- DL manuals

- Wacker Neuson

- Excavators

- 803

- Service Manual

Wacker Neuson 803 Service Manual

Summary of 803

Page 1

Service manual track excavator / machine model 803 edition 2.4 order no. 1000164843 language en.

Page 2

Documentation title language order no. Operator’s manual de 1000161345 service manual en 1000164843 spare parts list de/en/fr 1000161641 de/it/es 1000161643 legend edition issued 1.0 09/2006 1.1 10/2007 2.0 02/2011 2.1. 08/2012 2.2 06/2013 2.3 02/2014 2.4 04/2015 copyright – 2015 wacker neuson linz ...

Page 3: Table of Contents

Shb 803 en – edition 2.4 * 803s20ivz.Fm i-1 table of contents table of contents operation information on this service manual .......................................................................... 1-2 identification of warnings and dangers ............................................................

Page 4: Table of Contents

I-2 shb 803 en – edition 2.4 * 803s20ivz.Fm table of contents diesel fuel specification ................................................................................... 3-14 bleeding the fuel system .................................................................................. 3-15 fuel prefi...

Page 5: Table of Contents

Shb 803 en – edition 2.4 * 803s20ivz.Fm i-3 table of contents engine compartment ....................................................................................... 3-55 threaded fittings and attachments .................................................................. 3-55 pivots and hinges .....

Page 6: Table of Contents

I-4 shb 803 en – edition 2.4 * 803s20ivz.Fm table of contents pump unit: exploded view .................................................................................. 5-3 hydraulic pump pgp505b0040ca1h2nj7j5c-505a0040xb1j5b1b1 (tier iv final from 2012) ...............................................

Page 7: Table of Contents

Shb 803 en – edition 2.4 * 803s20ivz.Fm i-5 table of contents right handle ...................................................................................................... 6-6 working light ...........................................................................................................

Page 8: Table of Contents

I-6 shb 803 en – edition 2.4 * 803s20ivz.Fm table of contents.

Page 9: Operation

Operation.

Page 10: Operation

1-2 shb 803 en – edition 2.4 * 803s110.Fm operation 1 operation 1.1 information on this service manual this service manual contains important information on how to work safely, correctly and economically with the machine. Therefore, it aims not only at new personnel, but it also serves as a referenc...

Page 11: Operation

Shb 803 en – edition 2.4 * 803s110.Fm 1-3 operation 1.2 identification of warnings and dangers important indications regarding the safety of the personnel and the machine are identified in this operator’s manual with the following terms and symbols: danger ! Failure to observe the instructions ident...

Page 12: Operation

1-4 shb 803 en – edition 2.4 * 803s110.Fm operation 1.3 designated use and exemption from liability • the machine is intended for: • moving earth, gravel or rubble, and for hammer operation • see chapter 1.5 “fields of application, attachments” in the operator’s manual for more information on the us...

Page 13: Operation

Shb 803 en – edition 2.4 * 803s110.Fm 1-5 operation 1.4 labels serial number the serial number is located on the type label. The serial number is also stamped on the machine chassis. Refer to the operator’s manual of the machine for more information. Diesel engine type label the type label (arrow) i...

Page 14: Operation

1-6 shb 803 en – edition 2.4 * 803s110.Fm operation swivel unit type label the type label (arrow) is located on the swivel unit. Fig. 6: swivel unit type label.

Page 15: Operation

Shb 803 en – edition 2.4 * 803s110.Fm 1-7 operation 1.5 machine overview (up to serial no. Ai00966) fig. 7: machine outside views 1 boom light 2 boom 3 stick 4 track 5 travel gear 6 stabilizer blade 7 handhold 8 lifting eye for loading/tying down the machine 9 engine cover 10 storage bin for operato...

Page 16: Operation

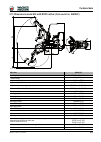

1-8 shb 803 en – edition 2.4 * 803s110.Fm operation 1.6 machine overview (from serial no. Ai00967) 2 3 1 4 5 6 8 9 11 7 13 14 12 fig. 8: machine outside views 1 boom light 2 boom 3 stick 4 track 5 travel gear 6 stabilizer blade 7 handhold 8 lifting eye for loading/tying down the machine 9 engine cov...

Page 17: Operation

Shb 803 en – edition 2.4 * 803s110.Fm 1-9 operation 1.7 control stand overview (up to serial no. Ai00814) 1 3 9 8 2 7 6 4 5 pos. Designation 1 operator seat 2 upper carriage lock 3 engine cover lock 4 preheating start switch 5 stabilizer blade/telescopic undercarriage lever 6 stabilizer blade/telesc...

Page 18: Operation

1-10 shb 803 en – edition 2.4 * 803s110.Fm operation 10 11 12 13 14 15 17 16 18 pos. Designation 10 boom swivel/auxiliary hydraulics pedal 11 footrest 12 control lever lock 13 throttle 14 control lever (left) 15 drive lever (left) 16 drive lever (right) 17 control lever (right) 18 indicators.

Page 19: Operation

Shb 803 en – edition 2.4 * 803s110.Fm 1-11 operation 1.8 control stand overview (from serial no. Ai00815) pos. Designation 1 operator seat 2 upper carriage lock 3 engine cover lock 4 starter 5 stabilizer blade/telescopic travel gear lever 6 stabilizer blade/telescopic travel gear changeover lever 7 ...

Page 20: Operation

1-12 shb 803 en – edition 2.4 * 803s110.Fm operation 1.9 display elements (overview) 22 20 24 21 23 pos. Designation 20 indicator light (red) – alternator charge function 21 indicator light (red) – engine oil pressure 22 indicator light (red) – coolant temperature 23 indicator light (yellow) – fuel ...

Page 21: Operation

Shb 803 en – edition 2.4 * 803s110.Fm 1-13 operation 1.10 engine compartment overview (up to serial no. Ai00814) pos. Designation 25 air filter 26 throttle cable 27 fuel filter 28 swivel unit 29 thermostat 30 filler neck 31 coolant filler inlet 32 coolant reservoir 29 31 30 25 27 26 32 28.

Page 22: Operation

1-14 shb 803 en – edition 2.4 * 803s110.Fm operation 1.11 engine compartment overview (from serial no. Ai00815) 37 39 38 33 34 35 40 36 pos. Designation 33 air filter 34 fuel filter 35 throttle cable 36 swivel unit 37 thermostat 38 filler neck 39 coolant filler inlet 40 coolant reservoir.

Page 23: Technical Data

Technical data.

Page 24: Technical Data

2-2 shb 803 en – edition 2.4 * 803s210.Fm technical data 2 technical data 2.1 chassis sturdy steel sheet chassis, rubber-mounted engine 2.2 engine engine model 803 product yanmar diesel engine type 3tnv70-vns design water-cooled 4 stroke diesel engine number of cylinders 3 fuel injection system indi...

Page 25: Technical Data

Shb 803 en – edition 2.4 * 803s210.Fm 2-3 technical data engine model 803 product yanmar diesel engine type 3tnv74f-snns design water-cooled 4 stroke diesel engine number of cylinders 3 fuel injection system indirect injection aspiration natural aspiration cooling system water-cooled/blowing fan lub...

Page 26: Technical Data

2-4 shb 803 en – edition 2.4 * 803s210.Fm technical data fuel injection pump engine capacities overview of capacities – see fluids and lubricants on page 3-2 engine tightening torques 2.3 hydraulic system type design in-line pump injection pressure 118 – 128 bar (1711 – 1856 psi) engine speed contro...

Page 27: Technical Data

Shb 803 en – edition 2.4 * 803s210.Fm 2-5 technical data auxiliary hydraulics oil flow notice! Output indications for auxiliary hydraulics with unpressurized return line 2.4 travel gear and swivel unit 2.5 stabilizer blade screwable hose burst valve pressure (bar/psi) p1 + p2 (l/min / gal/min) 12.5/...

Page 28: Technical Data

2-6 shb 803 en – edition 2.4 * 803s210.Fm technical data 2.6 electrical system fuses behind the right-hand trim electrical system dynamo 12 v 20 a starter 12 v 1.1 kw (1.5 hp) battery 12 v 30 ah socket for 12 v power outlet, for example; 15 a max. F1 f2 f3 fig. 9: fuses (up to serial number wnce0801...

Page 29: Technical Data

Shb 803 en – edition 2.4 * 803s210.Fm 2-7 technical data relays behind the right-hand trim fuses and relays with dual power option if the machine is equipped with the dual power option, the fuses and relays are located under the base plate. K8 k9 k7 fig. 11: relays relay no. Protected circuit k 7 st...

Page 30: Technical Data

2-8 shb 803 en – edition 2.4 * 803s210.Fm technical data 2.7 noise levels notice! Measurements performed on asphalted surface. 2.8 vibration vibration values indicated in m/s². 2.9 coolant compound table use the 1:1 concentration for warm outside temperatures, too: protection against corrosion, cavi...

Page 31: Technical Data

Shb 803 en – edition 2.4 * 803s210.Fm 2-9 technical data 2.10 model-specific tightening torques *) all connections with an * must be glued with loctite s2420 or varybond 12-43. 2.11 general tightening torques tightening torques for hydraulic threaded fittings (dry assembly) galvanized and dry surfac...

Page 32: Technical Data

2-10 shb 803 en – edition 2.4 * 803s210.Fm technical data torque tolerance: −10 %; countermaterial: steel/aluminum torque tolerance: –10 %; countermaterial: steel/aluminum threaded fittings with various seals for hydraulic applications (light execution) thread straight pipe fitting with thread and s...

Page 33: Technical Data

Shb 803 en – edition 2.4 * 803s210.Fm 2-11 technical data tightening torques for high-resistance threaded fittings din 912 – hexagon socket head cap screw; din 931/din 933 – hexagon head screw with/without shaft; din 7984 – hexagon socket head cap screw with short head all values subject to a fricti...

Page 34: Technical Data

2-12 shb 803 en – edition 2.4 * 803s210.Fm technical data 2.12 dimensions model 803 (up to serial no. Ai00966) 787 (31 in) 1294 (51 in) 1220 (48 in) 500 (20 in) 897 (35 in) 747 (29 in) 1906 (75 in) 323 (13 in) 1198 (47 in) fig. 14: machine dimensions (model 803) 198 1 507 700/860 18 0 18 0 340 700/8...

Page 35: Technical Data

Shb 803 en – edition 2.4 * 803s210.Fm 2-13 technical data 2.13 dimensions model 803 with rops rollbar (from serial no. Ai00967) fig. 15: machine dimensions (model 803) main data model 803 operating weight 1087 kg ( 2396 lbs) transport weight 990 kg (2182 lbs) height (transport position) 2248 mm (7'-...

Page 36: Technical Data

2-14 shb 803 en – edition 2.4 * 803s210.Fm technical data 2.14 dimensions model 803 without rops rollbar (from serial no. Ai00967) main data model 803 operating weight 1029 kg ( 2268 lbs) transport weight 932 kg (2055 lbs) height (transport position) 1436 mm (4'-9") upper carriage width 730 mm (2'-5...

Page 37: Technical Data

Shb 803 en – edition 2.4 * 803s210.Fm 2-15 technical data 2.15 lift capacity table 803 rd refer to the operator’s manual of the machine for specific data. 2.16 kinematics e pin diameter 25 mm (0.98'') f stick width 100 mm (3.9'') l pin distance from bucket mount 165 mm (6.5'') bucket stick.

Page 38: Technical Data

2-16 shb 803 en – edition 2.4 * 803s210.Fm technical data.

Page 39: Maintenance

Maintenance.

Page 40: Maintenance

3-2 shb 803 en – edition 2.4 * 803s310.Fm maintenance 3 maintenance 3.1 fluids and lubricants component/appli- cation fluid/lubricant specification season/temperature capacities 1 1. The capacities indicated are approximate values; the oil level check alone is relevant for the correct oil level capa...

Page 41: Maintenance

Shb 803 en – edition 2.4 * 803s310.Fm 3-3 maintenance oil grades for the diesel engine, depending on temperature additional oil change and filter replacement (hydraulic system) caution! An additional oil change and filter replacement can be required depending on how the machine is used. Failure to o...

Page 42: Maintenance

3-4 shb 803 en – edition 2.4 * 803s310.Fm maintenance oil grades for the hydraulic system, depending on temperature hydrau- lics oil grade ambient temperature (°c/°f) hvlp 1 °c -20 -15 -10 -5 0 5 10 15 20 25 30 35 40 50 iso vg32 iso vg46 iso vg68 °f -4 5 14 23 32 41 50 59 68 77 86 95 104 122 1. Acco...

Page 43: Maintenance

Shb 803 en – edition 2.4 * 803s310.Fm 3-5 maintenance 3.2 maintenance label explanation of symbols on the maintenance label symbol assembly explanation general visual check general grease instructions fuel system drain condensation water fuel system replace the fuel filter, clean the fuel prefilter ...

Page 44: Maintenance

3-6 shb 803 en – edition 2.4 * 803s310.Fm maintenance maintenance label (up to serial number af02412).

Page 45: Maintenance

Shb 803 en – edition 2.4 * 803s310.Fm 3-7 maintenance maintenance label (from serial number af02413).

Page 46: Maintenance

3-8 shb 803 en – edition 2.4 * 803s311.Fm maintenance 3.3 m ain tenan ce plan ( overview) work description for servicing and maintenance on the attachment, p lease refer to the ope ration and maintenance manual of the attachment manufacturer. Maint enan ce plan/o perat ing ho urs ( o/h ) maintenance...

Page 47: Maintenance

Shb 803 en – edition 2.4 * 803s311.Fm 3-9 maintenance air filter (damage) ●● remove dust from dust valve ●● prefilter with water separator: drain water ●● • c lean ●● check v-belt condition and tension ●● replace the v-belt ●● check the exhaust syste m for damage and condition ●● check the rollbar f...

Page 48: Maintenance

3-10 shb 803 en – edition 2.4 * 803s311.Fm maintenance check pin lock ●● check line fixtures ●● check indicator lights for correct function ●● couplings, dirt pile-up on hydraulic syste m dust caps ●● check insulating mats in engine compartment for damage/condition ●● check labels and operator’s man...

Page 49: Maintenance

Shb 803 en – edition 2.4 * 803s311.Fm 3-11 maintenance leakage check ( ): check for tightness, leaks and chafing: pi pes, flexible lines and threaded fitting s of the following asse mblies and components. Rectify if necessa ry: • visual check ●● ☞ engine, hydraulic system and hydraulic components ●●...

Page 50: Maintenance

3-12 shb 803 en – edition 2.4 * 803s312.Fm maintenance 3.4 service package please refer to the 803 spare parts catalogue for the article numbers of the 2 available ser- vice packages (for 50 and 500 operating hours). 3.5 introduction operational readiness and the service life of machines are heavily...

Page 51: Maintenance

Shb 803 en – edition 2.4 * 803s312.Fm 3-13 maintenance 3.7 fuel system specific safety instructions • extreme caution is essential when handling fuel – increased fire hazard! • never perform work on the fuel system near open flames or sparks! • do not smoke when working on the fuel system or when re...

Page 52: Maintenance

3-14 shb 803 en – edition 2.4 * 803s312.Fm maintenance stationary fuel pumps general only refuel from stationary fuel pumps. Fuel from barrels or cans is usually dirty. Even the smallest particles of dirt can cause • increased engine wear • malfunctions in the fuel system and • reduced effectiveness...

Page 53: Maintenance

Shb 803 en – edition 2.4 * 803s312.Fm 3-15 maintenance bleeding the fuel system danger! If the fuel, as it drains, comes into contact with hot engine parts or the exhaust system, there is an increased fire hazard! ☞ never bleed the fuel system if the engine is hot! Bleed the fuel system in the follo...

Page 54: Maintenance

3-16 shb 803 en – edition 2.4 * 803s312.Fm maintenance environment! Thread a is fitted with a hose. Collect the water as it drains with a suitable con- tainer and dispose of it in an environmentally friendly manner..

Page 55: Maintenance

Shb 803 en – edition 2.4 * 803s312.Fm 3-17 maintenance replacing the fuel filter danger! If the fuel, as it drains, comes into contact with hot engine parts or the exhaust system, there is an increased fire hazard! ☞ never change the fuel filter if the engine is hot! Environment! Use a suitable cont...

Page 56: Maintenance

3-18 shb 803 en – edition 2.4 * 803s312.Fm maintenance 3.8 engine lubrication system caution! If the engine oil level is too high or too low, or if an oil change is overdue, this can cause engine damage and loss of output! ☞ have the oil changed by a wacker neuson service center – see chapter 3.3 ma...

Page 57: Maintenance

Shb 803 en – edition 2.4 * 803s312.Fm 3-19 maintenance adding engine oil caution! Too much, not enough or incorrect engine oil can cause engine damage! For this reason: ☞ do not add engine oil above the max mark of oil dipstick 6/a ☞ do not fill in engine oil below the min mark of oil dipstick 6/a ☞...

Page 58: Maintenance

3-20 shb 803 en – edition 2.4 * 803s312.Fm maintenance changing engine oil danger! Caution when draining hot engine oil – burn hazard! ☞ wear protective gloves ☞ use suitable tools environment! Use a suitable container to collect the engine oil as it drains and dispose of it in an environmentally fr...

Page 59: Maintenance

Shb 803 en – edition 2.4 * 803s312.Fm 3-21 maintenance replacing the engine-oil filter cartridge danger! Caution when draining hot engine oil – burn hazard! ☞ wear protective gloves environment! Collect the drained engine oil in a suitable container. Dispose of used oil and filters in an environment...

Page 60: Maintenance

3-22 shb 803 en – edition 2.4 * 803s312.Fm maintenance 3.9 cooling system the radiator is located in the engine compartment, on the right of the engine. The coolant reservoir is also located in the engine compartment, behind the engine specific safety instructions • dirt on the radiator fins reduces...

Page 61: Maintenance

Shb 803 en – edition 2.4 * 803s312.Fm 3-23 maintenance checking the coolant level/adding coolant danger! Never open the coolant reservoir and never drain coolant if the engine is warm since the cooling system is under high pressure. Burn hazard! ☞ wait at least 15 minutes after stopping the engine! ...

Page 62: Maintenance

3-24 shb 803 en – edition 2.4 * 803s312.Fm maintenance notice! Check the coolant level once a day. We recommend checking it before starting the engine. Adding coolant after the engine has cooled down: ☞ release overpressure in the radiator ☞ carefully open the cap to the first notch and fully releas...

Page 63: Maintenance

Shb 803 en – edition 2.4 * 803s312.Fm 3-25 maintenance draining coolant danger! Never open the coolant reservoir and never drain coolant if the engine is warm since the cooling system is under high pressure burn hazard! ☞ wait at least 10 minutes after stopping the engine! ☞ wear protective gloves a...

Page 64: Maintenance

3-26 shb 803 en – edition 2.4 * 803s312.Fm maintenance 3.10 air filter (up to serial no. Ai00875) caution! The air filter element will be damaged if it is washed or brushed out! Bear in mind the following to avoid premature engine wear or damage: ☞ do not clean the air filter element. ☞ replace the ...

Page 65: Maintenance

Shb 803 en – edition 2.4 * 803s312.Fm 3-27 maintenance replacing air filter elements • replace the outside air filter element bas follows: ☞ stop the engine ☞ raise the lock lever ☞ remove the starting key and carry it with you ☞ let the engine cool down ☞ open the engine cover ☞ remove dirt and dus...

Page 66: Maintenance

3-28 shb 803 en – edition 2.4 * 803s312.Fm maintenance caution! Air filter elements degrade prematurely when in service in acidic air for longer periods of time. This risk is present, for example, in acid production facilities, steel and aluminum mills, chemical plants and other nonferrous-metal pla...

Page 67: Maintenance

Shb 803 en – edition 2.4 * 803s312.Fm 3-29 maintenance replace the inside air filter element c as follows: ☞ stop the engine ☞ raise the lock lever ☞ remove the starting key and carry it with you ☞ let the engine cool down ☞ open the engine cover ☞ remove dirt and dust from the air filter element an...

Page 68: Maintenance

3-30 shb 803 en – edition 2.4 * 803s312.Fm maintenance 3.12 v-belt danger! Only check or retighten/replace the v-belt when the engine is stopped – injury hazard! ☞ stop the engine before performing inspection work in the engine compart- ment! ☞ disconnect the battery or the battery master switch ☞ l...

Page 69: Maintenance

Shb 803 en – edition 2.4 * 803s312.Fm 3-31 maintenance retensioning the v-belt caution! Overtensioning the v-belt can damage the v-belt, the v-belt guide and the water pump bearing. Avoid contact of oil, grease or similar substances with the v-belt. ☞ checking v-belt tension – see checking v-belt te...

Page 70: Maintenance

3-32 shb 803 en – edition 2.4 * 803s312.Fm maintenance 3.13 pressure check general • run the machine warm before checking the pressure! Hydraulic oil temperature: 50 °c min. (operating temperature) • in order to measure the secondary pressure limiting valves of the swivel unit, replace the plug in t...

Page 71: Maintenance

Shb 803 en – edition 2.4 * 803s312.Fm 3-33 maintenance adjusting primary pressure limiting valve 1 (pplv 1) ☞ adjust the pressure at the primary pressure limiting valve (pplv 1) a on the main valve block ☞ loosen the locknut of the pressure limiting valve ☞ unscrew the pressure limiting valve until ...

Page 72: Maintenance

3-34 shb 803 en – edition 2.4 * 803s313.Fm maintenance maint ena nce 3.14 test report pum p 1 fu nct io n movement symbol pressure limiting valve measurement con- nection specified values measured ✔ rot ate left secondary pres- sure limiting valve splv-a1 and b1 micro measure- ment connection con tr...

Page 73: Maintenance

Shb 803 en – edition 2.4 * 803s313.Fm 3-35 maintenance boom swiveling left mai n pressu re li m- iting v alve pplv-2 ev l in flexib le lin e rated value 170 ±3 bar d rop 17 bar right rated value 170 ±3 bar d rop 17 bar bucket cylinder extend rated value 170 ±3 bar d rop 17 bar retract rated value 17...

Page 74: Maintenance

3-36 shb 803 en – edition 2.4 * 803s314.Fm maintenance 3.15 hydraulic system specific safety instructions • release the pressure in all lines carrying hydraulic oil prior to any maintenance and repair work. To do this: • lower the boom or the attachment to the ground • move all control levers of the...

Page 75: Maintenance

Shb 803 en – edition 2.4 * 803s314.Fm 3-37 maintenance checking the hydraulic oil level caution! Do not add oil if the oil level is above the full mark, otherwise the hydraulic system can be damaged and escaping oil can cause serious injury. ☞ check the hydraulic oil level each time the machine is p...

Page 76: Maintenance

3-38 shb 803 en – edition 2.4 * 803s314.Fm maintenance adding hydraulic oil danger ! Removing the filler plug can cause oil to escape. Accident hazard! ☞ carefully unscrew the plug to slowly reduce the pressure inside the oil res- ervoir. Do not add hydraulic oil unless the engine is stopped. Otherw...

Page 77: Maintenance

Shb 803 en – edition 2.4 * 803s314.Fm 3-39 maintenance changing hydraulic oil notice! Only change the hydraulic oil if it is warm (about 50 °c). Retract all hydraulic cylinders before changing the oil. ☞ open the filler plug to release pressure ☞ open drain valve c on the lower side of the reservoir...

Page 78: Maintenance

3-40 shb 803 en – edition 2.4 * 803s314.Fm maintenance checking hydraulic pressure lines specific safety instructions danger ! Caution when checking hydraulic lines, especially when searching for leaks. Hydraulic oil escaping under high pressure can penetrate the skin and cause serious injury. Injur...

Page 79: Maintenance

Shb 803 en – edition 2.4 * 803s314.Fm 3-41 maintenance 3.16 tracks • track wear can vary according to work and ground conditions. ☞ we recommend checking track wear and tension once a day. ☞ park the machine on firm and level ground to check and perform maintenance. Checking track tension danger ! W...

Page 80: Maintenance

3-42 shb 803 en – edition 2.4 * 803s314.Fm maintenance setting the tracks danger ! The lubricating valve can be squeezed out due to the high grease pressure in the hydraulic cylinder. Injury hazard! ☞ do not loosen and unscrew the lubricating valve by more than one turn. ☞ loosen no other component ...

Page 81: Maintenance

Shb 803 en – edition 2.4 * 803s314.Fm 3-43 maintenance 3.17 lubrication points on boom (up to serial number ai00966) fig. 42: lubrication points on the boom.

Page 82: Maintenance

3-44 shb 803 en – edition 2.4 * 803s314.Fm maintenance lubrication strip apply grease to the lubrication strip as follows: ☞ lubrication point a for live ring ball bearing ➥ grease: bp energrease mp-mg2 ☞ lubrication point b for the swiveling cylinder notice! Apply grease to lubrication points a and...

Page 83: Maintenance

Shb 803 en – edition 2.4 * 803s314.Fm 3-45 maintenance 3.18 overview of lubrication points (from serial no. Ai00967) 9 1 1 2 2 3 3 4 4 8 8 7 10 10 12 11 5 6.

Page 84: Maintenance

3-46 shb 803 en – edition 2.4 * 803s314.Fm maintenance notice! Keep the lubrication points clean and remove ejected grease. Parking the machine ☞ park the machine on level and horizontal ground. ☞ lower the boom and the attachment to the ground. ☞ lower the stabilizer blade to the ground. ☞ stop the...

Page 85: Maintenance

Shb 803 en – edition 2.4 * 803s314.Fm 3-47 maintenance lubrication points on swiveling console ☞ apply grease to lubrication points 9 of the swiveling console swiveling cylinder lubrication points ☞ stop and park the machine. ☞ open the engine cover. ☞ the lubrication point is located on the right u...

Page 86: Maintenance

3-48 shb 803 en – edition 2.4 * 803s314.Fm maintenance lubrication points on live ring (ball bearing) danger ! Do not rotate the machine during lubrication! Risk of serious crushing that can cause death or serious injury! ☞ stop and park the machine. – see chapter “parking the machine” on page 3-46 ...

Page 87: Maintenance

Shb 803 en – edition 2.4 * 803s314.Fm 3-49 maintenance lubrication points of live ring teeth danger ! Do not rotate the machine during lubrication! Risk of serious crushing that can cause death or serious injury! ☞ stop and park the machine. – see chapter “parking the machine” on page 3-46 ☞ stop an...

Page 88: Maintenance

3-50 shb 803 en – edition 2.4 * 803s314.Fm maintenance ball sockets (iso/sae changeover option) ☞ stop and park the machine. ☞ raise covers 1. ☞ slide the knurled sleeve 13 upward, and hold, unhitch and grease it with gleitmo 800 lubricant. ☞ the sleeve is safely locked if it is firmly connected wit...

Page 89: Maintenance

Shb 803 en – edition 2.4 * 803s314.Fm 3-51 maintenance 3.19 electrical system specific safety instructions • the battery contains sulfuric acid! This acid must not be allowed to come into contact with the skin, the eyes, clothing or the machine therefore when recharging or working near the battery: ...

Page 90: Maintenance

3-52 shb 803 en – edition 2.4 * 803s314.Fm maintenance instructions concerning specific components cables, bulbs and fuses always observe the following instructions: • malfunctioning components of the electrical system must always be replaced by a wacker neuson service center. Lamps and fuses may be...

Page 91: Maintenance

Shb 803 en – edition 2.4 * 803s314.Fm 3-53 maintenance battery battery charge condition ☞ stop and park the machine. Stop the engine. • the battery is maintenance-free according to din. • however check the battery at regular intervals to ensure that the electrolyte level is between the min and max m...

Page 92: Maintenance

3-54 shb 803 en – edition 2.4 * 803s314.Fm maintenance 3.20 general maintenance cleaning cleaning the machine is divided into 2 separate areas: • exterior of the machine • engine compartment the wrong choice of cleaning equipment and agents can impair the operating safety of the machine on the one h...

Page 93: Maintenance

Shb 803 en – edition 2.4 * 803s314.Fm 3-55 maintenance cleaning the seat belt: • clean the seat belt (which remains fitted in the machine) with a mild soap solution only. Do not use chemical agents as they can destroy the fabric! Exterior of the machine the following articles are generally suitable:...

Page 94: Maintenance

3-56 shb 803 en – edition 2.4 * 803s314.Fm maintenance 3.21 preparatory work before taking out of service the measures indicated below refer to putting the machine out of operation for 30 days or longer. • see chapter 2 “safety instructions for maintenance” in the operator’s manual • if the machine ...

Page 95: Maintenance

Shb 803 en – edition 2.4 * 803s314.Fm 3-57 maintenance • remove the starting key, put fuse f2 back in • start the diesel engine • let the engine run at idling speed at least 15 minutes without load. • check all oil levels in the units and add oil if necessary.

Page 96: Maintenance

3-58 shb 803 en – edition 2.4 * 803s314.Fm maintenance.

Page 97: Engine

Engine.

Page 98: Engine

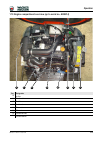

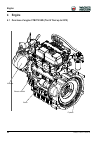

4-2 shb 803 en – edition 2.4 * 803s410.Fm engine engine 4 engine 4.1 overview of engine 3tnv70-vns (tier iv final up to 2012) alternator starter flywheel exhaust manifold.

Page 99: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-3 engine 4.2 fuel system fuel injection pump thermostat cylinder-head cover oil drain plug fan wheel.

Page 100: Engine

4-4 shb 803 en – edition 2.4 * 803s410.Fm engine fuel filte r pump ret urn injection line fi ller inl et fuel sensor fuel filter suc tion line.

Page 101: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-5 engine 4.3 checking and adjusting valve clearance ☞ standard setting of valve clearance is possible: ➥ on a cold engine ☞ remove the cylinder-head cover ☞ turn the engine with a screwdriver (as in 4.7) until the cylinder reaches the top dead center of the co...

Page 102: Engine

4-6 shb 803 en – edition 2.4 * 803s410.Fm engine 4.4 tightening order for cylinder head bolts ☞ install the cylinder-head bolts ➥ tightening torque: caution! Bear in the mind the order for tightening the cylinder-head bolts! ☞ see figure notice! Apply oil to the threads and contact surfaces before i...

Page 103: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-7 engine 4.5 checking the injection nozzles pressure check ☞ remove the injection line and the injection nozzle ☞ connect the injection nozzle with the high pressure line of the nozzle tester ☞ slowly increase pressure until the nozzle ejects fuel and read the...

Page 104: Engine

4-8 shb 803 en – edition 2.4 * 803s410.Fm engine 4.7 injection time checking and adjusting injection time • preparatory work: ☞ mark the actual position of the fuel injection pump on the engine block. ☞ trace the mark with a touch-up applicator. ☞ set the throttle to work position. ☞ unscrew only th...

Page 105: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-9 engine replacement of fuel injection pump ☞ mark the initial position on the pump and wheel case housing before removing the fuel injection pump – see fig. 9 ☞ remove gear casing cover 10/1 of the fuel injection pump ☞ mark the position of the gear of the fu...

Page 106: Engine

4-10 shb 803 en – edition 2.4 * 803s410.Fm engine 4.8 adjusting engine speed notice! The maximum engine speed is set and sealed by the manufacturer without the pump and may not be increased! Adjust engine speed without load! ☞ run the diesel engine until it reaches operating temperature ☞ check idli...

Page 107: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-11 engine ☞ warm up the thermostat in a container with water ☞ check whether the thermostat opens at the specified temperature (check with a tem- perature gage) ➥ thermostat opening temperature: 69.5 – 72.5 °c (157.1 – 162.5 °f) 4.11 checking the thermal switc...

Page 108: Engine

4-12 shb 803 en – edition 2.4 * 803s410.Fm engine 4.13 checking the coolant circuit leakage check ☞ fill up the radiator completely ☞ install an adapter on the radiator as shown ☞ increase the pressure in the cooling system by means of a hand pump to about 1 bar ➥ check the lines and the connections...

Page 109: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-13 engine 4.14 engine trouble problem possible cause engine does not start or is not easy to start wrong sae grade of engine lubrication oil fuel grade does not comply with specifications malfunctioning or empty battery loose or oxidized cable connections in s...

Page 110: Engine

4-14 shb 803 en – edition 2.4 * 803s410.Fm engine insufficient engine output oil level too high fuel grade does not comply with specifications dirty air filter malfunctioning air filter maintenance switch or gage wrong valve clearance injection line leaks malfunctioning fuel injector air in fuel sys...

Page 111: Engine

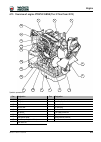

Shb 803 en – edition 2.4 * 803s410.Fm 4-15 engine 4.15 overview of engine 3tnv74f-snns (tier iv final from 2012) 1 2 3 4 5 6 7 8 16 15 14 13 12 11 9 10 symbolic representation 17 18 19 pos. Designation pos. Designation 1 lifting eye 2 water pump 3 lifting eye 4 injection pump fan wheel 5 v-belt 6 cr...

Page 112: Engine

4-16 shb 803 en – edition 2.4 * 803s410.Fm engine 1 symbolic representation 2 3 4 5 6 pos. Designation pos. Designation 1 oil filler neck 2 cylinder-head cover 3 flywheel 4 starter 5 exhaust manifold 6 alternator.

Page 113: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-17 engine 4.16 fuel system 1 2 3 4 5 6 pos. Designation pos. Designation 1 injection nozzle 2 injection pump drive pinion 3 fuel injection pump 4 fuel filter with water separator 5 fuel pump 6 water separator.

Page 114: Engine

4-18 shb 803 en – edition 2.4 * 803s410.Fm engine 4.17 cooling system 5 4 3 2 1 6 pos. Designation pos. Designation 1 cylinder head 2 thermostat 3 water pump 4 radiator 5 coolant reservoir 6 cylinder block.

Page 115: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-19 engine 4.18 altitude-dependent output reduction this engine is equipped with an altitude-dependent output reduction to prevent the forma- tion of black smoke a higher altitudes (fine particulate pollution). Engine output is reduced when the engine is starte...

Page 116: Engine

4-20 shb 803 en – edition 2.4 * 803s410.Fm engine 4.19 checking and adjusting valve clearance ☞ the standard valve clearance setting is performed on a cold engine: ➥ the firing order is 1 – 3 – 2, starter at the 240° position of the crankshaft rotation. Notice! The first cylinder is located on the p...

Page 117: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-21 engine setting valve clearance ☞ check the valve setting as described in the “valve clearance” section. ☞ loosen locknut c and adjusting screw b on the rocker arm. ☞ check the valve cap for abnormal wear – see fig. 22 ☞ for the correct valve clearance inser...

Page 118: Engine

4-22 shb 803 en – edition 2.4 * 803s410.Fm engine 4.20 tightening order for cylinder head bolts notice! Always perform work on the cylinder head on a cold engine! Order for removing the cylinder-head bolts: order for installing the cylinder-head bolts: notice! Apply a thin coat of oil to the threads...

Page 119: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-23 engine 4.21 checking the injection nozzles pressure check ☞ ball-type cock on fuel filter in the “off” position. ☞ clean the area around the nozzles and the injection pump. ☞ remove the injection line and the injection nozzle. ☞ connect the injection nozzle...

Page 120: Engine

4-24 shb 803 en – edition 2.4 * 803s410.Fm engine 4.22 checking the nozzle jet ☞ remove the injection lines and the injection nozzles. ☞ connect the injection nozzle with the high pressure line of the nozzle tester. ☞ quickly create pressure until the nozzle ejects fuel (ejection 3 – 4 times). ☞ hol...

Page 121: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-25 engine marks (standard specification) on the flywheel: ☞ turn until mark g on the ring gear for cylinder 1 are visible and at the same level as mark f on the flywheel housing. ➥ rated injection point 16° before top dead center (+/− 1°). ☞ mark the (rated) i...

Page 122: Engine

4-26 shb 803 en – edition 2.4 * 803s410.Fm engine ☞ then slowly turn back approximately two more rotations until about 30° before top dead center. ☞ remove any bubbles at the opening of the injection pump with your finger so that the opening of the injection pump is about half full with fuel. ☞ slow...

Page 123: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-27 engine 4.24 removing and installing the injection pump removing the injection pump ☞ remove the v-belt, pulley and fan wheel with a suitable tool. ☞ mark the original position of the injection pump on the pump and gear casing – see mark on pump housing on p...

Page 124: Engine

4-28 shb 803 en – edition 2.4 * 803s410.Fm engine ☞ mark position e of injection pump gear f in relation to gear position g. ☞ after marking, do not turn the crankshaft. ➥ tighten the screw of the pulley with a long spanner to fix the crankshaft in place. ☞ loosen lock nut h of gear f and unscrew un...

Page 125: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-29 engine • if the injection pump is installed in a diesel engine in which the gear casing was also removed, alignment is possible by means of the marks on the gears of the injection pump, camshaft, crankshaft and idler gear. ➥ ensure that all three marks (a, ...

Page 126: Engine

4-30 shb 803 en – edition 2.4 * 803s410.Fm engine 4.25 measuring and adjusting the engine speed measuring the engine speed the engine speed can be quickly and simply determined with a tachometer. ☞ measurement on the crankshaft disk or on the ring gear. Notice! The maximum engine speed is set and se...

Page 127: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-31 engine 4.27 checking the coolant thermostat • the thermostat is located on the water pump – see cooling system on page 4-18 ☞ remove the thermostat. ☞ drain the coolant. ☞ remove the coolant hose. ☞ remove the connecting line of the temperature sensor. ☞ un...

Page 128: Engine

4-32 shb 803 en – edition 2.4 * 803s410.Fm engine 4.29 oil pressure switch ☞ remove the cable connection from the oil pressure switch (in the area of the cutoff solenoid). ☞ start the engine, check for correct idling speed. ☞ measure the resistance of the oil pressure switch as shown by means of an ...

Page 129: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-33 engine 4.32 coolant and fuel hoses ☞ check the coolant and fuel hoses regularly to ensure that they are not kinked, cracked or damaged. ➥ renew coolant and fuel hoses every 2000 o/h. 4.33 crankcase vent • venting system by means of a spring-loaded diaphragm...

Page 130: Engine

4-34 shb 803 en – edition 2.4 * 803s410.Fm engine 4.35 engine trouble problem possible causes engine does not start or is not easy to start incorrect engine oil fuel grade does not comply with specifications malfunctioning or empty battery loose or oxidized cable connections in starter circuit malfu...

Page 131: Engine

Shb 803 en – edition 2.4 * 803s410.Fm 4-35 engine engine overheats, temperature warning system responds malfunctioning thermostat malfunctioning cylinder-head gasket malfunctioning piston ring malfunctioning radiator malfunctioning fan, torn or loose v-belt malfunctioning fuel injector not enough co...

Page 132: Engine

4-36 shb 803 en – edition 2.4 * 803s410.Fm engine engine smoke white malfunctioning piston ring malfunctioning piston/cylinder fuel grade does not comply with specifications malfunctioning fuel injector wrong injection time (too late!) malfunctioning thermostat too much cooling water in fuel system ...

Page 133: Hydraulic System

Hydraulic system.

Page 134: Hydraulic System

5-2 shb 803 en – edition 2.4 * 803s510.Fm hydraulic system hydraulic system 5 hydraulic system the hydraulic system is governed by a throttle 5.1 hydraulic pump pgp505b0050ca1h2nj7j5c-505a00 (tier iv final up to 2012) 2 coupled gear pumps 3 1 2 gear pump unit pos. Designation 1 suction line connecti...

Page 135: Hydraulic System

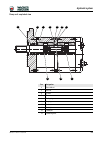

Shb 803 en – edition 2.4 * 803s510.Fm 5-3 hydraulic system pump unit: exploded view 6 11 7 8 10 9 12 4 13 5 pos. Designation 4 gear shaft set 5 gear set 6 lip seal 7 sleeve 8 sealing ring 9 prop ring 10 seal 11 parallel pin 12 parallel pin 13 connecting shaft.

Page 136: Hydraulic System

5-4 shb 803 en – edition 2.4 * 803s510.Fm hydraulic system 5.2 hydraulic pump pgp505b0040ca1h2nj7j5c-505a0040xb1j5b1b1 (tier iv final from 2012) 2 coupled gear pumps 3 1 2 gear pump unit pos. Designation 1 suction line connection 2 pressure line p1 connection 3 pressure line p2 connection.

Page 137: Hydraulic System

Shb 803 en – edition 2.4 * 803s510.Fm 5-5 hydraulic system pump unit: exploded view 6 11 7 8 10 9 12 4 13 5 pos. Designation 4 gear shaft set 5 gear set 6 lip seal 7 sleeve 8 sealing ring 9 prop ring 10 seal 11 parallel pin 12 parallel pin 13 connecting shaft.

Page 138: Hydraulic System

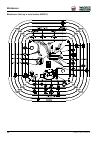

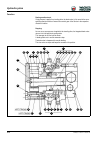

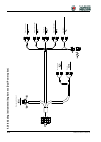

5-6 shb 803 en – edition 2.4 * 803s510.Fm hydraulic system 5.3 main valve block connections input p1 stabilizer blade/ telescopic undercarriage auxiliary hydraulics machine travel (right) boom input p2 rotate stick machine travel (left) swivel p1 b1 a1 t p2 a2 bucket b2 a3 b3 b4 a4 a5 a6 a7 a8 a9 b5...

Page 139: Hydraulic System

Shb 803 en – edition 2.4 * 803s510.Fm 5-7 hydraulic system legend main control lines pump/reservoir lines connection legend b1 rotation to the left a1 rotation to the right b2 stick cylinder rod side b1 stick cylinder base side b3 left-hand traveling drive reverse a3 left-hand traveling drive forwar...

Page 140: Hydraulic System

5-8 shb 803 en – edition 2.4 * 803s510.Fm hydraulic system main valve block diagram machine travel (left) rotate stick stabilizer blade/ telescopic undercarriage auxiliary hydraulics machine travel (right) bucket boom swivel.

Page 141: Hydraulic System

Shb 803 en – edition 2.4 * 803s510.Fm 5-9 hydraulic system pressure limiting valves 2 1 5 3 7 6 4 pos. Designation 1 primary pressure limiting valve p1 2 secondary pressure limiting valve, swivel, right 3 anticavitation valve 4 primary pressure limiting valve p2 5 secondary pressure limiting valve, ...

Page 142: Hydraulic System

5-10 shb 803 en – edition 2.4 * 803s510.Fm hydraulic system pump assignment hydraulic supply by pump 1 • upper carriage rotation section • stick section • left-hand drive section supplied by pumps 1 and 2 • stabilizer blade/telescopic undercarriage section • auxiliary hydraulics section hydraulic su...

Page 143: Hydraulic System

Shb 803 en – edition 2.4 * 803s510.Fm 5-11 hydraulic system 5.4 traveling drive the hydraulic motor is slow-running geroller motor without gears and with internal leak oil drain. 5 3 4 1 2 6 6 pos. Designation 1 input shaft 2 engine 3 damping 4 brake valve 5 non-return valve 6 connections.

Page 144: Hydraulic System

5-12 shb 803 en – edition 2.4 * 803s510.Fm hydraulic system function starting machine travel: if high pressure is applied to a traveling drive, the brake valve is first moved in the corre- sponding direction and the oil moves the eccentric gear of the gerotor in the respective direction of rotation....

Page 145: Hydraulic System

Shb 803 en – edition 2.4 * 803s510.Fm 5-13 hydraulic system pos. Designation pos. Designation 1 geroller unit 19 o-ring 2 geroller ring 20 prop ring 3 geroller star wheel 21 spring 4 geroller roller 22 control sleeve 5 housing assembly 23 pin 6 housing element (undercarriage side) 24 shaft 7 valve b...

Page 146: Hydraulic System

5-14 shb 803 en – edition 2.4 * 803s510.Fm hydraulic system 5.5 swivel unit the swivel unit is a slow-running gerotor motor without gears. If the gear motor is not actuated, the feed lines are closed by the spool, i.E. The upper car- riage stops and does not continue turning by itself. Notice! Ensur...

Page 147: Hydraulic System

Shb 803 en – edition 2.4 * 803s510.Fm 5-15 hydraulic system swivel unit pos. Designation pos. Designation 1 screw 16 oil sealing ring 2 geroller 17 dust seal 3 shaft 18 o-ring 4 geroller cover 19 type label 7 spacer washer 20 rivet 8 screwed flange 21 o-ring 9 axial bearing ball race 22 o-ring 10 ou...

Page 148: Hydraulic System

5-16 shb 803 en – edition 2.4 * 803s510.Fm hydraulic system 5.6 swivel joint 8-channel swivel joint sealing ☞ loosen the circlip on the lower side. ☞ pull the swivel joint apart. ☞ replace the sealing rings. ☞ push the inside and outside parts together again. ☞ insert the circlip again pos. Connecti...

Page 149: Hydraulic System

Shb 803 en – edition 2.4 * 803s510.Fm 5-17 hydraulic system 5.7 mechanical control all hydraulic functions of the 803 are controlled mechanically. Accessing the elements of the mechanical pilot control requires removing the plastic trims – see chapter 5.9 plastic trims on page 5-22. Control levers (...

Page 150: Hydraulic System

5-18 shb 803 en – edition 2.4 * 803s510.Fm hydraulic system drive levers (up to serial no. Ai00814) setting the drive levers ☞ place the machine horizontally ☞ adjust the length of the adjustment linkage so that the shackle on the drive lever remains horizontal in neutral position. ➥ a correct setti...

Page 151: Hydraulic System

Shb 803 en – edition 2.4 * 803s510.Fm 5-19 hydraulic system control levers (from serial number ai00815) all hydraulic functions of the 803 are controlled mechanically. Accessing the elements of the mechanical pilot control requires removing the plastic trims – see chapter 5.9 plastic trims on page 5...

Page 152: Hydraulic System

5-20 shb 803 en – edition 2.4 * 803s510.Fm hydraulic system drive levers (from serial number ai00815) setting the drive levers ☞ place the machine horizontally ☞ adjust the length of the adjustment linkage so that the shackle on the drive lever remains horizontal without any appreciable resistance i...

Page 153: Hydraulic System

Shb 803 en – edition 2.4 * 803s510.Fm 5-21 hydraulic system lock lever (from serial number ai00815) notice! When the lock lever is locked, all control stand functions are locked and the exca- vator is protected against unintentional operation of the levers. Lock lever locked lock lever open.

Page 154: Hydraulic System

5-22 shb 803 en – edition 2.4 * 803s510.Fm hydraulic system 5.8 troubleshooting in the hydraulic system 5.9 plastic trims removing the plastic trim on machines without rops bar (up to serial number ai00966) figure 1 ☞ stop and secure the excavator ☞ loosen clamp screws k on either side of the excava...

Page 155: Hydraulic System

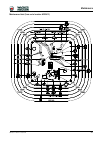

Shb 803 en – edition 2.4 * 803s511.Fm 5-23 hydraulic system hydraulic sy st em hydraulics diagram.

Page 156: Hydraulic System

5-24 shb 803 en – edition 2.4 * 803s511.Fm hydraulic system 5.10 hydraulics diagram (legend) pos. Designation 1 diesel engine 2 gear pump 3 main v alve bl oc k 4 swivel unit 5 stick cylinder 6 traveling drive (left) 7 traveling drive (right) 8 sta bilizer blade cylinder 9 telescopic cylinder 10 au x...

Page 157: Hydraulic System

Shb 803 en – edition 2.4 * 803s511.Fm 5-25 hydraulic system 5.1 1 hydraulics diagram.

Page 158: Hydraulic System

5-26 shb 803 en – edition 2.4 * 803s511.Fm hydraulic system 5.12 hydraulics diagram (dual power option) pos. Designation 1 diesel engine 2 gear pump 3 main valve block 4 swivel unit 5 stick cylinder 6 traveling drive (left) 7 traveling drive (rig ht) 8 stabilizer bla de cylinder 9 telescopic cylinde...

Page 159: Hydraulic System

Shb 803 en – edition 2.4 * 803s511.Fm 5-27 hydraulic system 5.13 main valve block diagram main control lines connection leg end a1, b1 swivel unit a2, b2 stick a3, b3 traveling drive (left) a4, b4 stabilizer blade/t elescopic undercarriage a5 auxiliary hydraulics a6, b6 traveling drive (right) a7, b...

Page 160: Hydraulic System

5-28 shb 803 en – edition 2.4 * 803s511.Fm hydraulic system.

Page 161: Electrical System

Electrical system.

Page 162: Electrical System

6-2 shb 803 en – edition 2.4 * 803s610.Fm electrical system electrical system 6 electrical system 6.1 ohm’s law (current, voltage, resistance); power it describes the interrelation between current, voltage and resistance. Current “i” – ampere (a) voltage “u” – volt (v) resistance “r” – ohm ( ) mnemo...

Page 163: Electrical System

Shb 803 en – edition 2.4 * 803s610.Fm 6-3 electrical system 6.3 cable color coding 6.4 relays use, mode of function relays are used for switching electric loads (high currents) whereby the control power of the relay coil is relatively low. Relays can therefore be controlled by microelectronics or mi...

Page 164: Electrical System

6-4 shb 803 en – edition 2.4 * 803s610.Fm electrical system 6.5 electrical system fuses behind the right-hand trim electrical system dynamo 12 v 20 a starter 12 v 1.1 kw (1.5 hp) battery 12 v 30 ah socket for 12 v power outlet, for example; 15 a max. F1 f2 f3 fig. 2: fuses (up to serial number wnce0...

Page 165: Electrical System

Shb 803 en – edition 2.4 * 803s610.Fm 6-5 electrical system relays behind the right-hand trim fuses and relays with dual power option if the machine is equipped with the dual power option, the fuses and relays are located under the base plate. K8 k9 k7 fig. 4: relays relay no. Protected circuit k 7 ...

Page 166: Electrical System

6-6 shb 803 en – edition 2.4 * 803s610.Fm electrical system 6.6 control lever push button right handle 6.7 working light fig. 7: right handle 1 pos. Designation 1 horn 2 pos. Designation 2 working light rotary switch.

Page 167: Electrical System

Shb 803 en – edition 2.4 * 803s610.Fm 6-7 electrical system 6.8 dynamo the dynamo supplies the alternating current (rectified by the rectifier) to the electric con- sumers and for charging the battery. 6.9 rectifier rectifier r rectifies the dynamo voltage. Wiring: 6.10 starter fig. 8: dynamo pos. D...

Page 168: Wiring Harnesses

6-8 shb 803 en – edition 2.4 * 803s611.Fm wiring harnesses.

Page 169: 6.1

Shb 803 en – edition 2.4 * 803s611.Fm 6-9 6.1 1 engine wiring harness le gend (t ier iv final up to 2012) no . To to colo r mm 2 1 bat te ry f1 /1 ma in fu se re d 6 2 ba tte ry a3 regulat or red 2.5 3 f1 /2 main f use s1/ 2 prehea ting st art s wit ch red 4 4 f1 /2 k9/ 30 red 2.5 5 s1 /6 prehe atin...

Page 170: 6.12

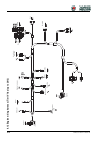

6-10 shb 803 en – edition 2.4 * 803s611.Fm 6.12 engine wiring harness (t ier iv final up to 2012) alternator st art er rectif ier engine oil pr essu re engine temperature swit ch cu tof f solenoid pr eheating bat ter y fuel pump cu to ff s ole - noid timer cutof f s olenoid star ting horn boo m ligh...

Page 171: 6.13

Shb 803 en – edition 2.4 * 803s611.Fm 6-11 6.13 engine wiring harness lege nd (t ier iv final from 2012) no . To to color mm 2 fun ct ion 1 batt ery f1/ 1 red 6 12 v 30 2 s1/1 a3 red 2.5 12 v 30 3 f1/2 s1/ 2 red 4 12 v 30 st art er 4 f1/2 k9/ 30 red 2.5 12 v 30 relay 5 s1/6 f2/ 1 blu 2.5 12 v/1 5 fu...

Page 172: 6.14

6-12 shb 803 en – edition 2.4 * 803s611.Fm 6.14 engine wiring harness (t ier iv final f rom 2012) alternator st art er re ct ifier engine oil pres sur e engine temperature sw itc h cutof f s olenoid pre heating bat ter y fuel p um p c utof f s ole- noid timer c utof f solenoid st art r elay horn w o...

Page 173: 6.15

Shb 803 en – edition 2.4 * 803s611.Fm 6-13 6.15 w iring harness for indicators (up to serial number wnce0801tp al00923) no. To to color mm² func tion 14 x1/8 h5 pn k 1 charge i ndicator lig ht 15 x1/5 h3 bl k/ grn 1 en gine tem peratur e switc h 16 x1/4 p1 wht/gr n 1 en gine oil pres sure 17 x1/4 h4...

Page 174: 6.16

6-14 shb 803 en – edition 2.4 * 803s611.Fm 6.16 wiring harness for indicators (f rom serial number wnce0801pp al00924) engine oil pressure charge in dicator light empty reservoir engine temperature ho ur me ter socket.

Page 175: 6.17

Shb 803 en – edition 2.4 * 803s611.Fm 6-15 6.17 tr aveling signal wiring harness (option) st ran d fro m to mm² color 1 x1.1/1 1 bl u 2 x1/1 s78.1 1 bl k 3 x1/1 s78.2 1 bl k 4 s78.1 x2/1 1 bl u 5 s78.2 x2/1 1 bl u 6 s78.1 x3 1 red 7 s78.2 x3 1 red 8 x2/2 x1/2 1 blk 9 x1.1/2 1 bl k.

Page 176: 6.18

6-16 shb 803 en – edition 2.4 * 803s611.Fm 6.18 horn wiring harness stran d fr om to color mm² fu nctio n 33 x2/1 s5 5 or g/blk 1 h orn 49 x2/1 s5 5 blk 1 g rou nd horn push button.

Page 177: 6.19

Shb 803 en – edition 2.4 * 803s611.Fm 6-17 6.19 battery lead battery lead + plus lead (red) minus lea d (black) battery lead po si tion 1 po si tion 1 po si tion 1 position 2 position 2 position 2 bl ac k bl ac k red red.

Page 178: 6.20

6-18 shb 803 en – edition 2.4 * 803s611.Fm 6.20 indicating instrument wiring harness (dual power option) press ure sw itc h for unit w or king light soc ket engine oil pres sur e char ge ind ic ator light fuel senso r engine temperature hour meter.

Page 179: 6.21

Shb 803 en – edition 2.4 * 803s611.Fm 6-19 6.21 engine/chassis wiring harness (dual power option) rect ifier alter nator st art er engine r estric tion so lenoid engine oil press ure c utof f s ole- noid timer b atter y c ont ro l c utof f solenoid starting relay hor n boom w orking lig ht fuel sens...

Page 180: 6.22

6-20 shb 803 en – edition 2.4 * 803s611.Fm 6.22 seat con sole wiring harness quickhit ch ro tating b eacon lights wiper quickhit ch relay sa fety sw itch ho rn he at in g s afe ty switch quickh itch p ush bu tton 12 v po w er ou tlet fa n q uickhitch pr essure swi tch.

Page 181: Electrical System

Shb 803 en – edition 2.4 * 803s612.Fm 6-21 electrical system wiring diagrams electrical system.

Page 182: Electrical System

6-22 sh b 80 3 en – ed itio n 2. 4 * 80 3s 61 2. Fm electrical system 6.23 w iring diagram no. Desi gnati on a3 regul ator b1 fu el indicator b2 horn e1 1 w orking light f1 mai n fus e f2 fu se: relay , indi cat or , cutof f sole noid f3 fuse: horn, working light g1 dynam o g2 battery h3 engi ne tem...

Page 183: Electrical System

Shb 803 en – edition 2.4 * 803s612.Fm 6-23 electrical system 6.24 wiring diagram t ier iv (y anmar) no. Desi gnati on a3 re gulator b1 fu el indicator b2 hor n b53 atmosphe ric press ure sensor e1 1 w orking light f1 mai n fus e f2 fu se : r elay , indi ca tor , c utof f s ol enoid f3 fuse: horn, wo...

Page 184: Electrical System

6-24 sh b 80 3 en – ed itio n 2. 4 * 80 3s 61 2. Fm electrical system 6.25 w iring diagram (dual power option) no. Desi gnati on a3 regul ator b1 fu el indicator b2 hor n b53 atmosphe ric press ure sensor e1 1 w orking light f1 mai n fus e f2 fu se : r elay , indi ca tor , c utof f s ol enoid f3 fus...

Page 185: Options

Options.

Page 186: Options

7-2 shb 803 en – edition 2.4 * 803s710.Fm options 7 options • article numbers for options and retrofit kits: please refer to the 803 spare parts list. 7.1 rollbar • tops – tip over protection structure for compact machines. • rops – roll over protection structure tops rollbar up to serial number af0...

Page 187: Options

Shb 803 en – edition 2.4 * 803s710.Fm 7-3 options lowerable rops rollbar (from serial no. Af01417 to serial no. Ai00966) danger ! The rops rollbar is very heavy, folding it up and down, or lowering and raising it, is very dangerous! ☞ use suitable lifting gear and auxiliary means to lower, raise and...

Page 188: Options

7-4 shb 803 en – edition 2.4 * 803s710.Fm options lowering and raising the rollbar lowering the rollbar: ☞ park the machine on level ground ☞ stop the engine ☞ lock the control levers ☞ install suitable lifting gear on the rollbar ☞ remove the split pins and pins b on either side ☞ slowly and carefu...

Page 189: Options

Shb 803 en – edition 2.4 * 803s710.Fm 7-5 options raising/lowering the rollbar: raising the rollbar: ☞ park the machine on level ground ☞ stop the engine ☞ lock the control levers ☞ install suitable lifting gear on the rollbar ☞ remove the linch pins and pins a on either side ☞ slowly and carefully ...

Page 190: Options

7-6 shb 803 en – edition 2.4 * 803s710.Fm options 7.2 iso/sae changeover (option) danger ! Accident hazard due to modified control lever operation! Can cause serious injury or death. Accident hazard! ☞ change over the controls only on level and firm ground, and only if the starting key is removed. ☞...

Page 191: Options

Shb 803 en – edition 2.4 * 803s710.Fm 7-7 options 7.3 traveling signal (option) a signal sounds if a drive lever is actuated. Danger ! Accident hazard during forward/backward machine travel. Danger of severe crushing causing death or serious injury. ☞ do not allow anyone to stay in the danger zone. ...

Page 192: Options

7-8 shb 803 en – edition 2.4 * 803s710.Fm options 7.4 telematic after installing the telematic system, module a is enabled and sends data to the telem- atic web portal. Technical data • this works in 90 countries with currently 160 roaming partners with a gprs data network. • the gps receiver regist...

Page 193: Options

Shb 803 en – edition 2.4 * 803s710.Fm 7-9 options 7.5 zero-emission dual power drive • diesel operation is identical to standard version. • during hpu operation, this unit ensures the oil supply by means of a connection on the travel gear (via the swivel joint to the double ball-type cock). • diesel...

Page 194: Options

7-10 shb 803 en – edition 2.4 * 803s710.Fm options.

Page 195

Wacker neuson linz gmbh keep abreast of the latest technical developments and con- stantly improve their products. For this reason, we may from time to time need to make changes to figures and descriptions in this documentation which do not reflect products that have already been delivered and that ...

Page 196

Wacker neuson linz gmbh flughafenstr. 7 a-4063 hörsching phone: +43 (0) 7221 63000 fax: +43 (0) 7221 63000-2200 e-mail: office.Linz@wackerneuson.Com www.Wackerneuson.Com order no. 1000164843 language en.