- DL manuals

- Wacker Neuson

- Compact Loader

- 1101C

- Operator's Manual

Wacker Neuson 1101C Operator's Manual

Summary of 1101C

Page 1

Operator’s manual compact loaders 901 s /901 sp 1101 c /1101 cp machine models s03-01 (901s/901sp) s03-02 (1101c/1101cp) edition 2.1 article number 1000185550 language en.

Page 2

Documentation documentation order no. Operator’s manual 1000185550 spare parts catalog de/en/fr (901) 1000187499 spare parts catalog de/en/fr (1101) 1000187759 spare parts catalog de/it/es (901) 1000187501 spare parts catalog de/it/es (1101) 1000187760 copyright © 2014 wacker neuson linz gmbh, hörsc...

Page 3: Table of Contents

Ba 901/1101 en - edition 2.1 * ba91101en2_1ivz.Fm i-1 table of contents table of contents i introduction important information on this operator’s manual ..................................................... 1-1 machine overview ...........................................................................

Page 4: Table of Contents

I-2 ba 901/1101 en - edition 2.1 * ba91101en2_1ivz.Fm table of contents cabin overview (models 901/1101) ......................................................................... 3-2 cabin (models 901/1101): legend ............................................................................ 3-3 inst...

Page 5: Table of Contents

Ba 901/1101 en - edition 2.1 * ba91101en2_1ivz.Fm i-3 table of contents air conditioning (option) ......................................................................................... 3-39 recirculated air mode ........................................................................................

Page 6: Table of Contents

I-4 ba 901/1101 en - edition 2.1 * ba91101en2_1ivz.Fm table of contents hammer operation ................................................................................................. 3-75 installing a hydraulic hammer on the mount .................................................... 3-75 malfunc...

Page 7: Table of Contents

Ba 901/1101 en - edition 2.1 * ba91101en2_1ivz.Fm i-5 table of contents general instructions for all areas of the machine ............................................ 5-30 inside the cabin ............................................................................................... 5-31 under the ...

Page 8: Index

I-6 ba 901/1101 en - edition 2.1 * ba91101en2_1six.Fm index a abbreviations .........................................................................................1-1 accelerator actuation ...........................................................................3-13 air filter .....................

Page 9: Index

Ba 901/1101 en - edition 2.1 * ba91101en2_1six.Fm i-7 index s safety instructions .................................................................................2-1 applications with lifting gear ............................................................2-6 general conduct .........................

Page 10: Index

I-8 ba 901/1101 en - edition 2.1 * ba91101en2_1six.Fm index.

Page 11: Introduction

Ba 901/1101 en – edition 2.1 * 91101b110.Fm 1-1 introduction 1 introduction 1.1 important information on this operator’s manual please store the operator’s manual in the storage box at the rear of the seat. This operator’s manual contains important information on how to work safely, correctly and ec...

Page 12: Introduction

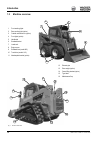

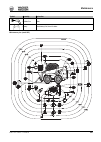

1-2 ba 901/1101 en – edition 2.1 * 91101b110.Fm introduction 1.2 machine overview fig. 1: machine outside views 1 front working lights 2 rear working light (option) 3 outside rearview mirror (option) 4 front lights (option) 5 handholds 6 standard bucket 7 loader unit 8 engine cover 9 standard tires ...

Page 13: Introduction

Ba 901/1101 en – edition 2.1 * 91101b110.Fm 1-3 introduction 1.3 brief description the model 901 and 1101 compact loaders are self-propelled work machines. Get informed on and follow the legal regulations of your country. This machine is a versatile and powerful helper for moving earth, gravel and d...

Page 14: Introduction

1-4 ba 901/1101 en – edition 2.1 * 91101b110.Fm introduction cabin (rops and fops) caution! Modifying or performing improper repair work on the cabin is dangerous. Do not modify the cabin. Repair work may only be performed by a wacker neuson service center. If the cabin has been damaged, check it be...

Page 15: Introduction

Ba 901/1101 en – edition 2.1 * 91101b110.Fm 1-5 introduction 1.4 fields of application, attachments the attachments will decide in the first place how the loader is used. Caution! In order to avoid damage to the machine, only the attachments listed below have been certified for installation on the m...

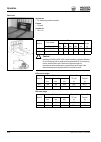

Page 16: Introduction

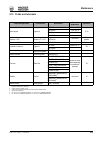

1-6 ba 901/1101 en – edition 2.1 * 91101b110.Fm introduction use: attachment possible attachments description of attachment weight capacity loader remarks standard bucket 219 kg 0.46 m 3 901 loosening, picking up, transporting and loading loose or solid material (material density p = 2 t/m³) 230 kg ...

Page 17: Introduction

Ba 901/1101 en – edition 2.1 * 91101b110.Fm 1-7 introduction 1.5 regulations requirements to be met by the operator earth moving machines may be driven and serviced only by persons who meet the follow- ing requirements: • 18 years or older • physically and mentally suited for this work • persons hav...

Page 18: Introduction

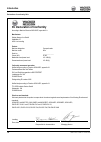

1-8 ba 901/1101 en – edition 2.1 * 91101b110.Fm introduction declaration of conformity 901s ec declaration of conformity according to machine directive 2006/42/ec, appendix ii a manufacturer wacker neuson linz gmbh haidfeldstr. 37 4060 linz-leonding product machine designation: compact loader machin...

Page 19: Introduction

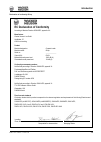

Ba 901/1101 en – edition 2.1 * 91101b110.Fm 1-9 introduction declaration of conformity 901sp ec declaration of conformity according to machine directive 2006/42/ec, appendix ii a manufacturer wacker neuson linz gmbh haidfeldstr. 37 4060 linz-leonding product machine designation: compact loader machi...

Page 20: Introduction

1-10 ba 901/1101 en – edition 2.1 * 91101b110.Fm introduction declaration of conformity 1101c ec declaration of conformity according to machine directive 2006/42/ec, appendix ii a manufacturer wacker neuson linz gmbh haidfeldstr. 37 4060 linz-leonding product machine designation: compact loader mach...

Page 21: Introduction

Ba 901/1101 en – edition 2.1 * 91101b110.Fm 1-11 introduction declaration of conformity 1101cp ec declaration of conformity according to machine directive 2006/42/ec, appendix ii a manufacturer wacker neuson linz gmbh haidfeldstr. 37 4060 linz-leonding product machine designation: compact loader mac...

Page 22: Introduction

1-12 ba 901/1101 en – edition 2.1 * 91101b110.Fm introduction 1.6 type labels and component numbers notice! Type, quantity and position of the labels depend on options, country and machine. Serial number the serial number is stamped on the machine chassis. It is located at the front left on the chas...

Page 23: Introduction

Ba 901/1101 en – edition 2.1 * 91101b110.Fm 1-13 introduction 7/8-digit serial number (up to 2012) notice! Wacker neuson track dumpers still have 7/8-digit serial numbers, even after 2012. 17-digit serial number (from 2012) for easier machine identification, wacker neuson introduced a 17-digit seria...

Page 24: Introduction

1-14 ba 901/1101 en – edition 2.1 * 91101b110.Fm introduction meaning the ce mark means that the machine meets the requirements of the machine directive and that the conformity procedure has been performed. The machine meets all the health and safety requirements of the machine directive. Location o...

Page 25: Introduction

Ba 901/1101 en – edition 2.1 * 91101b110.Fm 1-15 introduction 1.7 signs and symbols warning and safety labels the following states signs and symbols which are not unequivocally comprehensible. They do not contain explanatory text and are not explained in the following chapters. Meaning general indic...

Page 26: Introduction

1-16 ba 901/1101 en – edition 2.1 * 91101b110.Fm introduction meaning stay clear of the working range of the loader unit. Location 2 x on the loader unit on the left and right. Meaning caution: high-pressure fluids can escape location 1 x on the radiator on the right meaning receptacle (pressure acc...

Page 27: Introduction

Ba 901/1101 en – edition 2.1 * 91101b110.Fm 1-17 introduction meaning touch machine parts only after they have come to a full standstill. Location 1 x radiator meaning touch machine parts only after they have come to a full standstill. Location 1 x radiator meaning keep a safe distance from hot surf...

Page 28: Introduction

1-18 ba 901/1101 en – edition 2.1 * 91101b110.Fm introduction meaning do not use the loader unit for raising persons. Location 1 x on the loader unit on the left and right meaning disconnect the battery master switch before performing repair, maintenance and cleaning work. Location 1 x cabin (seat c...

Page 29: Introduction

Ba 901/1101 en – edition 2.1 * 91101b110.Fm 1-19 introduction meaning warns of a hot reservoir or container under pressure location on the hydraulic oil reservoir, on the radiator meaning lock the bucket and the loader unit before performing machine travel on roads. Location cabin (seat console) ope...

Page 30: Introduction

1-20 ba 901/1101 en – edition 2.1 * 91101b110.Fm introduction meaning always read the operator’s manual before starting the machine location cabin roof lining meaning describes the throttle lever function. – see chapter if the engine stalls or if it is stopped, only start the engine again after 6 se...

Page 31: Introduction

Ba 901/1101 en – edition 2.1 * 91101b110.Fm 1-21 introduction meaning noise levels produced by the machine. L wa = sound power level other information – see chapter 6.11 noise levels on page 6-6 location on the cabin options: meaning actuation of pressure reducing valve location inside the cabin on ...

Page 32: Introduction

1-22 ba 901/1101 en – edition 2.1 * 91101b110.Fm introduction meaning 901: from serial number wncs0301hpal00177 1101: from serial number wncs0302tpal00189 environmentally hazardous substances the tank and fuel lines contain diesel fuel according to the adr guidelines (european agreement concerning t...

Page 33: Introduction

Ba 901/1101 en – edition 2.1 * 91101b110.Fm 1-23 introduction 1.8 fire extinguisher the fire extinguisher is neither included in the machine’s standard equipment nor is it available as an option from wacker neuson. ☞ retrofitting a fire extinguisher according to din-en 3 must be performed by an auth...

Page 34: Introduction

1-24 ba 901/1101 en – edition 2.1 * 91101b110.Fm introduction.

Page 35: Safety Instructions

Ba 901/1101 en – edition 2.1 * 91101b210.Fm 2-1 safety instructions 2 safety instructions 2.1 identification of warnings and dangers important indications regarding the safety of the personnel and the machine are identified in this operator’s manual with the following terms and symbols: danger ! Fai...

Page 36: Safety Instructions

2-2 ba 901/1101 en – edition 2.1 * 91101b210.Fm safety instructions 2.3 designated use and exemption from liability • the machine is intended for: • moving earth, gravel, coarse gravel or ballast and rubble as well as for • working with the attachments indicated in chapter fields of application • ev...

Page 37: Safety Instructions

Ba 901/1101 en – edition 2.1 * 91101b210.Fm 2-3 safety instructions 2.4 general conduct and safety instructions organizational measures • the machine has been designed and built in accordance with state-of-the-art standards and the recognized safety regulations. Nevertheless, its use can carry a ris...

Page 38: Safety Instructions

2-4 ba 901/1101 en – edition 2.1 * 91101b210.Fm safety instructions • before working on or with the machine, remove jewelry, such as rings, wristwatches, bracelets, etc., and tie back long hair and do not wear loose-fitting garments, such as unbuttoned or unzipped jackets, ties or scarves. Injury ca...

Page 39: Safety Instructions

Ba 901/1101 en – edition 2.1 * 91101b210.Fm 2-5 safety instructions 2.5 safety instructions regarding operation normal operation • avoid any operational mode that might be prejudicial to safety! • before beginning work, familiarize yourself with the surroundings and circumstances of the job site. Th...

Page 40: Safety Instructions

2-6 ba 901/1101 en – edition 2.1 * 91101b210.Fm safety instructions • avoid any operation that might be a risk to machine stability! • during operation on slopes, perform machine travel or operation uphill or downhill. If performing machine travel across a slope cannot be avoided, bear in mind the t...

Page 41: Safety Instructions

Ba 901/1101 en – edition 2.1 * 91101b210.Fm 2-7 safety instructions trailers and attachments • no trailer operation! • prior to machine travel on public roads, remove all attachments that cannot be secured in compliance with the legal regulations of your country! • attachments and counterweights aff...

Page 42: Safety Instructions

2-8 ba 901/1101 en – edition 2.1 * 91101b210.Fm safety instructions 2.6 safety instructions for maintenance • avoid any operational mode that might be prejudicial to safety! • observe the adjustment, maintenance and inspection activities and intervals set forth in the operator’s manual, including in...

Page 43: Safety Instructions

Ba 901/1101 en – edition 2.1 * 91101b210.Fm 2-9 safety instructions • have loads fastened and crane operators guided by experienced persons only! The person guiding the operator must be within sight or sound of him • always use specially designed or otherwise safety-oriented ladders and working plat...

Page 44: Safety Instructions

2-10 ba 901/1101 en – edition 2.1 * 91101b210.Fm safety instructions 2.7 warning of special hazards electrical energy • use only original fuses with the specified current rating! Switch off the machine immediately and rectify the malfunction if trouble occurs in the electrical system! • during machi...

Page 45: Safety Instructions

Ba 901/1101 en – edition 2.1 * 91101b210.Fm 2-11 safety instructions noise • during operation all sound baffles must be closed • wear ear protectors if necessary! Oil, grease and other chemical substances • when handling oil, grease and other chemical substances (battery electrolyte – sulfuric acid,...

Page 46: Safety Instructions

2-12 ba 901/1101 en – edition 2.1 * 91101b210.Fm safety instructions.

Page 47: Operation

Ba 901/1101 en – edition 2.1 * 91101b320.Fm 3-1 operation 3 operation this chapter describes the controls, and contains information on the function and handling of the indicator lights and controls in the cabin. The pages stated in the table refer to the description of the controls. A combination of...

Page 48: Operation

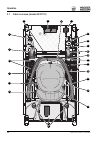

3-2 ba 901/1101 en – edition 2.1 * 91101b320.Fm operation 3.1 cabin overview (models 901/1101) 1 2 3 4 5 7 8 9 10 13 14 15 16 17 18 19 20 21 22 23 12 11 6.

Page 49: Operation

Ba 901/1101 en – edition 2.1 * 91101b320.Fm 3-3 operation 3.2 cabin (models 901/1101): legend pos. Description for more information see page 1 accelerator pedal ..............................................................................................................................................

Page 50: Operation

3-4 ba 901/1101 en – edition 2.1 * 91101b320.Fm operation 3.3 instrument panel overview.

Page 51: Operation

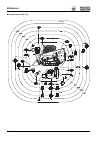

Ba 901/1101 en – edition 2.1 * 91101b320.Fm 3-5 operation opt. ! 24 26 30 34 33 31 44 45 46 47 32 27 48 49 50 51 52 53 28 29 25 39 38 36 35 37 54 42 41 40 43.

Page 52: Operation

3-6 ba 901/1101 en – edition 2.1 * 91101b320.Fm operation 3.4 instrument panel legend pos. Description for more information see page 24 indicator light (red) – air filter ....................................................................................................................................

Page 53: Operation

Ba 901/1101 en – edition 2.1 * 91101b320.Fm 3-7 operation 3.5 indicator lights and warning lights (overview) 28 indicator light (red) – hydraulic oil filter indicates inadmissibly high pressure in the hydraulic return line to the reservoir. In this case: ☞ have the hydraulic oil return filter checke...

Page 54: Operation

3-8 ba 901/1101 en – edition 2.1 * 91101b320.Fm operation 26 indicator light (yellow) – cold starter illuminates if the key in the preheating start switch is in position 2 . A glow plug preheats the air in the combustion chamber of the engine when the key is in this position. 27 indicator light (red...

Page 55: Operation

Ba 901/1101 en – edition 2.1 * 91101b320.Fm 3-9 operation 39 hour meter counts the engine operating hours with the engine running. 25 fuel level indicator the fuel level indicator indicates the remaining amount of fuel in the tank. If the fuel level indicator is in the red range: ➥ refuel the machin...

Page 56: Operation

3-10 ba 901/1101 en – edition 2.1 * 91101b320.Fm operation 3.6 putting into operation safety instructions • only use the steps and handholds provided when entering and leaving the cabin • never use the controls or movable lines and cables as handholds • never get on a moving machine. Never jump off ...

Page 57: Operation

Ba 901/1101 en – edition 2.1 * 91101b320.Fm 3-11 operation check lists the checklists below are intended to assist you in checking and monitoring the machine before, during and after operation. These checklists cannot claim to be exhaustive; they are merely intended as an aid for you in fulfilling y...

Page 58: Operation

3-12 ba 901/1101 en – edition 2.1 * 91101b320.Fm operation operation checklist after starting the engine and during operation, check and observe the following points: parking checklist check and observe the following points when parking the machine: no. Question ✔ 1 anyone in the danger zone of the ...

Page 59: Operation

Ba 901/1101 en – edition 2.1 * 91101b320.Fm 3-13 operation 3.7 performing machine travel preheating start switch (overview) notice! The engine can also be started without lowering the safety bar! Notice! If the engine stalls or if it is stopped, only start the engine again after 6 seconds. Accelerat...

Page 60: Operation

3-14 ba 901/1101 en – edition 2.1 * 91101b320.Fm operation speed control (option) enabling speed control: ☞ press switch 44 ➥ indicator light illuminates disabling speed control: ☞ press switch 44 ➥ indicator light goes out using speed control: ☞ if regulator s is turned toward a and both or one of ...

Page 61: Operation

Ba 901/1101 en – edition 2.1 * 91101b320.Fm 3-15 operation notice! Do not put the machine into operation if a brake test gives a negative result or if there are doubts as to the correct brake function. Contact a wacker neuson ser- vice center and have the malfunction rectified. The following tests a...

Page 62: Operation

3-16 ba 901/1101 en – edition 2.1 * 91101b320.Fm operation starting the engine: general • the starter cannot be actuated if the engine is already running (start repeat interlock) • do not run the starter for more than 10 seconds • wait about 1 minute so the battery and the starter can recover before...

Page 63: Operation

Ba 901/1101 en – edition 2.1 * 91101b320.Fm 3-17 operation starting caution! Actuating the preheating system too long can damage the preheater. ☞ never preheat the engine more than 20 seconds after you have completed the starting preparations: ☞ insert the starting key in the starter ☞ turn the star...

Page 64: Operation

3-18 ba 901/1101 en – edition 2.1 * 91101b320.Fm operation starting with the immobilizer (option) after you have completed the starting preparations: ☞ approach the transponder key to about 2 cm from the emitter/receiver unit a ☞ the machine can be started as soon as the red indicator light b goes o...

Page 65: Operation

Ba 901/1101 en – edition 2.1 * 91101b320.Fm 3-19 operation jump-starting the engine (supply battery) safety instructions • never jump-start the engine if the battery of the machine is frozen – explosion hazard! ☞ dispose of a frozen battery! • the loader must not touch the jump-starting vehicle when...

Page 66: Operation

3-20 ba 901/1101 en – edition 2.1 * 91101b320.Fm operation 3.8 battery master switch caution! Do not disconnect the battery while the engine is running! Notice! Power supply is interrupted directly after the battery, by means of a key • before working on the electrical system • as an antitheft preca...

Page 67: Operation

Ba 901/1101 en – edition 2.1 * 91101b320.Fm 3-21 operation starting at low temperatures caution! In order to warm up the engine and the hydraulic oil, let the engine run warm for at least five minutes before starting machine travel. ☞ turn the starting key to position 2 and hold it in this position ...

Page 68: Operation

3-22 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation 3.9 machine travel on public roads the machine is subject to the: • applicable legal regulations of your country also observe the applicable regulations for accident prevention of your country. Preparing machine travel on public roads notice...

Page 69: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-23 operation installing the bucket lock chain ☞ tilt in bucket e fully ☞ fasten lock chain f with both shackles g on chassis h and bucket e locking the auxiliary hydraulics pedal – see chapter 3.15 auxiliary hydraulics pedal on page 3-59 locking the oper...

Page 70: Operation

3-24 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation h controls: lock the operating hydraulics as follows: ☞ unscrew the wing nut ☞ lower lever 3 unlock the operating hydraulics as follows: ☞ unscrew the wing nut ☞ raise lever 3 caution! The lever must not be in center position correct correct...

Page 71: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-25 operation 3.10 starting machine travel notice! Machine travel will not start unless the safety bar is lowered. After starting the engine: ☞ the alternator charge indicator light goes out ☞ release the parking brake ☞ slowly actuate the drive lever ➥ m...

Page 72: Operation

3-26 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation control levers danger! Any sudden or fast movement of the control levers causes the machine to jerk or jolt uncontrollably – accident hazard! ☞ move the drive levers slowly and controllably danger! The machine has no spring suspension or dam...

Page 73: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-27 operation iso controls . The forward and backward travel speed can be set with the drive lever. For maximum traction force, move the levers fully forward at full engine speed. For safe control of the loader, always move the levers slowly and smoothly....

Page 74: Operation

3-28 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation h controls (option) . Forward or reverse travel speed depends on the position of the drive levers. For maximum traction force, move the levers fully forward at full engine speed. For safe control of the loader, always move the levers slowly ...

Page 75: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-29 operation hydrostatic service brake the control levers automatically return to their initial positions as soon as they are released, which creates sufficient hydraulic braking effect and stops the machine. Parking brake danger! Always apply the parkin...

Page 76: Operation

3-30 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation 3.11 machine travel on slopes follow these safety instructions carefully during machine travel and operation on slopes, in order to avoid accidents. Specific safety instructions ☞ always ensure that the parking brake works correctly before w...

Page 77: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-31 operation machine operation on rough terrain ☞ lower the loader unit and tilt in the bucket fully before starting machine travel. This not only enables you to better estimate your space requirements, but also ensures machine stability. ☞ move the cont...

Page 78: Operation

3-32 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation 3.12 parking the machine danger! Always park the machine on firm ground. Accident hazard! ☞ lower the loader unit to the ground ☞ park the machine on level ground ☞ secure the wheels/tracks accordingly (for example chocks). ☞ stop the machin...

Page 79: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-33 operation 3.13 2nd speed iso controls: press button g on the joystick on the left. The machine moves in 2nd speed. The machine shifts to 1st speed when pressing the button again. Caution! 2nd speed is only for machine travel, and not for machine opera...

Page 80: Operation

3-34 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation 3.15 light system lights (option) the switch panel for the light system is located on the instrument panel. Notice! The rear lights are only installed in the version certified for road traffic (option). The front lights are only installed if...

Page 81: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-35 operation h controls (option): notice! After having pressed button a or b , the turn indicators are active until button c is pressed. Hazard warning system (option) the switch for the hazard warning system is only installed in the version certified fo...

Page 82: Operation

3-36 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation working lights (option) danger! The working lights can blind motorists on public roads. ☞ do not switch on the working lights during machine travel on public roads. When operating the machine, only switch the working lights on when no one ca...

Page 83: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-37 operation 3.16 washer system (option) notice! Do not actuate the washer system if reservoir 22 is empty, otherwise this can damage the electric pump. Washer system reservoir reservoir 22 is located on the right in the leg room. Notice! Add only clean ...

Page 84: Operation

3-38 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation 3.17 ventilation (fully-glazed cabin option) cabin heating and ventilation notice! The cabin is fitted with 4 air nozzles. Each nozzle can be closed and directed separately. Open both nozzles to defrost the front window effectively. • direct...

Page 85: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-39 operation 3.18 air conditioning (option) • in order to achieve best cooling results: ☞ open both nozzles on the left and right behind the seat and direct them to the roof. Keep all other nozzles closed – see ventilation (fully-glazed cabin option) on ...

Page 86: Operation

3-40 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation 3.19 seat adjustment, safety bars and seat belt seat adjustment danger! Never change the seat position during machine travel or operation – see before starting the engine on page 3-15 accident hazard! ☞ adjust the operator seat before starti...

Page 87: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-41 operation horizontal adjustment ☞ sit down on the operator seat ☞ pull lever a upward and at the same time ☞ move the seat forward or backward fig. 84: horizontal seat adjustment a.

Page 88: Operation

3-42 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation safety bars danger! Lower the safety bar immediately before starting the machine. Incorrect use of, or a malfunctioning safety bar – accident and death hazard! ☞ lower the safety bars before starting the machine ☞ immediately have a malfunct...

Page 89: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-43 operation seat belt danger! Do perform machine travel or operation with the seat belt unbuckled – injury hazard! ☞ buckle up before starting machine travel or operation! • seat belt must not be twisted! • seat belt must run over the hips – not over th...

Page 90: Operation

3-44 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation 3.20 emergency exit the rear window can be used as an exit in an emergency. Danger! The machine has neither footholds nor handholds at the rear for a safe exit. Injury hazard! ☞ use the rear window as an exit only in an emergency! • proceed ...

Page 91: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-45 operation 3.22 maintenance flap notice! If it is running, the engine stops immediately if the maintenance flap is opened. The machine can only be started if the maintenance flap is closed. Danger! Closing and opening the maintenance flap – injury haza...

Page 92: Operation

3-46 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation 3.23 cabin raising/lowering the cabin danger! Careful when raising or lowering the cabin – accident hazard! ☞ always tighten lock screws b during machine travel and operation! ☞ park the machine on level and horizontal ground! ☞ close the do...

Page 93: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-47 operation lowering the cabin danger! Incorrect lowering of the cabin – accident and crushing hazard! ☞ ensure that no one is underneath the cabin ☞ remove the tools! ☞ before lowering the cabin all the way down, ensure that no limbs or equipment are s...

Page 94: Operation

3-48 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation cabin entry and exit danger! When leaving the cabin – accident hazard! ☞ bear in mind the following before leaving the cabin: • stop and secure the machine – see parking the machine on page 3-32 • lower the loader unit and the attachments • ...

Page 95: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-49 operation cabin access and exit (fully-glazed cabin option) door notice! Close the door as you put the machine into operation! Opening the door from the outside: ☞ turn door handle a to the right locking the door: ☞ turn the key in door lock b to the ...

Page 96: Operation

3-50 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation front window (with cabin option) danger! Careful when opening the front window – crushing hazard! ☞ stay clear (extremities, clothing) of the window channel ☞ always pull the front window upward with handholds b ☞ always let levers a lock in...

Page 97: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-51 operation 3.24 towing and transporting the machine towing danger! Keep out of the danger zone of the machine – accident hazard! ☞ ensure that no one is in the danger zone of the loader. ☞ ensure that no one is close to the towing equipment (towing bar...

Page 98: Operation

3-52 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation ☞ turn the starting key to position 1 . Ensure that symbol 30 (parking brake indicator light) on the instrument panel has gone out. Caution: do not tow the machine if this symbol illuminates, even if the brake is disabled with the switch. ☞ ...

Page 99: Operation

Ba 901/1101 en – edition 2.1 * 91101b330.Fm 3-53 operation • remove the starting key • leave the cabin, close the engine cover • tying down the machine notice! The manufacturer’s warranty shall not apply to accidents or damage caused by loading or transporting. Tying down the machine danger! The mac...

Page 100: Operation

3-54 ba 901/1101 en – edition 2.1 * 91101b330.Fm operation crane-lifting the machine safety instructions • the crane and the lifting gear must have suitable dimensions! • crane-lifting the machine requires suitable lifting gear! • secure the machine against unintentional movement! Danger! Incorrect ...

Page 101: Operation

Ba 901/1101 en – edition 2.1 * 91101b340.Fm 3-55 operation 3.9 control levers (iso controls) (overview) danger! Unintentional operation of control lever fig. 56/ 20 during machine travel on public roads – accident hazard! ☞ lock the operating hydraulics with switch 46 notice! Fast actuation of the c...

Page 102: Operation

3-56 ba 901/1101 en – edition 2.1 * 91101b340.Fm operation lowering the loader unit with the engine stopped lower the loader unit as follows: ☞ ensure that no one is in the danger zone of the machine ☞ close the safety bars ☞ turn the starting key to position “ 1 ” ☞ push and hold control lever 20 f...

Page 103: Operation

Ba 901/1101 en – edition 2.1 * 91101b340.Fm 3-57 operation 3.10 control lever (h controls) (overview) danger! Unintentional operation of control lever fig. 59/ 5/20 during machine travel on public roads accident hazard! ☞ lock the operating hydraulics with switch 46 notice! Fast actuation of the con...

Page 104: Operation

3-58 ba 901/1101 en – edition 2.1 * 91101b340.Fm operation lowering the loader unit with the engine stopped lower the loader unit as follows: ☞ ensure that no one is in the danger zone of the machine ☞ turn the starting key to position “ 1 ” ☞ keep control lever 5 / 20 pressed to the left ( a ), ➥ u...

Page 105: Operation

Ba 901/1101 en – edition 2.1 * 91101b340.Fm 3-59 operation 3.13 attachment controls (option) use the control lever on the right with 4 buttons if an electrohydraulic multifunctional attachment is installed on the machine. Each push button is assigned to an electric line: press and hold the button to...

Page 106: Operation

3-60 ba 901/1101 en – edition 2.1 * 91101b340.Fm operation auxiliary hydraulics pedal cover danger! Always lower the cover for locking the auxiliary hydraulics if it is not in use, in order to avoid pressing auxiliary hydraulics pedal 2 inadvertently – accident hazard! ☞ always cover auxiliary hydra...

Page 107: Operation

Ba 901/1101 en – edition 2.1 * 91101b340.Fm 3-61 operation 3.18 connections for auxiliary hydraulics connections a and b of the auxiliary hydraulics are both pressure and return lines. Both connections can be connected depending on how the pedal for the auxiliary hydraulics is to be controlled. Noti...

Page 108: Operation

3-62 ba 901/1101 en – edition 2.1 * 91101b340.Fm operation 3.20 re-equipping the loader unit re-equipping the attachments is described below for a standard bucket. If you are fitting or removing attachments with their own hydraulic functions – for example rotary broom or auger – you must follow the ...

Page 109: Operation

Ba 901/1101 en – edition 2.1 * 91101b340.Fm 3-63 operation ☞ raise the attachment. To do this: ☞ tilt in the bucket so that ➥ the upper cutting blade c is about 100 mm above the ground ➥ the rear edge of quickhitch d must have contact with the bucket ☞ stop the engine ☞ apply the parking brake dange...

Page 110: Operation

3-64 ba 901/1101 en – edition 2.1 * 91101b340.Fm operation 3.22 machine operation general safety instructions • never drive up to the edge of a pit from outside – risk of cave-in! • never undermine the foundations of walls – danger of collapse! • do not load under projecting earth. Stones or the pro...

Page 111: Operation

Ba 901/1101 en – edition 2.1 * 91101b340.Fm 3-65 operation transporting with a full bucket danger! Transporting full buckets in the raised position is dangerous – accident hazard! Pay particular attention to this when turning or performing machine travel on slopes. The lower the bucket and the cente...

Page 112: Operation

3-66 ba 901/1101 en – edition 2.1 * 91101b340.Fm operation if the material is hard to penetrate: ☞ proceed as for loading loose material, but in addition: ☞ slightly tilt the bucket in and out ending loading: ☞ tilt in the bucket c ☞ reduce engine speed ☞ reverse out of the material a ☞ raise the bu...

Page 113: Operation

Ba 901/1101 en – edition 2.1 * 91101b340.Fm 3-67 operation ☞ perform forward machine travel 1 once the bucket has penetrated the soil: ☞ set the digging angle slightly flatter 2 • layer being removed is as even as possible and • wheel spin is reduced ☞ proceed as for loading loose material removing ...

Page 114: Operation

3-68 ba 901/1101 en – edition 2.1 * 91101b340.Fm operation further recommendations for digging when planning and performing digging work, we recommend that you observe the following points: • exits from pits must be outside the digging line and as level as possible • dig by removing adjacent strips ...

Page 115: Operation

Ba 901/1101 en – edition 2.1 * 91101b340.Fm 3-69 operation 3.23 attachments notice! Please refer to the operator’s and maintenance manual of the attachment manufacturer for using and performing maintenance on attachments such as rotary brooms, augers, etc. Standard bucket application • for transport...

Page 116: Operation

3-70 ba 901/1101 en – edition 2.1 * 91101b340.Fm operation excavation bucket applications • as standard bucket • fitted with teeth, very good excavation and tearout features features • teeth are flat with underside of bucket • full steel available for • 901, 1101 multipurpose bucket applications • f...

Page 117: Operation

Ba 901/1101 en – edition 2.1 * 91101b340.Fm 3-71 operation lightweight material bucket applications • for picking up and transporting low-density material such as refuse or sawdust • excellent features for clearing snow features • full steel available for • 901, 1101 “4-in-1” bucket applications • m...

Page 118: Operation

3-72 ba 901/1101 en – edition 2.1 * 91101b340.Fm operation “4-in-1” bucket with teeth applications • multipurpose bucket used for a wide range of applications as a normal bucket, grader or grab, or for filling in material. • excavation work performed more easily with teeth features • full steel avai...

Page 119: Operation

Ba 901/1101 en – edition 2.1 * 91101b340.Fm 3-73 operation multipurpose bucket applications • heavy industrial applications in foundries, recycling plants, metal and paper recycling features • full steel • knife-steel base plate available for • 901, 1101 agricultural grab applications • for all agri...

Page 120: Operation

3-74 ba 901/1101 en – edition 2.1 * 91101b340.Fm operation pallet forks applications • for transporting material on pallets features • full steel available for • 901, 1101 caution! According to en474 and iso 14397 (machine stability), payload is defined as 50 % of the tipping load for machines with ...

Page 121: Operation

Ba 901/1101 en – edition 2.1 * 91101b340.Fm 3-75 operation 3.24 hammer operation danger! Before using a hydraulic hammer, always read the operator’s manual of this attachment accident hazard! ☞ the operator’s manual is supplied with the hydraulic hammer! Caution! Always wear protective goggles and e...

Page 122: Operation

3-76 ba 901/1101 en – edition 2.1 * 91101b340.Fm operation.

Page 123: Malfunctions

Ba 901/1101 en – edition 2.1 * 91101b410.Fm 4-1 malfunctions 4 malfunctions the information given in this chapter is provided for maintenance personnel, for fast and reliable detection of malfunctions and their appropriate repair. Repairs must only be performed by authorized personnel. 4.1 engine ma...

Page 124: Malfunctions

4-2 ba 901/1101 en – edition 2.1 * 91101b410.Fm malfunctions insufficient or no engine oil pressure oil level too low 5-5 machine inclination too high (max. 15°) wrong sae grade of engine lubrication oil 5-35 engine oil consumption too high oil level too high 5-5 machine inclination too high (max. 1...

Page 125: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b510.Fm 5-1 maintenance 5 maintenance 5.1 introduction operational readiness and the service life of machines are heavily dependent on maintenance. It is therefore in the interest of the machine owner to perform the mandatory maintenance before performing servicin...

Page 126: Maintenance

5-2 ba 901/1101 en – edition 2.1 * 91101b510.Fm maintenance 5.2 fuel system specific safety instructions • extreme caution is essential when handling fuel – increased fire hazard! • never perform work on the fuel system near open flames or sparks! • do not smoke when working on the fuel system or wh...

Page 127: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b510.Fm 5-3 maintenance notice! Fill up the tank with the correct fuel type at the end of each working day. This prevents condensation water from forming in the fuel tank over night. Do not fill the tank completely but leave some space for the fuel to expand. Stat...

Page 128: Maintenance

5-4 ba 901/1101 en – edition 2.1 * 91101b510.Fm maintenance bleeding the fuel system danger ! If the fuel, as it drains, comes into contact with hot engine parts or the exhaust system, there is an increased fire hazard! ☞ never bleed the fuel system if the engine is hot! Bleed the fuel system in the...

Page 129: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b510.Fm 5-5 maintenance 5.3 engine lubrication system caution! If the engine oil level is too low or if an oil change is overdue, this can cause engine damage and loss of output! ☞ have the oil changed by a wacker neuson service center – see chapter 5.20 maintenan...

Page 130: Maintenance

5-6 ba 901/1101 en – edition 2.1 * 91101b510.Fm maintenance adding engine oil caution! Too much or incorrect engine oil can cause engine damage! For this reason: ☞ do not add engine oil above the max mark of oil dipstick 90/ a ☞ use only the specified engine oil environment! Use a suitable container...

Page 131: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b510.Fm 5-7 maintenance 5.4 engine and hydraulics cooling system the oil and water radiator is located in the engine compartment, behind the engine. The water radiator cools the diesel engine, and the oil cooler cools the hydraulic oil of the travel and operating ...

Page 132: Maintenance

5-8 ba 901/1101 en – edition 2.1 * 91101b510.Fm maintenance checking the coolant level/adding coolant danger ! Never open the coolant reservoir and never drain coolant if the engine is warm since the cooling system is under high pressure burn hazard! ☞ wait at least 15 minutes after stopping the eng...

Page 133: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b510.Fm 5-9 maintenance checking the coolant level ☞ proceed as follows: • park the machine on level ground • stop the engine! • raise the safety bar • remove the key • allow the engine and the coolant to cool down for about 15 minutes • open the engine cover • ch...

Page 134: Maintenance

5-10 ba 901/1101 en – edition 2.1 * 91101b520.Fm maintenance 5.5 air filter caution! The filter cartridge will be damaged if it is washed or brushed out! Bear in mind the following to avoid premature engine wear! ☞ do not clean the filter cartridge ☞ replace the filter cartridge when the indicator l...

Page 135: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b520.Fm 5-11 maintenance replacing the filter • replace outside filter a as follows: ☞ stop the engine ☞ remove the key ☞ let the engine cool down ☞ open the engine cover ☞ remove dirt and dust from the air filter and the area around the air filter ☞ fold bow clip...

Page 136: Maintenance

5-12 ba 901/1101 en – edition 2.1 * 91101b520.Fm maintenance 5.6 v-belts danger! Only check or retighten/replace the v-belts when the engine is stopped – injury hazard! ☞ stop the engine before performing inspection work in the engine compartment! ☞ disconnect the battery or the battery master switc...

Page 137: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b520.Fm 5-13 maintenance retightening the v-belts caution! Overtightening the v-belts can damage the v-belts, the v-belt guide and the water pump bearing. Avoid contact of oil, grease or similar substances with the v-belts. ☞ check the v-belt tension – see checkin...

Page 138: Maintenance

5-14 ba 901/1101 en – edition 2.1 * 91101b520.Fm maintenance checking the v-belt of the air conditioning system (option) caution! Excessive or insufficient tension of the v-belt can cause damage to the v-belt or to the compressor of the air conditioning system. ☞ always ensure that the v-belt has th...

Page 139: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b520.Fm 5-15 maintenance 5.7 hydraulic system specific safety instructions • release the pressure in all lines carrying hydraulic oil prior to any maintenance and repair work. To do this: • lower all hydraulically controlled attachments to the ground • move all co...

Page 140: Maintenance

5-16 ba 901/1101 en – edition 2.1 * 91101b520.Fm maintenance • if the attachment is not positioned as shown: ☞ start the engine and let it run at idling speed ☞ retract the cylinders of the loader unit, lower the bucket to the ground ☞ stop the engine again. ☞ proceed as follows: • park the machine ...

Page 141: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b520.Fm 5-17 maintenance adding hydraulic oil danger! Removing the filler plug can cause oil to escape. Accident hazard! ☞ carefully unscrew the plug to slowly reduce the pressure inside the reservoir. Do not add hydraulic oil unless the engine is stopped. Otherwi...

Page 142: Maintenance

5-18 ba 901/1101 en – edition 2.1 * 91101b520.Fm maintenance checking hydraulic pressure lines specific safety instructions danger! Caution when checking hydraulic lines, especially when searching for leaks. Hydraulic oil escaping under high pressure can penetrate the skin and cause serious injury. ...

Page 143: Maintenance

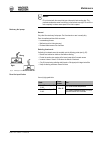

Ba 901/1101 en – edition 2.1 * 91101b530.Fm 5-19 maintenance 5.8 travel gear maintenance danger! Improper travel gear repairs accident hazard! ☞ all repair work on tracks, tires and rims may only be performed by authorized service centers notice! Regular inspections of the tires/tracks • improve ope...

Page 144: Maintenance

5-20 ba 901/1101 en – edition 2.1 * 91101b530.Fm maintenance 5.9 checking drive chain oil (model 901) caution! If the oil level is too low or if an oil change is overdue, this can cause damage or increased wear of the drive chains! ☞ have the oil changed by a wacker neuson service center – see chapt...

Page 145: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b530.Fm 5-21 maintenance 5.10 checking drive chain tension (model 901) danger! Secure the raised machine sufficiently, otherwise extreme accident hazard! ☞ prop the machine on firm ground and with means of sufficient load-bearing capacity. Caution! Too much or not...

Page 146: Maintenance

5-22 ba 901/1101 en – edition 2.1 * 91101b530.Fm maintenance 5.11 tires (model 901) danger! Use of wrong tires or wheels – accident hazard! ☞ use only wheels and tires authorized for your machine ☞ check the wheel nuts for tightness after every wheel or tire change! Caution! The wheels are heavy and...

Page 147: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b530.Fm 5-23 maintenance fitting the wheels ☞ proceed as follows: • place the wheel onto the wheel bolts • tighten all wheel nuts part-way • raise the machine from the jacks and lower it again on firm and level ground • fully tighten the wheel nuts with 175 nm of ...

Page 148: Maintenance

5-24 ba 901/1101 en – edition 2.1 * 91101b530.Fm maintenance 5.12 tracks (model 1101) danger! Use of wrong tracks accident hazard! ☞ use only tracks that have been released for your machine! ☞ check for tightness every time the tracks are changed! Track wear can vary according to work and ground con...

Page 149: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b530.Fm 5-25 maintenance adjusting track tension danger! The lubricating valve can be squeezed out due to the high grease pressure in the hydraulic cylinder. Injury hazard! ☞ do not loosen and unscrew the lubricating valve by more than one turn. ☞ loosen no other ...

Page 150: Maintenance

5-26 ba 901/1101 en – edition 2.1 * 91101b530.Fm maintenance 5.13 replacing tracks proceed as follows: ☞ raising and jacking up the machine ☞ reduce track tension – see chapter reducing track tension on page 5-25 ☞ replace the track ☞ further procedure in the reverse order ☞ check track tension ☞ – ...

Page 151: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b530.Fm 5-27 maintenance draining oil ☞ park the machine on level and horizontal ground ☞ position the machine so that filler plug b is at the bottom ☞ stop the engine ☞ let the engine cool down ☞ raise the safety bars ☞ unscrew screws a and b with a suitable tool...

Page 152: Maintenance

5-28 ba 901/1101 en – edition 2.1 * 91101b530.Fm maintenance servicing and maintenance at regular intervals before performing machine travel ☞ check every time before performing machine travel: • is the light system ok? • is the signaling and warning system ok? Every week ☞ check once a week: • elec...

Page 153: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b530.Fm 5-29 maintenance 5.16 battery danger! Battery acid is highly caustic! Caustic injury hazard! Therefore when recharging and/or working near the battery: ☞ always wear safety glasses and protective clothing with long sleeves! If acid is spilt: ☞ thoroughly r...

Page 154: Maintenance

5-30 ba 901/1101 en – edition 2.1 * 91101b530.Fm maintenance 5.17 general maintenance cleaning cleaning the machine is divided into 3 separate areas: • inside the cabin • exterior of the machine • engine compartment the wrong choice of cleaning equipment and agents can impair the operating safety of...

Page 155: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b530.Fm 5-31 maintenance inside the cabin caution! Never use high-pressure cleaners, steam jets or high-pressure water to clean inside the cabin. Water under high pressure can • penetrate into the electrical system and cause short circuits and • damage seals and d...

Page 156: Maintenance

5-32 ba 901/1101 en – edition 2.1 * 91101b530.Fm maintenance rear window danger! A dirty or foggy rear window offers limited visibility to the rear – accident hazard! ☞ clean the rear window if it is dirty or foggy threaded fittings and attachments all threaded fittings must be checked regularly for...

Page 157: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b530.Fm 5-33 maintenance maintenance prop of loader unit danger! Failure to use loader unit prop a for maintenance on the loader unit, or for maintenance that requires raising the loader unit – accident hazard! ☞ always use the loader unit prop a when performing m...

Page 158: Maintenance

5-34 ba 901/1101 en – edition 2.1 * 91101b530.Fm maintenance 5.18 maintenance if the machine is out of service for a longer period of time caution! If the machine is out of operation, run it once a month without load. Remove the grease from the piston rods first! Preparatory work before taking out o...

Page 159: Maintenance

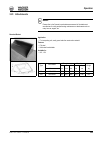

Ba 901/1101 en – edition 2.1 * 91101b530.Fm 5-35 maintenance 5.19 fluids and lubricants component/application fluid/lubricant specification season/ temperature capacities 1 diesel engine engine oil 1 sae 10w below − 5 °c 10.5 l sae 20w20 -10 to +10 °c sae 30 5° to 30 °c sae 10w40 year-round gearbox ...

Page 160: Maintenance

5-36 ba 901/1101 en – edition 2.1 * 91101b530.Fm maintenance oil grades for the diesel engine, depending on temperature engine oil grade ambient temperature (°c) °c -20 -15 -10 -5 0 5 10 15 20 25 30 35 40 sae 10w sae 20w sae 10w-40 dpi, cd, cf, cf-4, ci-4 sae 15w-40 acea a3, b3, e3, acea e3, e4, e5 ...

Page 161: Maintenance Plan (Overview)

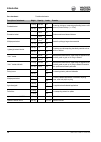

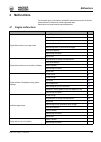

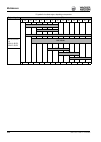

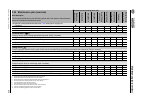

Ba 901/1101 en – edition 2.1 * 9110 1b540.Fm 5-37 maintenance plan (overview) 5.20 maintenance plan (overview) work description for service and maintenance on the attachment, please refer to the operation and maintenance manual of the attachment manufacturer as well. Maintenance plan/operating hours...

Page 162: Mai

5-38 ba 901/1101 en – edi tion 2.1 * 91101b54 0.Fm mai n te na nce pla n (ov erv iew) exhaust gas turbocharger: clean compressor outlet ● ● check valve clearance and adjust every 1500 o/h if necessary ● ● check the fuel injection pump ● ● check the injection pressure ● ● check the injection nozzles ...

Page 163: Maintenance Plan (Overview)

Ba 901/1101 en – edition 2.1 * 9110 1b540.Fm 5-39 maintenance plan (overview) lubricate the following assemblies/components – see traveling drive on page 5-26: • quickhitch ● ● • mobile parts of lock mechanism ● ● • attachments ● ● functional check ( ): check the function of the following assemblies...

Page 164: Maintenance

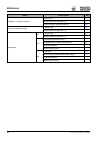

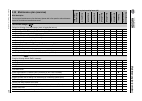

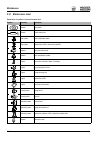

5-40 ba 901/1101 en – edition 2.1 * 91101b560.Fm maintenance 5.21 maintenance label explanation of symbols on the maintenance label symbol assembly explanation general visual check general grease instructions fuel system drain condensation water fuel system replace the fuel filter, clean the fuel pr...

Page 165: Maintenance

Ba 901/1101 en – edition 2.1 * 91101b560.Fm 5-41 maintenance maintenance plan (model 901) symbol assembly explanation radiator fins clean battery check battery fluid, check for leaks.

Page 166: Maintenance

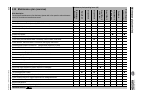

5-42 ba 901/1101 en – edition 2.1 * 91101b560.Fm maintenance maintenance plan (model 1101).

Page 167: Technical Data

Ba 901/1101 en – edition 2.1 * 91101b610.Fm 6-1 technical data 6 technical data 6.1 chassis sturdy steel sheet chassis, rubber-mounted engine 6.2 engine engine type naturally aspirated engine turbocharged engine model (901sp/1101c/1101cp) - •/•/• model (901s – up to serial no. Dc01239) • - model (90...

Page 168: Technical Data

6-2 ba 901/1101 en – edition 2.1 * 91101b610.Fm technical data 6.3 traveling drive 6.4 brakes variable displacement pump models 901s/901sp models 1101c/ 1101cp design infinitely variable axial piston pump with speed-sensitive control displacement 0 – 46 cm³/rev 0 – 46 cm³/rev max. Operating pressure...

Page 169: Technical Data

Ba 901/1101 en – edition 2.1 * 91101b610.Fm 6-3 technical data 6.5 operating hydraulics 6.6 pilot control 6.7 high flow additional control circuit hydraulic pump model 901s models 901sp/ 1101c/1101cp displacement 34 cm³/rev = 88.4 l/min at 2600 rpm 34 cm³/rev = 85 l/ min at 2500 rpm control valve 3 ...

Page 170: Technical Data

6-4 ba 901/1101 en – edition 2.1 * 91101b610.Fm technical data 6.8 electrical system fuse box behind the seat on the left electrical system alternator 14 v 95 ah starter 12 v 2.3 kw battery 12 v 88 ah socket for 12 v power outlet, for example; 15 a max. Fig. 117: fuse box f3 f4 f8 f9 f10 f5 f6 f7 f1...

Page 171: Technical Data

Ba 901/1101 en – edition 2.1 * 91101b610.Fm 6-5 technical data main fuse box with relays relay box at rear left of cabin fig. 118: relay box under the cabin f1 f2 k7 k5 k6 fuse no. Rated current (a) protected circuit f1, f2 80 a – main fuse relay no. Protected circuit k 5 – preheat k 6 – preheating ...

Page 172: Technical Data

6-6 ba 901/1101 en – edition 2.1 * 91101b610.Fm technical data 6.9 tires (model 901) tightening moments: wheel nuts: 175 nm nuts for airboss tire segments: 13 nm notice! Same tire sizes apply to airboss ® tires (option) as to standard tires. 6.10 tracks (model 1101) 6.11 noise levels notice! Measure...

Page 173: Technical Data

Ba 901/1101 en – edition 2.1 * 91101b610.Fm 6-7 technical data 6.12 vibration vibration values indicated in m/s². Directive 2002/44/ec of european parliament and council on minimum health and safety requirements regarding exposure of workers to risks arising from physical agents (vibration). Indicat...

Page 174: Technical Data

6-8 ba 901/1101 en – edition 2.1 * 91101b610.Fm technical data • use a machine and equipment of correct type and size. • follow the manufacturer’s recommendations for maintenance. • tire pressure. • brake and steering systems. • control elements, hydraulic system and linkage. • keep the job site in ...

Page 175: Technical Data

Ba 901/1101 en – edition 2.1 * 91101b610.Fm 6-9 technical data the harmonized data comply with measurements made by international institutes, organi- zations and manufacturers. This publication offers information on the calculation of whole- body vibrations for operators of earth moving machines. Th...

Page 176: Technical Data

6-10 ba 901/1101 en – edition 2.1 * 91101b610.Fm technical data 6.13 coolant compound table 6.14 weights weight of options (selection) notice! The actual machine weight depends on the selected options and must be read off the type label. Add the weight of all subsequently installed equipment to the ...

Page 177: Technical Data

Ba 901/1101 en – edition 2.1 * 91101b610.Fm 6-11 technical data 6.15 dimensions model 901 a b c i h g f e d k l p q o r m n s t v u fig. 120: machine dimensions (model 901) main data model 901 a maximum height 3935 mm b height below bucket joint 3110 mm c cabin height 2055 mm d ground clearance 240 ...

Page 178: Technical Data

6-12 ba 901/1101 en – edition 2.1 * 91101b610.Fm technical data 6.16 dimensions model 1101 main data model 1101 a maximum height 3945 mm b height below bucket joint 3120 mm c cabin height 2065 mm d ground clearance 250 mm e rear projection (rear axle onward) 810 mm f wheelbase 1150 mm g overall leng...

Page 179

Wacker neuson linz gmbh keep abreast of the latest technical developments and con- stantly improve their products. For this reason, we may from time to time need to make changes to figures and descriptions in this documentation which do not reflect products that have already been delivered and that ...

Page 180

Wacker neuson linz gmbh flughafenstr. 7 a-4063 hörsching phone: +43 (0) 7221 63000 fax: +43 (0) 7221 63000-2200 e-mail: office.Linz@wackerneuson.Com www.Wackerneuson.Com order no. 1000185550 language en.