- DL manuals

- Wacker Neuson

- Work Light

- 5200002722

- Operator's Manual

Wacker Neuson 5200002722 Operator's Manual

Summary of 5200002722

Page 1

Operator’s manual light tower ltn 6k-v, ltn 6k-vs ltn 8k-v, ltn 8k-vs ltn 6l-vs 60 hz type ltn 6k-v, ltn 6k-vs, ltn 8k-v, ltn 8k-vs, ltn 6l-vs (60 hz) document 5200004275 date 1115 version 03 language en 5 2 0 0 0 0 4 2 7 5.

Page 2

Copyright notice © copyright 2015 by wacker neuson production americas llc all rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permissio...

Page 3: Ltn

Ltn foreword wc_tx003092gb.Fm 3 foreword save these instructions—this manual contains important instructions for the machine models below. These instructions have been written expressly by wacker neuson production americas llc and must be followed during installation, operation, and maintenance of t...

Page 4: Foreword

Foreword ltn 4 wc_tx003092gb.Fm expectations for information in this manual this manual provides information and procedures to safely operate and main- tain the above wacker neuson model(s). For your own safety and to reduce the risk of injury, carefully read, understand, and observe all instruction...

Page 5: Table of Contents

Table of contents ltn wc_bo5200004275_03toc.Fm 5 foreword 3 1 safety information 9 1.1 signal words used in this manual ....................................................... 9 1.2 machine description and intended use ............................................. 10 1.3 safety guidelines for operat...

Page 6: Table of Contents

Table of contents ltn wc_bo5200004275_03toc.Fm 6 4.16 lowering the tower .............................................................................51 4.17 automatic shutdown ...........................................................................52 4.18 stopping the machine - ltn 6k/8k-v ........

Page 7: Table of Contents

Table of contents ltn wc_bo5200004275_03toc.Fm 7 10 technical data 90 10.1 engine - kubota .................................................................................. 90 10.2 engine - kohler ................................................................................... 91 10.3 generator ...

Page 8: Table of Contents

Table of contents ltn wc_bo5200004275_03toc.Fm 8.

Page 9: Ltn

Wc_si000704gb.Fm 9 ltn safety information 1 safety information 1.1 signal words used in this manual this manual contains danger, warning, caution, notice, and note signal words which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. Notice: ...

Page 10: Safety Information

Wc_si000704gb.Fm 10 safety information ltn 1.2 machine description and intended use machine description this machine is a mobile, trailer-mounted light tower. The wacker neuson light tower consists of a trailer with a cabinet containing a diesel engine, a fuel tank, a control panel, and an electric ...

Page 11: Ltn

Wc_si000704gb.Fm 11 ltn safety information glare from lights (lights may blind drivers of nearby motor vehicles if the lights are incorrectly positioned) typical hazards related to towing a trailer on roads and highways to protect yourself and others, make sure you thoroughly read and understand the...

Page 12: Safety Information

Wc_si000704gb.Fm 12 safety information ltn do not operate the machine if any safety devices or guards are missing or inoperative. Do not modify or defeat the safety devices. Only use accessories or attachments that are approved by wacker neuson. Safe operating practices when operating this machine: ...

Page 13: Ltn

Wc_si000704gb.Fm 13 ltn safety information description the lamps provided with your light tower are electric discharge lamps. They are designed for use with metal halide ballasts only, and require time to reach full brightness on initial startup and after a power interruption. These lamps comply wit...

Page 14: Safety Information

Wc_si000704gb.Fm 14 safety information ltn 1.4 service safety service training before servicing or maintaining the machine: read and understand the instructions contained in all manuals delivered with the machine. Familiarize yourself with the location and proper use of all controls and safety devic...

Page 15: Ltn

Wc_si000704gb.Fm 15 ltn safety information cleaning when cleaning and servicing the machine: keep the machine clean and free of debris such as leaves, paper, cartons, etc. Keep the labels legible. When cleaning the machine: do not clean the machine while it is running. Never use gasoline or other ty...

Page 16: Safety Information

Wc_si000704gb.Fm 16 safety information ltn 1.5 operator safety while using internal combustion engines operating safety when running the engine: keep the area around exhaust pipe free of flammable materials. Check the fuel lines and the fuel tank for leaks and cracks before starting the engine. Do n...

Page 17: Ltn

Wc_si000704gb.Fm 17 ltn safety information 1.6 safety guidelines for lifting and transporting the machine when lifting the machine: make sure slings, chains, hooks, ramps, jacks, forklifts, cranes, hoists, and any other type of lifting device used is attached securely and has enough weight- bearing ...

Page 18: Safety Information

Wc_si000704gb.Fm 18 safety information ltn 1.7 safety guidelines for towing the machine when towing the machine: do not tow the machine if the towing vehicle’s hitch or the trailer’s coupler are damaged. Do not tow the machine if any of the trailer’s lug nuts are missing. Do not tow the machine if t...

Page 19: Ltn

Wc_si000704gb.Fm 19 ltn safety information 1.8 reporting safety defects if you believe your trailer has a defect which could cause a crash or could cause injury or death, you should immediately inform the national highway traffic safety administration (nhtsa) in addition to notifying wacker neuson. ...

Page 20: Labels

Labels ltn 20 wc_si000705gb.Fm 2 labels 2.1 label locations wc_gr009301 a b r c c c s w h h x y d e f g h i j k l q p o n m.

Page 21: Ltn

Ltn labels wc_si000705gb.Fm 21 wc_gr009302 e b a z ee aa k bb w gg hh w x h ii cc jj ff w dd g.

Page 22: Labels

Labels ltn 22 wc_si000705gb.Fm 2.2 label meanings a warning avoid crushing area. B notice lifting point c fork lift pocket d d coolant overflow bottle only, not a return system. 176105 176105.

Page 23: Ltn

Ltn labels wc_si000705gb.Fm 23 e warning pressurized contents. Do not open when hot pinching / cutting hazards. Rotating machin- ery. F tower and light adjustment switches. The switch on the left controls the up and down movement of the tower. The switch on the right controls the auto- rotation of t...

Page 24: Labels

Labels ltn 24 wc_si000705gb.Fm i electrical ground j to lower tower: 1. Turn off all lights and engine. 2. Use switch inside door to lower tower. To secure tower for transport: 3. Loosen knob. 4. Use handle to rotate sets so lights are level. 5. Tighten knob. 6. Use switch inside door to rotate ligh...

Page 25: Ltn

Ltn labels wc_si000705gb.Fm 25 l towing instructions read operator’s manual. Use hitch rated from trailer’s “gross vehicle weight rating”. Securely attach trailer to tow vehicle. Attach safety chains using cross pattern. Attach breakdown chain to vehicle. Check trailer lights. M bb warning roll-over...

Page 26: Labels

Labels ltn 26 wc_si000705gb.Fm n see operator’s manual for metal halide lamp information and troubleshooting. Before starting the engine: 1. Check levels of engine oil fuel coolant 2. Move the circuit breakers to the off position. To start the engine: 1. On the engine control panel, turn the key swi...

Page 27: Ltn

Ltn labels wc_si000705gb.Fm 27 q danger contact with overhead electrical power lines will cause serious injury or death. Do not position light tower under electrical power lines. R low sulfur fuel or ultra low sulfur fuel only. S danger no sparks, flames, or burning objects near machine. Stop the en...

Page 28: Labels

Labels ltn 28 wc_si000705gb.Fm y this machine may be covered by one or more patents. Z read and understand the supplied opera- tor’s manual before operating the machine. Failure to do so increases the risk of injury to yourself and others. Aa to raise tower to allow easier access to lights: 1. Use s...

Page 29: Ltn

Ltn labels wc_si000705gb.Fm 29 cc transport position of the jack dd warning hot surface ee warning ultraviolet radiation from lamp can cause serious skin and eye irritation. Use only with undamaged lamps. Use only with provided undamaged lens cover and fixture. Ff warning hot surface gg hh gg hh dan...

Page 30: Labels

Labels ltn 30 wc_si000705gb.Fm ii warning crushing hazards. Stand clear of the front of the machine when the tower is being lowered with the hydraulic manual override valve. Jj warning hot surface 117039 117039 advertencia advertencia avertissement avertissement warning warning warnung warnung.

Page 31: Ltn

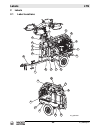

Wc_tx003095gb.Fm 31 ltn lifting and transporting 3 lifting and transporting 3.1 lifting the machine requirements properly rated lifting equipment (crane or hoist). See chapter technical data. Machine stopped. See topic stopping the machine. All doors and access covers closed and secured. Tower is co...

Page 32: Lifting and Transporting

Wc_tx003095gb.Fm 32 lifting and transporting ltn 3.2 preparing the machine for transport on a truck or trailer requirements machine stopped. Flatbed truck or trailer capable of supporting the machine’s weight. Chains, hooks, or straps capable of supporting the machine’s weight. Checklist before tran...

Page 33: Ltn

Wc_tx003095gb.Fm 33 ltn lifting and transporting 3.3 preparing the machine for towing before towing the machine, check the licensing requirements for trailers in your area. Also check the following items: machine check that all doors and access panels of the machine are closed. check that all el...

Page 34: Lifting and Transporting

Wc_tx003095gb.Fm 34 lifting and transporting ltn 3.4 towing the machine notice: wacker neuson recommends a maximum towing speed of 88km/h (55mph) on highways and paved roads and 16km/h (10mph) on rugged roads and terrain. Procedure perform the procedure below when towing the machine. 1. Read and fol...

Page 35: Ltn

Wc_tx003098gb.Fm 35 ltn operation 4 operation 4.1 preparing the machine for first use 1. Make sure all loose packaging materials have been removed from the machine. 2. Check the machine and its components for damage. If there is visible damage, do not operate the machine! Contact your wacker neuson ...

Page 36: Operation

Wc_tx003098gb.Fm 36 operation ltn 4.3 positioning the machine co alarms because this machine produces carbon monoxide (co), wacker neuson recommends that co alarms be installed in all structures in close proximity to the machine. Co alarms provide an extra measure of protection against this poison t...

Page 37: Ltn

Wc_tx003098gb.Fm 37 ltn operation 4.4 ground connection a ground connection (a) is located on the trailer frame. Function this ground connection is used for electrically grounding the light tower when necessary to comply with the national electrical code and other federal, state, and local regulatio...

Page 38: Operation

Wc_tx003098gb.Fm 38 operation ltn 4.5 leveling trailer procedure perform the procedure below to level the trailer. 1. Pull the locking pin on the tongue jack (a) and rotate the tongue jack down 90° as shown. Reinsert the pin once the jack is in position. 2. Block or chock the trailer wheels (b). 3. ...

Page 39: Ltn

Wc_tx003098gb.Fm 39 ltn operation 4.6 refueling the machine requirements machine shut down engine cool machine/fuel tank level with the ground fresh, clean fuel supply procedure perform the procedure below to refuel the machine. 1. Remove the fuel cap (a). 2. Fill the fuel tank, allowing a minimum o...

Page 40: Operation

Wc_tx003098gb.Fm 40 operation ltn 4.7 aiming the lights - ltn-v overview each individual light fixture can be aimed up, down, left, or right independent of one another. There are four total light fixtures on each machine. The light bars, which include two light fixtures each, can be tilted 45° in ea...

Page 41: Ltn

Wc_tx003098gb.Fm 41 ltn operation continued from the previous page. Aiming left or right 1. Grasp the light fixture and aim it to the light left or right. If necessary, loosen the bracket nut (c) to allow movement of the fixture. Notice: do not loosen the nut (b). Damage to the light fixture may occ...

Page 42: Operation

Wc_tx003098gb.Fm 42 operation ltn continued from the previous page. Aiming the light bars perform the procedure below to aim the light bars. 1. Loosen the knob (d), grasp the handles (e), and tilt the light bar to the desired angle. 2. Tighten the knob (d) when the light bar is in the desired positi...

Page 43: Ltn

Wc_tx003098gb.Fm 43 ltn operation 4.8 control panels wc_gr009973 6k 8k e a b b c d c d c d 1 l f l f g k k g h j i 2 ref description ref description 1 floodlight control panel f hour meter 2 tower control panel g 30a receptacle a 25a main circuit breaker h 30a receptacle breaker b 30a lights circuit...

Page 44: Operation

Wc_tx003098gb.Fm 44 operation ltn 4.9 control panels - ltn 6l-vs 1: floodlight control panel 2: engine control panel ref. Description ref. Description a 50 amp circuit breaker k high coolant temperature shut- down indicator b 30 amp lights circuit breaker l alternator indicator c 20 amp circuit brea...

Page 45: Ltn

Wc_tx003098gb.Fm 45 ltn operation 4.10 before starting before putting the light tower into service, review each item on the following checklist. Light towers often run unattended for long periods of time. Therefore, it is important to make sure that the machine is set up properly to avoid possible o...

Page 46: Operation

Wc_tx003098gb.Fm 46 operation ltn 4.11 starting the machine - ltn 6k-v, ltn 8k-v requirements before starting checks completed. See before starting notices do not use evaporative starting fluids (for example, ether) to start the engine. Do not start the engine under load. Procedure perform the proce...

Page 47: Ltn

Wc_tx003098gb.Fm 47 ltn operation 4.12 starting the machine - ltn 6l pre-start checklist check the following items before starting the machine. engine oil, fuel and coolant are filled to the proper levels. electrical cables in good condition with no cuts or abrasions in the insulation. circuit...

Page 48: Operation

Wc_tx003098gb.Fm 48 operation ltn 4.13 operating the lights requirements all items in “before starting” checklist have been checked tower is raised to the desired height engine is running and has warmed up procedure perform the procedure below to operate the lights. 1. Turn on the main circuit break...

Page 49: Ltn

Wc_tx003098gb.Fm 49 ltn operation 4.14 raising the tower - ltn -v overview the tower is raised by the action of a hydraulic cylinder (c). Note: the tower can be raised without running the engine. Procedure perform the procedure below to raise the tower. 1. If equipped, engage the parking brake on th...

Page 50: Operation

Wc_tx003098gb.Fm 50 operation ltn 4.15 manually rotating the mast overview the operator can rotate the mast 360° while the tower is lowered. Procedure to rotate the mast, perform the procedure below. 1. Pull out the locking pin (a) on the bottom of the mast. 2. Rotate the mast to the desired positio...

Page 51: Ltn

Wc_tx003098gb.Fm 51 ltn operation 4.16 lowering the tower overview a low-voltage electrical circuit controls the release of pressure in the hydraulic cylinder (c). When pressure is released, the tower will lower. Notes the engine does not need to be running to lower the tower. The hydraulic circuit ...

Page 52: Operation

Wc_tx003098gb.Fm 52 operation ltn 4.17 automatic shutdown description this machine is equipped with a low oil, high temperature automatic shutdown system. This system will automatically interrupt the fuel supply to the engine if the oil pressure drops too low or the engine exceeds normal operating t...

Page 53: Ltn

Wc_tx003098gb.Fm 53 ltn operation 4.19 stopping the machine - ltn 6l-v notice: do not stop the machine without turning off the lights. Damage to the electrical generator will occur. Procedure follow the procedure below to stop the machine. 1. Remove all connected loads from the machine. 2. Turn the ...

Page 54: Operation

Wc_tx003098gb.Fm 54 operation ltn 4.20 emergency shutdown procedure general procedures if a breakdown or accident occurs while the machine is operating, follow the procedure below: 1. Stop the engine. 2. Disconnect all loads from the machine. 3. Lower the tower. 4. Allow the machine to cool before o...

Page 55: Ltn

Wc_tx003098gb.Fm 55 ltn operation 4.21 using the convenience receptacles - 60 hz description this machine is equipped with one or more convenience receptacles (b) for running accessories and tools from the generator. Each receptacle is protected by its own circuit breaker (a). Power to the receptacl...

Page 56: Factory-Installed Options

Factory-installed options ltn 56 wc_tx001650gb.Fm 5 factory-installed options this machine may be equipped with one or more of the following factory-installed options. To verify if any of these options are installed on your machine, contact wacker neuson corporation at 1-800-770-0957. A nameplate li...

Page 57: Ltn

Ltn factory-installed options wc_tx001650gb.Fm 57 5.3 oil pan heater cold, thick engine oil does not flow freely and may cause engine starting difficulties. An oil pan heater installed on the engine oil pan keeps the oil warm and flowing. Heat from this electrical device warms the supply of engine o...

Page 58: Factory-Installed Options

Factory-installed options ltn 58 wc_tx001650gb.Fm 5.5 led lights the led light option includes 4 x 320 watt led fixtures that require less than 1 second warm-up time, no maintenace, and 100-264 vac. The led fixtures are rated for use in extreme cold temperatures to -40° f and offer voltage and curre...

Page 59: Ltn

Wc_tx003101gb.Fm 59 ltn maintenance 6 maintenance 6.1 preparing for maintenance do not perform even routine service (oil/filter changes, cleaning, etc.) unless all electrical components are shut down. Use the checklist below to prepare this machine for maintenance. key switch in the “off” position...

Page 60: Maintenance

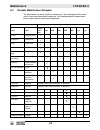

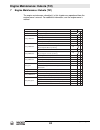

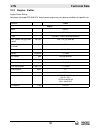

Wc_tx003101gb.Fm 60 maintenance ltn 6k/8k-v 6.2 periodic maintenance schedule the table below lists basic machine maintenance. Tasks designated with check marks may be performed by the operator. Tasks designated with square bullet points require special training and equipment. Interval (hours of ser...

Page 61: Ltn 6K/8K-V

Wc_tx003101gb.Fm 61 ltn 6k/8k-v maintenance * change engine oil and filter after first 50 hours of operation. 6.3 cleaning the machine when as needed requirements clean water supply mild detergent clean, dry cloths notice: do not use a pressure washer to clean this machine. Pressurized water can sev...

Page 62: Maintenance

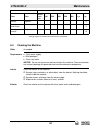

Wc_tx003101gb.Fm 62 maintenance ltn 6k/8k-v 6.4 inspecting the machine when daily overview inspect the machine before each use. A thorough inspection will help to identify mechanical faults or potentially unsafe operating conditions. Correct these problems before operating the machine. External insp...

Page 63: Ltn 6K/8K-V

Wc_tx003101gb.Fm 63 ltn 6k/8k-v maintenance 6.5 checking the engine oil requirements park the machine on a level surface shut down the machine when every 10 hours of service or daily procedure perform the procedure below to check the engine oil. 1. Clean around the dipstick (a). 2. Extract the dipst...

Page 64: Maintenance

Wc_tx003101gb.Fm 64 maintenance ltn 6k/8k-v 6.6 changing the engine oil when change the engine oil every 200 hours. Requirements warm engine plastic sheet and container of suitable size to collect drained oil replacement oil (see technical data for oil quantity and type) note: in the interests of en...

Page 65: Ltn 6K/8K-V

Wc_tx003101gb.Fm 65 ltn 6k/8k-v maintenance 6.7 checking the engine coolant level when daily requirements machine shut down engine cool 50/50 coolant/water solution (as needed) notice: use a long-life ethylene glycol coolant/water solution in this engine. Refer to the engine owner’s manual for more ...

Page 66: Maintenance

Wc_tx003101gb.Fm 66 maintenance ltn 6k/8k-v 6.8 flushing the radiator when every 500 hours requirements engine is stopped and cool to the touch plasitc sheet container of suitable size to collect drained coolant fresh 50/50 coolant/water solution notice: use a long-life ethylene glycol coolant/water...

Page 67: Ltn 6K/8K-V

Wc_tx003101gb.Fm 67 ltn 6k/8k-v maintenance continued from the previous page. 4. Open the radiator drain cock (b) and let the coolant drain into the container. 5. Open the engine block coolant drain cock (c) and let the remaining coolant drain into the container. 6. Close both drain cocks. 7. Inspec...

Page 68: Maintenance

Wc_tx003101gb.Fm 68 maintenance ltn 6k/8k-v 6.9 cleaning the air filter element when clean the air filter element every 100 hours. Procedure perform the procedure below to clean the air filter element. 1. Remove the cover (b) from the air filter housing (a). 2. Remove the air filter element (c). 3. ...

Page 69: Ltn 6K/8K-V

Wc_tx003101gb.Fm 69 ltn 6k/8k-v maintenance 6.10 maintaining the battery location the battery (a) is located beneath the control panel. Safety precautions observe the following safety precautions to prevent serious damage to the electrical system. Do not disconnect the battery while the machine is r...

Page 70: Maintenance

Wc_tx003101gb.Fm 70 maintenance ltn 6k/8k-v 6.11 checking fan belt tension when check the fan belt for proper tension and wear every 250 hours. Overview correct fan belt tension is critical to proper engine operation. An over-tensioned fan belt can damage the fan belt and bearings. A fan belt that i...

Page 71: Ltn 6K/8K-V

Wc_tx003101gb.Fm 71 ltn 6k/8k-v maintenance 6.12 checking radiator hoses when check the condition of the radiator hoses every 250 hours. Overview dry, cracked radiator hoses or loose clamps can cause a coolant leak. A coolant leak will cause the engine to overheat, possibly leading to permanent dama...

Page 72: Maintenance

Wc_tx003101gb.Fm 72 maintenance ltn 6k/8k-v 6.13 performing coolant solution analysis when every 500 hours or 12 months, whichever comes first. Overview engine coolant must be regularly tested to ensure that it remains at an acceptable ph level. Unacceptably low ph levels in coolant create an acidic...

Page 73: Ltn 6K/8K-V

Wc_tx003101gb.Fm 73 ltn 6k/8k-v maintenance 6.14 testing the cooling system pressure when test the cooling system pressure every 1200 hours, or 24 months (whichever comes first). Background the cooling system is under pressure while the engine is operating. Internal or external leaks will cause the ...

Page 74: Maintenance

Wc_tx003101gb.Fm 74 maintenance ltn 6k/8k-v continued from the previous page. 3. Attach the radiator cap (b) to the pressure tester (c) according to the instructions provided by the manufacturer. 4. Pressure test the radiator cap, observing the pressure reading on the tester. 5. Attach the pressure ...

Page 75: Ltn 6K/8K-V

Wc_tx003101gb.Fm 75 ltn 6k/8k-v maintenance 6.15 removing and replacing lamps prerequisites engine shut down light circuit breakers turned off lamps and fixtures cool to the touch eye and hand protection this procedure continues on the next page. Warning burn hazard. Lamps become extremely hot in us...

Page 76: Maintenance

Wc_tx003101gb.Fm 76 maintenance ltn 6k/8k-v continued from the previous page. Perform the procedures below to remove and install the lamp. Removing the lamp 1. Remove the screws (a) securing the flange rings (b) and remove the flange rings. 2. Remove the lens (c) with the gasket (d) attached. 3. Rem...

Page 77: Ltn 6K/8K-V

Wc_tx003101gb.Fm 77 ltn 6k/8k-v maintenance 6.16 long-term storage introduction extended storage of equipment requires preventive maintenance. Performing these steps helps to preserve machine components and ensures the machine will be ready for future use. While not all of these steps necessarily ap...

Page 78: Maintenance

Wc_tx003101gb.Fm 78 maintenance ltn 6k/8k-v 6.17 machine disposal / decommissioning introduction this machine must be properly decommissioned at the end of its service life. Responsible disposal of recyclable components, such as plastic and metal, ensures that these materials can be reused—conservin...

Page 79: Ltn 6K/8K-V

Wc_tx003101gb.Fm 79 ltn 6k/8k-v maintenance.

Page 80

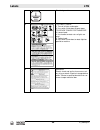

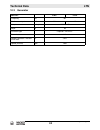

Wc_tx003733gb.Fm 80 engine maintenance: kubota (t4f) 7 engine maintenance: kubota (t4f) the engine maintenance schedule(s) in this chapter are reproduced from the engine owner’s manual. For additional information, see the engine owner’s manual. Eng lis h interval item ref. Page every 50 hours check ...

Page 81

Wc_tx003733gb.Fm 81 engine maintenance: kubota (t4f) the viscosity of the engine oil is an important factor when determining the correct engine oil to use in your machine. Use an engine oil of appropriate viscosity based on the expected outside air temperature. See the table below. Warning most used...

Page 82

Wc_tx003733gb.Fm 82 engine maintenance: kubota (t4f) eng lis h $ oil us ed in the engi ne sh ou ld have api classi fi cati on and prop er sae engine oil accor ding to the ambi ent temper atu res as s how n below: $ recom mended a pi classifica tion refer t o t he following tabl e fo r the sui tabl e...

Page 83

Wc_tx003733gb.Fm 83 engine maintenance: kubota (t4f).

Page 84: ***

Wc_tx003649gb.Fm 84 engine maintenance: kohler (t4f) 8 engine maintenance: kohler (t4f) the viscosity of the engine oil is an important factor when determining the correct engine oil to use in your machine. Use an engine oil of appropriate viscosity based on the expected outside air temperature. See...

Page 85

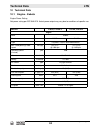

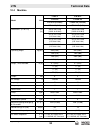

Wc_tx003649gb.Fm 85 engine maintenance: kohler (t4f) the engine maintenance schedule(s) in this chapter are reproduced from the engine owner’s manual. For additional information, see the engine owner’s manual. Opera tion description - descrizione operazione description de l ’opÉra tion - beschreibun...

Page 86

Wc_tx003649gb.Fm 86 engine maintenance: kohler (t4f) check - controllo - contrô le - kontrolle - comprobacÍon - contrô le cooling hoses - manicotti liquido di raf freddamento - manchons de liquide de refroidissement - muf fen des kühlmittels - manguitos de líquido de refrogeración - casquilhos para ...

Page 87

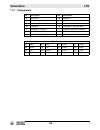

Wc_tx003649gb.Fm 87 engine maintenance: kohler (t4f) replacement - sostituzione - remplacement - auswechseln - sustituciÓn - substituiÇÃo opera tion description - descrizione operazione description de l ’opÉra tion - beschreibung des arbeitsvorgangs descripciÓn de la operaciÓn - descriÇÃo da operaÇÃ...

Page 88: Troubleshooting

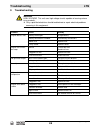

Wc_tx003104gb.Fm 88 troubleshooting ltn 9 troubleshooting warning high voltage! This unit uses high voltage circuits capable of causing serious injury or death. F only a qualified electrician should troubleshoot or repair electrical problems occurring in this equipment. Problem cause remedy engine d...

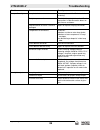

Page 89: Ltn 6K/8K-V

Wc_tx003104gb.Fm 89 ltn 6k/8k-v troubleshooting lamp will not light lamp is too hot allow lamp to cool 10–15 minutes before restarting. Faulty lamp connection check that lamp is tight in socket. Check connections inside connection boxes on light fixtures and tower. Plug connection at fixture is loos...

Page 90: Technical Data

Wc_td000530gb.Fm 90 technical data ltn 10 technical data 10.1 engine - kubota engine power rating net power rating per iso 3046 ifn. Actual power output may vary due to conditions of specific use. Machine ltn 6k, ltn 6k-v ltn 8k, ltn 8k-v engine make kubota model d1005 d1105 type 3-cylinder, 4-cycle...

Page 91: Ltn

Wc_td000530gb.Fm 91 ltn technical data 10.2 engine - kohler engine power rating net power rating per iso 3046 ifn. Actual power output may vary due to conditions of specific use. Machine ltn 6l engine make kohler model kdw1003 type 3-cylinder, 4-cycle, liquid-cooled diesel max. Power rating @ rated ...

Page 92: Technical Data

Wc_td000530gb.Fm 92 technical data ltn 10.3 generator machine: ltn 6 ltn 8 frequency hz 60 continuous output kw 6.0 8.0 output volts/phase 120/240, 1Ø amps a 50 excitation type capacitor / brushless power factor 1.0 voltage regulation - no load to full load % ± 6.0 speed (no-load) rpm 1800

Page 93: Ltn

Wc_td000530gb.Fm 93 ltn technical data 10.4 machine model unit ltn 6-v ltn 8k-v ltn 6-vs ltn 8k-vs ltn 6-vs (custom) ltn 8k-vs (custom) ltn 6-vs (c.W.) ltn 8k-vs (c.W.) dimensions (l x w x h) cm (in) 330 x 120 x 230 (130 x 48 x 90.5) 330 x 120 x 230 (130 x 48 x 90.5) 318 x 122 x 249 (125 x 48 x 98) ...

Page 94: Technical Data

Wc_td000530gb.Fm 94 technical data ltn 10.5 radiation compliance this machine meets the radio interference radiated emission requirements of european standard en 13309 for construction machinery. The lamps provided with this machine are electric discharge lamps. They are designed for use with metal ...

Page 95: Ltn

Wc_tx003107gb.Fm 95 ltn schematics 11 schematics 11.1 ltn 8k-v lighting schematic 17 bk 10 2 4 1 3 16 bk 10 23 wh 10 23 wh 10 22 gn/yl 10 22 gn/yl 10 16 bk 10 18 bk 10 19 bk 10 18 bk 10 19 bk 10 3 bk 10 6 bk 14 12 bk 14 14 bk 14 26 wh 10 25 bk 10 24 bk 10 27 gn/yl 10 27 gn/yl 10 8 wh 10 9 wh 10 28 b...

Page 96: Schematics

Wc_tx003107gb.Fm 96 schematics ltn 11.2 components ref. Description ref. Description a generator h light bar b terminal strip (short) s transformers c main circuit breaker m capacitors, 24 mf d floodlights o receptacle, 120/240v 30a e receptacle, 120v gfi t capacitor, generator excitation f circuit ...

Page 97: Ltn

Wc_tx003107gb.Fm 97 ltn schematics 11.3 ltn 6k-v lighting schematic.

Page 98: Schematics

Wc_tx003107gb.Fm 98 schematics ltn 11.4 components ref. Description ref. Description a generator h light bar b terminal strip (short) s transformers c main circuit breaker m capacitors, 24 mf d floodlights o receptacle, 120/240v 30a e receptacle, 120v gfi t capacitor, generator excitation f circuit ...

Page 99: Ltn

Wc_tx003107gb.Fm 99 ltn schematics 11.5 generator capacitor excitation schematic wc_gr011005 common 6 2 2 8 4 3 5 7 1 c1 + – l1 l1 l2 l3 l3 l4 l4 8 1 + – 120v 60 hz 115v 50 hz 120v 60 hz 115v 50 hz 240v 60 hz 230v 50 hz ref. Description ref. Description 1 rotor 4 capacitor 2 stator 5 generator/termi...

Page 100: Schematics

Wc_tx003107gb.Fm 100 schematics ltn 11.6 engine wiring m o n k p b c e i g h a wc_gr011346 l b ig st b 17 rd 19 rd 16 wh 15 rd 15 rd 16 wh 10 rd 10 rd or 9 br 3 rd 9 br 4 yl 4 yl 3 rd 7 yl 13 bu 14 bk 12 bk 2 or/bk 8 rd 5 red/bk 6 bk 2 3 rd 2 rd j 6 rd 6 rd 18 rd r 5 rd 5 r 20 rd 7 rd 17 4 rd 4 r 1 ...

Page 101: Ltn

Wc_tx003107gb.Fm 101 ltn schematics 11.7 components ref. Component ref. Component a bypass relay i fuel solenoid b diode j 15a fuse c glow plug timer k hour meter d glow plugs m battery e starter n glow plug indicator f alternator o key switch g oil switch p float switch (containment skid option) h ...

Page 102: Schematics

Wc_tx003107gb.Fm 102 schematics ltn 11.8 hydraulic schematic - ltn 6k-v, ltn 8k-v ref. Description ref. Description a hydraulic pump c alarm b hydraulic valve d mast switch wire colors bk black rd red yl yellow or orange gn green tn tan br brown pu purple bu blue vio violet cl clear sh shield pk pin...

Page 103: Ltn

Wc_tx003107gb.Fm 103 ltn schematics 11.9 hydraulic schematic- ltn 6k-vs, ltn 8k-vs ref. Description ref. Description a hydraulic pump c alarm b hydraulic valve d mast switch wire colors bk black rd red yl yellow or orange gn green tn tan br brown pu purple bu blue vio violet cl clear sh shield pk pi...

Page 104: Schematics

Wc_tx003107gb.Fm 104 schematics ltn 11.10 trailer wiring ref. Description ref. Description a right stop, turn and tail light d side light, red b left stop, turn and tail light e license plate light c side light, amber — — wire colors bk black rd red yl yellow or orange gn green tn tan br brown pu pu...

Page 106

Important: for spare parts information, please see your wacker neuson dealer, or visit the wacker neuson website at http://www.Wackerneuson.Com/. Wichtig! Informationen über ersatzteile erhalten sie von ihrem wacker neuson händler oder besuchen sie die wacker neuson website unter http://www.Wackerne...