- DL manuals

- Wacker Neuson

- Saw

- BFS 1318AS

- Operator's Manual

Wacker Neuson BFS 1318AS Operator's Manual

Summary of BFS 1318AS

Page 1

Concrete saw bfs series re v. 02/07 www.Wackergroup.Com www.Wackergroup.Com floor saw bfs 1318as bfs 2002as operator’s manual 0162594en 001 0207 0 1 6 2 5 9 4 e n www.Wackergroup.Com floor saw bfs 1318as bfs 2002as operator’s manual 0162594en 001 0207 0 1 6 2 5 9 4 e n.

Page 2

Revision 03/05/07 bfs series page intentionally left blank.

Page 3

Revision 03/05/07 bfs series table of contents 1. Foreword..................................................................................................................... . Safety information......................................................................................................4 ...

Page 4

4 revision 03/05/07 bfs series table of contents 5.6 wet cutting..............................................................................................18 5.7 dry cutting...............................................................................................18 5.8 aligning the saw with ...

Page 5

5 revision 03/05/07 bfs series california proposition 65 warning: engine exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. 1. Foreword this manual provides informa...

Page 6

6 revision 03/05/07 bfs series safety information . Safety information this manual contains danger, warning, caution, notice and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is use...

Page 7

7 revision 03/05/07 bfs series safety information .1 operating safety familiarity and proper training are required for the safe operation of equipment! Equipment operated improperly or by untrained personnel can be dangerous! Read the operating instructions contained in both this manual and the engi...

Page 8

8 revision 03/05/07 bfs series safety information always guide the saw in such a way that the operator is not squeezed between the saw and solid objects. Special care is required when working on uneven ground or when compacting coarse material. Make sure to stand firmly when operating the machine un...

Page 9

Revision 03/05/07 bfs series safety information . Service safety poorly maintained equipment can become a safety hazard! In order for the equipment to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. Do not attempt to clean or service...

Page 10

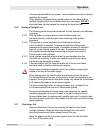

10 revision 03/05/07 bfs series safety information .4 hazard symbols symbol meaning explosive fuel gasoline is extremely flammable and its vapors can explode if ignited. Store gasoline only in approved containers, in well-ventilated, unoccupied buildings, away from sparks or flames. Do not fill the ...

Page 11

11 revision 03/05/07 bfs series safety information .5 damage prevention messages other important messages that are designed to help prevent damage to your wacker bfs series concrete saw, other property, or the environment are preceded by the word notice. Notice: your wacker bfs series concrete saw o...

Page 12

1 revision 03/05/07 bfs series technical data . Saw features the wacker bfs series concrete saw is designed for wet or dry, general application sawing. The heavy duty steel, one piece box frame is precision jig welded and reinforced. This precisely reinforced steel construction with balanced weight ...

Page 13

1 revision 03/05/07 bfs series technical data . Tach / hourmeter a digital readout tach/hourmeter is factory installed on the bfs series models . When the engine is running, the display will indicate the engine’s rpm. When the engine is shut off, the display will switch to run time, initially in min...

Page 14

14 revision 03/05/07 bfs series preparation 4. Unpacking, assembly and preparation your wacker bfs-series has been shipped from the factory fully assembled and requires only minimal service to insure proper machine preparation prior to use. The following instructions should be followed closely. Care...

Page 15

15 revision 03/05/07 bfs series preparation add oil to fill the crankcase with oil, place the engine level. In order for this to be accomplished the blade must not be installed, and the depth adjustment must be down (until the engine is level). Refer to the manufacturer’s instructions for details on...

Page 16

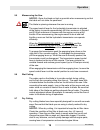

16 revision 03/05/07 bfs series preparation 4.5 mounting the blade when mounting the blade, locate the direction arrow on the blade and install the blade in the proper orientation. The blade rotates clockwise when viewed from the right side of the saw. The blade must be properly fitted over the blad...

Page 17

17 revision 03/05/07 bfs series operation 5. Saw operations this section of the manual describes the operating procedures, and safety precautions for proper use of this concrete saw. This saw is intended for industrial applications by experienced operators. It is to be operated in conformance with a...

Page 18

18 revision 03/05/07 bfs series operation 5. Buried or concealed hazards prior to operation of this machine the operator must determine the existence and location of any subsurface features which may be hazardous or could damage the equipment (i.E. Electric cable, natural gas line, etc.). 5. Operati...

Page 19

1 revision 03/05/07 bfs series operation 5.5 maneuvering the saw notice: raise the blade as high as possible when maneuvering so that the blade will not strike the pavement. The blade is spinning whenever the saw is running. The speed control lever for the hydrostatic transmission is adjusted at the...

Page 20

0 revision 03/05/07 bfs series operation saw only as deep as the specifications and job conditions require. Remember, airflow helps to cool the blade during dry cutting. Cutting too deep with one pass, or exerting excessive forward or side pressure can be dangerous. Step cut in increments of 2 inche...

Page 21

1 revision 03/05/07 bfs series operation if the saw should stall for any reason, raise the blade out of the cut before restarting the engine! When lowering the blade into a partially made cut, the blade must be perfectly aligned within the cut before starting to saw again. Do not force the blade int...

Page 22

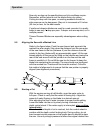

Revision 03/05/07 bfs series operation 5.1 cutting with the blade on the left side left side cutting can be easily accomplished by moving the blade guard to the left hand side of the saw belt guard using the following steps: turn kill switch to off position. Disconnect water hose from blade guard. R...

Page 23

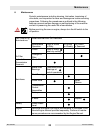

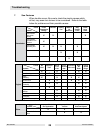

23 revision 03/05/07 bfs series maintenance 6. Maintenance periodic maintenance including cleaning, lubrication, tensioning of drive belts, and inspection for wear and damage are routine servicing procedures. Following the procedures as outlined in the following table can prevent serious damage or m...

Page 24

4 revision 03/05/07 bfs series maintenance shut off the engine before performing any maintenance. If the engine must be run after a maintenance operation make sure the area is well ventilated. The exhaust contains poisonous carbon monoxide gas! Exposure can cause loss of consciousness and may result...

Page 25

5 revision 03/05/07 bfs series maintenance 6.4 controls stiff or sluggish response of controls must be corrected immediately. Periodically clean and lubricate the throttle cable, the throttle and choke controls. The frequency of this maintenance will depend on the utilization rate and the amount of ...

Page 26

6 revision 03/05/07 bfs series maintenance place the transmission in neutral by moving the transmission control arm back and forth while manually rotating the transmission pulley. When the pulley spins freely and no movement of the drive chain is observed, the neutral position has been obtained. Tig...

Page 27

7 revision 03/05/07 bfs series maintenance 6.10 electrical system a fuse protects the battery charging circuit. The fuse and the battery are the only user serviceable parts of the electrical system. A short circuit or a battery connected in reverse polarity will blow the fuse. Refer to the honda eng...

Page 28

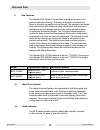

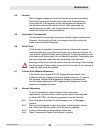

8 revision 03/05/07 bfs series transmission cause problem loose transmission linkage oil level cooling fan water in oil reservoir dirty cooling fans loose drive chain transmission jerky when starting x x x transmission operates in one direction x transmission operating hot x x x x oil color is black...

Page 29

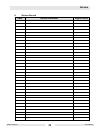

Revision 03/05/07 bfs series date service performed engine hours service 8. Service record.

Page 30

Rev. 02/07 www.Wakergroup.Com wacker construction equipment ag · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02 - 0 · fax: +49 - (0)89-3 54 02-3 90 wacker corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 ...