- DL manuals

- Wacker Neuson

- Utility Vehicle

- 0620058

- Repair Manual

Wacker Neuson 0620058 Repair Manual

Summary of 0620058

Page 1

5000192242 02 0912 5 0 0 0 1 9 2 2 4 2 repair manual roller rd 12 en.

Page 2

Copyright notice © copyright 2012 by wacker neuson production americas llc all rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permissio...

Page 3: Rd 12/rd 12A

Rd 12/rd 12a foreword wc_tx000663gb.Fm 3 operating / parts information you must be familiar with the operation of this machine before you attempt to troubleshoot or repair it. Basic operating and maintenance procedures are described in the operator’s manual supplied with the machine. Keep a copy of ...

Page 4: Foreword

Foreword rd 12/rd 12a wc_tx000663gb.Fm 4 california proposition 65 warning: engine exhaust, some of its constituents, and certain vehicle components, contain or emit chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. All rights, especially copyin...

Page 5: Rd 12/rd 12A

Rd 12/rd 12a table of contents 5 1 safety information 9 1.1 operating safety ................................................................................ 10 1.2 operator safety while using internal combustion engines ................ 12 1.3 service safety ...........................................

Page 6: Table of Contents

Table of contents rd 12/rd 12a wc_br0170797en_002toc.Fm 6 5 drive system 48 5.1 checking the tow valve ......................................................................49 5.2 adjusting the drive control cable .......................................................50 5.3 checking the drive syste...

Page 7: Rd 12/rd 12A

Rd 12/rd 12a table of contents 7 9.7 removing the rear drum ................................................................... 71 9.8 installing the rear drum ..................................................................... 73 9.9 removing the brake and brake cable ...............................

Page 8: Table of Contents

Table of contents rd 12/rd 12a wc_br0170797en_002toc.Fm 8 11 technical data 128 11.1 engine ...............................................................................................128 11.2 roller ....................................................................................................

Page 9: Rd 12/rd 12A

Rd 12/rd 12a safety information wc_si000302gb.Fm 9 1 safety information this manual contains danger, warning, caution, notice and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is us...

Page 10: Safety Information

Safety information rd 12/rd 12a wc_si000302gb.Fm 10 1.1 operating safety notice: state health safety codes and public resources codes specify that in certain locations spark arresters be used on internal combustion engines that use hydrocarbon fuels. A spark arrester is a device designed to prevent ...

Page 11: Rd 12/rd 12A

Rd 12/rd 12a safety information wc_si000302gb.Fm 11 1.1.12 always remain aware of changing positions and the movement of other equipment and personnel on the job site. 1.1.13 always remain seated and wear the seat belt at all times while operating the machine. 1.1.14 always remain aware of changing ...

Page 12: Safety Information

Safety information rd 12/rd 12a wc_si000302gb.Fm 12 1.2 operator safety while using internal combustion engines internal combustion engines present special hazards during operation and fueling. Read and follow the warning instructions in the engine owner’s manual and the safety guidelines below. Fai...

Page 13: Rd 12/rd 12A

Rd 12/rd 12a safety information wc_si000302gb.Fm 13 1.3 service safety a poorly maintained machine can become a safety hazard! In order for the machine to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. 1.3.1 some service procedures ...

Page 14: Safety Information

Safety information rd 12/rd 12a wc_si000302gb.Fm 14 1.3.14 keep the area around the muffler free of debris such as leaves, paper, cartons, etc. A hot muffler could ignite the debris and start a fire. 1.3.15 replace worn or damaged components with spare parts designed and recommended by wacker neuson...

Page 15: Rd 12/rd 12A

Rd 12/rd 12a safety information wc_si000302gb.Fm 15 1.4 label locations x ff.

Page 16: Safety Information

Safety information rd 12/rd 12a wc_si000302gb.Fm 16 1.5 safety and operating labels wacker neuson machines use international pictorial labels where needed. These labels are described below: ref. Label meaning a warning! Read and understand the supplied operator’s manual before operating the machine....

Page 17: Rd 12/rd 12A

Rd 12/rd 12a safety information wc_si000302gb.Fm 17 g warning! Hot surface! H warning! Hot surface! I hydraulic oil reservoir fill tube. Torque nuts to 13.6-14.7 nm (120-130 in.Lbs.) maximum. J caution lifting point. K warning! To prevent hearing loss, wear hearing protection when operating this mac...

Page 18: Safety Information

Safety information rd 12/rd 12a wc_si000302gb.Fm 18 t choke: 0 = open l = closed u grease points: inspect and lubricate every 100 hours of operation. V warning! Avoid crushing area. Articulated steering joint locking location. Lock the articulated steering joint before servicing the machine. Read re...

Page 19: Rd 12/rd 12A

Rd 12/rd 12a safety information wc_si000302gb.Fm 19 y a nameplate listing the model number, item number, revision number, and serial number is attached to each unit. Please record the information found on this plate so it will be available should the nameplate become lost or damaged. When ordering p...

Page 20: Safety Information

Safety information rd 12/rd 12a wc_si000302gb.Fm 20 ff this machine may be covered by one or more patents. Ref. Label meaning.

Page 21: Rd 12/rd 12A

Rd 12/rd 12a safety information wc_si000302gb.Fm 21 notes.

Page 22: Operation

Operation rd 12/rd 12a wc_tx000865gb.Fm 22 2 operation 2.1 operation and service locations see graphic: wc_gr002946 ref. Description ref. Description 1 air cleaner 24 operator’s platform 2 articulated joint 25 engine oil filter 3 hand holds 26 rear drum fill/drain plug 4 control panel 27 rear drum—s...

Page 23: Rd 12/rd 12A

Rd 12/rd 12a operation wc_tx000865gb.Fm 23 wc_gr002946 20 5 13 1 21 25 2 23 24 42 32 35 4 8 6 19 44 37 12 43 37 11 18 41 33 29 9 3 31 34 10 15 3 39 40 17 22 28 36 28 30 38 7 16 28 7 27 30 26 33 38 28 14 45.

Page 24: Operation

Operation rd 12/rd 12a wc_tx000865gb.Fm 24 2.2 control panel see graphic: wc_gr004114 ref. Description ref. Description 47 hour meter 55 ignition switch 50 vibration on indicator 56 low fuel indicator 53 lights switch - on and off (if equipped) 61 water spray switch - on and off 54 throttle switch -...

Page 25: Rd 12/rd 12A

Rd 12/rd 12a operation wc_tx000865gb.Fm 25 53 47 54 61 50 62 55 wc_gr004114 56.

Page 26: Operation

Operation rd 12/rd 12a wc_tx000865gb.Fm 26 2.3 vibration see graphic: wc_gr002955 the vibration is turned on or off by a push button (10) located on the forward/reverse control (15). Press the button to turn vibration on; press it again to turn it off. The vibration on indicator (50) will light when...

Page 27: Rd 12/rd 12A

Rd 12/rd 12a operation wc_tx000865gb.Fm 27 2.4 water spray system see graphic: wc_gr002946, wc_gr003638 water from the tank is fed to the spray bars by an electric pump. The flow of the water is controlled by a switch and a rotary dial. Press the upper half of the water spray switch (61) to turn the...

Page 28: Operation

Operation rd 12/rd 12a wc_tx000865gb.Fm 28 2.5 starting see graphic: wc_gr002951 exhaust gases are toxic. Do not start the engine in an enclosed space. 2.5.1 sit down in the operator’s seat and fasten the seat belt. 2.5.2 set the forward/reverse control (15) in the neutral position. 2.5.3 if the eng...

Page 29: Rd 12/rd 12A

Rd 12/rd 12a operation wc_tx000865gb.Fm 29 wc_gr002951 n f r 55 42 44 54 10 15.

Page 30: Operation

Operation rd 12/rd 12a wc_tx000865gb.Fm 30 2.6 stopping/parking see graphic: wc_gr002953 2.6.1 stop the machine on a flat surface with a suitable load bearing capacity. 2.6.2 turn the vibration off by pressing the vibration control button (10) on the forward/reverse lever (15). 2.6.3 press the water...

Page 31: Rd 12/rd 12A

Rd 12/rd 12a operation wc_tx000865gb.Fm 31 2.7 auxiliary battery positive terminal this machine is equipped with an auxiliary battery positive terminal (45) located on top of the hydraulic tank (rd 12) or above the battery disconnect stud (rd 16). Caution! Electric shock hazard. Never touch this ter...

Page 32: Rd 12/rd 12A

Honda engine starting system rd 12/rd 12a wc_tx000693gb.Fm 32 3 honda engine starting system prerequisites before troubleshooting engine starting issues, check the battery and the cable connections to the battery. The battery must be fully charged (approximately 12v). Sequence complete the troublesh...

Page 33: Rd 12/rd 12A

Rd 12/rd 12a honda engine starting system wc_tx000693gb.Fm 33 3.1 checking the 20a main fuse prerequisites key switch in off position. Background there are three 20a fuses protecting the circuits in the rd 12: main electricals voltage regulator circuit optional light circuit procedure follow the pro...

Page 34: Rd 12/rd 12A

Honda engine starting system rd 12/rd 12a wc_tx000693gb.Fm 34 3.2 checking wiring to the starter solenoid & anti-backfire solenoid prerequisites fully-charged (approximately 12v) battery background black wire #20 delivers 12vdc to the starter solenoid when the key is in the start position. If this w...

Page 35: Rd 12/rd 12A

Rd 12/rd 12a honda engine starting system wc_tx000693gb.Fm 35 continued from the previous page. 4. If the engine still won’t start but cranks, remove the anti-backfire solenoid (c) and clean the valve portion of it with carburetor cleaner. Re-install it and try to start the engine. The wiring to the...

Page 36: Rd 12/rd 12A

Honda engine starting system rd 12/rd 12a wc_tx000693gb.Fm 36 3.3 checking the key switch prerequisites multimeter fully-charged (approximately 12v) battery functioning 20a main fuse background the key switch is a three-position switch: on, start, and off. When in the start posi- tion, the key switc...

Page 37: Rd 12/rd 12A

Rd 12/rd 12a honda engine starting system wc_tx000693gb.Fm 37 3.4 checking the crank relay prerequisites multimeter fully-charged (approximately 12v) battery functioning 20a main fuse functioning key switch background the coil of the crank relay is energized when the key switch is in the start posi-...

Page 38: Rd 12/rd 12A

Honda engine starting system rd 12/rd 12a wc_tx000693gb.Fm 38 3.5 checking the neutral switch prerequisites multimeter fully-charged (approximately 12v) battery functioning main fuse functioning key switch seat platform in raised position. See section rear frame access. Background the neutral switch...

Page 39: Rd 12/rd 12A

Rd 12/rd 12a honda engine starting system wc_tx000693gb.Fm 39 3.6 checking the neutral relay prerequisites multimeter fully-charged (approximately 12v) battery functioning 20a main fuse functioning crank relay functioning neutral switch background the neutral relay relays battery voltage to the star...

Page 40: Rd 12/rd 12A

Wacker neuson engine starting system rd 12/rd 12a wc_tx000746gb.Fm 40 4 wacker neuson engine starting system prerequisites before troubleshooting engine starting issues, check the battery and the cable connections to the battery. The battery must be fully charged (approximately 12v). Sequence comple...

Page 41: Rd 12/rd 12A

Rd 12/rd 12a wacker neuson engine starting system wc_tx000746gb.Fm 41 4.1 checking the 20a main fuse prerequisites key switch in off position. Background there are three 20a fuses protecting the circuits in the rd 12: main electricals voltage regulator circuit optional light circuit procedure follow...

Page 42: Rd 12/rd 12A

Wacker neuson engine starting system rd 12/rd 12a wc_tx000746gb.Fm 42 4.2 checking the wiring to the starter solenoid & anti-backfire solenoid prerequisites fully-charged (approximately 12v) battery background black wire #20 delivers 12vdc to the starter solenoid when the key is in the start positio...

Page 43: Rd 12/rd 12A

Rd 12/rd 12a wacker neuson engine starting system wc_tx000746gb.Fm 43 4.3 checking the key switch prerequisites multimeter fully-charged (approximately 12v) battery functioning 20a main fuse background the key switch is a three-position switch: on, start, and off. When in the start posi- tion, the k...

Page 44: Rd 12/rd 12A

Wacker neuson engine starting system rd 12/rd 12a wc_tx000746gb.Fm 44 4.4 checking the crank relay prerequisites multimeter fully-charged (approximately 12v) battery functioning 20a main fuse functioning key switch background the coil of the crank relay is energized when the key switch is in the sta...

Page 45: Rd 12/rd 12A

Rd 12/rd 12a wacker neuson engine starting system wc_tx000746gb.Fm 45 4.5 checking the neutral switch prerequisites multimeter fully-charged (approximately 12v) battery functioning main fuse functioning key switch seat platform in raised position. See section rear frame access. Background the neutra...

Page 46: Rd 12/rd 12A

Wacker neuson engine starting system rd 12/rd 12a wc_tx000746gb.Fm 46 4.6 checking the neutral relay prerequisites multimeter fully-charged (approximately 12v) battery functioning 20a main fuse functioning crank relay functioning neutral switch background the neutral relay relays battery voltage to ...

Page 47: Rd 12/rd 12A

Rd 12/rd 12a wacker neuson engine starting system wc_tx000746gb.Fm 47 5. Check the voltage between terminal 87 (black wire #20) and ground. For this test, the plug (b) must be connected to the crank relay. Position the plug as shown to allow access to terminal 87. Is battery voltage (approximately 1...

Page 48: Drive System

Drive system rd 12/rd 12a wc_tx000667gb.Fm 48 5 drive system background the hydraulic system is powered by two pumps (exciter and drive) mounted in tandem— connected along their shafts through a solid-mounted coupling—and driven directly by the engine crankshaft through a flex coupling. Drive pump t...

Page 49: Rd 12/rd 12A

Rd 12/rd 12a drive system wc_tx000667gb.Fm 49 5.1 checking the tow valve background in order for the machine to operate properly, the tow valve must be completely closed. Procedure follow the procedure below to open and close the tow valve. 1. Turn the shaft of the valve (a) counterclockwise 90° to ...

Page 50: Drive System

Drive system rd 12/rd 12a wc_tx000667gb.Fm 50 5.2 adjusting the drive control cable background if the roller tends to drift in either direction when the forward/reverse control is in neutral, the drive control cable (a) must be adjusted. Prerequisites machine on a hard, level surface engine running ...

Page 51: Rd 12/rd 12A

Rd 12/rd 12a drive system wc_tx000667gb.Fm 51 5.3 checking the drive system operating pressure background failure of the drive circuit to reach operating pressures is normally caused by a worn or damaged drive pump; however, the problem could also be the result of a badly worn motor. Prerequisites m...

Page 52: Drive System

Drive system rd 12/rd 12a wc_tx000667gb.Fm 52 5.4 checking the drive system relief pressure prerequisites machine on a firm, level surface 5000-psi pressure gauge procedure follow the procedure below to check the relief presure. 1. Place blocks in front of and behind both drums to prevent the machin...

Page 53: Rd 12/rd 12A

Rd 12/rd 12a drive system wc_tx000667gb.Fm 53 5.5 checking drive motors for binding background high operating pressures indicate binding in the drive system. Binding can occur in the drive motor or may be the result of a poor or failing drive bearing. Prerequisites machine stopped parking brake on b...

Page 54: Drive System

Drive system rd 12/rd 12a wc_tx000667gb.Fm 54 continued from the previous page. 5. Secure the drum support with an appropriate crane and sling (e). 6. Remove the screws that secure the drum support and remove the drum support. 7. Rotate the drive plate (f) by hand and make sure the motor turns freel...

Page 55: Rd 12/rd 12A

Rd 12/rd 12a drive system wc_tx000667gb.Fm 55 5.6 checking oil flow through the drive motors background the drive motors are plumbed in series. Oil flow through one motor is virtually identical to the flow through the other, unless a problem with one of the motors exists. Procedure follow the proced...

Page 56: Rd 12 / Rd 12A

Vibration system and steering rd 12 / rd 12a wc_tx000668gb.Fm 56 6 vibration system and steering both the vibration and steering system share the same open loop, series circuit, driven by a fixed displacement, gear-type pump (exciter pump). The system includes separate relief valves for vibration an...

Page 57: Rd 12 / Rd 12A

Rd 12 / rd 12a vibration system and steering wc_tx000668gb.Fm 57 6.1 checking the engine speed and vibration speed prerequisites vibrotach vibration must turn on procedure follow the procedure below to check the engine rpm and drum vpm. 1. Start the engine and place the throttle switch in the fast p...

Page 58: Rd 12 / Rd 12A

Vibration system and steering rd 12 / rd 12a wc_tx000668gb.Fm 58 6.2 troubleshooting a system that vibrates poorly prerequisites 3000-psi pressure gauge compactible surface such as a bed of gravel or old tires background the exciter pump is designed to put out a constant flow of oil at a set engine ...

Page 59: Rd 12 / Rd 12A

Rd 12 / rd 12a vibration system and steering wc_tx000668gb.Fm 59 continued from the previous page. 5. Turn on the vibration and measure the relief and operating pressures. The relief pressure is the pressure registered on the gauge as soon as the vibration is turned on. The system will then settle i...

Page 60: Rd 12 / Rd 12A

Vibration system and steering rd 12 / rd 12a wc_tx000668gb.Fm 60 6.3 checking the vibration solenoid valve background when the roller’s engine is running, the solenoid (a) of the vibration manifold (b) receives power through the white wire via the vibration switch. When energized, the vibration sole...

Page 61: Rd 12 / Rd 12A

Rd 12 / rd 12a vibration system and steering wc_tx000668gb.Fm 61 6.4 checking the vibration switch background when the roller’s engine is running, the solenoid of the vibration manifold receives power through the white wire via the vibration switch. To check the function of the vibration electrical ...

Page 62: Steering System

Steering system rd 12/rd 12a wc_tx000669gb.Fm 62 7 steering system 7.1 checking the steering system hydraulic pressure prerequisites 200-bar (3000-psi) pressure gauge procedure follow the procedure below to check the steering system hydraulic pressure. 1. Open the engine compartment. 2. Locate the e...

Page 63: Rd 12/rd 12A

Rd 12/rd 12a steering system wc_tx000669gb.Fm 63 7.2 troubleshooting the steering system background low hydraulic pressure in the steering circuit can be the result of a defective or worn steering valve or poor seals in the steering cylinder. A badly worn exciter pump will affect both the steering a...

Page 64: Spray System

Spray system rd 12/rd 16 wc_tx000670gb.Fm 64 8 spray system 8.1 troubleshooting the spray system prerequisites the machine must be able to start in order to troubleshoot the spray system. If the machine does not start, see engine starting troubleshooting. Components the electrical components of the ...

Page 65: Rd 12/rd 16

Rd 12/rd 16 spray system wc_tx000670gb.Fm 65 8.2 checking power to the spray bar pump prerequisites seat platform in raised position. See section rear frame access. Procedure follow the procedure below to check power to the spray bar pump. 1. Disconnect the wiring from the water pump (a). 2. Place t...

Page 66: Spray System

Spray system rd 12/rd 16 wc_tx000670gb.Fm 66 8.3 checking the pump timer module background the pump timer module is fed power in two locations: via key switch on pink wire #01 via spray system switch on pink wire #18 procedure follow the procedure below to check power to the pump timer module. 1. Re...

Page 67: Rd 12/rd 16

Rd 12/rd 16 spray system wc_tx000670gb.Fm 67 8.4 checking the spray system switch background the spray system switch is fed power via the key switch on pink wire #29. When in the on position, the spray system switch allows power to the pump control timer via pink wire #18. Procedure follow the proce...

Page 68: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 68 9 disassembly & assembly 9.1 tools required for disassembly/assembly procedures it is up to the mechanic to use common sense and good judgment in tool selection to reduce the risk of injury while repairing the machine. In cases where a special ...

Page 69: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 69 9.5 removing the articulating joint prerequisites crane and jacks procedure follow the procedure below to remove the articulating joint. 1. Support the rear half of the machine with jacks and the front half with an appropriate crane so that the...

Page 70: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 70 9.6 installing the articulating joint prerequisites crane and jacks procedure follow the procedure below to install the articulating joint. 1. Support the rear half of the machine with jacks and the front half with an appropriate crane so that ...

Page 71: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 71 9.7 removing the rear drum prerequisites jacks crane and appropriate sling procedure follow the procedure below to remove the rear drum. 1. Chock the front drum. 2. Support the machine with jacks (a). 3. Remove the drum support covers (b). 4. R...

Page 72: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 72 continued from the previous page. 7. Support the drum support with an appropriate sling and crane. 8. Remove the four screws (f) that secure the drum support to the machine and slide the drum (g) from underneath the machine. The procedure to re...

Page 73: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 73 9.8 installing the rear drum prerequisites crane and appropriate sling non-drive-motor side drum support installed procedure follow the procedure below to install the rear drum. 1. Chock the front drum. 2. Install the bearing (h) onto the shaft...

Page 74: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 74 continued from the previous page. 7. Install the brake cable (d) to the drum. 8. Install the drum support covers (b). The procedure to install the rear drum is now complete. Wc_gr004200 d b.

Page 75: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 75 9.9 removing the brake and brake cable prerequisites engine off procedure follow the procedure below to remove the brake. 1. Chock the drums. 2. Remove the drum support cover (a). 3. Remove the screws (b) that secure the brake lever assembly to...

Page 76: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 76 continued from the previous page. 8. Support the rear of the machine with an appropriate crane. 9. Remove the screws (i) that secure the drive plate to the shock mounts. 10.Remove the screws (h) that secure the brake caliper to the drive plate....

Page 77: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 77 9.10 installing the brake and brake cable prerequisites appropriate crane and sling procedure follow the procedure below to install the brake. 1. Raise the rear half of the machine approximately 10 cm (4 in.) off the rear drum. 2. Away from the...

Page 78: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 78 continued from the previous page. 7. Install the two screws (g), nuts, and bracket which secure the cable (h) to the machine. 8. Install the hitch pin (e) and the clevis pin (f). 9. Run the cable through the drum support and connect it to the b...

Page 79: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 79 9.11 removing rear drive motor prerequisites rear drum removed procedure follow the procedure below to remove the rear drive motor. 1. Rotate the drive motor assembly as needed to reach the three screws (a) which mount the drive plate to the dr...

Page 80: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 80 continued from the previous page. 6. Remove the motor guard (g). 7. Remove the brake bracket (h). 8. Remove the drive motor (i) from the drum support. 9. Remove the hydraulic lines (j) and fittings from the drive motor if not already removed. T...

Page 81: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 81 9.12 installing the rear drive motor prerequisites rear drum removed procedure follow the procedure below to install the rear drive motor. 1. Connect the hydraulic lines (j) and fittings to the drive motor. 2. Apply loctite 243 to the screws an...

Page 82: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 82 continued from the previous page. 7. Install the brake assembly (c). See section installing the brake. 8. Using an appropriate crane, position the drum support/drive motor assembly (b) on the drum. Using loctite 243 on the three screws (a), sec...

Page 83: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 83 9.13 removing the front drum prerequisites crane and appropriate sling jacks procedure follow the procedure below to remove the front drum. 1. Support the front half of machine with jacks (a). 2. Remove the drum support covers (b) from each sid...

Page 84: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 84 continued from the previous page. 7. Remove the screws (g) that secure the drum support to the machine. 8. Lift the drum support (h) and drive motor from the machine. 9. Disconnect and plug the hydraulic lines (i) from the exciter motor. Then, ...

Page 85: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 85 9.14 installing the front drum prerequisites crane and appropriate sling jacks procedure follow the procedure below to install the front drum. 1. Slide the drum into position underneath the machine. 2. Apply loctite 243 to the screws (a) and se...

Page 86: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 86 continued from the previous page. 5. Position the drum so that the drive plate can be installed to the three shock mounts (d). Install the drive plate to the drum. Torque the nuts (e) to 76 nm (56 ft.Lbs.). 6. Reconnect the hydraulic lines (f) ...

Page 87: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 87 9.15 removing the front drive motor prerequisites front drum removed puller procedure follow the procedure below to remove the front drive motor. 1. Remove the front drum. See section removing the front drum. 2. Remove the nut (a) that secures ...

Page 88: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 88 9.16 installing the front drive motor prerequisites front drum removed procedure follow the procedure below to install the front drive motor. 1. Apply loctite 243 to the screws and install the drive motor (a) to the drum support (b). Torque the...

Page 89: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 89 9.17 removing the exciter prerequisites front drum removed procedure follow the procedure below to remove the exciter. 1. Remove the screws (a) that secure the drum support (b) to the shock mounts and remove the drum support. 2. Mark (c) the po...

Page 90: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 90 continued from the previous page. 7. Pull the exciter (h) up and out of the drum. The procedure to remove the exciter is now complete. Wc_gr004164 h.

Page 91: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 91 9.18 installing the exciter prerequisites front drum removed drive-motor-side exciter bearing installed procedure follow the procedure below to install the exciter. 1. Install the key and the gear (a) of the exciter motor coupling onto the exci...

Page 92: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 92 continued from the previous page. 5. Using loctite 243 on the six screws (e), secure the bearing cover (f) and the shock mount plate (g) to the drum support. Torque the screws to 50 nm (36 ft.Lbs.). . The procedure to install the exciter is now...

Page 93: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 93 9.19 disassembling the exciter bearings prerequisites front drum removed puller procedure on the exciter side of the drum, two bearings and their flanges make up the drum hub (d). Follow the procedure below to disassemble the exciter bearings. ...

Page 94: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 94 continued from the previous page. 3. On the larger bearing flange, remove the outer seal (i) and use the two set screws (j) to push the outer bearing race (k1) from the larger bearing flange. 4. Remove the inner seal (l) if necessary. In order ...

Page 95: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 95 9.20 assembling the exciter bearings prerequisites front drum removed procedure follow the procedure below to assemble the exciter bearings. 1. Press new inner bearing races (c2 and k2) onto the exciter. 2. Install the outer bearing race into t...

Page 96: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 96 continued from the previous page. 4. Be sure set the screws (j) are recessed on the larger bearing flange (g). Install a new inner seal (l). Lightly grease the outer bearing race and press it into the larger bearing flange. 5. Install a new out...

Page 97: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 97 9.21 removing the control cable and control lever prerequisites machine off and engine cool seat platform in raised position procedure follow the procedure below to remove the control cable and the control lever. 1. Disconnect the control cable...

Page 98: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 98 continued from the previous page. 5. Remove the screws (e) that secure the control lever assembly (f) and remove the con- trol lever assembly from the machine. 6. Disconnect the control cable (a) from the control lever assembly. The procedure t...

Page 99: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 99 9.22 installing the control cable and control lever prerequisites seat platform in raised position procedure follow the procedure below to install the control cable and the control lever. 1. Check that the clamp bracket is positioned correctly....

Page 100: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 100 9.23 removing the exciter pump prerequisites machine off and engine cool hose plug procedure follow the procedure below to remove the exciter pump. 1. Place a plastic sheet and a container under the machine to collect any liquid which drains o...

Page 101: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 101 9.24 installing the exciter pump prerequisites machine off and engine cool. Procedure follow the procedure below to install the exciter pump. 1. Place a plastic sheet and a container under the machine to collect any liquid which drains off. Di...

Page 102: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 102 9.25 removing the drive pump prerequisites machine off and engine cool exciter pump removed procedure follow the procedure below to remove the drive pump. 1. Place a plastic sheet and a container under the machine to collect any liquid which d...

Page 103: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 103 9.26 installing the drive pump prerequisites engine and adapter installed procedure follow the procedure below to install the drive pump. 1. Place a plastic sheet and a container under the machine to collect any liquid which drains off. Dispos...

Page 104: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 104 9.27 removing the engine prerequisites crane and appropriate sling exciter pump and drive pump removed procedure follow the procedure below to remove the engine. 1. Disconnect the harness (a) and the wiring (b). 2. Disconnect the exhaust (c) a...

Page 105: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 105 continued from the previous page. 5. Disconnect the lanyard (g) from the hydraulic tank. 6. Disconnect the air cylinder (h) from the hydraulic tank. Support the hood in the open position. 7. Disconnect and plug the exciter motor hydraulic line...

Page 106: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 106 9.28 installing the engine prerequisites machine off and engine cool. Procedure follow the procedure below to install the engine. 1. Position the engine into the frame. 2. Reconnect the exhaust (a). 3. Apply loctite 243 to the screws and secur...

Page 107: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 107 continued from the previous page. 8. Reconnect the lanyard (g) to the hydraulic tank. 9. Reconnect the air cylinder (h) to the hydraulic tank. 10.Reconnect the exciter motor hydraulic line (i) from the hydraulic tank. 11.Secure the hydraulic t...

Page 108: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 108 9.29 removing the steering valve prerequisites machine off and engine cool. Procedure follow the procedure below to remove the steering valve. 1. Remove the front console panel (a). 2. Remove the cable clamp (b). 3. Remove the small cover (c) ...

Page 109: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 109 continued from the previous page. 7. Remove the screws (g) that secure the bracket (h) to the console. 8. Remove the screws (i) that secure the steering servo. Maneuver the steering valve (j) out of the control console. The procedure to remove...

Page 110: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 110 9.30 installing the steering valve prerequisites machine off and engine cool procedure follow the procedure below to install the steering valve. 1. Position the steering valve (j) and bracket (h) into the control console. Secure the steer- ing...

Page 111: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 111 continued from the previous page. 5. Install the steering wheel and secure it with the nut (d). 6. Install the small cover (c) on the steering wheel. 7. Install the cable clamp (b). 8. Install the front console panel (a) the procedure to insta...

Page 112: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 112 9.31 removing the hydraulic tank prerequisites engine cool procedure follow the procedure below to remove the hydraulic tank. 1. Place a plastic sheet and a container under the machine to collect any liquid which drains off. Dispose of this li...

Page 113: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 113 continued from the previous page. 7. Loosen the hose clamps that secure the hydraulic hoses (d and e) to the drive and exciter pumps. 8. Pull the hydraulic tank from the hydraulic hoses (loosen the fittings if necessary) and out of the frame. ...

Page 114: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 114 9.32 installing the hydraulic tank prerequisites engine cool procedure follow the procedure below to install the hydraulic tank. 1. Place a plastic sheet and a container under the machine to collect any liquid which drains off. Dispose of this...

Page 115: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 115 continued from the previous page. 5. Connect the lanyard (g) and the air cylinder (h) to the hydraulic tank. 6. Connect the three hydraulic lines (a). 7. Fill the hydraulic tank. See section changing hydraulic oil and filter. The procedure to ...

Page 116: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 116 9.33 removing the fuel tank prerequisites machine shut down platform in upright position. See section rear frame access. Procedure follow the procedure below to remove the fuel tank. 1. Drain the fuel from the fuel tank by disconnecting the fu...

Page 117: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 117 continued from the previous page. 5. Disconnect the fuel sensor (e) from the wiring harness. 6. Remove the gas strut brackets (f) from the water tank and the fuel tank. Remove the cable clip (g). 7. Remove the mounting plate (h) from the water...

Page 118: Disassembly & Assembly

Disassembly & assembly rd 12/rd 12a wc_tx000671gb.Fm 118 9.34 installing the fuel tank prerequisites platform in upright position. See section rear frame access. Procedure follow the procedure below to install the fuel tank. 1. Route the fuel level sensor wiring (i) around the control lever side of ...

Page 119: Rd 12/rd 12A

Rd 12/rd 12a disassembly & assembly wc_tx000671gb.Fm 119.

Page 120: Schematics

Schematics rd 12/rd 12a wc_tx001073gb.Fm 120 10 schematics 10.1 hydraulic schematic.

Page 121: Rd 12/rd 12A

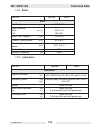

Rd 12/rd 12a schematics wc_tx001073gb.Fm 121 10.2 hydraulic schematic components 10.3 electrical schematic identification—rd 12a use the chart below to determine which electrical schematic applies to your machine. Ref. Description ref. Description 1 steering cylinder 8 return filter 2 steering unit ...

Page 122: Schematics

Schematics rd 12/rd 12a wc_tx001073gb.Fm 122 10.4 electrical schematic “a”—rd 12a.

Page 123: Rd 12/rd 12A

Rd 12/rd 12a schematics wc_tx001073gb.Fm 123 10.5 electrical schematic “a” components—rd 12a ref. Description ref. Description 1 work light switch 16 rear light (optional) 2 throttle switch 17 left head light (optional) 3 pump switch 18 right head light (optional) 4 key switch 19 to magneto kill 5 v...

Page 124: Schematics

Schematics rd 12/rd 12a wc_tx001073gb.Fm 124 10.6 electrical schematic “b”—rd 12a.

Page 125: Rd 12/rd 12A

Rd 12/rd 12a schematics wc_tx001073gb.Fm 125 10.7 electrical schematic “b” components—rd 12a ref. Description ref. Description 1 work light switch 16 rear light (optional) 2 throttle switch 17 left head light (optional) 3 pump switch 18 right head light (optional) 4 key switch 19 to magneto kill 5 v...

Page 126: Schematics

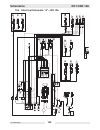

Schematics rd 12/rd 12a wc_tx001073gb.Fm 126 10.8 electrical schematic—rd 12.

Page 127: Rd 12/rd 12A

Rd 12/rd 12a schematics wc_tx001073gb.Fm 127 10.9 electrical schematic components—rd 12 ref. Description ref. Description 1 work light switch 17 left head light (optional) 2 throttle switch 18 right head light (optional) 3 pump switch 19 to magneto kill 4 key switch 20 crank relay 5 vibration indica...

Page 128: Technical Data

Technical data rd 12/rd 12a wc_td000311gb.Fm 128 11 technical data 11.1 engine engine power rating rd 12a: net power rating per sae j1349. Actual power output may vary due to conditions of specific use. Rd 12: gross power rating per sae j1995. Actual power output may vary due to conditions of specif...

Page 129: Rd 12/rd 12A

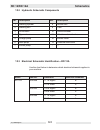

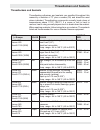

Rd 12/rd 12a technical data wc_td000311gb.Fm 129 11.2 roller 11.3 lubrication item no. Rd 12a rd 12 roller dry weight kg (lb.) 1002 (2171) curb clearance: right left mm (in.) 400 (15.7) 208 (8.2) water tank capacity l (gal.) 100 (26.4) outside turning radius m (ft.) 2.44 (8.0) forward / reverse spee...

Page 130: Technical Data

Technical data rd 12/rd 12a wc_td000311gb.Fm 130 11.4 dimensions mm (in.) 2300 (90.6) 560 (22) 1265 (49.8) 1824 (71.8) 900 (35.4) 1035 (40.8).

Page 131: Rd 12/rd 12A

Rd 12/rd 12a technical data wc_td000311gb.Fm 131 11.5 sound measurements the operating sound level, measured per the requirements of appendix 1, paragraph 1.7.4.F of the ec-machine regulations, is: • the guaranteed sound power level (l wa ): rd 12 = 102 db(a) • the sound pressure level at operator’s...

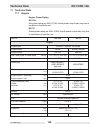

Page 132: Technical Data

Technical data rd 12/rd 12a wc_td000311gb.Fm 132 11.7 hydraulic pressures * values for hard-packed surface shown. Values may differ depending on surface. ** charge pressure: 11.4 – 12.8 bar (165–185 psi). System operating pressure relief pressure bar psi bar psi drive** 55–69 800–1000 200 2900 steer...

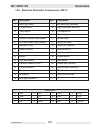

Page 133: Threadlockers and Sealants

Threadlockers and sealants threadlockers and sealants threadlocking adhesives and sealants are specified throughout this manual by a notation of “s” plus a number (s#) and should be used where indicated. Threadlocking compounds normally break down at temperatures above 175°c (350°f). If a screw or b...

Page 134: Threadlockers and Sealants

Threadlockers and sealants threadlockers and sealants (continued) threadlocking adhesives and sealants are specified throughout this manual by a notation of “s” plus a number (s#) and should be used where indicated. Threadlocking compounds normally break down at temperatures above 175°c (350°f). If ...

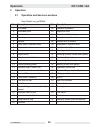

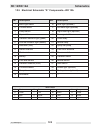

Page 135: Torque Values

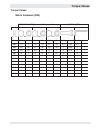

Torque values torque values metric fasteners (din) torque values (based on bolt size and hardness) wrench size size nm ft.Lb. Nm ft.Lb. Nm ft.Lb. Metric inch metric inch m3 1.2 *11 1.6 *14 2.1 *19 5.5 7/32 2.5 – m4 2.9 *26 4.1 *36 4.9 *43 7 9/32 3 – m5 6.0 *53 8.5 6 10 7 8 5/16 4 – m6 10 7 14 10 17 ...

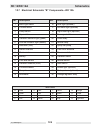

Page 136: Torque Values

Torque values torque values (continued) inch fasteners (sae) size nm ft.Lb. Nm ft.Lb. Nm ft.Lb. Metric inch metric inch no.4 0.7 *6 1.0 *14 1.4 *12 5.5 1/4 – 3/32 no.6 1.4 *12 1.9 *17 2.4 *21 8 5/16 – 7/64 no.8 2.5 *22 3.5 *31 4.7 *42 9 11/32 – 9/64 no.10 3.6 *32 5.1 *45 6.8 *60 – 3/8 – 5/32 1/4 8.1...

Page 138

Wacker neuson se · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02-0 · fax: +49 - (0)89-3 54 02-390 wacker neuson corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker neuson limited - room 1701–03 & 171...