - wheel bearing housing 15 - self-locking bolt/washer, 125 nm (92 ft lb) 16 - drive shaft removin...

Page 53

40-39 18 - hex bolt camber adjustment page 44-1 before loosening, mark installation position 19 - hex bolt 20 - bracket 21 - stop 22 - self-locking hex nut, 60 nm (44 ft lb) loosening and tightening fig. 1 23 - suspension strut disassembling and assembling page 40-23 24 - self-locking hex nut, 95 nm...

Page 54

40-40 fig. 1 suspension strut to body, loosening and tightening fig. 2 hub, pressing out of wheel bearing housing page 40 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.40.1.

Page 55

40-41 only use puller with leg clamp e.G. Kukko 204-2 (commercial type). Fig. 3 inner race, pulling off hub fig. 4 wheel bearing, pressing out of wheel bearing housing page 41 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&ty...

Page 56

40-42 fig. 5 wheel bearing, pressing into wheel bearing housing fig. 6 hub, pressing into wheel bearing housing page 42 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.40.1.

Page 57

40-43 drive shaft, removing and installing (plus running gear) removing - loosen 12-point nut with vehicle standing on its wheels. - disconnect drive shaft from transmission drive flange. - remove bolts (arrow -a-). - loosen bolt (arrow -b-). - separate connection between ball joint/control arm. (fi...

Page 58

40-44 installing - remove remains of locking fluid from outer joint and hub splines. (splines must be free of oil and grease). - apply locking fluid d 185 400 a2 to splines as shown in illustration. Bead cross section approx. 3 mm. - install drive shaft. - connect ball joint to control arm. - instal...

Page 59

40-45 tightening torques: drive shaft to flange shaft/transmission 45 nm (33 ft lb) drive shaft to wheel bearing 90 nm (66 ft lb) and housing turn 45 further ( 1 / 8 turn) ball joint/control arm 35 nm (26 ft lb) page 45 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypubl...

Page 60

40-46 drive shaft, repairing drive shafts on vehicles with plus suspension have shorter and finer splines on the outer joint. The wheel bearing is secured by a 12-point nut. The splines of the outer joint and the hub on plus suspensions are secured with locking fluid d 185 400 a2. Drive shaft, remov...

Page 61

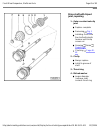

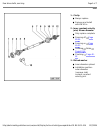

40-47 1 - circlip always replace remove and install with vw161 a 2 - gasket always replace. Pull off protective foil and stick onto joint. (only on 100 mm diameter constant velocity joints 3 - inner constant velocity joint 100 mm diameter only replace complete pressing off fig. 3 pressing on fig. 4 ...

Page 62

40-48 5 - boot for 100 mm diameter constant velocity joint rubber version with vent hole check for tears and chafing installation position for left drive shaft fig. 5 installation position for right drive shaft fig. 6 coat inside of cap with d3 drive off with drift 6 - drive shaft left shaft, solid ...

Page 63

40-49 8 - boot for 90 mm diameter constant velocity joint polyester elastomer version check for tears and chafing the balance pressure briefly ventilate boot before tensioning the small clamp fig. 7 installation position for left shaft, wheel end fig. 10 and fig. 11 installation position for right s...

Page 64

40-50 10 - dished washer outer diameter (concave side) contacts thrust washer 11 - thrust washer 12 - circlip always replace insert in shaft groove 13 - outer constant velocity joint, 90 mm diameter only replace complete removing fig. 2 installing: drive onto shaft with plastic hammer until compress...

Page 65

40-51 14 - outer constant velocity joint, 90 mm diameter for vehicles with 16v and vr6 wedge splines, larger diameter only replace complete removing fig. 2 installing: drive onto shaft with plastic hammer until compressed circlip seats greasing notes page 40-46 checking page 40- 60 15 - vibration da...

Page 66

40-52 16 - clamp always replace 17 - support rings on rubber type boot only on transmission end only see parts catalog 18 - boot for 100 mm diameter constant velocity joint polyester elastomer version check for tears and chafing to balance pressure briefly ventilate boot before tensioning the small ...

Page 67

40-53 the damper consists of two halves. Both halves are joined to one another by spring pins (arrow). Installation position fig. 1 note: fig. 1 vibration damper, removing and installing only replace vibration damper with drive shaft removed before driving in spring pin protect shaft paint finish ag...

Page 68

40-54 fig. 2 outer constant velocity joint, removing - drive joint off drive shaft with a firm blow from an aluminium hammer. Note: fig. 3 inner constant velocity joint, pressing off first drive boot off with drift support ball hub page 54 of 82 front wheel suspension, shafts and axle 12/7/2004 http...

Page 69

40-55 note: chamfer on inner diameter of ball hub (splines) must face the contact shoulder on the drive shaft. Fig. 4 inner constant velocity joint, pressing on - press on joint up to stop. - install circlip. Dimension "a" = 17 mm note: before assembling boot on drive shaft mark position, dimension ...

Page 70

40-56 the large diameter of vent chamber -a- must fit on the larger diameter. Fig. 6 installation position of right drive shaft transmission end joint boot b - vent hole often the boot is pushed in when installing on the joint body. This creates a vacuum inside the boot which draws a fold in (arrow)...

Page 71

40-57 fig. 8 larger clamp, tensioning - use pliers vag 1682 as shown in illustration. Ensure that the jaws of the pliers seat in the -arrow -b- of the clamp. - tension clamp by turning the spindle with a torque wrench (do not tilt pliers). Note: fig. 9 smaller clamp, tensioning 40 the clamp can only...

Page 72

40-58 cuff seating tolerance "a": 1 / 2 to 1 1 / 2 grooves visible at end of cuff. Note: this installation position tolerance is also valid for the left drive shaft transmission end boot (polyester elastomer version). Fig. 10 installation position of left drive shaft wheel end joint boot, shaft diam...

Page 73

40-59 cuff seating tolerance "a": from cuff position to chamfer up to 1 / 2 a groove visible. Fig. 12 installation position of right drive shaft, wheel end joint boot page 59 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&typ...

Page 74

40-60 outer constant velocity joint, checking the joint should be disassembled to replace dirty grease or for checking the balls and ball tracks for wear and damage. Removing - before disassembling mark position of the ball hub in relation to the ball cage and housing with an electric scriber or oil...

Page 75

40-61 note: the 6 balls of each joint belong to one tolerance group. Check stub axle, hub, cage and balls for indentations (pitting) and signs of seizure. Excessive backlash in joint will be noticed as a knock during load changes. In such cases the joint must be replaced. Polished areas and ball tra...

Page 76

40-62 inner constant velocity joint, checking the joint should be disassembled to replace dirty grease and when checking the balls and ball tracks for wear and damage. Note: the ball hub and joint are paired and must not be interchanged. - swivel ball hub and ball cage. - press out ball cage in dire...

Page 77

40-63 note: excessive backlash in joint will be noticed as a knock during load changes. In such cases the joint must be replaced. Polished areas and ball track marks are not a reason for changing the joint. Installing note: - insert ball hub over both chamfers into the ball cage. Any installed posit...

Page 78

40-64 - swivel in ball hub, whereby the hub must be swivelled out of the cage (arrows) far enough to allow the balls to fit into the ball tracks. Checking operation of constant velocity joint: the constant velocity joint is correctly assembled when the ball hub can be moved by hand backward and forw...

Page 79

40-65 drive shaft with tripod joint, repairing 1 - outer constant velocity joint replace complete removing fig. 1 installing: drive onto the shaft with plastic hammer until circlip comes out greasing notes page 40-46 checking page 40- 62 2 - circlip always replace install in groove of shaft 3 - thru...

Page 80

40-66 5 - clamp always replace tightening, fig. 2 and fig. 3 6 - boot for constant velocity joint, 90 mm dia. Check for cracks and abrasion before tightening the small clamp, ventilate boot briefly so pressure is equalized, fig. 2 7 - clamp always replace tightening, fig. 2 and fig. 4 8 - drive shaf...

Page 81

40-67 9 - inner splined screw, 45 nm (33 ft lb) 10 - drive shaft, right, with inner tripod joint repair of inner joint and replacement of boot not possible at this time replace if damaged page 67 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/di...

Page 82

40-68 fig. 1 constant velocity joint, outer, removing - drive off from drive shaft with forceful blow using an alloy hammer. The boot is pressed on forcefully when installing on the joint body. This creates a vacuum in the boot that makes a dent during driving (arrow). Briefly ventilate the boot at ...

Page 83

40-69 note: fig. 3 clamp, tightening on large diameter - install pliers vag 1682 as in illustration. Make sure that the blades of the pliers lie in the corners (arrow -b-) of the clamp. - tighten clamp by turning the spindle with a torque wrench (do not tilt pliers during this process). Because of t...

Page 84

40-70 drive axle with triple-rotor joint, removing and installing removing right-side drive axle the right drive axle removal instructions remain unchanged from the current repair manual procedure. Removing left-side drive axle - set up engine support bridge. Page 70 of 82 front wheel suspension, sh...

Page 85

40-71 - remove rear transmission mounting bolt (arrow). - remove front engine mounting bolt (arrow). - lift engine/transmission assembly - loosen drive axle nut while vehicle is standing on its wheels. Page 71 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com...

Page 86

40-72 - disconnect drive axle from transmission drive flange. - mark installation position of bolts (arrows) and remove. Installing - swing wheel outward (if necessary, place block of wood or equivalent between strut and wheel housing as shown). - push engine/transmission assembly toward front and r...

Page 87

40-73 drive axle with triple-rotor joint, servicing 1 - outer constant velocity (cv) joint replace complete part only removing fig. 1 installing: drive onto shaft with plastic hammer until circlip seats (springs into groove) greasing page 40- 12 2 - circlip always replace insert in groove in shaft 3...

Page 88

40-74 9 - clamp for triple-rotor joint 10 - boot 11 - clamp for triple-rotor joint 12 - cover destroyed when disassembling no longer required for assembly; not available as replacement part 13 - rectangular sealing ring included in repair kit; not used in production 14 - o-ring not required for asse...

Page 89

40-75 fig. 1 removing outer cv joint - drive joint off axle shaft with firm blow from soft mallet. Page 75 of 82 front wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.40.1.

Page 90

40-76 make sure plier jaws seat in grooves of clamp (arrows -b-) note: fig. 2 tightening outer cv joint boot clamp - position vag 1682 pliers or equivalent (e.G. Snap- on ya 3080) as shown in illustration. - tension clamp by using torque wrench to turn spindle (keep pliers at right angle to shaft). ...

Page 91

40-77 triple-rotor joint, disassembling - open hose clamp - open clamp on shaft small end and push back boot. Note: - drive screwdriver or similar tool into cover and pry open. If the cover will not pry open, insert screwdriver and pry from the opposite side. The cover is destroyed in the removal pr...

Page 92

40-78 1 - triple-rotor joint housing 2 - triple-rotor star 3 - axle shaft note: caution! Do not let the rollers slide off the triple-rotor star and fall to the floor. - remove o-ring -arrow- from groove. - mark installation positions of parts -1-, -2- and -3-. Noises while driving may result if the ...

Page 93

40-79 - remove rollers and place on clean surface. -1- pliers commercially available - remove circlip. - press triple-rotor star off axle shaft. - pull triple-rotor joint housing off axle shaft. - clean shaft and triple-rotor joint housing. Page 79 of 82 front wheel suspension, shafts and axle 12/7/...

Page 94

40-80 triple-rotor joint, assembling - slide small diameter boot clamp onto shaft. - slide triple-rotor joint boot onto shaft. - slide triple-rotor joint housing onto shaft. Mounting triple-rotor star note: the side of the star with a chamfer (arrow) goes onto the axle shaft splines first. - place t...

Page 95

40-81 note: a seal is formed directly between the triple-rotor joint and the drive flange by the rectanular sealing ring. The cover is no longer required. - install rectangular sealing ring (arrow) from repair kit. 90 grams into joint and 90 grams behind joint - press 180 grams of axle shaft grease ...

Page 96

40-82 - tighten small diameter clamp with vag 1275 pliers or equivalent (e.G. Kd 474). Caution! Secure the triple-rotor joint with tape so that the housing is not inadvertently pushed back when installing the axle shaft. Remove tape just prior to bolting to drive flange. Page 82 of 82 front wheel su...

Page 97: Rear Wheel

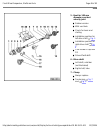

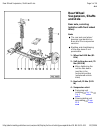

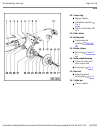

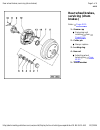

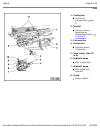

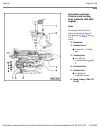

42-1 rear wheel suspension, shafts and axle rear axle, servicing (vehicles with front wheel drive) note: the rear axle and wheel bearings are identical on base and plus suspension versions. Welding and straightening of the axle beam is not permissible. 1 - wheel bolt 110 nm (81 ft lb) 2 - self-locki...

Page 98

42-2 5 - wheel bearing servicing vehicles with drum brakes page 42-15 vehicles with disc brakes page 42-24 6 - 80 nm (59 ft lb) use only self-locking nuts with captive washers when tightening nut, the axle beam must be in the horizontal position (unladened vehicle state) 7 - hex bolt installed from ...

Page 99

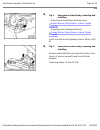

42-3 9 - mounting bracket with retainer for brake pressure regulator installation position fig. 4 check and if necessary adjust rear axle total toe after installation if possible do not loosen when removing the rear axle 10 - hex nut/washer, 35 nm (26 ft lb) 11 - regulator spring bracket 12 - bonded...

Page 100

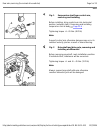

42-4 repair manual, body exterior, interior, repair group 70. Repair manual, body exterior, interior, repair group 68. Inertia reel bolt (arrow) tightening torque: 40 nm (30 ft lb) fig. 1 suspension strut at body, removing and installing - removing and installing inertia reel cover - removing and in...

Page 101

42-5 suspension strut is attached to the body by 4 retaining lugs in addition to the bolts. To remove, turn suspension strut until retaining lugs are positioned above the cut-outs. Fig. 3 suspension strut, removing and installing angle of inclination to axle beam 13 30' 1 . Fig. 4 bolting mounting b...

Page 102

42-6 note: before using special tool 3111 it is important to grease spindle with molybdenum grease. Fig. 5 bonded rubber mounting, pressing 1st half out of axle beam thread base plate into the pressure plate 3111/5 from the opposite side. Note: mounting must not be driven out. Otherwise the mounting...

Page 103

42-7 protruding segment of bonded rubber mounting faces forward on inside and rearward on outside. Fig. 7 rubber bonded mounting, installation position press both halves in one after the other until the mounting conical section contacts the axle beam. Fig. 8 rubber bonded mounting, presssing into ax...

Page 104

42-8 reworking cap nut in side member (front wheel drive vehicles) if the threads of the cap nut in the side member are damaged, it must either be retapped or the cap nut must be drilled out. When drilling out proceed as follows: - remove rear axle. - drill through damaged cap nut in the side member...

Page 105

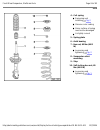

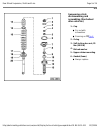

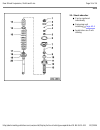

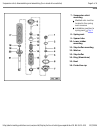

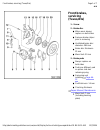

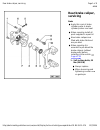

42-9 suspension strut, disassembling and assembling (front wheel drive vehicles) 1 - cap pry out with screwdriver pressing on fig. 4 2 - o-ring 3 - self-locking hex nut, 25 nm (18 ft lb) 4 - dished washer 5 - upper rubber mounting 6 - gasket (foam) always replace page 9 of 14 rear wheel suspension, ...

Page 106

42-10 7 - suspension strut bearing always replace foam gasket welded nuts must be located in the spring seat recesses align welded nuts and cap to shock absorber lower bushing fig. 3 8 - spacer tube 9 - lower rubber mounting 10 - metal cap higher on wagon than sedan 11 - washer 12 - spring seat thin...

Page 107

42-11 13 - stop buffer shorter on wagon than sedan 14 - protective tube longer on wagon than sedan 15 - plastic cap 16 - coil spring removing and installing fig. 1 allocation parts catalog wagon has protective hose at top 17 - packing 18 - circlip 19 - lower spring plate page 11 of 14 rear wheel sus...

Page 108

42-12 20 - shock absorber can be replaced individually removing and installing page 42-4 application see parts catalog page 12 of 14 rear wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.42.1.

Page 109

42-13 note: instead of vag 1403, vag 1752/1 may be used. Fig. 1 spring, removing and installing fig. 2 spring seat, installation position page 13 of 14 rear wheel suspension, shafts and axle 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.42.1.

Page 110

42-14 fig. 3 suspension strut mounting to shock absorber bushing, aligning a - shock absorber bushing axis b - suspension strut mounting axis "a" 50 c - cap axis 90 offset to shock absorber bushing axis -a-. Fig. 4 cap in suspension strut mounting, pressing in. Page 14 of 14 rear wheel suspension, s...

Page 111: Wheel Bearings,

42-15 wheel bearings, servicing drum brakes (front wheel drive vehicles), wheel bearings, servicing note: careful sealing, absolute cleanliness and precise adjustment are requirements for long wheel bearing service life. Therefore note the following points: install oil seal and grease cap as shown. ...

Page 112

42-16 2 - cotter pin always replace 3 - locking ring 4 - hex nut adjusting wheel bearing play fig. 4 5 - thrust washer 6 - outer wheel bearing drive out outer race with copper drift pressing in fig. 6 7 - hex socket head bolt, 10 nm (7 ft lb) 8 - speed sensor only on vehicles with abs 9 - stub axle ...

Page 113

42-17 10 - brake backing plate bolt together with stub axle onto rear axle 11 - oil seal fill between sealing lips with multi-purpose grease. Driving in fig. 8 12 - dished washer larger contact surface (concave side) to brake backing plate 13 - hex bolt, 60 nm (44 ft lb) 14 - inner wheel bearing dri...

Page 114

42-18 16 - brake drum before removing release brake shoe adjustment through wheel bolt hole fig. 5 when removing the brake drum make sure that the outer wheel bearing does not fall out. Fill hub with multi- purpose grease before installing page 4 of 18 wheel bearings, servicing 12/7/2004 http://ebah...

Page 115

42-19 loosen grease cap from seat by tapping lightly on the claw. Fig. 1 grease cap, pressing off fig. 2 grease cap, pressing off page 5 of 18 wheel bearings, servicing 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.42.2.

Page 116

42-20 note: fig. 3 grease cap, driving on always replace damaged (dented) grease caps. Damaged (dented) grease caps allow ingress of moisture, therefore always use the illustrated tool. Note: using a screwdriver it must be possible to move the thrust washer by finger pressure (without prying). Fig. ...

Page 117

42-21 fig. 5 brake shoe adjustment, releasing - insert a screwdriver through a hole in the brake drum and push the wedge upward. Fig. 6 outer wheel bearing outer race, pressing in page 7 of 18 wheel bearings, servicing 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=...

Page 118

42-22 fig. 7 inner wheel bearing outer race, pressing in fig. 8 oil seal, driving in page 8 of 18 wheel bearings, servicing 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.42.2.

Page 119

42-23 fig. 9 rotor, pressing in page 9 of 18 wheel bearings, servicing 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.42.2.

Page 120

42-24 wheel bearings, servicing - disc brakes (front wheel drive vehicles) note: careful sealing, absolute cleanliness and precise adjustment are requirements for long wheel bearing service life. Therefore note the following points: install oil seal and grease cap as shown. Only reinstall clean bear...

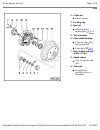

Page 121

42-25 3 - speed sensor only on vehicles with abs before installing sensor, clean mounting hole inner surface and coat with lubricating paste g 000 650 4 - brake hose bracket 5 - hex socket head bolt, 65 nm (48 ft lb) 6 - self-locking hex bolt, 35 nm (26 ft lb) always replace 7 - guide pins 8 - prote...

Page 122

42-26 10 - cover ring always replace installation position fig. 5 drive on with tube vw 519 11 - pad carrier 12 - brake pads removing and installing page 46- 33 13 - brake caliper servicing page 47- 15 14 - outer wheel bearing drive out outer race with copper drift pressing in fig. 6 15 - hex nut ad...

Page 123

42-27 17 - grease cap pressing off fig. 1 and fig. 2 driving on fig. 3 18 - locking ring 19 - thrust washer 20 - wheel bolt, 110 nm (81 ft lb) 21 - brake disc before installing fill hub with multi-purpose grease 22 - inner wheel bearing drive out outer race with copper drift pressing in fig. 7 23 - ...

Page 124

42-28 26 - dished washer large contact surface (concave side) to backing plate 27 - backing plate 28 - axle beam straightening work is not permissible! Only use stub axles with 6 mounting holes. 29 - parking brake cable adjusting parking brake page 46-36 30 - spring clip page 14 of 18 wheel bearings...

Page 125

42-29 fig. 1 grease cap, pressing off - loosen grease cap by tapping lightly on the claw. Fig. 2 grease cap, pressing off page 15 of 18 wheel bearings, servicing 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.42.2.

Page 126

42-30 note: fig. 3 grease cap, driving on always replace damaged (dented) grease caps. Damaged (dented) grease caps allow ingress of moisture, therefore always use the illustrated tool. Note: using a screwdriver it must be possible to move the thrust washer by finger pressure (without prying). Fig. ...

Page 127

42-31 dimension "a" = 9.5 mm fig. 5 cover ring, installation position - drive on cover ring with tube vw 519 fig. 6 outer wheel bearing outer race, pressing in page 17 of 18 wheel bearings, servicing 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su0...

Page 128

42-32 fig. 7 inner wheel bearing outer race, pressing in fig. 8 oil seal, driving in page 18 of 18 wheel bearings, servicing 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.42.2.

Page 129: Rear Axle,

42-33 rear axle, servicing (four wheel drive vehicles) note: when removing and installing the rear axle, it is recommended to remove axle and differential together and to separate away from the vehicle. If only the axle beam is to be removed and installed, the wishbones can remain attached to the sh...

Page 130

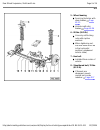

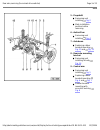

42-34 1 - suspension strut removing and installing page 42- 4 , fig. 1 and page 42-37 disassembling and assembling page 42-53 application see parts catalog 2 - drive shaft removing and installing fig. 2 and fig. 3 servicing page 42- 46 3 - final drive removing and installing from axle beam fig. 9 4 ...

Page 131

42-35 5 - propshaft removing and installing fig. 2 mark installation position before removing 6 - anti-roll bar removing and installing fig. 4 7 - axle beam replacing rubber bonded mounting fig. 10 and fig. 11 8 - rear axle mounting bracket removing and installing at body fig. 14 9 - control arm rem...

Page 132

42-36 repair manual, suspension, wheels,brakes, steering, repair group 46 and47 10 - wheel bearing servicing page 42- 59 servicing brakes 11 - hex bolt, 85 nm (63 ft lb) 12 - hex bolt for seat belt strut, 25 nm (18 ft lb) page 4 of 13 rear axle, servicing (four wheel drive vehicles) 12/7/2004 http:/...

Page 133

42-37 before installing, bring control arm into horizontal position (unladen state). Removing and installing suspension strut at body page 42-4 . Tightening torque -a-: 65 nm (48 ft lb) note: support control arm otherwise damage may occur to constant velocity joint as a result of over-stressing. Fig...

Page 134

42-38 loosen and tighten only when vehicle is standing on its wheels (danger of accident). Tightening torque: 90 nm (66 ft lb) and turn 45 further ( 1 / 8 turn) note: any paint residue and/or corrosion on the thread of the outer joint must be removed before the nut is installed. Fig. 3 drive shaft, ...

Page 135

42-39 before tightening bring control arm into horizontal position (unladen state). To remove the right-hand control arm inner bolt, remove brake pressure regulator from axle beam. Tightening torque -a-: 120 nm (89 ft lb) fig. 5 control arm, removing and installing fig. 6 rubber bonded mounting, rem...

Page 136

42-40 before installing coat with acid free lubricant, e.G. Soft soap. Installation position: shoulder on outer mounting to outside, to inside on inner mounting (to center of vehicle). Note: deviations from the rear axle toe and camber specifications can be corrected by using a bonded rubber mountin...

Page 137

42-41 the rubber mounting -a- is equipped with an eccentric bushing which can change the position of the control arm. This rubber mounting may only be installed in the control arm inner mounting. The camber and/or toe can be changed according to installation position. Note: with this mounting the ca...

Page 138

42-42 removing and installing viscous coupling repair manual, 5 spd. Manual transmission 02a; repair group 39 tightening torque -a-: 45 nm (33 ft lb) fig. 9 final drive, removing and installing from axle beam page 10 of 13 rear axle, servicing (four wheel drive vehicles) 12/7/2004 http://ebahn.Bentl...

Page 139

42-43 connect segment corners of bonded rubber mounting metal core with a line. The continued line must pass through the center of hole (arrow). Note: the kidney-shaped recess must be pointing in direction of travel when viewed from the center of vehicle. Fig. 10 installation position, determining p...

Page 140

42-44 remove and install complete when assembling mounting bracket and final drive carrier away from the vehicle, make sure parts are correctly located relative to each other. It is essential that the bonded rubber mounting is installed stress free in the vehicle. Fig. 12 mounting bracket and final ...

Page 141

42-45 mark mounting bracket installation position relative to body longitudinal member, otherwise the rear axle must be realigned on an axle alignment stand after reinstalling. Fig. 14 mounting bracket on body, removing and installing tightening torque -a- 130 nm (96 ft lb) -b- 60 nm (44 ft lb) -c- ...

Page 142: Rear Drive Shafts, Servicing

42-46 rear drive shafts, servicing removing and installing drive shafts page 42- 37 note: grease quantity: - - outer constant velocity joint 80 g g-6.3 - - inner constant velocity joint 80 9 g-6.3 greasing outer joint: press half of the grease into the joint, and the other half evenly into the boot....

Page 143

42-47 1 - circlip always replace remove and install with vw161 a 2 - inner constant velocity joint, 81 mm diameter only replace complete pressing off page 40-54 pressing on page 40-55 greasing notes page 42-46 checking page 40- 62 3 - dished washer inner diameter splined installation position: outer...

Page 144

42-48 4 - boot for 94 mm diameter constant velocity joint rubber version check for tears and chafing installation position: at cuff 1 to 1-1/2 grooves visible coat inside of cap with d3 drive off with drift 5 - drive axle different drive axle lengths - short shaft right 6 - hose clamp always replace...

Page 145

42-49 7 - boot for 81 mm diameter constant velocity joint polyester elastomer version check for tears and chafing installation position: at cuff 1 to 1-1/2 grooves visible to balance pressure briefly ventilate boot before tensioning the small clamp 8 - hose clamp always replace tensioning page 40-57...

Page 146

42-50 11 - circlip always replace insert in shaft groove 12 - outer constant velocity joint: 81 mm diameter only replace complete removing page 40- 54 installing: drive onto shaft with plastic hammer until compressed circlip seats greasing notes page 42-46 checking page 40- 60 13 - inner support rin...

Page 147

42-51 reworking cap nut in side member (four wheel drive vehicles) if the threads of the cap nut in the side member are damaged, it must either be retapped or the cap nut must be drilled out. - remove control arm if necessary. - drill through damaged cap nut in the side member using a 10.2 mm diamet...

Page 148

42-52 - cut new thread in the cap nut, m 12 x 1.5. - use new bolts, part no. N 010 137.1 and washer, part no. N 011 531.7 to secure the rear axle. Tightening torque: 65 nm (48 ft lb) note: the procedure described here must only be performed on one cap nut on each side of the vehicle. Page 7 of 7 rea...

Page 149: Suspension Strut,

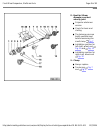

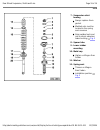

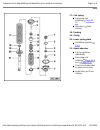

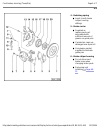

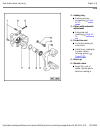

42-53 suspension strut, disassembling and assembling (four wheel drive vehicles) 1 - cap pry out with screwdriver pressing on fig. 5 installation position fig. 5 2 - seal 3 - self locking hex nut, 30 nm (22 ft lb) always replace 4 - dished washer 5 - upper rubber mounting 6 - gasket (foam) always re...

Page 150

42-54 7 - suspension strut mounting welded nuts must be located in the spring seat recesses installation position to spring seat fig. 3 8 - spring seat 9 - spacer tube 10 - lower rubber mounting 11 - stop buffer mounting 12 - washer 13 - stop buffer 14 - ring (aluminium) 15 - boot 16 - protective ca...

Page 151

42-55 17 - coil spring removing and installing page 42- 13 allocation parts catalog 18 - packing 19 - circlip 20 - lower spring plate installation position fig. 1 21 - shock absorber can be replaced individually removing and installing page 42-4 and page 42-37 check shock absorber for leaks and nois...

Page 152

42-56 the spring plate must be installed so that the holes "a" align with the bushing -2- in the shock absorber eye. Otherwise, in extreme driving situations spring plate -1- could contact the tire. Fig. 1 lower spring plate, installation position 1 - lower spring plate 2 - shock absorber eye bushin...

Page 153

42-57 the upper suspension strut mounting and the spring seat (arrow a) both have markings (arrow b). These must be installed pointing forward, otherwise damage will occur to the suspension strut piston rod. Fig. 3 suspension strut mounting to spring seat, installation position fig. 4 suspension str...

Page 154

42-58 fig. 5 cap, pressing into suspension strut mounting page 6 of 6 suspension strut, disassembling and assembling (four wheel drive vehicles) 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.42.5.

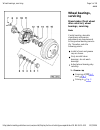

Page 155: Wheel Bearings,

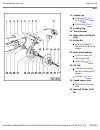

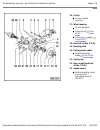

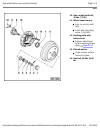

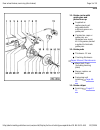

42-59 wheel bearings, servicing - disc brakes (four wheel drive vehicles) note: if a vehicle has to be moved after removing the drive shaft, first install an outer joint and tighten to 50 nm (37 ft lb). Otherwise the wheel bearing will be damaged. 1 - control arm 2 - self locking hex socket head bol...

Page 156

42-60 repair manual, suspension, wheels, brakes, steering, repair group 46 repair manual, suspension, wheels,brakes, steering, repair group 47 4 - guide pins 5 - protective cap 6 - pad securing springs always replace when changing pads 7 - brake pads repair information 8 - brake caliper servicing 9 ...

Page 157

42-61 repair manual, suspension, wheels, brakes, steering, repair group 46 12 - self-locking hex nut always tighten to 90 nm (66 ft lb) and turn 45 further ( 1 / 8 turn) to tighten use recommend angle measuring wrench vag 1756 or equivalent before installing nut on outer joint remove any paint remai...

Page 158

42-62 16 - circlip ensure seated correctly 17 - wheel bearing 72 mm diameter pressing out page 42-64 pressing in page. Page 42-65 18 - hex bolt, 10 nm (7 ft lb) 19 - backing plate 20 - parking brake cable adjusting parking brake page 46-36 21 - spring clip 22 - hex socket head bolt, 10 nm (7 ft lb) ...

Page 159

42-63 24 - drive shaft with speed sensor rotor removing and installing drive shaft page 42-37 and page 42-38 removing and installing rotor, fig. 6 25 - brake line page 5 of 8 wheel bearings, servicing - disc brakes (four wheel drive vehicles) 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/d...

Page 160

42-64 fig. 1 hub, pressing out fig. 2 wheel bearing, pressing out page 6 of 8 wheel bearings, servicing - disc brakes (four wheel drive vehicles) 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.42.6.

Page 161

42-65 note: only use puller with leg clamp e.G. Kukko 204-2 (commercial type). Fig. 3 inner race, pulling off of hub note: first install lower circlip. Fig. 4 wheel bearing, pressing in page 7 of 8 wheel bearings, servicing - disc brakes (four wheel drive vehicles) 12/7/2004 http://ebahn.Bentleypubl...

Page 162

42-66 note: first install backing plate on control arm. Tightening torque: 10 nm (7 ft lb) fig. 5 hub, pressing in fig. 6 speed sensor rotor, pressing in - drive rotor off outer joint using a drift (rotor will be destroyed). - drive new rotor carefully onto stop using a plastic hammer. Page 8 of 8 w...

Page 163: Vehicle Alignment

44-1 vehicle alignment test requirements: measuring equipment correctly calibrated vehicle unladen 1) tires inflated to correct pressure vehicle accurately aligned, suspension bounced and rocked several times suspension, steering and steering linkage checked for excessive play and damage. Note: vehi...

Page 164

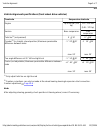

44-2 vehicle alignment specifications (front wheel drive vehicles) front axle suspension strut axle engine up to 85 kw (115 hp) 110 - 128 kw (148 - 172 hp) version base suspension plus suspension total toe 1) (not pressed) 0 10' 0 10' camber 2) (in straight- ahead position) maximum permissible diffe...

Page 165

44-3 rear axle torsion beam trailing arm axle engine/version all camber 1) maximum permissible difference between sides -1 30' 10' max. 20' total toe 1) (at specified wheel camber) maximum permissible deviation from direction of travel +20' 10' max. 20' 1) not adjustable page 3 of 7 vehicle alignmen...

Page 166

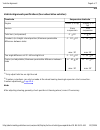

44-4 vehicle alignment specifications (four wheel drive vehicles) front axle suspension strut axle engine 85 kw (115 hp) 128 kw (172 hp) version base suspension plus suspension total toe 1) (not pressed) 0 10' 0 10' camber 2) (in straight- ahead position) maximum permissible difference between sides...

Page 167

44-5 rear axle semi-trailing arm axle engine 85 kw, 128 kw (115 hp, 172 hp) camber 1) maximum permissible difference between sides -1 15' 30' max. 30' total toe 1) (at specified camber) maximum permissible deviation from direction of travel +15' 20' max. 20' 1) camber and toe corrections possible us...

Page 168

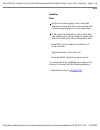

44-6 front wheel camber, adjusting note: - install special tool as shown in illustration and slightly pre-tension. - loosen suspension strut/wheel bearing housing connection. - adjust camber by turning the spindle to specified setting. - tighten suspension strut/wheel bearing housing connection. - c...

Page 169

44-7 calculating the direction of travel: - if both toe figures have the same preceding sign (+/+ or -/-), subtract the smaller figure from the larger figure and divide by 2 example. Left rear wheel toe right rear wheel toe + 15' + 5' 15' - 5' = 10' 10' : 2 = 5' deviation from direction of travel = ...

Page 170: Anti-Locking Brake System

45-1 anti-locking brake system (abs) and anti-locking brake system with electronic differential lock (abs/edl) teves 04 the abs, abs/edl brake system is divided diagonally. The servo-assist is effected pneumatically, by the vacuum brake servo unit. Located between the brake master cylinder and the v...

Page 171

45-2 notes for repair work on abs, abs/edl before doing any repair work on the anti-locking system, determine the cause of the malfunction using on board diagnostic (obd). Repair manual, brake system on board diagnostic (obd), repair group 01 before working on the abs, abs/edl system, disconnect the...

Page 172

45-3 thoroughly clean all unions and the adjacent areas before loosening, do not use aggressive cleaning agents such as brake cleaner, petrol, thinners or similar. Place removed parts on a clean surface and cover. Do not use fluffy cloth. Carefully cover or seal open components if repairs cannot be ...

Page 173

45-4 control module, removing and installing location under the rear seat, left note: switch off ignition before disconnecting and connecting connectors. Removing - fold up rear seat. - press control module securing clips together and pull out. - to pull connector off control module, release control...

Page 174

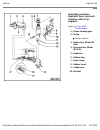

45-5 wheel speed sensor and rotor for speed sensor, removing and installing speed sensor when installing speed sensor ensure wiring is not twisted. Before installing speed sensor, clean mounting hole and coat with lubricating paste, g 000 650. Rotors before installing check that rotor is clean and u...

Page 175: Anti-Lock Brake System (Abs)

45-6 anti-lock brake system (abs) and abs with electronic differential lock (abs/edl), teves 20 gi general information the abs or abs/edl braking system is divided diagonally. Brake pedal pressure is boosted pneumatically, by the vacuum brake booster. Vehicles with teves 20 gi abs or abs/edl do not ...

Page 176

45-7 safety precautions warning! Brake fluid is poisonous. Caution! Before working on the abs or abs/edl system, disconnect the battery ground (gnd) strap. For anti-theft coded radios, first make sure that the radio code is available. Brake fluid must not contact painted parts. Brake fluid absorbs m...

Page 177

45-8 caution! During the final road test, make sure that at least one controlled brake test is included (pulsations must be felt at the brake pedal). Absolute cleanliness is required when working on the abs or abs/edl system. Do not use any products that contain mineral oil, such as oils, greases, e...

Page 178: Abs, Abs/edl

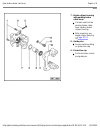

45-9 abs, abs/edl hydraulic unit, vacuum brake booster and brake master cylinder (teves 20 gi), servicing caution! Do not separate the abs hydraulic pump from the valve block. 1 - brake servo (vacuum brake booster) 2 - brake master cylinder 3 - brake fluid reservoir 4 - cap 5 - self-locking nut alwa...

Page 179

45-10 8 - rubber damper 9 - retainer 10 - abs hydraulic unit 11 - abs control module 12 - brake line connection abs hydraulic unit to right-front brake caliper 13 - brake line connection abs hydraulic unit to left-rear brake caliper or wheel cylinder 14 - brake line connection abs hydraulic unit to ...

Page 180

45-11 abs hydraulic unit and abs control module (teves 20 gi), removing and installing carefully read and follow all cautions and warnings page 45-7 before beginning work. Location the abs control module is bolted to the abs hydraulic unit, located on the left-side of the engine compartment. Caution...

Page 181

45-12 after separating abs control module from abs hydraulic unit, always install valve dome transportation protection on hydraulic unit. Warranty claims for abs hydraulic units on which the valve dome transportation protection was not used will not be accepted. Removing caution! Determine correct r...

Page 182

45-13 - release retainer and disconnect abs control module connector (arrows). - connect bleeder hose and bleeder bottle to left- front brake caliper bleeder screw, and open bleeder screw. - depress brake pedal at least 60 mm (2-3/8 in.). - install brake pedal loading device from special tool vag 12...

Page 183

45-14 - remove torx socket-head bolts (t25) from abs hydraulic unit bracket. - remove abs hydraulic unit/abs control module assembly. - disconnect abs hydraulic pump connector from abs control module. Caution! - remove abs control module mounting bolts (arrows) and pull off abs control module. Pull ...

Page 184

45-15 installing note: remove the sealing plugs from a new abs hydraulic unit one at a time, and only when the corresponding brake line is to be connected. If the plugs are removed too soon, brake fluid can escape and it can no longer be certain that the unit is sufficiently filled or adequately ble...

Page 185

45-16 note: for vehicles equipped with abs/edl, on which the brake fluid reservoir has been completely empty (e.G. Leaks in brake system), it is necessary to initiate the "basic setting" function of the on board diagnostic (obd) program: repair manual, brake system on board diagnostic (obd), repair ...

Page 186

45-17 brake hydraulic system, bleeding and filling vehicles with abs/edl for vehicles with abs/edl, when the brake fluid reservoir has been completely emptied (e.G. Due to leaks in the brake system) it is necessary to initiate the "basic setting" function of the on board diagnostic (obd) program. Re...

Page 187: Assembly Overview

45-18 assembly overview - hydraulic unit, brake servo/brake master cylinder note: repair manual, brake system on board diagnostic (obd), repair group 01 pump and valve block must not be separated from one another. Illustration shows an exploded view of the abs/edl unit. Servicing of abs unit is iden...

Page 188

45-19 2 - spacer cap various versions page 45-25 3 - sealing ring always replace 4 - circlip always replace 5 - brake line brake master cylinder/primary piston circuit to hydraulic unit 6 - brake servo 7 - carrier plate 8 - sealing ring 9 - pin 10 - securing clip 11 - brake fluid reservoir page 2 of...

Page 189

45-20 repair manual, brake system on board diagnostic (obd), repair group 01 12 - cap 13 - hex socket head screw for brake fluid reservoir 14 - series resistor only on vehicles with abs/edl checking 15 - self-locking hex nut, 25 nm (18 ft lb) 16 - tandem brake master cylinder 17 - protective plate 1...

Page 190

45-21 19 - abs hydraulic unit connections (arrow) show pipe work from tandem master cylinder to abs hydraulic unit removing and installing page 45- 23 20 - abs/edl hydraulic unit removing and installing page 45- 23 21 - brake line connection hydraulic unit to front right brake caliper thread connect...

Page 191

45-22 24 - brake line connection hydraulic unit to rear right wheel cylinder thread connection: m12 x1, 18 nm (13 ft lb) 25 - brake line connection hydraulic unit to front left brake caliper thread connection: m10 x1, 15 nm (11 ft lb) 26 - brake line master brake cylinder/secondary piston circuit to...

Page 192

45-23 hydraulic unit, removing and installing note: for easier disassembling and assembling, it is more practical to remove the hydraulic unit complete with brake servo and brake master cylinder. Removing - disconnect battery ground (gnd) strap. - separate all electrical connections on abs unit. - r...

Page 193

45-24 - remove nuts from brake servo/bulkhead. - carefully remove hydraulic unit and brake servo with brake master cylinder from engine compartment. Installing note: hydraulic units supplied as replacement parts are already filled with hydraulic fluid and bled. Only remove sealing plugs on hydraulic...

Page 194

45-25 brake pedal position sensor, removing and installing note: the brake pedal position sensor is only supplied as a repair kit. Apart from the sender, this repair kit contains a sealing ring, circlip and four different spacer caps. - - one white spacer cap - - one green spacer cap - - one blue sp...

Page 195

45-26 removing - release brake servo vacuum by operating the brake pedal several times. - remove connector from expansion tank. - swing coolant expansion tank to side. - pull connector off sensor. - expand circlip with a small screwdriver in a clockwise direction and pull sensor (arrow) out of brake...

Page 196

45-27 installing note: when installing new circlip ensure opening is uppermost - installation position (arrow). - install new sealing ring to sensor. (coat sealing ring with lubricant e.G. Soft soap). Note: - sensor notch must point downward when inserting into brake servo and be heard to engage. - ...

Page 197: Front Brakes,

46-1 front brakes, servicing (girling caliper) note: after replacing brake pads, depress brake pedal firmly several times with vehicle stationary so that the brake pads are properly seated in their normal operating position. To remove brake fluid from the reservoir, use a bleeder bottle which is use...

Page 198

46-2 1 - brake disc, not ventilated when worn always replace on both sides brake disc diameter: 256 mm brake disc thickness: 13 mm wear limit: 11 mm 2 - brake disc, ventilated when worn always replace on both sides brake disc diameter: 256 mm brake disc thickness: 20 mm wear limit: 18 mm 3 - screw 4...

Page 199

46-3 repair manual, maintenance 5 - brake pad with brake pad wear indicator always replace on both sides removing and installing page 46-6 pad thickness: non- ventilated brake disc, 14 mm pad thickness: ventilated brake disc, 11 mm checking thickness wear limit: 7 mm (including backplate) 6 - hub re...

Page 200

46-4 10 - wheel bearing housing 11 - brake carrier with guide pins and protective caps supplied as replacement part assembled with sufficient amount of grease on guide pins if protective caps are damaged use repair kit use grease packet supplied to lubricate guide pins 12 - heat shield install in pi...

Page 201

46-5 14 - self-locking hex bolt, 35 nm (26 ft lb) always replace 15 - guide pin 16 - ribbed bolt, 125 nm (92 ft lb) 17 - protective cap 18 - hex socket head bolt, 10 nm (7 ft lb) 19 - speed sensor only on vehicles with abs before inserting sensor clean mounting hole inner surface and coat with lubri...

Page 202

46-6 brake pads, removing and installing removing - remove lower brake caliper housing securing bolt. Counter-hold on guide pin. - swing brake caliper housing upward. - remove brake pads. Page 6 of 7 front brakes, servicing (girling caliper) 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/di...

Page 203

46-7 installing note: before inserting new brake pads, press piston back into the cylinder with resetting tool. Before pressing the piston back, remove some brake fluid from the reservoir with a bleeder bottle. If reservoir has been topped up, fluid may overflow and cause damage. Note: - press pisto...

Page 204: Front Brakes,

46-8 front brakes, servicing (teves/ate) repair manual, maintenance 1 - screw 2 - brake disc when worn always replace on both sides remove brake caliper prior to removing ventilated brake disc diameter: 288 mm brake disc thickness: 25 mm wear limit: 23 mm 3 - brake pads always replace on both sides ...

Page 205

46-9 4 - retaining spring insert in both brake caliper housing drillings 5 - brake carrier supplied as replacement part assembled with sufficient amount of grease on guide pins if protective caps are damaged use repair kit use grease packet supplied to lubricate guide pins 6 - brake caliper housing ...

Page 206

46-10 7 - guide pins, 25 nm (18 ft lb) removing and installing from page 46-12 8 - protective cap 9 - seal always replace pry out with suitable tool 10 - brake hose 11 - banjo bolt, 30 nm (22 ft lb) 12 - ribbed bolt, 125 nm (92 ft lb) 13 - wheel bearing housing 14 - hex socket head bolt, 10 nm (7 ft...

Page 207

46-11 16 - splash plate 17 - hex bolt, 10 nm (7 ft lb) 18 - speed sensor rotor only on vehicles with abs 19 - hub removing and installing page 40- 14 20 - countersunk bolt page 4 of 7 front brakes, servicing (teves/ate) 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type...

Page 208

46-12 brake pads, removing and installing removing note: if reusing brake pads mark location and install in same position or uneven braking may result. - remove protective caps. - pry off brake pad retaining spring from brake caliper housing with a screwdriver and remove. Page 5 of 7 front brakes, s...

Page 209

46-13 installing note: before installing new brake pads, press piston back into the cylinder with resetting tool. Before pressing the piston back, remove some brake fluid from the reservoir with a bleeder bottle. If reservoir has been topped up, fluid may overflow and cause damage. - remove both gui...

Page 210

46-14 - install brake pad with retaining spring in brake caliper housing (piston). - install outer brake pad in brake carrier. - secure brake caliper housing with both guide pins to brake carrier. - install both protective caps. - install retaining spring into brake caliper housing. Note: after repl...

Page 211: Rear Wheel Brakes,

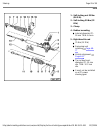

46-15 rear wheel brakes, servicing (drum brakes) notes page 42-15 1 - grease cap removing and installing from page 42-19 2 - cotter pin always replace 3 - locking ring 4 - hex nut adjusting wheel bearing play page 42-20 5 - thrust washer page 1 of 4 rear wheel brakes, servicing (drum brakes) 12/7/20...

Page 212

46-16 6 - outer wheel bearing 7 - wheel speed sensor rotor only on vehicles with abs 8 - brake drum vehicles with front wheel drive brake drum diameter: 230 mm wear limit: 231.5 mm clean thoroughly, check for wear, damage, tolerances, damaged wheel bolt threads and condition of braking surface fill ...

Page 213

46-17 10 - hex socket head bolt, 10 nm (7 ft lb) 11 - wheel speed sensor only on vehicles with abs insert with lubricating paste, g 000 650 12 - backing plate with brake shoes release adjustment before removing brake drum page 46-18 13 - dished washer large contact surface faces back plate 14 - hex ...

Page 214

46-18 brake shoe adjustment, releasing - insert a screwdriver through hole in brake drum and push wedge upward. Page 4 of 4 rear wheel brakes, servicing (drum brakes) 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.46.3.

Page 215: Rear Wheel Brakes,

46-19 rear wheel brakes, servicing note: after working on the rear wheel brakes: release parking brake. Firmly depress the brake pedal once. 1 - spring plate to remove, push against the spring and turn through 90 2 - spring 3 - brake shoe with lever for parking brake removing and installing page 46-...

Page 216

46-20 repair manual, maintenance 4 - upper return spring unhook with pliers 5 - lower return spring lubricate contact points with g 000 650 paste 6 - wedge spring 7 - brake shoe removing and installing page 46- 23 minimum lining thickness 2.5 mm checking thickness 8 - cap remove to check brake linin...

Page 217

46-21 11 - backing plate 12 - hex socket head bolt, 10 nm (7 ft) 13 - wheel cylinder checking for leaks fig. 1 14 - wedge to remove and install the brake drum, push upwards through a wheel bolt hole page 46-18 15 - push rod lubricate contact points with g 000 650 paste 16 - locating spring unhook wi...

Page 218

46-22 note: care is to be exercised to ensure the seal is not damaged when lifting the dust boot (only use a blunt instrument, e.G. Plastic wedge). Fig. 1 wheel cylinder, checking for leaks - lift dust boot - if brake fluid is found in the dust boot then replace wheel cylinder page 4 of 8 rear wheel...

Page 219

46-23 brake shoes, removing and installing removing - remove brake drum. - remove spring plate. - unhook lower return spring. - remove brake shoes. - unhook parking brake cable. - clamp brake shoes in vice. - remove wedge spring. - remove upper return spring. - unhook locating spring. Page 5 of 8 re...

Page 220

46-24 installing - connect locating spring and install brake shoes on the push rod. - insert wedge. - insert brake shoe with brake lever in push rod. - connect upper return spring. - connect parking brake cable to brake lever. - place brake shoes on wheel cylinder pistons. - connect lower return spr...

Page 221

46-25 - attach wedge spring. - install springs and spring plates. - install brake drum and adjust wheel bearing play. Adjusting wheel bearing play page 42- 20 - firmly depress brake pedal once, this adjusts the rear brakes. Page 7 of 8 rear wheel brakes, servicing 12/7/2004 http://ebahn.Bentleypubli...

Page 222

46-26 parking brake, adjusting (drum brakes) note: due to the automatic rear wheel brake adjustment there is no requirement to adjust the parking brake. Adjustment is only necessary after replacing parking brake cables, backing plate or brake linings - release parking brake. - firmly depress brake p...

Page 223: Rear Wheel Brakes,

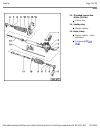

46-27 rear wheel brakes, servicing (disc brakes) girling rear wheel disc brakes (front and four wheel drive vehicles) note: only items 5, 6, 7, 8, 9, 10, 11 and 12 apply for four wheel drive. 1 - axle beam 2 - hex socket head bolt, 10 nm (7 ft lb) 3 - wheel speed sensor only for vehicles with abs in...

Page 224

46-28 4 - brake hose bracket 5 - hex socket head bolt, 65 nm (48 ft lb) 6 - self-locking bolt, 35 nm (26 ft lb) always replace when loosening and tightening, counter- hold on guide pin 7 - guide pin 8 - protective cap 9 - pad retaining springs always replace when changing pads 10 - backing plate rin...

Page 225

46-29 repair manual, maintenance 11 - brake carrier with guide pins and protective cap supplied as replacement part assembled with sufficient grease on guide pins if protective caps or guide pins are damaged use repair kit. Use grease packet supplied to lubricate guide pins. 12 - brake pads thicknes...

Page 226

46-30 14 - outer wheel bearing 15 - hex nut adjusting wheel bearing play using a screwdriver it must be possible to move the thrust washer by finger pressure (without leverage) page 42- 20 secure with locking ring and new cotter pin 16 - cotter pin always replace 17 - grease cap removing and install...

Page 227

46-31 21 - brake disc brake disc diameter for vehicles with front wheel drive: 226 mm removing and installing page 42- 24 brake disc diameter for vehicles with four wheel drive: 239 mm removing and installing page 42- 59 brake disc thickness, for both versions: 10 mm wear limit: 8 mm when worn, alwa...

Page 228

46-32 24 - wheel speed sensor rotor insert drift through wheel bolt holes and drive off drive on with suitable sleeve 25 - hex bolt, 60 nm (44 ft lb) 26 - dished spring washer larger seating surface towards backing plate 27 - backing plate 28 - stub axle 29 - parking brake cable adjusting parking br...

Page 229

46-33 brake pads, removing and installing note: mark brake pads when removing if they are to be reused. Re-install in their original position to prevent uneven braking! Removing - remove wheels. - remove parking brake cable from brake caliper (arrow). - remove securing bolts from brake caliper housi...

Page 230

46-34 installing note: before pressing the piston back, remove some brake fluid from the reservoir. Use a bleeder bottle or a plastic bottle which is only used for brake fluid. Brake fluid is poisonous and must not be siphoned by mouth through a hose. Note: - thread in piston by turning knurled whee...

Page 231

46-35 - secure brake caliper housing with new self- locking bolts. Note: - attach parking brake cable (arrow) to brake caliper housing. After each brake pad change firmly depress brake pedal several times with vehicle stationary, so that the brake pads are properly seated in their normal operating p...

Page 232

46-36 parking brake, adjusting (disc brakes) note: due to the self-adjusting rear brakes there is no requirement to adjust the parking brake. Adjustment is only necessary after replacing parking brake cables, brake calipers, brake pads and brake discs. Remove hand grip and central console to allow a...

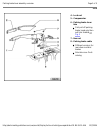

Page 233: Parking Brake Lever

46-37 parking brake lever assembly overview 1 - parking brake lever different versions for rear drum and disc brakes before removing remove center console 2 - hand grip pry trim up with a small screwdriver then pull forward to remove fig. 2 3 - adjusting nut adjusting parking brake: - vehicles with ...

Page 234

46-38 4 - lock nut 5 - compensator 6 - parking brake lever trim first pull off parking brake hand grip then pull trim forward fig. 2 7 - hex nut 8 - parking brake cable different versions for rear drum and disc brakes allocation see parts catalog page 2 of 9 parking brake lever assembly overview 12/...

Page 235

46-39 the parking brake cable is secured by clamps to the axle beam in the center of the two colored marks (arrow). Fig. 1 parking brake cable installation position fig. 2 hand grip, removing - pry up parking brake cable trim with a screwdriver and pull grip and trim off forward. Page 3 of 9 parking...

Page 236

46-40 fig. 3 center console, removing - remove rear ashtray (center console). - remove console rear securing screws (arrows). Page 4 of 9 parking brake lever assembly overview 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.46.6.

Page 237

46-41 brake pedal/brake servo, removing and installing caution! The brake pedal travel must not be restricted by additional floor coverings. Note: grease all mountings before installing with g 000 602 grease. 1 - securing clip ensure securely seated 2 - pin 3 - brake servo push rod clevis 4 - self-l...

Page 238

46-42 repair manual, 5 spd. Manual transmission 02a, repair group 30 repair manual, 5 spd. Manual transmission 02a, repair group 30 6 - brake pedal return spring 7 - return spring mounting tube 8 - brake pedal mounting bushing 9 - brake pedal 10 - clutch pedal removing and installing 11 - pedal clus...

Page 239

46-43 16 - securing clip ensure seated securely 17 - brake light switch adjusting page 46- 45 page 7 of 9 parking brake lever assembly overview 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.46.6.

Page 240

46-44 brake pedal, removing and installing note: grease all mounting and contact surfaces with mos 2 grease. To remove brake servo disconnect brake pedal at clevis only. Removing - before removing brake pedal remove trim - remove brake pedal clevis pin connection securing clip. - remove pin. - remov...

Page 241

46-45 brake light switch, adjusting note: the brake light switch must be removed for adjusting. - remove trim under instrument panel. - disconnect harness connector for brake light switch. - remove brake light switch by turning to right through 90 . - pull brake light switch plunger fully out. - dep...

Page 242: Assembly

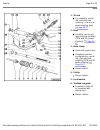

47-1 assembly overview: brake master cylinder/brake servo note: brake master cylinders and brake servos from different manufacturers are installed. Complete master cylinders and brake servos can be replaced independently of each other. 1 - seal for brake servo 2 - self-locking hex nut, 20 nm (15 ft ...

Page 243

47-2 6 - brake servo on gas engines the vacuum required is taken from the intake manifold. On diesel engines an exhauster is installed to create the required vacuum. Functional check - with engine switched off, depress brake pedal firmly several times (to exhaust the vacuum in the unit). - now depre...

Page 244

47-3 7 - sealing ring always replace 8 - self-locking hex nut, 20 nm (15 ft lb) 9 - brake master cylinder cannot be repaired. If faulty, replace complete. 10 - sealing plug moisten with brake fluid and press into reservoir 11 - seal page 3 of 4 assembly overview: brake master cylinder/brake servo 12...

Page 245

47-4 12 - cap 13 - brake fluid reservoir 14 - non-return valve page 4 of 4 assembly overview: brake master cylinder/brake servo 12/7/2004 http://ebahn.Bentleypublishers.Com/vw/servlet/display?Action=goto&type=repair&id=vw.B4.Su01.47.1.

Page 246: Girling Front Brake

47-5 girling front brake caliper, servicing note: when repairing install all parts supplied in repair kit. Apply thin coat of brake cylinder paste to brake cylinders, pistons and sea/s. 1 - protective seal 2 - bleed valve apply thin coat of brake cylinder paste to threads before screwing in 3 - brak...

Page 247

47-6 5 - seal remove using a screwdriver page 47-7 6 - piston removing and installing page 47-7 apply thin coat of brake cylinder paste before inserting 7 - protective seal do not damage when inserting piston 8 - brake carrier with guide pins and protective caps brake carrier with guide pins and pro...

Page 248

47-7 front brake caliper pistons, removing and installing removing note: place a piece of wood in the recess to prevent damaging the piston. - force piston out of brake caliper housing using compressed air. Note: when removing ensure that the surface of the cylinder is not damaged. - remove seal wit...

Page 249

47-8 installing - place protective seal with the outer sealing lip on the piston. Note: hold piston in front of caliper housing. - using a screwdriver, insert the inner sealing lip into the cylinder groove. Page 4 of 5 girling front brake caliper, servicing 12/7/2004 http://ebahn.Bentleypublishers.C...

Page 250