- DL manuals

- WABECO

- Lathe

- D2000E

- Operating Instructions Manual

WABECO D2000E Operating Instructions Manual

Operating instructions

Universal Lathes

D2000 E

D2400 E

D3000 E

Walter Blombach GmbH

Tool and Machine Factory

D-42899 Remscheid Am Blaffertsberg 13 Phone: 0049 (2191) 597-0

Fax: 0049 (2191) 597-40

E-Mail: info@wabeco-remscheid.de

D-54673 Neuerburg WABECO Str. 1-10 Phone: 0049 (6564) 9697-0 Fax: 0049 (6564) 9697-25 E-Mail: neuerburg@wabeco-remscheid.de

www.wabeco-remscheid.de

Summary of D2000E

Page 1

Operating instructions universal lathes d2000 e d2400 e d3000 e walter blombach gmbh tool and machine factory d-42899 remscheid am blaffertsberg 13 phone: 0049 (2191) 597-0 fax: 0049 (2191) 597-40 e-mail: info@wabeco-remscheid.De d-54673 neuerburg wabeco str. 1-10 phone: 0049 (6564) 9697-0 fax: 0049...

Page 2: Index

2 index ec-conformity declaration 4 1. Product range 6 1.1 universal lathe d2000 e 6 1.2 universal lathe d2400 e 7 1.3 universal lathe d3000 e 8 2. Drawings and list of parts 9 2.1 headstock 9 2.2 support with motor and cover for d2400 e, d3000 e 10 2.3 leading spindle drive for d2000 e, d2400 e 12 ...

Page 3: Index

3 index 10.2.1 general note 36 10.2.2 application of change gears 36 10.2.3 altering the feeds or thread pitches 37 10.2.4 changing of feeds or thread pitche d3000 e 39 11. Pair of toothed wheels for left-hand thread 40 12. Angle plate with milling table 41 13. Three jaw-chuck and four jaw-chuck 42 ...

Page 4

4 ec – conformity declaration in the name of the manufacturer walter blombach gmbh tool and machine factory based in remscheid and neuerburg d-42871 remscheid postfach 12 01 61 phone: 0049 (2191) 597-0 fax: 0049 (2191) 597-40 d-54673 neuerburg wabeco str. 1-10 phone: 0049 (6564) 9697-0 fax: 0049 (65...

Page 5: Outlay

5 outlay dear customer! Congratulations on choosing the wabeco universal lathe. We have taken great care in its manufacture and we have given it a thorough quality control test. These operating instructions are to help you to work with it safely and properly. After unpacking the machine please check...

Page 6: Technical Data

6 1 . Technical data 1.1 universal lathe d2000 e working range centre distance .......................................................... 350 mm centre height.............................................................. 110 mm work spindle power ........................................................

Page 7: Technical Data

7 1 . Technical data 1.2 universal lathe d2400 e working range centre distance ............................................................. 500 mm centre height................................................................. 110 mm work spindle main drive..............................................

Page 8: Technical Data

8 1 . Technical data 1.3 universal lathe d3000 e working range centre distance ............................................................. 500 mm centre height................................................................. 110 mm work spindle main drive..............................................

Page 9: Drawings and List of Parts

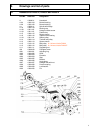

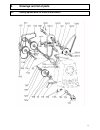

9 2. Drawings and list of parts 2.1 headstock for d2000 e, d2400 e and d3000 e part-no. Order-no. Designation 11 10200011 headstock 1124 10201124 bronze bushing 1128 10201128 bronze bushing 111 10200111 spindle with flange 1118 10201118 bearing cap 11181 10211181 hexagon socket screw 11121 10211121 ...

Page 10: Drawings and List of Parts

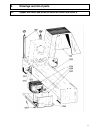

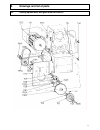

10 2. Drawings and list of parts 2.2 support with motor and protective cover for d2400 e and d3000 e part-no. Order-no. Designation 125 10200125 cover 1251 10201251 stud bolt + radial nut 1252 10201252 support 1253 10201253 potentiometer 1254 10201254 master switch with undervoltage release 1255 102...

Page 11: Drawings and List of Parts

11 2. Drawings and list of parts 2.2 support with motor and protective cover for d2400 e and d3000 e.

Page 12: Drawings and List of Parts

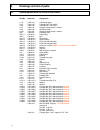

12 2. Drawings and list of parts 2.3 leading spindle drive for d2000 e and d2400 e part-no. Order-no. Designation 1119 10201119 lubricating nipple 1145 10201145 toothed belt z 120 xl037 1146 10201146 toothed belt z 140 xl037 1147 10201147 hexagon socket screw + washer 1149 10201149 quadrant holder 1...

Page 13: Drawings and List of Parts

13 2. Drawings and list of parts 2.3 leading spindle drive for d2000 e and d2400 e.

Page 14: Drawings and List of Parts

14 2. Drawings and list of parts 2.4 leading spindle drive for d3000 e part-no. Order-no. Designation 1 10300001 d.C. Motor 2 10300002 toothed belt 3 10300003 toothed belt pulley 4 10300004 motor bearing 5 10300005 3 screws 6 10300006 bracket 7 10300007 2 scres 8 10300008 2 adjusting nuts 9 10300009...

Page 15: Drawings and List of Parts

15 2. Drawings and list of parts 2.4 leading spindle drive for d3000 e 1 2 3 4 5 7 6 21 20 19 18 17 16 15 14 13 12 11 10 9 8.

Page 16: Drawings and List of Parts

16 2. Drawings and list of parts 2.5 leading spindel drive with gear motor for d2000 e part-no. Order-no. Designation 1152 10101152 support 119 10100119 with a.C. Motor 119 10101120 with rotary current motor 11912 10111912 bearing plate 116 10100116 mounting support of quadrant 1161 10101161 hexagon...

Page 17: Drawings and List of Parts

17 2. Drawings and list of parts 2.5 leading spindle drive with gear motor for d2000 e.

Page 18: Drawings and List of Parts

18 2. Drawings and list of parts 2.6 cross table part-no. Order no. Designation 311 10200311 lower part of cross slide 3111 10203111 nut holder 31111 10231111 bolts + washers 31112 10231112 bronze nut 3112 10203112 bronze nut 3113 10203113 shim 31131 10231131 clamping bolt 3114 10203114 wiper ring 3...

Page 19: Drawings and List of Parts

19 2. Drawings and list of parts 2.6 cross table.

Page 20: Drawings and List of Parts

20 2. Drawings and list of parts 2.7 tailstock part-no. Order-no. Designation 41 10200041 lower part of tailstock 411 10200411 shim 412 10200412 capstan with stud bolt 414 10200414 washer 415 10200415 hexagon nut 42 10200042 upper part of tailstock 421 10200421 quill 422 10200422 flange 1151 1020115...

Page 21: Drawings and List of Parts

21 2 drawings and list of parts 2.8 rear support with guide rods part-no. Order-no. Designation 5 10200005 rear support (only the cast iron part) 51 10200051 guide rods 52 10200052 feed spindle 522 10200522 washer 523 10200523 axial needle bearing 31212 10231212 ball-ended crank 4231 102h4231 spacer...

Page 22: Block Circuit Diagram

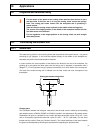

22 3. Block circuit diagram 3.1 for d2000 e and d2400 e mains plug emergency off main switch reversing switch switch for protection cap potentiometer date danger control electronics motor.

Page 23: Block Circuit Diagram

23 3. Block circuit diagram 3.2 for d3000 e p otentiomete r ca p acito r rectifie r transforme r reversin g switch main switch emer g enc y off mains p lu g p otentiomete r control electronics motor feed motor control electronics reversing switch fo r protection cap.

Page 24: Delivery and Installation

24 4. Delivery and installation the lathes are carefully packed in our factory. Please check the following on delivery: 1. Whether the packaging has been damaged and/or: 2. Whether the lathes shows signs of transport damage or if there are grounds for complaint. In this case we request your immediat...

Page 25: Starting-Up and Maintenance

25 5. Starting-up and maintenance i fix the machine on a sturdy, level support use sharp processing tools adjust speed setting and feed to fit the material and diameter of the tool clamp the tools so that the clamping position is as near possible to the workpiece clamp the workpieces fast and withou...

Page 26: 7. Safety

26 7. Safety instructions 1. The feed line for the motor may only be connected to a shock-proof socket or junction box. (have the socket or junction box checked by an electrician beforehand; protection against children being able to put into operation). The socket or junction box must be close enoug...

Page 27: Startup and Maintenance

27 8. Startup and maintenance 8.1 electrical equipment the lathes are fitted with a master switch with undervoltage release, i.E. This switch must be switched on before the machine can be switched on via the reserving switch. The master switch must also be switched on again following a power failure...

Page 28: Startup and Maintenance

28 8. Startup and maintenance 8.4 lubrication prior to every putting into operation all lubricating points of the lathe must receive a grease for roller bearings having commercial quality. Both guiding bars have to be greased, too, preceding every putting into operation. The two dovetail guides of t...

Page 29: Startup and Maintenance

29 8. Startup and maintenance 8.5 initial cleaning of the machine prior to putting the machine into operation for the first time all maked parts have to be cleaned applying petroleum or gasoline used for cleaning, because these parts have been treated with slushing oil before leaving the factory. 8....

Page 30: Startup and Maintenance

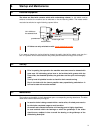

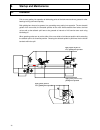

30 8. Startup and maintenance 8.7 compound rest the compound rest consists of a longitudinal and a transverse slide rest. Its dovetail guides are ajustable. Counter nuts longitudinal slide counter nuts transverse hexagon socket screw for tightening the compound rest take-up screw + take-up screw + 8...

Page 31: Startup and Maintenance

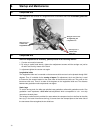

31 8. Startup and maintenance 8.8 tailstock the tailstock is attached to the slide bars in such a way that it is slidable. It can be easily tightened in any position by screwing the lower t-handle (4251). It can be separated into barrel and base. By loosening the spanner bolt (424), the tailstock ba...

Page 32: 9. Speed

32 9. Speed regulation 9.1 speed selection the spindle speed is to be selected according to the type of material and the diameter of the work piece: small diameter ⇒ relatively high speed large diameter ⇒ low speed the cutting speed is the result of speed and diameter. With a known and required cutt...

Page 33: 9. Speed

33 9. Speed regulation 9.1.3 speed setting for working with brass, copper workpiece- Ø approx. R.P.M.. Cutting speed m/min 10 mm 2300 80 20 mm 1270 80 40 mm 640 80 60 mm 425 80 80 mm 320 80 100 mm 250 80 9.2 changing of speed rotational speed 45 - 2300 min-1: the rotational speed of the work spindle...

Page 34: Applications

34 10 . Applications 10.1 longitudinal and transverse turning longitudinal turning: in the case of longitudinal turning tool moves parallel to the axis of the workpiece. For roughing at longitudinal turning the use of either a straight or arcuated turning tool is favourably. Transverse turning: the ...

Page 35: Applications

35 10 . Applications 10.1 longitudinal and transverse turning i for the reason of the power at the turning chisel take care that the tool is short and fast fixed. If the lever arm is to long the turning chisel curves and springs back. The cutting part enters uneven into the workpiece and is producin...

Page 36: Applications

36 10 . Applications 10.2.1 general note feed: the feed is switched on by means of the t-handle on the front side of the spindle head. I when cutting threads it must be remembered that the feed remains on throughout to ensure that the turning chisel always returns to the same positon when cutting mo...

Page 37: Applications

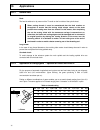

37 10 . Applications 10.2.2 application of change gears - optional for d2000 and d2400 e table automatic longitudinal feed for d2000 - d2400 e mm/ 0,085 0,16 a1 48 48 a2 14 18 b1 48 48 b2 14 20 c 48 48 10.2.3 altering the feeds or thread pitches for d2000 e and d2400 e when altering the feeds or thr...

Page 38: Applications

38 10 . Applications 10.2.3 altering the feeds or thread pitches for d2000 e and d2400 e 2. Changing the feed from 0,085 mm to a metric pitch of 1,5 mm a. - c. Start the procedure exactly as already described under pos. 1, a-c, expect for the hexagonal nut being removed as well from the shearing bus...

Page 39: Applications

39 10 . Applications 10.2.4 changing of feeds or thread pitch for d3000 e 1. Working with the automatic longitudinal feed a. Turn the handle (19) on the symbol longitudinal turning. For the connection of the clutch disk turn with with the handle (31212) a little. B. Switch-on the direction switch on...

Page 40: 11.

40 11. Pair of toothed wheels for left-hand thread to cut left-hand threads, the toothed belt gear no. 11214 on bolt a is to be exchanged for the toothed gear z 75 and the toothed belt gear no. 1114 on the work spindle exchanged for the toothed gear z 50. To do this, proceed in the following manner:...

Page 41

41 12 . Angle plate with milling table for drilling and milling the milling is used to produce flat surfaces and grooves. When milling the advance and feed motion are effected with the angle plate from the workpiece. If the angle plate is correctly mounted on the compound rest (see assembly instruct...

Page 42: Collet Chuck

42 13 . Three jaw-chuck and four jaw-chuck the three-jaw chuck serves to clamp circular, triangular and hexagonal workpieces centrically to the spindle axis. The four-jaw chuck serves to clamp square workpieces centrically to the spindle axis. I danger of accident do not try to clamp larger workpiec...

Page 43: Steady and Follow Rest

43 15 . Steady and follow rest steady and follow rest compensate for the deflection of long shafts caused by resultant cutting forces. The roller jaws of the rests prevent the pieces to be turned form deflection. They are to be adjusted in such a manner that the turning axis of the workpiece is in t...

Page 44: Hand Tool Rest

44 17 . Hand tool rest for turning wood die handstahlauflage wird auf die führungsstangen der drehmaschine montiert. There are two alternative adjustments: 1. By loosening the lower part by means of the knurled screw, the hand tool rest can be adjusted to any position or be swivelled to the workpiec...

Page 45: Unit For Lubrication Coolant

45 19 . Unit for lubrication coolant the unit for lubrication coolant consists of: 1. Tray with lubrication coolant sump which collects the lubrication coolant mixture for the feed pump. Contents generally 19 litres. 2. Feed pump with the following electrical data - nominal voltage 230 v - frequency...

Page 46: 21.

46 20 . Declaration of noise levels in accordance with din en 24871 (german industrial standard) noise levels while running idle acoustic capacity level 67 db (a) sound pressure level on operator’s ear 63 db (a) the stated values reflect emission levels and not necessarily working levels. Although t...