Summary of VI770

Page 1

Model vi770 digital inverter generator user’s manual january 2015.

Page 2: Preface

Thank you for purchasing a voltmaster® inverter generator. This manual covers operation and maintenance of the vi770 generator. All information in this publication is based on the latest product information available at the time of approval for printing. We reserve the right to make changes at any t...

Page 3: Contents

Contents 1. Safety instructions 2. Safety label locations 3. Component indentificaction 4. Pre-operation check 5. Starting the engine 6. Generator use 7. Stopping the engine 8. Maintenance 9. Transporting/storage 10. Troubleshooting 11. Specifications 12. Electric diagram - - 1 3 4 5 9 12 16 18 25 2...

Page 4: 1. Safety Instructions

- - warning operate carefully to ensure safety. 1. Safety instructions warning our generators are designed to give safe and depend-able service if operated according to instructions. Read and understand the owner's manual before operating the generator. Failure to do so could result in personal inju...

Page 5

- - warning warning connections for standby power to a building's electrical system must be made by a qualified electrician and must comply with all applicable laws and electrical codes. Improper connections can allow electrical current from the generator to back feed into the utility lines. Such ba...

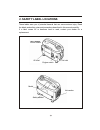

Page 6: 2. Safety Label Locations

- - 2. Safety label locations chock handle oil level model safety caution hot caution engine switch air inlet these labels warn you of potential hazards that can cause serious injury. Read the labels and safety notes and precautions described in this manual carefully. If a label comes off or becomes...

Page 7: 3. Component Identification

- - 3. Component identification chock lever engine switch fuel cap lever oil filler cap spark plug maintenance cover muffler maintenance cover starter grip control panel.

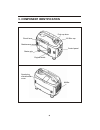

Page 8

- - output indicator light overload indicator light low oil alarm indicator light ac receptacle smart switch ground terminal note smart throttle switch on off control panel smart throttle: engine speed is kept at idle automatically when the electrical appliance is disconnected and it returns to the ...

Page 9

- - 4. Pre-operation check be sure to check the generator on a level surface with the engine stopped. 1. Check the engine oil level. Caution -25 -30 -15 -40 10w-30 15w-40 ambient temperature engine oil type using nondetergent oil or 2-stroke engine oil could shorten the engine's service life. Use a ...

Page 10

- - upper lever upper limit lower limit oil rule oil filler hole 2. Check the fuel level. Use automotive gasoline (unleaded or low-leaded is preferred to minimize combustion chamber deposits). If the fuel level is low, refuel the fuel tank until the level as specified. Never use an oil/gasoline mixt...

Page 11

Gasoline containing alcohol if you decide to use a generator containing alcohol (gasohol), be sure it's octane rating is at least as high as that recommended by us. There are two types of gasohol: one containing ethanol, and the other containing methanol. Do not use gasohol that contains more than 1...

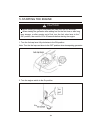

Page 12

- - 5. Starting the engine fuel cap lever on engine switch caution before starting the engine, disconnect the load from the dc terminals. When starting the generator after adding fuel for the first time or after long term storage, or after running out of fuel, turn the fuel valve lever to the '' on'...

Page 13

Run - - 3.Move the choke lever to the start position. Note: do not use the choke when the engine is warm or the air temperature is high. 4. Pull the starter grip until resistance is felt, then pull the starter grip briskly toward the arrow as shown below. Do not allow the starter grip to snap back, ...

Page 14

- - 5. Move the choke lever to the run position after the engine warms up. Run choke lever run caution if the engine stops and will not restart, check the engine oil level before troubleshooting in other areas. High altitude operation at high altitude, the standard carburetor air-fuel mixture will b...

Page 15: 6. Generator Use

- - 6. Generator use warning to prevent electrical shock from faulty appliances, the generator should be grounded. Connect a length of heavy wire between the generator's ground terminal and an external ground source. Connections for standby power to a building's electrical system must be made by a q...

Page 16

- - output indicator light(green) overload indicator light(red) smart switch plug ac applications 1.Start the engine and make sure the output indicator light (green) comes on. 2.Confirm that the appliance to be used is switched off, and plug in the appliance. Caution be sure that all appliances are ...

Page 17

- - 1. Connect the ground terminal. Grounding terminal caution caution before connecting an appliance to the generator, check that it is in good order, and that its electrical rating does not exceed that of the generator. Then connect the power cord of the appliance, and start the engine. Indicator ...

Page 18

4. Switch on the equipment to be used. In case of overload operation or when trouble occurs for the equipment being used, the output indicator light(green) will go out, the overload indicator light(red) will light continuously, and no power will be put out. At this time, the engine will not stop, so...

Page 19: 7. Stopping The Engine

- - 7. Stopping the engine engine switch plug off ~ to stop the engine in an emergency, turn the engine switch to the off position. In normal use: 1. Switch off the connected equipment and pull the inserted plug. 2 .Turn the engine switch to the off position..

Page 20

- - 3.Turn the cap lever fully counterclockwise to the "off"position off fuel cap lever be sure the fuel cap lever, choke and the engine switch are "off" when stopping, transporting and/or storing the generator. Caution.

Page 21: 8. Maintenance

The purpose of the maintenance and adjustment schedule is to keep the generator in the best operating condition. 7.1 maintenance schedule 8. Maintenance warning shut off the engine before performing any maintena-nce. If the engine must be run, make sure the area is well ventilated. The exhaust conta...

Page 22

Confirm if engine lever and ventilation lever of oiling port are turned to the off side before the oil drainage. Caution 1.Changing oil drain the oil while the engine is still warm to assure rapid and complete draining. 1. Loosen the cover screw and remove the left side maintenance cover. 2. Remove ...

Page 23

2. Air cleaner service a dirty air cleaner will restrict air flow to the carburetor. To prevent carburetor malfunction, service the air cleaner regularly. Service more frequently when operating the generator in extremely dusty areas. A. Loosen the cover screw and remove the left side maintenance cov...

Page 24

- - caution 3. Spark plug service recommented spark plug: ur5 to ensure proper engine operation, the spark plug must be properly gapped and free of deposits. (1). Remove the spark plug maintenance cover. (2). Remove the spark plug cap. (3). Clean any dirt from around the spark plug base. (4). Use th...

Page 25

- - clearance (5). Visually inspect the spark plug. Discard it if the insulator is cracked or chipped. Clean the spark plug with a wire brush if it is to be reused. (6). Measure the plug gap with a feeler gauge. The gap should be 0.6-0.7mm(0.024-0.028in). Correct as necessary by carefully bending th...

Page 26

- - 4. Spark arrester maintenance (1). Remove the four m5 screws, and remove the muffler protector. (2). Remove the there m6 bolts, and remove the muffler, the spark arrester and the muffler gasket warning if the generator has been running, the muffler will be very hot. Allow it to cool before proce...

Page 27

- - (3). 3.Use a brush to remove carbon deposits from the spark arrester screen. (4). Check the muffler gasket; replace if damaged. Reinstall the muffler gasket, the spark arrester, the muffler and the muffler protector in the reverse order of removal ..

Page 28: 9. Transportint/storage

To prevent fuel spillage when transporting or during temporary storage, the genera-tor should be secured upright in its normal operating position, with the engine switch off. Turn the cap lever fully counterclockwise to the "off" position. Before storing the unit for an extended period: 1. Be sure t...

Page 29

- - a. Drain all gasoline from the fuel tank into an approved gasoline container. B. Turn the engine switch on, and loosen the carburetor drain screw and drain the gasoline from the carburetor into a suitable container. C. With the drain screw loosened remove the spark plug cap, and pull the starter...

Page 30: 10.

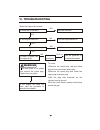

- - 10. Troubleshooting when the engine will not start: refill the fuel tank. Turn the engine switch on. Add the recommended oil. Is there fuel in the tank? Is the engine switch on? Yes no yes yes no no no still no spark replace the spark plug. Warning to check: 1)remove the spark plug cap and clean...

Page 31

- - appliance does not operate: is the output indicator light on? Yes no no yes check the electrical appli- ance or equipment for any defects. Take the generator to an authorized dealer. No take the generator to an authorized dealer. Yes replace the electrical appliance or equipment take the electri...

Page 32: 11.

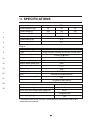

- - 1 3 4 5 9 12 16 18 25 27 29 30 11. Specifications vi770 50 230 3.04 6000 0.70 0.77 60 240 2.92 kg140 37.68ml (40 30mm) 8.5:1 1.00/6000 6000 t.C.I ur5 recoil starter automotive unleaded gasoline 450 cd grade or sae 10w/30 fuel tank capacity (l) continuous running time (hr) (at rated output) noise...

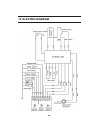

Page 33: 12.

-30- -30- 12. Electric diagram.

Page 34

Wanco inc. 5870 tennyson street arvada, colorado 80003 800-730-3927 303-427-5700 303-427-5725 fax www.Voltmaster.Com ©2015 wanco inc. All rights reserved. Voltmaster is a wanco brand. Voltmaster, wanco, and the voltmaster and wanco logos are registered trademarks of wanco inc. All other trademarks a...