- DL manuals

- W & H

- Steriliser

- Lisa

- Instructions For Use Manual

W & H Lisa Instructions For Use Manual

Summary of Lisa

Page 1

Instruction for use um009eng lisa fully automatic 201 10 rev.4.

Page 3

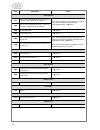

A table of contents 1. Introduction................................................................................................................................................... 1 1.1 scope ............................................................................................................

Page 4

B 6.7.1 system info ................................................................................................................................ 25 6.7.2 formatting the memory card ...................................................................................................... 25 6.8 user ...

Page 5

1 1. Introduction 1.1 scope the purpose of this user manual is to provide you with information about lisa 517/522 sterilizers to ensure: • proper installation and set-up. • optimal use. • safe and reliable operation. • compliance with regular maintenance and servicing requirements. Note: all drawing...

Page 6

2 1.5 symbols displayed on the sterilizer consult this table whenever one you see one of these symbols in this manual or on the sterilizer. Attention where this symbol is displayed on the sterilizer, the user must refer to this document. When shown in the user manual this symbol means attention impo...

Page 7

3 2. Unpacking 2.1 unpacking the sterilizer if the sterilizer had been kept in a place with temperature and humidity different from the installation location, wait for an appro- priate time before installing and switching on the sterilizer. Steri- lizers arriving from cold locations could contain mo...

Page 8

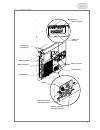

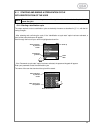

4 3. Unit description 3.1 front view 3.2 service door sliding cover for manual filling of the clean water tank service door chamber door door seal sterilization chamber dust filter touch- screen door pin water tank cover bacteriological filter main switch quick connector for manual draining of used ...

Page 9

5 3.3 rear view circuit breaker (manual reset) mains plug socket condenser vent mains cable guide air filter fitting for continuous draining of used water fitting for an external water supply system female serial port male serial port parallel port (printer) safety valve cover test connection.

Page 10

6 3.4 description of the internal water tanks the sterilizer is equipped with two independent water tanks, one for clean water and one for used water. The tank on the right side is called "clean water tank" and has to be filled with distilled or demineralized water required for the sterilization pro...

Page 11

7 3.5 chamber rack insert the rack into the sterilization chamber, align it at the center/bottom of the chamber and push it gently into position until it clicks. The chamber rack is reversible and can be used for: 5 trays horizontally or 3 cassettes vertically; or, if inserted in a 90° degree rotate...

Page 12

8 4. Installation 4.1 setup the sterilizer has been calibrated and intensively tested in the factory prior to shipping. It does not require any calibration during installation. Observe the following environmental conditions: working temperature range: from +5°c to +40°c / re lative humidity: 0 - 90%...

Page 13

9 4.2 electrical power supply the electrical power supply of the sterilizer must comply with all applicable standards in the country of use. The following characteristics are required: - single - phase 200 - 240 vac ±10%, 50/60 hz, 10 a, on a dedicated circuit . - installation category / mains overl...

Page 14

10 4.4 lisaware - connecting the sterilizer to a computer (optional) connect up to four lisa 517/522 sterilizers to a computer or computer network with lisaware, a computer software that allows automatic saving of cycle data on a computer and the remote monitoring of the cycle progress on the comput...

Page 15

11 4.5 automatic water supply your sterilizer can be connected to an external water supply system and to a continuous drain line. Once connected, the clean water tank will be automatically filled when empty, and the used water will drain con- tinuously. Thus, neither manual filling nor draining are ...

Page 16

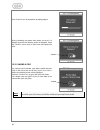

12 5. Getting started 5.1 the user interface to power the sterilizer press the main switch located behind the service door (see image to the left). When the sterilizer is switched on, the chamber automati- cally heats to 120°c. This process (pre-heating) takes approximately 10 minutes. If a steriliz...

Page 17

13 5.2 initial warnings and sleep mode this message will appear if the sterilizer is switched on and the clean water tank is empty. Fill the clean water tank with distilled or demineralized water (see § 5.4). Note: if this message is displayed it is not possible to initiate a sterilization cycle. Th...

Page 18

14 5.4 filling the clean water tank 5.4.1 manual filling use only high quality distilled or demineralized water (see appendix 7). • slide the tank cover to the right to access the clean water tank inlet. • remove the cap (1) from the tank inlet. • insert the funnel and fill the clean water tank with...

Page 19

15 5.5 draining the used water tank when the waste water in the used water tank reaches the maximum level, the following message is displayed: the message will disappear once the used water tank got drained. Keep draining the tank until it is completely empty. 5.5.1 manual draining • open the servic...

Page 20

16 6. Programming lisa 517/522 sterilizers allow the user to program a number of different features. The following section shows step by step how each of these features can be programmed. Press the menu icon to view the list of availa- ble options. The available menu options are shown below: 6.1 set...

Page 21

17 6.1.2 sleep mode in “sleep mode” the sterilizer reduces the power consumption to a minimum. The steri- lizer will switch to sleep mode whenever it is idling without being used. Use this menu to program the time before the sterilizer automat- ically switches to sleep mode. The time range is from 0...

Page 22

18 6.1.10 date format use this menu to change the date format. Press the “scroll up” and “scroll down” icons to select the format. Press the “confirm” icon to save the selection. 6.1.11 clock format use this menu to change the clock format. Press the “scroll up” and “scroll down” icons to select the...

Page 23

19 6.1.15 night cycle shortcut if you frequently use the delayed cycle start option (see § 6.2) you can activate an icon on the main screen (cycle selection screen) that will serve as a shortcut to the delayed cycle start submenu. Select the “night cycle shortcut” option by pressing ”scroll up” and ...

Page 24

20 6.1.16 connection to pc/log use this menu if you want your sterilizer to communicate with a computer in conjunction with the lisaware software package. For further details please see § 4.4. Select the “connection to pc/log?” op- tion by pressing the “scroll up” and “scroll down” icons. Press “con...

Page 25

21 6.2 test cycles use this menu to run a variety of test cycles that might be mandatory in your country. Press the "menu" icon on the main screen and select "test cycles" from the menu (see § 6). Select the test cycle by pressing the ”scroll up” and “scroll down” icons and initiate the cycle by pre...

Page 26

22 6.3 delayed cycle start use this menu to delay the start of one or up to three consecutive cycles (e.G., if you want to load the steri- lizer in the evening and run a vacuum test followed by bowie and dick test or a standard sterilization cycle early the next morning before office hours). It is p...

Page 27

23 6.4 cycle history use this menu to view cycle data of the most recent 30 sterilization and/or test cycles. Cycle data is recorded on the main cpu board on a “first in – first out” basis. Press the “menu” icon on the main screen and se- lect “cycle history” from the menu (see § 6). Use the “scroll...

Page 28

24 6.5 maintenance certain consumables have to be replaced periodically to guarantee a faultless operation of the sterilizer. Display messages will inform you whenever it is time to replace one of those components (see § 8). Press the "menu" icon on the main screen and select "maintenance" from the ...

Page 29

25 6.7.1 system info use this menu to view the sterilizer system information. • model • serial number • firmware revision • loader revision • power fw revision 6.7.2 formatting the memory card use this menu to format your memory card in case you want to erase all the data on the card. Press the “men...

Page 30

26 6.9 functions available for the administrator 6.9.1 access the administrator functions to access the administrator functions: 1) press the “menu” icon on the main screen that appears when the unit is switched on. 2) scroll the options until the “user authentication" option is highlighted and conf...

Page 31

27 5) select the desired option using the scroll buttons and confirm your selection: you can choose the following options: 1) modify a user name 2) change my password 3) reset a user’s passwords to the default value (0000) 4) delete a user 5) add a new user 6) define the user identification options ...

Page 32

28 6.9.3 changing the administrator’s password the default password for the administrator (and for any new user) is 0000. To change the administrator’s password proceed as follows: 1) scroll through the menu options and select the “change my password” option and confirm. 2) enter the new four-digit ...

Page 33

29 6.9.4 resetting a user’s password to the default value (0000) use this function if a user has lost or forgotten his/her own password: it can be reset to "0000" so that the user can then enter with “0000” and save a new valid password. To reset a user’s password proceed as follows: 1) scroll throu...

Page 34

30 6.9.5 deleting a user to delete the name of a user who no longer uses the sterilizer, proceed as follows: 1) scroll through the menu options and select the “delete user” option. 2) select the user to be deleted and confirm 3) confirm the operation abort and return to previous screen confirm the c...

Page 35

31 6.9.6 adding a new user this function allows to create a new user who is permitted to operate the sterilizer. 1) scroll through the menu options, select the “add new user” option and confirm. 2) enter the user name using the up and down buttons to select the correct letter, and previous and next ...

Page 36

32 6.9.7 setting the user identification options for all users depending on the organization of the practice and the traceability requirements, the administrator can set the following options: • - identification and saving of the operator who has started the cycle; • - password-protected cycle start...

Page 37

33 6.10 functions available to the operator(s): password modification proceed as follows: 1) press the “menu” icon on the main screen that appears when the unit is switched on. 2) scroll the menu options and select the “user authentication” option. 3) a list of users will be displayed: scroll throug...

Page 38

34 5) the “change my password” function is now available: select it by pressing the confirmation button. 6) the password keypad appears. Enter your new four-digit password. Warning! The password is saved as soon as the fourth digit has been entered. If you are unsure of the sequence you have entered...

Page 39

35 6.11 starting and ending a sterilization cycle with identification of the user note the instructions in this chapter are valid only if the “user authentication” option is acti- vated. See § 6.8 6.11.1 starting a sterilization cycle the steps required to start a sterilization cycle are basically t...

Page 40

36 6.11.2 end of a sterilization cycle at the end of a cycle when the door is opened, if the “user name at load release” option has been acti- vated, a list of all authorized users will appear. Scroll through the list until your name is highlighted and confirm. - if the “password at load release” op...

Page 41

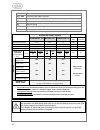

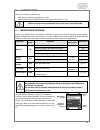

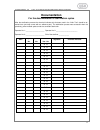

37 7. Running a sterilization cycle 7.1 the available sterilization cycles the following table shows the available sterilization cycles and the different type of loads that can be processed in the sterilizer. In total there are 3 type b sterilization cycles available; all offering the eco- dry featu...

Page 42

38 legend: pv1 – pv3 vacuum pulse (removal of air from the sterilization chamber/load) pp1 - pp2 pressure pulse (steam injection) pph pressure pulse and heating (steam injection and heating to sterilization temp.) pr process (plateau/sterilization/holding time) dv vacuum drying sep water separator d...

Page 43

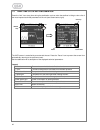

39 7.1.1 starting a sterilization cycle exit from sleep mode by pressing the "sleep mode" icon. Select a cycle by pressing the "cycle selection" icon and confirm the selection by pressing the "se- lection confirmation" icon. Once a cycle is selected and confirmed, the following screen informs about ...

Page 44

40 7.1.3 cycle in-progress while a cycle is in progress, the following parameters are displayed on the touch-screen: • sterilization temperature and pressure – measured inside the chamber. • elapsed time – time elapsed from the beginning of the sterilization cycle. • residual time - time remaining u...

Page 45

41 7.2 manual stop a sterilization cycle in progress can be aborted manually at any time by pressing the manual stop icon. Once pressed, a warning screen will appear asking for a confirmation (see image below, top right). If the manual stop is confirmed, the alarm code a990 (see picture below) is di...

Page 46

42 7.3 real-time cycle data information press the “info” icon at any time during the sterilization cycle or when the sterilizer is idling to view a list of the most important technical parameters of the unit (see screen below, right). The info screen is controlled by an automatic timeout. Press the ...

Page 47

43 7.4 cycle data summary press the "info" icon at the end of a cycle before unlocking the chamber door (see image below, left) to view a summary of the cycle parameters (see images below, middle and right). The information screen lists the following parameters: • cycle name • cycle counter • time/d...

Page 48

44 8. Display messages once the sterilizer is switched on, a variety of messag- es can appear on the touch-screen. Messages show the status of the sterilizer; an example is shown aside. A message counter indicates the number of messages pending (e.G., message 01/02). Messages are divided into three ...

Page 49

45 note: when these messages appear on the screen: • it is not possible to initiate a cycle (the cycle selection icon will disappear). • the message must be acknowledged by pressing the “confirm” icon. • the “yes” or “no” option from the "reset counter" screen must be selected. • the necessary actio...

Page 50

46 9. Alarms lisa sterilizers constantly monitor a variety of parameters during the sterilization cycle to assure a proper sterilization of the load. In case any of the parameters are off, potentially affecting the sterilization efficien- cy, the cycle is immediately interrupted and an alarm message...

Page 51

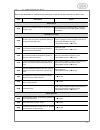

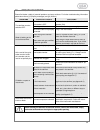

47 10. Alarm code table refer to the table below for troubleshooting assistance in case the sterilizer generates an alarm code. Code description action power supply a010 power failure or significant drop in voltage occurred during the cycle. The load cannot be considered sterile. The cycle must be r...

Page 52

48 code description action vacuum pump a310 during a vacuum phase of the cycle, a vacuum of –0.20 bar or lower could not be achieved. Clean, check or replace the door seal (§11.2) and the face side of the chamber; repeat the cycle. If the problem persists service. A320 during a vacuum phase of the c...

Page 53

49 11. Maintenance there are two levels of maintenance: - maintenance performed regularly by the user. - maintenance carried out by authorized service technicians (see § 11.10). Before carrying out any maintenance on the unit, remove the mains cable. 11.1 maintenance program certain consumables have...

Page 54

50 11.2 cleaning the door seal attention! Operation to be carried out when the sterilization chamber is cold clean the door seal and the chamber face side with a non ab- rasive cloth and a mild detergent solution. Rinse with clean wa- ter. 11.3 cleaning the chamber and chamber components attention! ...

Page 55

51 11.5 cleaning the external sterilizer surfaces • disconnect the mains cable. • never use disinfectants or abrasive products. • clean all external covers with a damp cloth and a mild detergent solution. • do not use excessive amounts of water to wash the sterilizer as this may damage the electrica...

Page 56

52 11.8 cleaning the water tanks • disconnect the mains cable. • completely drain both tanks (see § 5.5). • leave the drain tube attached to one of the drain quick connectors. • turn the 5 screws of the tank cover a ½ turn counter- clockwise with the use of a screwdriver (or coin; see image to the r...

Page 57

53 11.9 replacing the door seal attention! Operation to be carried out when the sterilization chamber is cold • fully open the chamber door of the sterilizer. • pull out the used door seal by hand. • carefully clean the seal seat and the chamber face side with a cotton swab moistened with isopropyl ...

Page 58

54 11.10 service conducted by an authorized service technician regular service is imperative to ensure continuously effective sterilization. Lisa 517/522 sterilizers require servicing every 4000 cycles or 5 years by authorized service technicians. The service includes replace- ment of consumables an...

Page 59

55 12. Use of the memory card lisa 517/522 sterilizers come with a digital cycle data recording system. Cycle data is automatically saved on a removable/rewritable memory card. Data from memory cards can be managed with your pc or mac. Memory cards are supplied with a usb cable and an external usb r...

Page 60

56 12.4 connecting the external usb card reader to your pc/mac to connect the usb reader to your pc/mac, follow these steps: - start the pc/mac - connect the usb reader to a free usb port on your computer. Note 1 most operating systems recognize the usb reader and install the device automatically. I...

Page 61

57 12.9 memory card management as soon as a memory card is inserted the unit automati- cally checks the card. In case the recorder detects that the memory card is damaged or defective, the following screen is shown. Press the “confirm” icon and replace the card. If the card is not formatted or if it...

Page 62

58 if the “confirm” icon is pressed the formatting begins. During formatting the system also checks for errors. If it detects any errors the following screen is displayed. Press the “confirm” icon to return to main menu and replace the card. 12.10 saving a file if a memory card is inserted, cycle da...

Page 63

59 13. Troubleshooting please find below a table of potential problems and easy solutions. For further troubleshooting information please also refer to § 8 (display messages) and § 9 (alarms). Problems potential causes solutions the sterilizer remains switched off. The main switch or network cir- cu...

Page 64

60 14. Recycling / disposal instructions lisa 517/522 sterilizers are mainly built from fiber-reinforced polymers, metals and electronic components. In case of disposal, separate the various components according to the materials they are made of. Drop the sterilizer with a company that specializes o...

Page 65

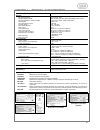

61 appendix 1 technical characteristics electrical supply: single phase 200-240 vac (±10%); 50/60 hz; 10 a sterilizer: working temperature working relative humidity storage temperature / relative humidity max. Altitude min. Atmospheric pressure nominal voltage max. Absorbed power max. Current overal...

Page 66

62 abort and return to previous appendix 2 sterilization load preparation 1. Cleaning the instruments thorough cleaning of all items prior to sterilization is imperative to ensure effective sterilization. If visible debris and bio-burden is not removed through cleaning prior to sterilization, it wil...

Page 67

63 appendix 3 maintenance of dental handpieces 1. External disinfection this procedure reduces the risk of infection during cleaning and maintenance of the instrument. • wear protective gloves during disinfection. • refer to the instructions of the instrument manufacturer. • avoid using abrasive dis...

Page 68

64 appendix 4 bowie and dick test the bowie & dick (b&d) test device, also called steam penetration test device, is representative of the small porous type load. It comprises several sheets of paper wrapped in a small packet in the middle of which there is a chemical heat-sensitive indicator sheet. ...

Page 69

65 appendix 5 helix test the helix test device is representative of the type a hol- low load (en 13060). It consists of a 1,500 mm long tube that is open on one side and closed with a capsule on the other side. An indicator strip is placed inside of the cap- sule. This test is used to validate the s...

Page 70

66 appendix 6 vacuum test use this test to validate the performance of the sterilizer in terms of leakage. During the test the following is checked: • efficiency of the vacuum pump. • tightness of the pneumatic circuit. The cycle profile specific for this test includes: • a vacuum phase up to p1 (-0...

Page 71

67 appendix 7 water quality w&h lisa sterilizers use distilled or demineralized water to generate steam for the sterilization process. Water quality sensors constantly monitor the quality of the water used for sterilization as water of too high mineral content can seriously damage the sterilizer and...

Page 72

68 appendix 8 example of a cycle data report lisa 517 06-5790 0.0.0.0 -------------------------------------- -------------------------------------- -------------------------------------- -------------------------------------- dr. Smith cycle: b universal 134 number: 01898 date: 02/05/06 10:12:30 pha...

Page 73

69 appendix 9 accessories description ordering number printer dp40 19721107 perforated anodized aluminium tray f523204x (lisa 517) f523205x (lisa 522) chamber racks: reversible rack (europe) 190x43x300/375 * 190x43x300/375 * 190x43x300/375 * f523008x (lisa 517) f523009x (lisa 522) reversible rack (u...

Page 74

70 description ordering number door seal f460504x dust filter f364502x wall spacer f190107x usb mmc reader a801002x multi media card a801001x narrow bench securing bracket kit x051019x drain tube mounting kit with fittings a812110x.

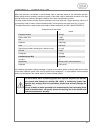

Page 75: Documentation

71 appendix 10 helix test documentation form documentation for the documentation of sterilization cycles after the sterilization process the chemical indicator strip that was used in the “helix test” should be at- tached here (the strip comes with an adhesive part). The sterilization process was suc...

Page 76

Authorized w&h service partners find your nearest w&h service partner at http://wh.Com simply go to the menu option »service« for full details. Alternatively please contact: w&h w&h w&h w&h uk limited uk limited uk limited uk limited, 6 stroud wood business centre, park street, st.Albans, herts al2 ...

Page 78

Manufacturer manufacturer manufacturer manufacturer w&h w&h w&h w&h sterilization s.R.L italy, i-24060 brusaporto (bg), via bolgara, 2 t +39/035/66 63 000 f +39/035/50 96 988 wh.Com wh.Com wh.Com wh.Com um009eng lisa fully automatic 201 10 rev. 4 subject to alterations iso 13485, 93/42/eec – annex i...