- DL manuals

- Volkswagen

- Engine

- TDI 350-8

- Operating Manual

Volkswagen TDI 350-8 Operating Manual

Summary of TDI 350-8

Page 1

B o o ts m o to re n v o n v o lk sw a g e n m a ri n e 8 tdi 350-8 operating manual b oat engines from v o lk sw age n m a rin e 8 cylinder tdi tdi 350-8.

Page 2: You Have Decided On A

2 foreword you have decided on a volkswagen marine boat engine - thank you for putting your trust in us. Volkswagen marine boat engines have been specially developped for use in boats. Volkswagen marine offers a wide model range to meet your specific requirement. Volkswagen marine boat engines are c...

Page 3: What You Should Know

Operation manual structure 3 this manual contains important information on using your volkswagen marine engine. You should read this manual carefully before first use of your engine to quickly familiarise yourself with the engine and so that you know how to operate and handle it correctly. In additi...

Page 4

Operation 4 manual structure note when your boat is craned or slipped, water can enter the exhaust system of your engine. Make sure that the exhaust system of the engine is drained of any remaining water before craning or slipping to avoid damage..

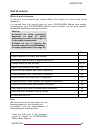

Page 5: Contents

Contents manual structure what you should know before you read this manual 3 . . . . . Operation general view of the engine 6 . . . . . . Starting the engine 7 . . . . . . . . . . . . . . Engine break-inngine 7 . . . . . . . . . . . . Switching off the engine 7 . . . . . . . . Instruments / switches...

Page 6: Bm8-- 001M

Operation 6 operation bm8-- 001m engine description tdi 350-8 -- four-stroke diesel engine -- common-rail direct injection -- v8 cylinder arrangement -- 4.2 litre displacement -- crankshaft mounted on 4 bearings -- valves control by chain connected to overhead cam -- hydraulically adjusted bucket ta...

Page 7: Switch Off Engine

Operation operation 7 warning o never start or operate the engine in an unventilated or enclosed space. The engine exhaust contains, amongst other gases, odourless and colourless carbon monoxide, a poisonous and life-threatening gas! Carbon dioxide can cause uncon- sciousness and death. O observe th...

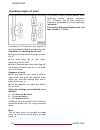

Page 8: Bm6--018M

Operation 8 operation the figure shows the control unit buttons for the individual instrumentation. 1 - control unit item 1 button for dimmer regulation and instrument lighting the brightness of the instrument lighting can be adjusted by pressing the button. 2 acknowledge button for acoustic signal ...

Page 9: Bm6--027M

Operation operation 9 bm6--027m 2 - coolant temperature gauge the gauge works once the ignition is turned on. When the ignition is switched on, the warning lamp -1- lights up for a few seconds as an operating check. Note avoid high engine speeds and do not subject the engine to heavy loading as long...

Page 10: Bm5--048M

Operation bm5--048m 3 - rev. Counter never run the cold engine at high speeds - either when idling or during running. If the needle of the rev. Counter goes above 4500 rpm, you should cut back on the throttle to prevent engine damage. In the case of a system error the multi function display of the ...

Page 11: Bm6--026M

Operation operation 11 bm6--026m 5 - alternator the warning lamp -1- illuminates when the ignition is switched on. It must go out after the engine starts. If the alternator warning lamp lilluminates during running: - switch off the engine immediately and check the ribbed v-belt. If the ribbed v-belt...

Page 12: Bm5--019M

Operation bm5--019m 1 - fuel supply interrupted, engine off 2 - running position 3 - starting the engine warning always remove the ignition key if you leave the boat - even for a short time. This is particularly important when children remain in the boat. Otherwise they could start the engine or ope...

Page 13: Bm6--042M

Operation operation 13 bm6--042m when midipanel instrumentation* is installed, the engine can be started using the start button* -8- (see figure above). Insert the ignition key in the ignition lock turn to the running position (see page 12). Press the start button to start the engine. * does not for...

Page 14: Bm8--027M

Operation starting an engine with two control stands 1. Switch the ignition on. - you will hear a short acoustic signal and the throttle lever control light of the selec ted control stand (see item a on the illustration) flashes twice a second. 2. Make sure that the throttle levers of both control ...

Page 15: Bm8--029M

Operation operation 15 bm8--029m starting the engines with a single control stand. Start the engines one after the other as described below:stand 1. Switch the ignition of the selected engine on. - you will hear a short acoustic signal and the throttle lever control light of the selected engine (see...

Page 16: Bm8--008M

Operation synchronous operation is possible from 5% to 95% of the set speed range. Provided that the throttle levers are not more than 10% apart from each other in this range, the synchronous operation lamp –d- (see fig. On page 15) lights up and the engines are controlled to run at synchronous spee...

Page 17

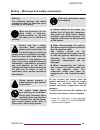

Tips and hints operating instructions 1 7 when performing any work on the engine or in the engine compartment, e. G. Check ing and topping up the operating fluids, there is a risk of scalding, injuries, acci dents- and fire. Warning when carrying out any work on the engine or in the engine room us...

Page 18

Tips and hints 1 8 operating instructions o if work on the fuel system or the electrical system is required: -- always disconnect the battery from the engine. -- do not smoke. -- never work near to an open flame. -- always have a fire extinguisher at the ready. Avoid contact with operating materials...

Page 19: Diesel

Tips and hints operating instructions 1 9 diesel used must comply with din en 1) 590 . Cn 2 ) not lower than 51. Notes on the fuel system during the installation of fuel system components, it has to be made sure that non-ferrous metals such as copper lines, brass nipples or galvanized tanks are not ...

Page 20: Self-Help

Tips and hints 20 operating instructions o genuine volkswagen marine parts are available from a vw marine service partner. Obviously they will also be able to ensure installation is carried out correctly. O if modifications are carried out, always observe our specifications. This ensures that no dam...

Page 21

Tips and hints self-help 21 fault engine does not start starter does not turn cause remedy throttle lever is not in neutral position move throttle lever into neutral throttle lever neutral switch does not generate an output signal (only with z drive) check operation of neutral switch neutral switch ...

Page 22

Tips and hints 2 2 self-help fault no or faulty fuel supply cause remedy fuel cock closed open fuel cock no fuel in tank fill tank tank dirty clean fuel lines clogged check lines and clean if necessary water level in circulation filter* too high drain water from circulation filter* circulation filte...

Page 23

Tips and hints self-help 2 3 fault engine becomes too hot cause remedy seawater valve closed open seawater valve seawater filter is clogged close seawater valve and clean seawater filter. Seawater pump aspirates air check cover of seawater filter for proper seating and leaks and check suction hose. ...

Page 24: Bm8--007M

Tips and hints 24 self-help bm8--007m the individual circuits are protected by fuses. It is advisable to always carry a few replacement fuses available from volkswagen marine service partners. Warning o observe the safety precautions beginning on page 17 before performing any work on the engine or i...

Page 25: Bm8--030M

Tips and hints self-help 25 colour code for fuses: orange: 5 amps . . . . . . . . . . . . . . . . . . . . . . Blue: 15 amps . . . . . . . . . . . . . . . . . . . . . . . Green: 30 amps . . . . . . . . . . . . . . . . . . . . . . O pull out the appropriate fuse. O replace blown fuse (recognisable by ...

Page 26: Service And Care

Inspection 26 inspection the broad network of volkswagen marine service partners with trained professionals, modern equipment and all required special tools is available to you for the care and service of your volkswagen marine boat engine. If an inspection service is required, all checking and adju...

Page 27: Start Of Season

Inspection inspection 27 work at start of season at the start of the season, visually check and inspect the engine. You should have the service work on your volkswagen marine boat engine conducted by your volkswagen marine service partner, as the work requires specialised knowledge and special tools...

Page 28: Daily Checks

Inspection 28 inspection visual inspection before each sailing before sailing check and visually inspect the engine. Scope of work page visual inspection for leaks and damage check engine oil level 32 check circulation filter* (bowl) and drain off water if necessary 36 check coolant level and top up...

Page 29: End Of Season

Inspection inspection 2 9 work at end of season at the end of the season you should subject the engine to a check and visual inspection. You should have the service work on your volkswagen marine boat engine conducted by your volkswagen marine service partner, as the work requires specialised knowle...

Page 30: Service Scope

Inspection 30 inspection your volkswagen marine boat engine must be serviced once a year at the end of the season or every 200 operating hours. You should have the service work on your volkswagen marine boat engine conducted by your volkswagen marine service partner, as the work requires specialised...

Page 31: Additional Work

Inspection inspection 31 this additional work on your volkswagen marine boat engine must be carried out every 1,000 operating hours. You should have the additional work on your volkswagen marine boat engine conducted by your volkswagen marine service partner, as the work requires specialised knowled...

Page 32: Additional Work

Inspection 32 inspection this additional work on your volkswagen marine boat engine must be carried out every 5 years or every 3,000 operating hours. You should have the additional work on your volkswagen marine boat engine conducted by your volkswagen marine service partner, as the work requires sp...

Page 33: Engine Oil

Inspection inspection 33 specifications a special volkswagen marine longlife oil that can be used all-year round is used to fill the engine at the factory. It has special corrosion protection properties to protect the engine in an aggressive environment such as salty sea air. It also protects the en...

Page 34: A02--0018

Inspection 34 inspection a02--0018 during normal running, the engine consumes oil. Therefore, the engine oil level must be checked at regular intervals. Conditions for checking the oil level o engine oil temperature must be at least 60 0 c o the boat must be at rest when measuring the oil level. O w...

Page 35: A10--1037

Inspection inspection 35 a10--1037 2 remove the cap of the oil filler neck –arrow- and pour in small quantities of engine oil. Make sure that you also check the oil level by using the dipstick. Illustration above). The oil level must never be above range a (see figure on page 34). Otherwise oil may ...

Page 36: A24- 10 558

Inspection 36 inspection a24- 10 558 o loosen the protective cap -1- of the oil filter housing -2- (see illustration above) using a 32 mm socket wrench, so that the return valve opens and the used oil can flow back into the oil sump. O the supplied oil change hose -3- is already connected on to the ...

Page 37: A17--10093

Inspection inspection 37 a17--10093 o loosen the protective cap -1- of the oil filter housing -6- (see illustration above) using a 32 mm socket wrench and remove the cap together with the filter element -3-. O remove the filter element -3- from the cap -1- and wipe the cap with a clean cloth o repla...

Page 38: Bm5--026M

Inspection 38 inspection bm5--026m warning if you wish to change the circulation filter element*, always follow the guidelines and instructions provided by the manu facturer as well as the following notes. O close the cut-off valve if present. If the engine is equipped with a single filter, switch ...

Page 39: Fine

Inspection inspection 39 warning if you wish to change the circulation filter element, always follow the guidelines and instructions provided by the manufacturer. Fine element fuel filter water drainage warning if you want to drain the water from the fine element fuel filter, then please be sure to ...

Page 40: Bm6--017M

Inspection 40 inspection bm6--017m warning if you want to change the fine element fuel filter yourself, then please be sure to observe the following points: o please make sure that no diesel fuel gets onto the coolant hoses. Clean hoses immediately if necessary. O wear eye protection. O if your hand...

Page 41: Bm5--006M

Inspection inspection 41 bm5--006m warning o never open the filter housing with the seawater valve open to prevent water from entering. O observe the safety precautions beginning on page 17 before performing any work on the engine or in the engine compartment. As the degree of soiling of the seawate...

Page 42: Bm8--021M

Inspection 42 inspection bm8--021m the air filter must be regularly cleaned. A dirty air filter can be detected in that the dirt particles will have settled in the small openings of the filter (see figure). If the engine is operated in very dusty areas, clean the filter more frequently. Removing the...

Page 43: Cooling System

Inspection inspection 43 the cooling system must be filled with a mixture of water and our coolant additive g12++ (corrosion inhibitor and ethylene-based antifreeze) at a ratio of 60% (water) to 40% (coolant additive). This ratio provides the necessary antifreeze protection down to approx. -25°c and...

Page 44: 8-- 003M

Inspection 44 inspection bm 8-- 003m the coolant level can only be properly checked with the engine stopped. The right coolant level is important for the proper operation of the cooling system. Therefore, the coolant level should be checked regularly. With the engine cold, the coolant must be above ...

Page 45: Bm6--011M

Inspection inspection 45 bm6--011m warning observe the safety precautions beginning on page 17 before performing any work on the engine or in the engine compartment. In accordance with the specifications in the service schedule, the impeller must be checked and replaced if necessary. Note o close th...

Page 46: Bm8--012M

Inspection 46 inspection bm8--012m the sacrificial anode in the cooling system must be checked in accordance with the specifications in the service schedule and replaced if necessary. Check the sacrificial anode, as it protects the engine from galvanic corrosion. O ă close the seawater valve. O ă sc...

Page 47: Bm5--034M

Inspection inspection 47 bm5--034m sequence of work 1. Remove the dipstick by rotating its grip anticlockwise (see fig. Bm5-007, p. 46) bm5-007m) before withdrawing the dipstick from the housing. 2. Wipe the dipstick off with a clean and dust-free cloth ensuring all oil is removed. 3. Insert the dip...

Page 48: Bm5--033M

Inspection 48 inspection bm5--033m screw out the oil dipstick -1-, wipe with a clean cloth and screw in the dipstick again up to the stop. Then screw out the dipstick again and read off the oil level: a - if the oil level is within range a, no oil should be added. B - if the oil level is within rang...

Page 49

Inspection inspection 49 warning the following warnings and safety precautions must be observed when working on the battery. Wear eye protection. Do not allow acidic or lead-con- taining particles to get into the eyes or on to the skin or clothing. Battery acid has a highly corrosive. Wear protectiv...

Page 50: Battery*

Inspection 50 inspection warning observe the safety precautions beginning on page 17 before performing any work on the engine or in the engine compartment. Recommended starter battery nominal voltage: 12v cold starting power: 520a capacity: 110ah cable diameters 50 mm 2 acid level please observe the...

Page 51: Bim--023M

Inspection inspection 51 the acid level is always to be at the max. Mark on the long side. Never fill above the max. Mark and do not allow the acid level to drop below the min. Mark. The concerned battery cells must be filled up to the max.- mark before the acid level reaches the min.- mark. Do not ...

Page 52: Bim--022M

Inspection 52 inspection bim--022m battery replacement if the battery is replaced, the new battery must have the same voltage (12 v), design and safety characteristics such as central venting and an o-ring seal for the battery plugs. The amperage and capacity should match. Volkswagen marine service ...

Page 53: Engine Test Run

Inspection inspection 53 warning observe the safety precautions beginning on page 17 before performing any work on the engine or in the engine compartment. Warning lamps check the warning lamps for the coolant, the alternator and the engine oil pressure. The warning lamps light up when the engine is...

Page 54: Bm8--024M

Inspection 54 inspection bm8--024m warning observe the safety precautions beginning on page 17 before performing any work on the engine or in the engine compartment. Flushing and subsequent draining of the seawater cooling system with fresh water is very important for preventing corrosion and frost ...

Page 55: Bleeding The Fuel System

Inspection inspection 55 note there is a possibility that the engine will not start if the fuel system of the boat has not yet been completely bled. Make sure to properly bleed the fuel system in order to avoid engine starting problems. The fuel system can be bled as follows: 1. First make sure that...

Page 56: Winter Operation

Inspection 56 inspection if the engine is not used for several weeks at extremely low sub-zero temperatures, the battery should be removed and stored in a frost-proof room to prevent it from freezing and being destroyed. Cable connections check and clean all cable connections, as oxidised connection...

Page 57

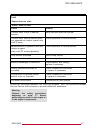

Technical data diesel engines 57 engine data engine code cema output at rpm 257 kw (350 bhp) / 4200 maximum torque in nm at rpm 700 / 2000 - 3250 number of cylinders, displacement 8 cylinder, 4.134 cm 3 compression 16.4 bore/stroke in mm 83.0 / 95.5 turbocharging 2 exhaust-gas turbochargers vtg 2) c...

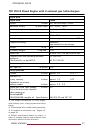

Page 58: Engine Characteristic Data

Technical data 58 characteristic data important note please always specify the model with the engine number or the engine code when making all queries, any complaints and when ordering spare parts. This will prevent misunderstanding when processing your query. Before you read of the characteristic d...

Page 59

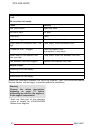

Index a air filter, - cleaning 42 . . . . . . . . . . . . Alternator 11 . . . . . . . . . . . . . . . . . . . . . Antifreeze 43 . . . . . . . . . . . . . . . . . . . . . B battery 50 . . . . . . . . . . . . . . . . . . . . . . . - charging 53 . . . . . . . . . . . . . . . . . . . - removal 52 . . . ...

Page 60

Index g general view of engine 6 . . . . . . . . . . Glow plug system 12 . . . . . . . . . . . . . I ignition lock 13 . . . . . . . . . . . . . . . . . . . Inspection intervals 30 . . . . . . . . . . . . Inspection service - air filter cleaning 42 . . . . . . . . . . . . - check engine oil level 34 ...

Page 61

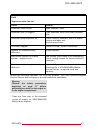

Index s sacrificial anode 47 . . . . . . . . . . . . . . . Safety precautions 17 . . . . . . . . . . . . . Seawater cooling system 56 . . . . . . . Seawater filter, - clean 41 . . . . . . . . . Seawater pump 46 . . . . . . . . . . . . . . . . Self-help 20 . . . . . . . . . . . . . . . . . . . . . . ...

Page 64

© 2009 v vo ollk ks sw wa ag ge en n m ma arriin ne e volkswagen marine is constantly working on the further development of all types and models. Please be aware, therefore, that changes in the equipment supplied in terms of shape, accessories and technology may occur at any time. Therefore no claim...