- DL manuals

- Wacker Neuson

- Saw

- BFS 614B

- Operator's Manual

Wacker Neuson BFS 614B Operator's Manual

Summary of BFS 614B

Page 1

Operator’s manual floor saw bfs 614b 0400240en 002 0110 0 4 0 0 2 4 0 0 0 1.

Page 2

Copyright notice © copyright 2010 by wacker neuson corporation. All rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permission from wack...

Page 3: Bfs 614B

Bfs 614b table of contents wpm_bo0400240002entoc.Fm 1 foreword 3 1. Safety information 4 1.1 laws pertaining to spark arresters ...................................................... 4 1.2 operating safety .................................................................................. 5 1.3 opera...

Page 4: Table of Contents

Table of contents bfs 614b wpm_bo0400240002entoc.Fm 2 4. Maintenance 25 4.1 periodic maintenance schedule ..........................................................25 4.2 spark plug ...........................................................................................26 4.3 air cleaner ...........

Page 5

Wc_tx000001gb.Fm 3 california proposition 65 warning: engine exhaust, some of its constituents, and certain vehicle components, contain or emit chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. Foreword this manual provides information and proce...

Page 6: Safety Information

Safety information bfs 614b wpm_si000338gb.Fm 4 1. Safety information this manual contains danger, warning, caution, notice, and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is use...

Page 7: Bfs 614B

Bfs 614b safety information wpm_si000338gb.Fm 5 1.2 operating safety familiarity and proper training are required for the safe operation of the machine. Machines operated improperly or by untrained personnel can be hazardous. Read the operating instructions contained in this manual and the engine ma...

Page 8: Safety Information

Safety information bfs 614b wpm_si000338gb.Fm 6 1.3 operator safety while using internal combustion engines internal combustion engines present special hazards during operation and fueling. Read and follow the warning instructions in the engine owner’s manual and the safety guidelines below. Failure...

Page 9: Bfs 614B

Bfs 614b safety information wpm_si000338gb.Fm 7 1.4 service safety a poorly maintained machine can become a safety hazard! In order for the machine to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. 1.4.1 do not attempt to clean or s...

Page 10: Safety Information

Safety information bfs 614b wpm_si000338gb.Fm 8 1.5 label locations wpmgr006724.

Page 11: Bfs 614B

Bfs 614b safety information wpm_si000338gb.Fm 9 1.6 warning and informational labels wacker neuson machines use international pictorial labels where needed. These labels are described below: label meaning warning! Always wear hearing and eye protection when operating this machine. Warning! Hot surfa...

Page 12: Safety Information

Safety information bfs 614b wpm_si000338gb.Fm 10 machine name sticker throttle control lever: turtle = idle or slow rabbit = full or fast danger! Engines emit carbon monoxide; operate only in well-ventilated area. Read the operator’s manual. No sparks, flames, or burning objects near the machine. Sh...

Page 13: Bfs 614B

Bfs 614b safety information wpm_si000338gb.Fm 11 this machine may be covered by one or more patents. Label meaning.

Page 14: Technical Data

Technical data bfs 614b wpm_td000346gb.Fm 12 2. Technical data 2.1 engine data engine power rating net power rating per sae j1349. Actual power output may vary due to conditions of specific use. Bfs 614b 0009526 engine engine make wacker engine model wm170 maximum rated power @ rated speed kw (hp) 4...

Page 15: Bfs 614B

Bfs 614b technical data wpm_td000346gb.Fm 13 2.2 machine data bfs 614b 0009526 machine dry weight (w/o blade) kg (lbs.) 61.5 (135.6) nominal blade speed rev/min 2890.5 arbor diameter mm (in) 25.4 (1.00).

Page 16: Technical Data

Technical data bfs 614b wpm_td000346gb.Fm 14 2.3 dimensions mm (in.) 20 20 917 (36.1) 484 (19) 831 (32.7) wpmgr006726.

Page 17: Bfs 614B

Bfs 614b operation wpm_tx001178gb.Fm 15 3. Operation 3.1 recommended fuel the engine requires regular grade unleaded gasoline. Use only fresh, clean gasoline. Gasoline containing water or dirt will damage fuel system. Consult engine owner’s manual for complete fuel specifications. 3.2 application th...

Page 18: Operation

Operation bfs 614b wpm_tx001178gb.Fm 16 3.3 before starting 3.3.1 read and understand the safety and operating instructions at the beginning of this manual. 3.3.2 check: • oil level in the engine • fuel level • condition of the air cleaner • tightness of the external fasteners • condition of the fue...

Page 19: Bfs 614B

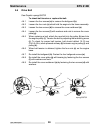

Bfs 614b operation wpm_tx001178gb.Fm 17 3.4 to start see graphic: wc_gr000655 3.4.1 open fuel valve by moving lever down (a1). Note: if engine is cold, move choke lever to close position (d2). If engine is hot, set choke to open position (d1). 3.4.2 turn engine switch to “on” (b2). 3.4.3 open thrott...

Page 20: Operation

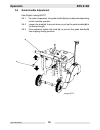

Operation bfs 614b wpm_tx001178gb.Fm 18 3.6 guide handle adjustment see graphic: wpmgr006727 3.6.1 for ease of operation, the guide handle (b) can be adjusted depending on the machine operator. 3.6.2 loosen the knob (a), then push down or pull up the guide handle (b) to the desired length. 3.6.3 onc...

Page 21: Bfs 614B

Bfs 614b operation wpm_tx001178gb.Fm 19 3.7 use of cutting blade 3.7.1 general application instructions for use of diamond cutting blades: 3.7.1.1 never use a diamond cutting blade of a diameter larger than necessary to cut down to a certain depth. 3.7.1.2 pull the blade out of the cut if it has sto...

Page 22: Operation

Operation bfs 614b wpm_tx001178gb.Fm 20 do not cut into the crushed stone layer or similar material layer when working with a diamond blade. Uneven wear may occur when cutting along road edges or two different types of materials (cutting along joints). Special care is required if the material to be ...

Page 23: Bfs 614B

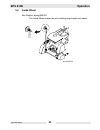

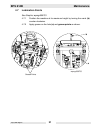

Bfs 614b operation wpm_tx001178gb.Fm 21 3.7.3 removal of cutting blade: see graphic: wpmgr006728 3.7.3.1 make sure that the engine and the water feed is switched "off", and the blade is cool. 3.7.3.2 turn the crank (a) counter-clockwise until the blade no longer touches the floor. 3.7.3.3 fold up bl...

Page 24: Operation

Operation bfs 614b wpm_tx001178gb.Fm 22 3.8 converting the cutting blade position see graphic: wpmgr006731 you can change the position of the cutting blade guard together with the guide wheel to use the cutting blade on the left side. Proceed as follows for the conversion of the blade position: 3.8....

Page 25: Bfs 614B

Bfs 614b operation wpm_tx001178gb.Fm 23 3.9 guide wheel see graphic: wpmgr006729 the guide wheel makes the job of cutting long straight cuts easier. Wpmgr006729.

Page 26: Operation

Operation bfs 614b wpm_tx001178gb.Fm 24 3.10 cutting depth adjustment see graphic: wpmgr006730 the cutting depth can be precisely set with the crank (a). One turn of the crank is equal to 5 mm (0.20 in) cutting depth. A clockwise turn deepens the cutting depth. A counter clockwise turn reduces the c...

Page 27: Bfs 614B

Bfs 614b maintenance wpm_tx001179gb.Fm 25 4. Maintenance 4.1 periodic maintenance schedule the chart below lists basic engine maintenance. Refer to the engine manufacturer’s operation manual for additional information. Daily before starting after first 20 hrs. Every 2 weeks or 50 hrs. Every month or...

Page 28: Maintenance

Maintenance bfs 614b wpm_tx001179gb.Fm 26 4.2 spark plug see graphic: wc_gr000028 clean or replace the spark plug as needed to ensure proper operation. Refer to your engine operator’s manual. The muffler becomes very hot during operation and remains hot for a while after stopping the engine. Do not ...

Page 29: Bfs 614B

Bfs 614b maintenance wpm_tx001179gb.Fm 27 4.3 air cleaner see graphic: wc_gr000656 never use gasoline or other types of low-flash point solvents for cleaning the air cleaner. A fire or explosion could result. Notice: never run the engine without the air cleaner. Severe engine damage will occur. The ...

Page 30: Maintenance

Maintenance bfs 614b wpm_tx001179gb.Fm 28 4.4 engine oil see graphic: wc_gr000087 4.4.1 drain oil while engine is still warm. Note: in the interests of environmental protection, place a plastic sheet and a container under the machine to collect any liquid which drains off. Dispose of this liquid in ...

Page 31: Bfs 614B

Bfs 614b maintenance wpm_tx001179gb.Fm 29 4.5 cleaning fuel strainer see graphic: wc_gr001093 4.5.1 to remove water and dirt, close the fuel lever and remove the fuel strainer. 4.5.2 inspect the fuel strainer (a) for water and dirt. 4.5.3 after removing any dirt and water, wash the fuel cup with a n...

Page 32: Maintenance

Maintenance bfs 614b wpm_tx001179gb.Fm 30 4.6 drive belt see graphic: wpmgr006732 to check belt tension or replace the belt: 4.6.1 loosen the four screws (a) to remove the beltguard (b). 4.6.2 loosen the four nuts (c) which hold the engine to the frame assembly. 4.6.3 loosen the two screws (d) to re...

Page 33: Bfs 614B

Bfs 614b maintenance wpm_tx001179gb.Fm 31 4.7 lubrication points see graphic: wpmgr006733 4.7.1 position the machine at its maximum height by turning the crank (b) counter-clockwise. 4.7.2 apply grease on the hole (a) and grease points as shown. B a grease points wpmgr006733.

Page 34: Maintenance

Maintenance bfs 614b wpm_tx001179gb.Fm 32 4.8 lifting the machine see graphic: wpmgr006734 to lift the machine manually: 4.8.1 switch the engine to "off" and empty the water tank. 4.8.2 fold up the guide wheel and remove the cutting blade. 4.8.3 turn the crank so that the machine is in its lowest cu...

Page 35: Bfs 614B

Bfs 614b maintenance wpm_tx001179gb.Fm 33 4.9 storage if the machine will be stored for more than 30 days: 4.9.1 remove dirt from the machine. 4.9.2 empty the water tank. 4.9.3 clean or replace engine air filter. 4.9.4 change engine oil and clean engine thoroughly with an oiled cloth. 4.9.5 place mu...

Page 36

Wacker construction equipment ag · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02 - 0 · fax: +49 - (0)89-3 54 02-3 90 wacker neuson corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker asia pacific ope...