- DL manuals

- Wacker Neuson

- Excavators

- 28Z3

- Operator's Manual

Wacker Neuson 28Z3 Operator's Manual

Summary of 28Z3

Page 1

Track excavator 28z3 operator’s manual 5200005459 1.0 0312 5 2 0 0 0 0 5 4 5 9.

Page 2

Copyright – 2010 wacker neuson linz gmbh, linz-leonding printed in michigan u.S.A all rights reserved no part of this publication may be reproduced, translated or used in any form or by any means – graphic, electronic or mechanical including photocopying, recording, taping or information storage or ...

Page 3: Supplementary Sheet Vds 28Z3

28z3 - ausgabe 1.0 * vds_28z3_en.Fm 1-1 1.1 tilting the upper carriage – vertical digging system 28z3 (option) vertical digging on slopes is possible by tilting the upper carriage hydraulically by 15° with the vds. Tilting the upper carriage: ☞ hold button 1 ☞ press control lever 2  to the right ...

Page 4

1-2 28z3 - ausgabe 1.0 * * vds_28z3_en.Fm vds lubrication points (option) apply grease to lubrication points a once a week. Abb. 2: vds lubrication points a a.

Page 5: Excavators

Edition 1.0 supplementary operator’s manual for protective structures for excavators 1-1 supplementary operator’s manual for protective structures for excavators supplementary operator’s manual for protective structures for excavators edition 1.0 language us article number 1000293107 valid for machi...

Page 6

1-2 edition 1.0 * supplementary operator’s manual for protective structures for excavators supplementary operator’s manual for protective structures for excavators definition of the term “protective structure” protective structures are additional elements that protect the operator or user against ri...

Page 7: Warnung

Edition 1.0 supplementary operator’s manual for protective structures for excavators 1-3 supplementary operator’s manual for protective structures for excavators 1.2 safety symbols found in this manual important indications regarding the safety of the personnel and the machine are identified in this...

Page 8: Warnung

1-4 edition 1.0 * supplementary operator’s manual for protective structures for excavators supplementary operator’s manual for protective structures for excavators 1.3 mechanical integrity warnung warning w accident hazard due to modified cab and protective struc- tures. Incorrect work on the cab an...

Page 9

Edition 1.0 supplementary operator’s manual for protective structures for excavators 1-5 supplementary operator’s manual for protective structures for excavators 1.4 differentiation of protective structures important • machine operation is only allowed with a correctly installed and intact cab , cor...

Page 10

1-6 edition 1.0 * supplementary operator’s manual for protective structures for excavators supplementary operator’s manual for protective structures for excavators definition of fops/front guard categories category i: fops and front guard to protect against small falling objects or small objects pen...

Page 11: Warnung

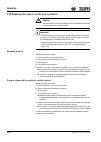

Edition 1.0 supplementary operator’s manual for protective structures for excavators 1-7 supplementary operator’s manual for protective structures for excavators protective fops structure/small screen – category i (option) warnung danger crushing hazard. Falling objects. Objects will cause severe in...

Page 12: Warnung

1-8 edition 1.0 * supplementary operator’s manual for protective structures for excavators supplementary operator’s manual for protective structures for excavators protective fops structure/large screen – category i (option) warnung danger crushing hazard. Falling objects. Objects will cause severe ...

Page 13: Warnung

Edition 1.0 supplementary operator’s manual for protective structures for excavators 1-9 supplementary operator’s manual for protective structures for excavators protective fops structure/canopy – category i (option) warnung danger crushing hazard. Falling objects. Objects will cause severe injury o...

Page 14: Warnung

1-10 edition 1.0 * supplementary operator’s manual for protective structures for excavators supplementary operator’s manual for protective structures for excavators protective fops structure/large screen – category ii (option) warnung danger crushing hazard. Falling objects. Objects will cause sever...

Page 15: Warnung

Edition 1.0 supplementary operator’s manual for protective structures for excavators 1-11 supplementary operator’s manual for protective structures for excavators protective front guard structure with integrated fops/category i respectively (option) warnung danger stabbing/puncture/crushing hazard f...

Page 16: Warnung

1-12 edition 1.0 * supplementary operator’s manual for protective structures for excavators supplementary operator’s manual for protective structures for excavators protective front guard structure category i (option) warnung danger stabbing/puncture/crushing hazard from falling objects (fragments o...

Page 17: Warnung

Edition 1.0 supplementary operator’s manual for protective structures for excavators 1-13 supplementary operator’s manual for protective structures for excavators protective front guard structure category ii (option) warnung danger stabbing/puncture/crushing hazard from falling objects (fragments or...

Page 18: Warnung

1-14 edition 1.0 * supplementary operator’s manual for protective structures for excavators supplementary operator’s manual for protective structures for excavators emergency exit for cab equipped with protective front guard structure warnung warning w cutting hazard. Risk of injury due to broken gl...

Page 19: Warnung

Edition 1.0 supplementary operator’s manual for protective structures for excavators 1-15 supplementary operator’s manual for protective structures for excavators shatter protection (option) warnung danger stabbing/puncture/crushing hazard from falling objects (fragments or splinters) projected from...

Page 20

1-16 edition 1.0 * supplementary operator’s manual for protective structures for excavators supplementary operator’s manual for protective structures for excavators important a shatter protection must be installed on a canopy version if an attachment (a hammer, for instance) causes fragments to fly....

Page 21

Om 28z3 us - edition 2.0 * ba28z3us2_0ivz.Fm i-1 table of contents table of contents i introduction important operator information ................................................................................ 1-1 machine overview ......................................................................

Page 22

I-2 om 28z3 us - edition 2.0 * * ba28z3us2_0ivz.Fm table of contents safety guidelines for maintenance .......................................................................... 2-9 general maintenance notes ............................................................................... 2-9 personal...

Page 23

Om 28z3 us - edition 2.0 * ba28z3us2_0ivz.Fm i-3 table of contents cab heating and ventilation ................................................................................... 3-24 heating adjustment .......................................................................................... 3-25 w...

Page 24

I-4 om 28z3 us - edition 2.0 * * ba28z3us2_0ivz.Fm table of contents rotating the upper carriage ............................................................................. 3-54 rotating upper carriage ................................................................................... 3-55 releasi...

Page 25

Om 28z3 us - edition 2.0 * ba28z3us2_0ivz.Fm i-5 table of contents specific safety instructions ................................................................................ 5-9 draining coolant ............................................................................................... 5-11 a...

Page 26

I-6 om 28z3 us - edition 2.0 * * ba28z3us2_0ivz.Fm table of contents noise levels .............................................................................................................. 6-4 vibration ................................................................................................

Page 27

Om 28z3 us - edition 2.0 * ba28z3us2_0six.Fm i-7 index symbole “hose burst valve” safety feature (option) ............................................3-68 a abbreviations .........................................................................................1-1 air filter ............................

Page 28

I-8 om 28z3 us - edition 2.0 * * ba28z3us2_0six.Fm index s seat adjustment backrest adjustment .....................................................................3-27 horizontal adjustment ...................................................................3-27 weight adjustment ......................

Page 29: 1 Introduction

Om 28z3 us – edition 2.0 * 28z3b110.Fm 1-1 introduction 1 introduction 1.1 important operator information store the operator's manual in the storage compartment at the rear of the seat. This operator's manual contains important information on how to work safely, correctly and economically with the m...

Page 30

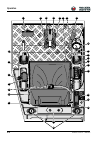

1-2 om 28z3 us – edition 2.0 * * 28z3b110.Fm introduction 1.2 machine overview 1 working lights 2 boom light 3 boom 4 stick 5 rubber tracks 6 undercarriage 7 stabilizer blade 8 cab 9 engine cover 10 handle fig. 1: machine outside views 17 7 10 14 11 16 16 13 13 15 2 17 9 8 1 14 11 fuel filler inlet ...

Page 31

Om 28z3 us – edition 2.0 * 28z3b110.Fm 1-3 introduction 1.3 brief description the model 28z3 excavator is a self-propelled work machine. Get informed on and follow the legal regulations of your country. This machine is a versatile and powerful tool for moving earth, gravel and debris on con- structi...

Page 32

1-4 om 28z3 us – edition 2.0 * * 28z3b110.Fm introduction 1.4 fields of application, attachments the attachments installed determine the intended use of this machine. Notice in order to avoid damage to the machine, only the attachments listed below have been certified for installation on the machine...

Page 33

Om 28z3 us – edition 2.0 * 28z3b110.Fm 1-5 introduction 1.5 operator qualifications requirements to be met by the operator earth moving machines may be operated and serviced only by persons who meet the fol- lowing requirements: • 18 years or older. • physically and mentally suited for this work. • ...

Page 34

1-6 om 28z3 us – edition 2.0 * * 28z3b110.Fm introduction 1.6 ec declaration of conformity for machines delivered before the 29th december 2009 ec declaration of conformity according to ec directive 98/37/ec, 2000/14/ec appendix 6 wacker neuson linz gmbh haidfeldstr. 37 a-4060 linz-leonding declare,...

Page 35: Ec Declaration of Conformity

Om 28z3 us – edition 2.0 * 28z3b110.Fm 1-7 introduction 1.7 ec declaration of conformity for machines delivered after the 29th december 2009 ec declaration of conformity according to machine directive 2006/42/ec, appendix ii a manufacturer wacker neuson linz gmbh haidfeldstr. 37 a-4060 linz-leonding...

Page 36: Declaration of Conformity

1-8 om 28z3 us – edition 2.0 * * 28z3b110.Fm introduction 1.8 declaration of conformity for machines without the ce mark at the type plate declaration of conformity manufacturer wacker neuson linz gmbh haidfeldstr. 37 a-4060 linz-leonding product machine designation: hydraulic excavator machine mode...

Page 37

Om 28z3 us – edition 2.0 * 28z3b110.Fm 1-9 introduction 1.9 type labels and component numbers serial number the serial number is stamped on the machine chassis. It is also located on the type label. The type label is located at the front right on the machine chassis (at cab level) type label informa...

Page 38

1-10 om 28z3 us – edition 2.0 * * 28z3b110.Fm introduction hydraulic quickhitch system powertilt fig. 5: type label (hydraulic quickhitch system) fig. 6: powertilt type label.

Page 39

Om 28z3 us – edition 2.0 * 28z3b110.Fm 1-11 introduction 1.10 symbols (up to ag01685) the following symbols are displayed on the machine to provide pictorial information to the user.The information and explanations are provided to avoid misinterpretation by the user.The symbols have been chosen to p...

Page 40

1-12 om 28z3 us – edition 2.0 * * 28z3b110.Fm introduction description the ce mark means that the machine meets the requirements of the machine directive and that the conformity procedure has been performed. The machine meets all the health and safety requirements of the machine directive. Location ...

Page 41

Om 28z3 us – edition 2.0 * 28z3b110.Fm 1-13 introduction description this safety label warns of the following dangers: cutting hazard. Cooling fan can cut when rotating. Stop engine before working on the engine or cooling system. Entanglement hazard.You can be pinched or entangled in the engine v-be...

Page 42

1-14 om 28z3 us – edition 2.0 * * 28z3b110.Fm introduction description press the boom and the stabilizer blade into the ground as you leave the machine, remove the starting key and place chocks on the left and right under the tracks. – see parking checklist on page 3-8 location cab roof lining descr...

Page 43

Om 28z3 us – edition 2.0 * 28z3b110.Fm 1-15 introduction 1.11 symbols (from ag01686) overview.

Page 44

1-16 om 28z3 us – edition 2.0 * * 28z3b110.Fm introduction symbols the following symbols are displayed on the machine to provide pictorial information to the user. The information and explanations are provided to avoid misinterpretation by the user. The symbols have been chosen to provide important ...

Page 45

Om 28z3 us – edition 2.0 * 28z3b110.Fm 1-17 introduction description hydraulic oil reservoir. Use hydraulic fluid only. Location on the filler cap. Description explains the functions of the joysticks (control pattern ”a”) and of other controls. If the machine is fitted with a “changeover valve”, che...

Page 46

1-18 om 28z3 us – edition 2.0 * * 28z3b110.Fm introduction safety labels always follow the instructions on the safety labels! Description the label means the following: • grease may be ejected under high pressure the track tension system. • always read the operator's manual before loosening or tight...

Page 47

Om 28z3 us – edition 2.0 * 28z3b110.Fm 1-19 introduction description the tank is hot and under pressure! • allow the fluids to cool down! Carefully and slowly open the cover only after the radiator has cooled down, to allow the pressure to escape. Wear safety goggles and gloves when opening the cove...

Page 48

1-20 om 28z3 us – edition 2.0 * * 28z3b110.Fm introduction description indicates that persons other than the driver must keep a safe distance to the machine dur- ing operation. Stay clear of machine! Location on the boom swivelling console on either side of the chassis. Description indicates that pe...

Page 49

Om 28z3 us – edition 2.0 * 28z3b110.Fm 1-21 introduction description before performing maintenance or repairs on the machine, stop the engine, remove the key, and read and understand the operator's manual and the service manual. Before leaving the machine lower all equipment to the ground, remove th...

Page 50

1-22 om 28z3 us – edition 2.0 * * 28z3b110.Fm introduction meaning the powertilt function is enabled once the excavator is started. This function is not assigned. The powertilt unit can be rotated with the slide switch on the right-hand side control lever. Fig. 51: cab label.

Page 51

Om 28z3 us – edition 2.0 * 28z3b110.Fm 1-23 introduction 1.12 fire extinguisher the fire extinguisher is not supplied with the machine. ☞ retrofitting a fire extinguisher according to nfpa must be performed by an authorized wacker neuson service center. ☞ location: ➥ in the cab, on the left in drivi...

Page 52

1-24 om 28z3 us – edition 2.0 * * 28z3b110.Fm introduction.

Page 53: 2 Safety Information

Om 28z3 us – edition 2.0 * 28z3b210.Fm 2-1 safety information 2 safety information 2.1 safety symbols found in this manual this is the safety alert symbol. It is used to alert you to potential personal hazards. • obey all safety messages that follow this symbol. Danger! Danger! Danger indicates a ha...

Page 54

2-2 om 28z3 us – edition 2.0 * * 28z3b210.Fm safety information 2.2 warranty warranty claims must be submitted to your wacker neuson dealer only. 2.3 designated use 1. In accordance with its designated use, the machine may be used only for moving earth, gravel, coarse gravel or ballast and rubble. I...

Page 55

Om 28z3 us – edition 2.0 * 28z3b210.Fm 2-3 safety information • the user/owner commits himself to operate and keep the machine in serviceable condition and, if necessary or required by law, to require the operating or servicing persons to wear protective clothing and safety equipment user training a...

Page 56

2-4 om 28z3 us – edition 2.0 * * 28z3b210.Fm safety information • acoustic and optical warning device â see chapter 3.20  safe load indicator (option)  on page 3-72 â¢Â hose burst valve â see chapter 3.17  âhose burst valveâ safety feature (option)  on page 3-65 â¢Â proper equ...

Page 57

Om 28z3 us – edition 2.0 * 28z3b210.Fm 2-5 safety information 2.5 operator and technician qualifications and basic responsibilities user/owner responsibility • only allow trained and experienced individuals to drive, maintain, or repair the machine. Never let unauthorized or underaged persons operat...

Page 58

2-6 om 28z3 us – edition 2.0 * * 28z3b210.Fm safety information • always adjust the seat position before starting work. Never change the seat position when driving or working! • make sure that all safety devices are properly installed and functional before starting work. • before putting the machine...

Page 59

Om 28z3 us – edition 2.0 * 28z3b210.Fm 2-7 safety information • during operation on slopes, drive or work uphill or downhill. If traveling across a slope cannot be avoided, bear in mind the tilting limit of the machine. Always keep the attachments/work equipment close to the ground. This also applie...

Page 60

2-8 om 28z3 us – edition 2.0 * * 28z3b210.Fm safety information 2.7 applications with lifting gear general information • craning applications are procedures involving raising, transporting and lowering loads with the help of slings and load-securing devices (for example, ropes and tracks). In doing ...

Page 61

Om 28z3 us – edition 2.0 * 28z3b210.Fm 2-9 safety information installation notes • couple and uncouple hydraulic hoses/lines (hydraulic quick couplers) only if the engine is stopped and the controls actuated to release the hydraulic pressure remaining in the circuit. Follow the operating instruction...

Page 62

2-10 om 28z3 us – edition 2.0 * * 28z3b210.Fm safety information personal safety measures • brief the technician and the operator before beginning maintenance or repair work. Appoint someone to supervise the activities. • always work in groups of two when diagnosing a machine problem requiring the e...

Page 63

Om 28z3 us – edition 2.0 * 28z3b210.Fm 2-11 safety information • wear a safety harness when performing elevated maintenance work. Keep all handles, steps, handrails, platforms, landings, and ladders free from dirt, snow and ice. • always use specially designed or otherwise safety-oriented ladders an...

Page 64

2-12 om 28z3 us – edition 2.0 * * 28z3b210.Fm safety information • avoid contact with hot parts, such as the engine block or the exhaust system during the operation of the machine and for some time afterwards – danger of burns! • retainer pins can fly out or splinter when struck with force – danger ...

Page 65

Om 28z3 us – edition 2.0 * 28z3b210.Fm 2-13 safety information msds • when handling oil, grease, and other chemical substances such as battery electrolyte or hydraulic fluid, observe the product-related safety regulations (material safety data sheet (msds). Gas, dust, steam, smoke • operate the mach...

Page 66

2-14 om 28z3 us – edition 2.0 * * 28z3b210.Fm safety information.

Page 67: 3 Operation

Om 28z3 us – edition 2.0 * 28z3b320.Fm 3-1 operation 3 operation this chapter describes the controls, and contains information on the function and handling of the indicator lights and controls in the cab. The pages stated in the table refer to the description of the controls. A combination of digits...

Page 68

3-2 om 28z3 us – edition 2.0 * * 28z3b320.Fm operation 3 16 8 18 10 1 2 17 12 21 24 23 25 26 5 20 22 19 13 15 28 11 6 4 27 29 9.

Page 69

Om 28z3 us – edition 2.0 * 28z3b320.Fm 3-3 operation 3.1 cab overview pos. Description for more information see page 1 hammer pedal for boom swivel ..............................................................................................................................................3-40 2 con...

Page 70

3-4 om 28z3 us – edition 2.0 * * 28z3b320.Fm operation 31 34 30 32 33 35 36 39 38 40 43 44 45 46 37 control element on control console control element on cab wall 39 38 40 42 41 43 44 45 46 control element on cab wall control element on control console control elements for proportional controls vers...

Page 71

Om 28z3 us – edition 2.0 * 28z3b320.Fm 3-5 operation 3.2 instrument panel overview pos. Description for more information see page 30 hydraulic oil filter indicator light (red) ...............................................................................................................................

Page 72

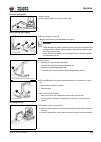

3-6 om 28z3 us – edition 2.0 * * 28z3b320.Fm operation 3.3 operating the excavator caution! Slipping or falling hazard when entering or leaving the operator station. ☞ inspect and confirm that the handholds and steps are undamaged and free of mud and debris. ☞ always use a three point technique with...

Page 73

Om 28z3 us – edition 2.0 * 28z3b320.Fm 3-7 operation check lists the checklists below are intended to assist you in checking and monitoring the machine before, during and after operation. These checklists cannot claim to be exhaustive; they are merely intended as an aid for you in fulfilling your du...

Page 74

3-8 om 28z3 us – edition 2.0 * * 28z3b320.Fm operation operation checklist after starting the engine and during operation, check and observe the following points: parking checklist check and observe the following points when parking the machine: no. Question ✔ 1 anyone dangerously close to the machi...

Page 75

Om 28z3 us – edition 2.0 * 28z3b320.Fm 3-9 operation 3.4 operating the excavator preheating / start switch: overview important! The engine can only be started if the left-hand side control lever base is folded down. Throttle lever: overview the throttle lever controls the engine speed as follows: • ...

Page 76

3-10 om 28z3 us – edition 2.0 * * 28z3b320.Fm operation indicator lights and warning lights: overview 30 hydraulic oil filter indicator light (red) indicates inadmissibly high pressure in the hydraulic return line to the reservoir. In this case: ☞ have the hydraulic oil return filter checked and, if...

Page 77

Om 28z3 us – edition 2.0 * 28z3b320.Fm 3-11 operation 34 cold starter indicator light (yellow) comes on if the key in the preheating start switch is in position 2 . A glow plug preheats the air in the combustion chamber of the engine when the key is in this position. 35 indicator light (red) – safe ...

Page 78

3-12 om 28z3 us – edition 2.0 * * 28z3b330.Fm operation before starting the engine ☞ adjust seat position and rearview mirror – see seat adjustment on page 3-26 important! Adjust the seat so that the operator controls are comfortable to use and can be moved throughout the full range of motion withou...

Page 79

Om 28z3 us – edition 2.0 * 28z3b330.Fm 3-13 operation starting with the drive interlock (option) after you have completed the starting preparations: 1 approach the transponder key to about 2 cm (0.78 in.) to the emitter/receiver unit 29 2 the machine can be started as soon as the red indicator light...

Page 80

3-14 om 28z3 us – edition 2.0 * * 28z3b330.Fm operation when the engine has started ... ☞ check whether all indicator lights have gone out: ☞ let the engine warm up at cold temperatures: ☞ increase the engine speed slowly ☞ do not run the engine at full load until it has reached its operating temper...

Page 81

Om 28z3 us – edition 2.0 * 28z3b330.Fm 3-15 operation procedure ☞ move the jump-starting vehicle close enough to the machine so that the jump leads can reach to connect the two batteries. ☞ let the engine of the jump-starting vehicle run. ☞ first connect one end of the red jump lead ( + ) to the + t...

Page 82

3-16 om 28z3 us – edition 2.0 * * 28z3b330.Fm operation special instructions for operating on public roads the machine is subject to the: • applicable legal regulations of your country also observe the applicable regulations for accident prevention of your country. Traveling operation important! The...

Page 83

Om 28z3 us – edition 2.0 * 28z3b330.Fm 3-17 operation high speed the machine has two speed ranges which can be selected as follows: ☞ press switch – see instrument panel overview on page 3-5 ➥ the machine now moves at higher speed or ☞ press and hold switch a on the left-hand side drive lever ➥ this...

Page 84

3-18 om 28z3 us – edition 2.0 * * 28z3b330.Fm operation 3.5 operating on slopes specific safety instructions warning! Tip-over hazards. Follow these safety instructions carefully when operating on slopes. • raise the bucket about 20 – 30 cm (8’’—12’’) off the ground as you move the machine. Avoid re...

Page 85

Om 28z3 us – edition 2.0 * 28z3b330.Fm 3-19 operation operating on slopes proceed as follows to prevent the machine from tipping over or slipping sideways. ☞ when traveling uphill, keep the attachment about 20 – 30 cm (8’’—12’’)above the ground. In an emergency, lower the attachment immediately to t...

Page 86

3-20 om 28z3 us – edition 2.0 * * 28z3b330.Fm operation stabilizer blade operation important! Possible loss of machine control. Stabilizer blade lever is unprotected and can be moved unintentionally. • avoid moving the stabilizer blade lever inadvertently. Notice possibility of equipment damage. Low...

Page 87

Om 28z3 us – edition 2.0 * 28z3b330.Fm 3-21 operation 3.6 stopping and parking the machine important! Possibility of inadvertent machine movement. To avoid unintentional movement of the machine once it has been parked: • park the machine on level, stable ground. • place stop chocks at the ends of th...

Page 88

3-22 om 28z3 us – edition 2.0 * * 28z3b330.Fm operation parking the machine on slopes ☞ avoid stopping the machine abruptly. Always make sure there is enough space for stopping the machine. • park the machine on level ground with sufficient bearing capacity. Never park on slopes. If you cannot avoid...

Page 89

Om 28z3 us – edition 2.0 * 28z3b330.Fm 3-23 operation 3.7 light system the switch panel for the light system is located on the instrument panel. Roof lights (option) warning! Traffic accident hazard. Working lights can temporarily blind motorists on pub- lic roads. • do not switch on the working lig...

Page 90

3-24 om 28z3 us – edition 2.0 * * 28z3b330.Fm operation interior light rotating beacon (option) important! Observe the legal regulations of your country for operating the rotating beacon. 3.8 cab heating and ventilation important! • do not place flammable or explosive material or objects near the no...

Page 91

Om 28z3 us – edition 2.0 * 28z3b330.Fm 3-25 operation heating adjustment adjust cab temperature as follows: • cooling: ☞ turn heater valve 1 towards a until you reach the required temperature. • heating: ☞ turn heater valve 1 towards b until you reach the required temperature. Important! To increase...

Page 92

3-26 om 28z3 us – edition 2.0 * * 28z3b330.Fm operation tank for washer system the tank's filler inlet is located in the engine compartment. Important! Use a blended mix of water and windshield washer fluid. A blended mix will mini- mize freeze damage, prolong wiper life, and reduce streaking. In wi...

Page 93

Om 28z3 us – edition 2.0 * 28z3b330.Fm 3-27 operation weight adjustment important! Adjust the seat suspension correctly to ensure a high level of ride comfort. Use the lever to adjust the seat suspension. Adjust the seat only without load! Adjust the seat to the driver's weight as follows: ➥ less sp...

Page 94

3-28 om 28z3 us – edition 2.0 * * 28z3b330.Fm operation 3.11 seat belt warning! Personal injury hazard. The seat belt provides positive support in the operator seat during operation and travel that keeps the operator located within the comfort zone for control operation. It also reduces the risk of ...

Page 95

Om 28z3 us – edition 2.0 * 28z3b330.Fm 3-29 operation unfastening the seat belt: ☞ unfasten seat belt 12 as follows: • hold the seat belt. • press red catch c on buckle b. ➥ latch a is released from buckle b by spring pressure. • slowly return the seat belt to the retractor. Longer/shorter lap belt ...

Page 96

3-30 om 28z3 us – edition 2.0 * * 28z3b330.Fm operation 3.13 front window caution! Crush hazard. Sliding window can pinch or crush extremities. • keep extremities and clothing free of the window run. Always pull the front window upward with both handles b ! Always let levers a lock into place on eit...

Page 97

Om 28z3 us – edition 2.0 * 28z3b330.Fm 3-31 operation 3.14 door important! Possibility of equipment damage or injury to others. An open door on a moving machine may slam against the machine, damaging the door frame or window glass. The door may also strike nearby objects or people. • always make sur...

Page 98

3-32 om 28z3 us – edition 2.0 * * 28z3b330.Fm operation releasing the door opener: pull button e to release the door from the latch. 3.15 side window opening the side window: ☞ press button f up. ☞ at the same time, move the window to one of the positions marked with seven arrows. 3.16 engine cover ...

Page 99

Om 28z3 us – edition 2.0 * 28z3b330.Fm 3-33 operation 3.17 exit through the door caution! Personal injury hazard. Before entering or leaving the operator station, confirm that the stepping surfaces are clean and firm to avoid slipping or tripping. ☞ take the following steps before entering or leavin...

Page 100

3-34 om 28z3 us – edition 2.0 * * 28z3b330.Fm operation 3.18 armrest adjustment adjust the armrest as follows: ☞ loosen knurled screw a. ➥ the armrest can be adjusted by raising or lowering it. ☞ retighten knurled screw a. 3.19 towing the track excavator towing warning! Personal injury hazard. Use e...

Page 101

Om 28z3 us – edition 2.0 * 28z3b330.Fm 3-35 operation ☞ make sure the excavator can be towed safely. ☞ use towing bracket a for towing the machine. ☞ do not use towing bracket a to tow another machine, other equipment, or trailers. ☞ secure clevis b with the clevis pin and a lock pin. ☞ mount a towi...

Page 102

3-36 om 28z3 us – edition 2.0 * * 28z3b330.Fm operation 3.20 lifting excavator safety instructions • the crane and the lifting gear must have suitable capacity and dimensions. • lifting the machine requires suitable lifting gear. • secure the machine against unintentional movement! • check the cab f...

Page 103

Om 28z3 us – edition 2.0 * 28z3b330.Fm 3-37 operation 3.21 loading and transporting the machine loading and transporting instructions • the transport vehicle must be of adequate size – refer to chapter 6 “specifications” for the machine's dimensions and weights! • remove any mud, snow or ice from th...

Page 104

3-38 om 28z3 us – edition 2.0 * * 28z3b330.Fm operation 3.22 tying down the excavator warning! Improper loading, strapping, and transporting of the machine can be hazard- ous. • ensure that the machine is properly strapped down. • read the safety instructions at the beginning of this chapter and fol...

Page 105

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-39 operation 3 3.23 operating the machine general safety instructions avoiding cave-in or collapse: • do not operate at the edge of an open excavation. • do not undermine wall foundations. Preventing tip-overs: • do not excavate deeply under the front side of...

Page 106

3-40 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation 3.24 control levers/control pattern ’’a’’: overview important! Fast actuation of the control lever for the attachment moves the attachment fast. Slow actuation of the control lever moves the attachment slowly. Left-hand side control lever warni...

Page 107

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-41 operation auxiliary hydraulics actuating the auxiliary hydraulics: oil flow in 1st direction: ☞ move hammer pedal 19 to the left. Oil flow in 2nd direction: ☞ move hammer pedal 19 to the right. Right-hand side control lever fig. 46: auxiliary hydraulics 19...

Page 108

3-42 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation lowering the boom with the engine stopped lower the boom as follows: ☞ make sure no one is dangerously close to the machine. ☞ turn the starting key to position “ 1 ”. ☞ press forward and hold the control lever ( a and e ). ➥ until the arm syst...

Page 109

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-43 operation swivel unit brake upper carriage hydraulic brake: the upper carriage's rotation is sufficiently braked by moving control lever 2 back to initial position. Moving the control lever in the opposite direction (counteraction) brakes the upper carriag...

Page 110

3-44 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation 3.25 changeover valve for control pattern’’b’’(option) important! Possible loss of machine control. Changing the control valve mode selection posi- tion will reverse the function control of the hand levers. The left hand lever controls the boom...

Page 111

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-45 operation directional valve the changeover valve switches from iso to sae controls and vice versa. ☞ tighten wing nut j after changing control mode. Warning! Possible equipment damage or injury hazard. Never drive or work with the machine if wing nut j is ...

Page 112

3-46 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation 3.26 control lever with proportional controls (option): overview important! Fast actuation of the control lever for the attachment moves the attachment quickly. Slow actuation of the control lever moves the attachment slowly. Function this cont...

Page 113

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-47 operation measures to be taken in case of malfunctions notice possibility of uncontrolled valve function. The system still works cor- rectly if only one component breaks down. However, if more than one component breaks down, the pressure regulating valves ...

Page 114

3-48 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation boom swivel controls swivel boom to the left: ☞ move hammer pedal 1 to the left. Swivel boom to the right: ☞ move hammer pedal 1 to the right. Auxiliary hydraulics actuating the auxiliary hydraulics: oil flow in 1st direction: ☞ move hammer ped...

Page 115

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-49 operation adjusting control response: characteristic curve 1 (slow movements): ☞ disengage the starter. Better switch off ignition ☞ then move slide switch b to the left d . ☞ hold slide switch b to the left d and turn the starter key to position “ 1 ” at ...

Page 116

3-50 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation right-hand side control lever lowering the boom with the engine switched off lower the boom as follows: ☞ make sure no one is within the hazardous area of the machine. ☞ turn the starter key to position “ 1 ”. ☞ press forward and hold the contr...

Page 117

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-51 operation rotating the upper carriage rotating the upper carriage is described with standard iso controls. Important! • until the hydraulic fluid reaches operating temperature, the upper carriage can creep slightly after the control is placed in the neutra...

Page 118

3-52 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation 3.27 control lever if equipped with 3rd control circuit (option): overview important! Fast actuation of the control lever for the attachment moves the attachment quickly. Slow actuation of the control lever moves the attachment slowly. Left-han...

Page 119

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-53 operation auxiliary hydraulics actuating the auxiliary hydraulics: oil flow in 1st direction: ☞ move hammer pedal 19 to the left. Oil flow in 2nd direction: ☞ move hammer pedal 19 to the right. Right-hand side control lever fig. 70: auxiliary hydraulics 19...

Page 120

3-54 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation lowering the boom with the engine switched off lower the boom as follows: ☞ make sure no one is dangerously close to the machine. ☞ turn the starter key to position “ 1 ”. ☞ press forward and hold the control lever ( a and e ). ➥ until the arm ...

Page 121

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-55 operation rotating upper carriage upper carriage hydraulic brake: the upper carriage's rotation is sufficiently braked by moving control lever 2 back to initial position. Moving the control lever in the opposite direction (counteraction) brakes the upper c...

Page 122

3-56 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation 3.28 releasing the pressure on the work hydraulics caution! Before connecting or removing hydraulic lines from the attachment, make sure the work hydraulics is not under pressure! Important! The hydraulic system of the machine is still pressuri...

Page 123

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-57 operation 3.29 coupling and uncoupling attachments coupling and uncoupling the attachments is described below for a bucket. If you are fitting or removing attachments with their own hydraulic functions – e.G. Grab or offset bucket – you must follow the spe...

Page 124

3-58 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation removing a bucket ☞ proceed as follows: • lower the bucket to the ground with its flat side facing down. • stop the engine. • remove linch pin a . • first remove pin b , and then pin c . Carefully release pins that are stuck with a hammer and a...

Page 125

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-59 operation 3.30 quickhitch (option) warning! Possibility of crushing / striking injury from attachments. An unlocked quick hitch attachment can move unexpectedly and strike nearby people or objects. • before using the excavator, make sure the attachment is ...

Page 126

3-60 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation 3.31 hydraulic quickhitch (option) caution! Before putting this feature into operation, specific training must be performed by authorized technical staff and must be understood by the operator. For reasons of safety, the quickhitch must be oper...

Page 127

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-61 operation operation picking up an attachment caution! Personal injury or equipment damage hazards. An improperly connected attachment can detach or fall unexpectedly. • before connecting an attachment, clear all personnel from the work area. • make sure th...

Page 128

3-62 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation setting down an attachment proceed as follows: ☞ lower the attachment to about 5 – 10 cm (2’’ - 4’’) above the ground ☞ actuate switch b ➥ the buzzer sounds ☞ press and hold the foot-operated tip switch c ☞ operate the stabilizer blade (raise a...

Page 129

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-63 operation 3.32 powertilt (option) two versions are available: • powertilt with hydraulic quickhitch (option) – see chapter 3.31 hydraulic quickhitch (option) on page 3-60 • powertilt welded onto an attachment. Danger of crushing due to the rotating movemen...

Page 130

3-64 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation re-equipping warning! Re-equipping attachments – danger of personal injury! ☞ observe the following instructions: • stop the engine. • fold the control lever base up. • re-equip attachments only with suitable tools. • do not align components wi...

Page 131

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-65 operation important! Place the bucket only with minimum pressure on the ground as you remove the pins. The higher the pressure on the ground, the higher the resistance and the more difficult it is to remove the pins. Port ☞ remove the covers on ports 1 and...

Page 132

3-66 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation right-hand side control lever (powertilt) the powertilt functions are operated with the right-hand side control lever . A b fig. 90: right-hand side control lever position lever function • a ☞ to the left ➥ powertilt turns to the left • b ☞ to ...

Page 133

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-67 operation 3.33 connections for auxiliary hydraulics important! Follow the instructions in the operator's manual of the attachment manufacturer for connecting the auxiliary hydraulics to attachments. Grab couplings connect and disconnect the hydraulic coupl...

Page 134

3-68 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation 3.34 attachments important! Please refer to the operator's and maintenance manual of the attachment manu- facturer for using and performing maintenance on attachments such as hammers, grapple forks etc. 3.35 load holding control valve (option) ...

Page 135

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-69 operation 3.36 working with the excavator working with the standard bucket the following section describes work operations with the machine equipped with the stan- dard bucket. The standard bucket is mainly used for digging earth, and for loosening, pickin...

Page 136

3-70 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation avoid tipping the machine and then releasing the boom hydraulics to break up material or compact the work surface. ☞ this is not only hazardous operation; it is abusive operation. Retracting attachments ☞ make sure the bucket does not hit the s...

Page 137

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-71 operation excavator work position proceed as follows: ☞ place stabilizer blade a on the side you want to dig. Bucket position when digging ☞ move the bucket as shown in a ➥ move the flat side of the bucket parallel to the ground. Important! Position b caus...

Page 138

3-72 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation loading • loading in confined areas with a limited angle of rotation is more efficient ☞ by positioning the truck so as to ensure maximum visibility for the driver of the exca- vator. • loading material on trucks is easier and faster if the hyd...

Page 139

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-73 operation working alongside trenches notice possible piston rod damage. To avoid damage to the boom cylinder, do not raise the stabilizer blade with the boom lift cylinder in the retracted position shown in fig. 60. • always use stabilizer blade b for stab...

Page 140

3-74 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation recommendations for digging when planning and performing digging work, observe the following points: • exits from pits must be outside the excavation face and as level as pos- sible. • dig by removing adjacent strips if possible. • always trave...

Page 141

Om 28z3 us – edition 2.0 * 28z3b340.Fm 3-75 operation 3.37 grading warning! Possibility of crushing / striking injury from a moving stabilizer blade. • make sure no one is in the area of danger when working with the stabi- lizer blade grading ☞ lower the stabilizer blade to the ground – see chapter ...

Page 142

3-76 om 28z3 us – edition 2.0 * * 28z3b340.Fm operation.

Page 143: 4 Troubleshooting

Om 28z3 us – edition 2.0 * 28z3b410.Fm 4-1 troubleshooting 4 troubleshooting the information given in this chapter is provided for maintenance personnel for fast and reliable detection of malfunctions and their appropriate repair. Repairs must beperformed by an authorized wacker neuson service cente...

Page 144

4-2 om 28z3 us – edition 2.0 * * 28z3b410.Fm troubleshooting 4.1 engine trouble problem possible causes see engine does not start or is not easy to start wrong sae grade of engine lubrication oil 5-34 fuel grade does not comply with specifications 5-34 malfunctioning or flat battery 5-29 loose or ox...

Page 145

Om 28z3 us – edition 2.0 * 28z3b410.Fm 4-3 troubleshooting 4.2 malfunctions of the powertilt unit engine oil consumption too high oil level too high/wrong oil 5-6 worn oil scraper ring machine inclination too high engine smoke blue oil level too high/wrong oil 5-6 machine inclination too high white ...

Page 146

4-4 om 28z3 us – edition 2.0 * * 28z3b410.Fm troubleshooting.

Page 147: 5 Maintenance

Om 28z3 us – edition 2.0 * 28z3b510.Fm 5-1 maintenance 5 maintenance 5.1 introduction operational readiness and the service life of machines are heavily dependent on mainte- nance. It is therefore in the interest of the machine owner to perform the prescribed maintenance work. Before performing serv...

Page 148

5-2 om 28z3 us – edition 2.0 * * 28z3b510.Fm maintenance 5.2 fuel system specific safety instructions warning! Fire and fume inhalation hazards . • do not refuel in closed rooms. • never perform maintenance or repair work on the fuel system in the vicinity of open flames or sparks. • never smoke whe...

Page 149

Om 28z3 us – edition 2.0 * 28z3b510.Fm 5-3 maintenance draining the fuel warning! Fire and burn hazard. Draining fuel may ignite if it comes into contact with hot engine parts or the exhaust system. Hot fuel may cause burns. • always wear protective equipment and safety glasses when working with fue...

Page 150

5-4 om 28z3 us – edition 2.0 * * 28z3b510.Fm maintenance diesel fuel specification use only high-grade fuels bleeding the fuel system warning! Fire and burn hazard. Draining fuel may ignite if it comes into contact with hot engine parts or the exhaust system. Hot fuel may cause burns. • stop the eng...

Page 151

Om 28z3 us – edition 2.0 * 28z3b510.Fm 5-5 maintenance water separator interrupt fuel supply as follows: ☞ turn ball-type cock b to the off mark. ➥ fuel supply is interrupted. ☞ turn ball-type cock b to the on mark. Fuel supply is open again. Check the water separator as follows: ☞ if the red indica...

Page 152

5-6 om 28z3 us – edition 2.0 * * 28z3b510.Fm maintenance 5.3 engine lubrication system notice possibility of equipment damage. If the engine oil level is too low or if an oil change is overdue, this can cause engine damage or loss of power. • have the oil changed by an authorized service facility. •...

Page 153

Om 28z3 us – edition 2.0 * 28z3b510.Fm 5-7 maintenance adding engine oil notice possibility of engine damage from too much oil or incorrect engine oil. • do not add engine oil above the max mark of oil dipstick 117/ a • use only the specified engine oil environment! Use a suitable container to colle...

Page 154

5-8 om 28z3 us – edition 2.0 * * 28z3b510.Fm maintenance 5.4 engine and hydraulics cooling system the hydraulic fluid cooler and engine coolant radiator are located in the engine compart- ment next to the engine. The cooling system maintains the optimum operating temperature in the hydraulic work an...

Page 155

Om 28z3 us – edition 2.0 * 28z3b510.Fm 5-9 maintenance specific safety instructions warning! Burn hazard. The coolant in the system is hot under normal operating conditions and under about 1 bar (15 psi) pressure. • never open the coolant tank or drain coolant if the engine is hot. • wait at least 1...

Page 156

5-10 om 28z3 us – edition 2.0 * * 28z3b510.Fm maintenance checking the coolant level ☞ proceed as follows: • park the machine on level ground. • stop the engine. • fold the control lever base up. • remove the key and carry it with you. • let the engine and the coolant cool down. • open the engine co...

Page 157

Om 28z3 us – edition 2.0 * 28z3b510.Fm 5-11 maintenance draining coolant warning! Burn hazard. The coolant in the system is flammable and becomes very hot under normal operating conditions. • always use appropriate protective equipment, e.G. Protective gloves! • do not drain the cooling system unles...

Page 158

5-12 om 28z3 us – edition 2.0 * * 28z3b520.Fm maintenance 5.5 air filter notice possible equipment damage. The filter cartridge will be damaged if it is washed or brushed out. Keep in mind the following to avoid premature engine wear: • do not clean the filter cartridge • replace the filter cartridg...

Page 159

Om 28z3 us – edition 2.0 * 28z3b520.Fm 5-13 maintenance ☞ clean the parts with a clean, lint-free cloth. ☞ do not use compressed air. ☞ check the air filter cartridges for damage. ☞ install only a new or undamaged, serviceable primary filter element. ☞ carefully insert the new primary filter b in th...

Page 160

5-14 om 28z3 us – edition 2.0 * * 28z3b520.Fm maintenance 5.6 v-belt caution! Crushing, cutting or burn hazards. • stop the engine and permit a cool down time. Wait until the engine is comfortable to touch. • only check, retighten, or replace the v-belt when the engine is stopped. • disconnect the b...

Page 161

Om 28z3 us – edition 2.0 * 28z3b520.Fm 5-15 maintenance retightening the v-belt notice possible engine damage. Overtightening the v-belt may damage the v-belt, the v-belt guide, the alternator bearing and the water pump bearing. • avoid contact of oil, grease or similar substances with the v-belt. •...

Page 162

5-16 om 28z3 us – edition 2.0 * * 28z3b520.Fm maintenance 5.7 hydraulic system specific safety instructions warning! Pressurized hydraulic oil hazard. Hydraulic oil escaping under high pressure can catch fire, damage property, penetrate the skin and cause severe burns and injuries. • do not operate ...

Page 163

Om 28z3 us – edition 2.0 * 28z3b520.Fm 5-17 maintenance environment! Collect drained hydraulic oil and biodegradable oil in a suitable container! Dispose of drained oil and used filters by an ecologically safe method. Always contact the relevant authorities or commercial establishments in charge of ...

Page 164

5-18 om 28z3 us – edition 2.0 * * 28z3b520.Fm maintenance adding hydraulic oil warning! Pressurized hydraulic oil hazard. Removing the hydraulic filter plug can cause pressurized oil to escape. Escaping oil may cause serious injuries. • permit the hydraulic oil to cool to a temperature that is comfo...

Page 165

Om 28z3 us – edition 2.0 * 28z3b520.Fm 5-19 maintenance important information for the use of biodegradable oil • use only the biodegradable hydraulic fluids which have been tested and approved by wacker neuson gmbh. Always contact wacker neuson for the use of other products which have not been recom...

Page 166

5-20 om 28z3 us – edition 2.0 * * 28z3b520.Fm maintenance 5.8 pilot valve notice possible equipment damage. Dirty oil can damage the piston valves within the pilot valves. • check the pilot control filter every 1000 s/h and cleat it if necessary. • in order to protect the piston valves in the pilot ...

Page 167

Om 28z3 us – edition 2.0 * 28z3b520.Fm 5-21 maintenance checking hydraulic pressure lines specific safety instructions warning! Pressurized hydraulic oil hazard. Hydraulic oil escaping under high pressure can catch fire, damage property, penetrate the skin and cause severe burns and injuries. • do n...

Page 168

5-23 om 28z3 us – edition 2.0 * * 28z3b530.Fm maintenance 5.9 tracks • track wear can vary according to work and ground conditions. ☞ we recommend checking track wear and tension once a day. ☞ park the machine on firm and level ground to check and perform maintenance. Checking track tension warning!...

Page 169

Om 28z3 us – edition 2.0 * 28z3b530.Fm 5-24 maintenance adjusting the track tension caution! Projectile hazard.The grease fitting for track adjustment is subject to high pressure. The grease fitting can become a projectile if pressure caused by track tension is not properly relieved.. • do not remov...

Page 170

5-25 om 28z3 us – edition 2.0 * * 28z3b530.Fm maintenance 5.10 track propulsion final drive warning! Burn hazard. The traveling drive and the oil inside can remain hot and under pressure even after the engine has been switched off. This hot oil may leak from the traveling drive. • wait until the eng...

Page 171

Om 28z3 us – edition 2.0 * 28z3b530.Fm 5-26 maintenance maintenance of attachments important! Correct maintenance and service is absolutely necessary for smooth and continu- ous operation, and for an increased service life of the attachments. Observe the lubrication and maintenance instructions in t...

Page 172

5-27 om 28z3 us – edition 2.0 * * 28z3b530.Fm maintenance 5.11 electric system specific safety instructions warning! Batteries can explode or cause chemical burns. A battery contains sulfuric acid and emits explosive gases when heavily discharged. • do not smoke or use an open flame near the battery...

Page 173

Om 28z3 us – edition 2.0 * 28z3b530.Fm 5-28 maintenance every week ☞ check once a week: • electric fuses – see chapter fuse box in engine compartment on page 6-3 • cable and earth connections • battery charge condition – see battery on page 5-29 • condition of battery terminals instructions concerni...

Page 174

5-29 om 28z3 us – edition 2.0 * * 28z3b530.Fm maintenance battery warning! Battery acid hazard. The battery contains highly caustic sulphuric acid. This acid must not be allowed to come into contact with the skin, the eyes, clothing, or the machine. • when recharging and/or working near the battery,...

Page 175

Om 28z3 us – edition 2.0 * 28z3b530.Fm 5-30 maintenance 5.12 general maintenance work cleaning cleaning the machine is divided into 3 separate areas: • inside the cab • exterior of the machine • engine compartment to avoid personal injury and damage to the machine, always follow the recommendations ...

Page 176

5-31 om 28z3 us – edition 2.0 * * 28z3b530.Fm maintenance inside the cab notice possible equipment damage from high-pressure cleaning. Water under high pressure can penetrate the electrical system, cause short circuits, damage seals, and disable the controls. • never use high-pressure cleaners, stea...

Page 177

Om 28z3 us – edition 2.0 * 28z3b530.Fm 5-32 maintenance threaded connections and fasteners all threaded connectors and fasteners must be checked regularly for tightness, even if they are not listed in the maintenance schedules. ☞ engine fastening screws. ☞ fastening screws on the hydraulic system. ☞...

Page 178

5-33 om 28z3 us – edition 2.0 * * 28z3b530.Fm maintenance 5.13 maintenance if the machine is out of service for a longer period of time notice possibility of equipment damage from improper maintenance. • if the machine is out of operation, run it once a month without load. Remove the grease from the...

Page 179

Om 28z3 us – edition 2.0 * 28z3b530.Fm 5-34 maintenance 5.14 fluids and lubricants component/ application engine/machine fluid specification season/tempera- ture capacities 1 1. The capacities indicated are approximative values; the oil level check alone is relevant for the correct oil level capacit...

Page 180

5-35 om 28z3 us – edition 2.0 * * 28z3b530.Fm maintenance oil grades for the diesel engine, depending on temperature additional oil change and filter replacement (hydraulics) notice possible hydraulic component damage. An additional oil change and filter replacement can be required depending on how ...

Page 181

Om 28z3 us – edition 2.0 * 28z3b530.Fm 5-36 maintenance oil grades for the hydraulic system, depending on temperature hydrau- lics oil grade ambient temperature hvlp 1 °c -20 -15 -10 -5 0 5 10 15 20 25 30 35 40 50 iso vg32 iso vg46 iso vg68 °f -4 5 14 23 32 41 50 59 68 77 86 95 104 122 1. According ...

Page 182

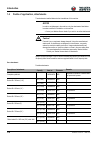

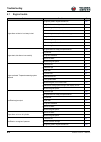

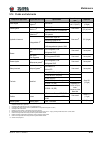

5-35 om 28z3 us – edition 2.0 * * 28z3b540.Fm maintenance 5.15 main tenan ce plan ( overview) work description for service and mainten ance work on the attachment, please refer to the operation and maintenance manual of the attachment man ufacturer a s well. Maintenance plan/service hours (s/h) main...

Page 183

Om 28z3 us – edition 2.0 * * 28z3b540.Fm 5-36 maintenance check exhau st system for damage and condition ●● check valve clearance. Adjust if necessary ●● clean and adjust the fuel injection p ump 7 ●● check and adjust the injection pressure of the in jection nozzles, clea n the injection needle s/no...

Page 184

5-37 om 28z3 us – edition 2.0 * * 28z3b540.Fm maintenance check the powertilt for damage ●● check powertilt for axial play (m ust not be over 0.38 mm / 0,014 in) ●● actuate p owertilt swivel device in final po sition for 1 minute 9 ●● lubrication service ( ): lubricate the following assemblies/ comp...

Page 185

Om 28z3 us – edition 2.0 * * 28z3b540.Fm 5-38 maintenance • h ydraulic qui ckhi tch sys tem (loc k) ●● • c heck the powertilt ●● leakage check ( ): check for tightness, leaks and chafing: p ipes, flexible lines and screw connections of the following assemblies and compo nents. Recti fy if nec essary...

Page 186

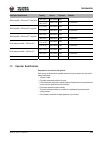

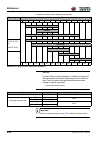

5-40 om 28z3 us – edition 2.0 * * 28z3b560.Fm maintenance 5.16 maintenance label explanation of symbols on the maintenance label symbol assembly explanation general visual check general grease instructions fuel system drain condensation water fuel system replace the fuel filter, clean the fuel prefi...

Page 187

Om 28z3 us – edition 2.0 * 28z3b560.Fm 5-41 maintenance symbol assembly explanation radiator fins clean heating replace the recirculated air filter 1000h 500h 500h 1000h d d 1000173185 api cf 1000h 10h 50h 3 2 4 d 1 d 1 1 3 50h 10h 1 3 1 -34°c / -29°f astm d4985 50h 10h 4 / 6 10h 500h 250h 1000h 1 s...

Page 188

5-42 om 28z3 us – edition 2.0 * * 28z3b560.Fm maintenance.

Page 189: 6 Specifications

Om 28z3 us – edition 2.0 * 28z3b610.Fm 6-1 specifications 6 specifications 6.1 chassis sturdy steel sheet chassis, rubber-mounted engine 6.2 engine 6.3 hydraulic system engine model 28z3 product yanmar diesel engine type 3tnv76-nns design water-cooled 4 stroke diesel engine no. Of cylinders 3 displa...

Page 190

6-2 om 28z3 us – edition 2.0 * * 28z3b610.Fm specifications 6.4 undercarriage and swivel unit 6.5 stabilizer blade 6.6 work hydraulics undercarriage/swivel unit model 28z3 2 speed ranges 2.1/3.8 km/h (1.3/2.4 mph) climbing ability 30°/58 % track width 300 mm (11.8’’) no. Of track rollers on either s...

Page 191

Om 28z3 us – edition 2.0 * 28z3b610.Fm 6-3 specifications 6.7 electric system fuse box in engine compartment electric system alternator 12 v 40 a starter 12 v 1.1 kw battery 12 v 43 ah socket e.G. For 12v power outlet; 15 a max. Fig. 138: fuse box f10 f9 f5 f4 f3 f8 f7 f6 f1 f2 fuse no. Rated curren...

Page 192

6-4 om 28z3 us – edition 2.0 * * 28z3b610.Fm specifications 6.8 noise levels important! Measurement of sound power level according to ec directive 2000/14 ec. Noise level at the driver's ear measured according to ec directives 84/532/eec, 89/514/ eec and 95/27/eec. Measurements performed on asphalte...

Page 193

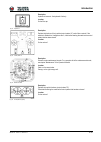

Om 28z3 us – edition 2.0 * 28z3b610.Fm 6-5 specifications 6.12 dimensions model 28z3 fig. 141: machine dimensions (model 28z3) main data model 28z3 service weight with cab/canopy 2670/2577 kg (5886,3 / 5681.3 lbs) height 2415 mm (7’11’’) width 1570 mm (5’2’’) transport length 4263 mm (14’’) max. Dig...

Page 194

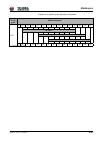

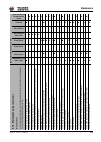

6-6 om 28z3 us – edition 2.0 * * 28z3b610.Fm specifications 6.13 lift capacity table 28z3 all table indications in kg (lbs.) and horizontal position on firm ground without bucket. If equipped with a bucket or other attachments, lift capacity or tilt load is reduced by bucket or attachment dead weigh...

Page 195

Om 28z3 us – edition 2.0 * 28z3b610.Fm 6-7 specifications 6.14 lift capacity table 28z3, long stick option all table indications in kg (lbs.) and horizontal position on firm ground without bucket. If equipped with a bucket or other attachments, lift capacity or tilt load is reduced by bucket or atta...

Page 196

6-8 om 28z3 us – edition 2.0 * * 28z3b610.Fm specifications 6.15 lift capacity table 28z3, extra weight option all table indications in kg (lbs.) and horizontal position on firm ground without bucket. If equipped with a bucket or other attachments, lift capacity or tilt load is reduced by bucket or ...

Page 197

Om 28z3 us – edition 2.0 * 28z3b610.Fm 6-9 specifications 6.16 lift capacity table 28z3, long stick and extra weight options all table indications in kg (lbs.) and horizontal position on firm ground without bucket. If equipped with a bucket or other attachments, lift capacity or tilt load is reduced...

Page 198

6-10 om 28z3 us – edition 2.0 * * 28z3b610.Fm specifications.

Page 199

Wacker neuson linz gmbh keep abreast of the latest technical developments and con- stantly improve their products. For this reason, we may from time to time need to make changes to diagrams and descriptions in this documentation which do not reflect products which have already been delivered and whi...

Page 200

Wacker neuson corporation p. O. Box 9007 menomonee falls, wi 53052-9007 telephone: (262) 255-0500 fax: (262) 255-0550 telephone: (800) 770-0957 www.Wackerneuson.Com wacker neuson linz gmbh haidfeldstr. 37 a-4060 linz/leonding telephone +43 (0) 732/90590-0 fax +43 (0) 732/90590-0 e-mail: office@neuso...