- DL manuals

- Wacker Neuson

- Power Tool

- BH 65

- Operator's Manual

Wacker Neuson BH 65 Operator's Manual

Summary of BH 65

Page 1

Operator's manual gasoline demolition hammer bh 23, 24, 65 11.2010 0226390en / 003 www.Jackhammers.Com matw, inc. 800-241-9669.

Page 2: Www.Jackhammers.Com

Manufacturer wacker neuson se preußenstraße 41 80809 münchen www.Wackerneuson.Com tel.: +49-(0)89-354 02-0 fax: +49-(0)89-354 02-390 translation of the original operator's manual in german www.Jackhammers.Com matw, inc. 800-241-9669.

Page 3: Www.Jackhammers.Com

3 1 foreword .................................................................................................................... 5 2 introduction ............................................................................................................... 6 2.1 means of representation for this op...

Page 4: Www.Jackhammers.Com

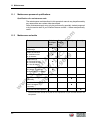

4 11 maintenance ............................................................................................................ 39 11.1 maintenance personnel qualifications .............................................................. 40 11.2 maintenance schedule ........................................

Page 5: Www.Jackhammers.Com

1 foreword 5 1 foreword this operator's manual contains information and procedures for the safe opera- tion and maintenance of your wacker neuson machine. In the interest of your own safety and to prevent accidents, you should carefully read through the safety information, familiarize yourself with ...

Page 6: Www.Jackhammers.Com

2 introduction 6 2 introduction 2.1 means of representation for this operator's manual warning symbols this operator's manual contains safety information of the categories: danger, warning, caution, notice. They should be followed to prevent danger to life and limb of the operator or dam- age to equ...

Page 7: Www.Jackhammers.Com

2 introduction 7 2.2 wacker neuson representative depending on your country, your wacker neuson representative is your wacker neuson service, your wacker neuson affiliate or your wacker neuson dealer. You can find the addresses in the internet at www.Wackerneuson.Com . The address of the manufacture...

Page 8: Www.Jackhammers.Com

2 introduction 8 2.5 nameplate data the nameplate lists information that uniquely identifies your machine. This infor- mation is needed to order spare parts and when requesting additional technical information. F enter the information of your machine into the following table: item designation your i...

Page 9: Www.Jackhammers.Com

3 safety 9 3 safety 3.1 principle state of the art this machine has been constructed with state-of-the-art technology according to the recognized rules of safety. Nevertheless, when used improperly, dangers to the life and limb of the operator or to third persons or damage to the machine or other ma...

Page 10: Www.Jackhammers.Com

3 safety 10 structural modifications never attempt to modify the machine without the written permission of the man- ufacturer. To do so will endanger your safety and the safety of other people! In addition, this will void the warranty and the liability on behalf of the manufacturer. Especially the f...

Page 11: Www.Jackhammers.Com

3 safety 11 malfunctions if you detect a malfunction, you must shut down and secure the machine imme- diately. Eliminate the malfunctions that impair safety immediately! Have damaged or defective components replaced immediately! For further information, refer to chapter malfunctions. Spare parts, ac...

Page 12: Www.Jackhammers.Com

3 safety 12 operator's controls always keep the operator's controls of the machine dry, clean and free of oil or grease. Operating elements such as on/off switch, gas handles etc. May not be locked, manipulated or changed without authorization. Checking for signs of damage inspect the machine when i...

Page 13: Www.Jackhammers.Com

3 safety 13 work recommendations please observe the recommendations below: work only if you are in a good physical condition. Work attentively, particularly as you finish. Do not operate the machine when you are tired. Carry out all work calmly, circumspectly and carefully. Never operate the machine...

Page 14: Www.Jackhammers.Com

3 safety 14 3.4 transport switching off the machine before you transport the machine, it must be switched off, and the engine must be given sufficient time to cool down. Emptying the tank wacker neuson recommends that the fuel tank be emptied and the carburetor run dry prior to transporting it. Fuel...

Page 15: Www.Jackhammers.Com

3 safety 15 3.5 operating safety explosible environment never operate the machine in a potentially explosive environment. Work environment familiarize yourself with your work environment before you start work. This in- cludes e.G. The following items: obstacles in the work and traffic area. Load-car...

Page 16: Www.Jackhammers.Com

3 safety 16 caution with hot parts do not touch any hot parts such as tools, tool holders, mufflers or guide cylinders during operation or for a short period afterwards. These parts can become very hot and can cause severe burns. Caution with movable parts keep your hands, feet and loose clothing aw...

Page 17: Www.Jackhammers.Com

3 safety 17 3.6 safety during the operation of hand machines safe working with hand machines secure loose workpieces with suitable methods. While working, as a rule hold the machine on the provided handles with both hands. While working, hold the machine in such a way that hand injuries are avoided ...

Page 18: Www.Jackhammers.Com

3 safety 18 preventing fires open flames and smoking are strictly prohibited in the immediate vicinity of the machine. Make sure that waste, such as paper, dry leaves or grass do not accumulate around the exhaust muffler. The waste materials may ignite. Safety precautions when refueling please obser...

Page 19: Www.Jackhammers.Com

3 safety 19 not using starter sprays highly flammable starter sprays pose a fire hazard. Do not use any starter sprays. Starter sprays are highly flammable and can cause backfiring and engine dam- age. Shutting off the fuel tap when the machine stops, shut off the fuel tap. Cleaning the engine clean...

Page 20: Www.Jackhammers.Com

3 safety 20 handling operating fluids safely observe the following points when handling operating fluids, e.G. Fuels, oils, greases, coolants etc.: always wear personal safety clothing. Avoid skin and eye contact with operating fluids. Do not inhale or swallow operating fluids. In particular, avoid ...

Page 21: Www.Jackhammers.Com

3 safety 21 3.9 safety devices burn protector the burn protector the operator against emitted heat. Warning danger of injury due to open moving parts. F only operate the machine with properly installed and functioning safety de- vices. F do not modify or remove safety devices. Warning hot exhaust. T...

Page 22: Www.Jackhammers.Com

4 safety and information labels 22 4 safety and information labels your machine has adhesive labels containing the most important instructions and safety information. Make sure that all the labels are kept legible. Replace any missing or illegible labels. The item numbers for the labels are in the p...

Page 23: Www.Jackhammers.Com

4 safety and information labels 23 6 us machines warning. 7 us machines danger. 8 japan machines use only specified spark plug. 9 japan machines grease every 20 hours with lithium grease. Do not use other grease. (grease at central grease point) 10 japan machines total vibration value of the acceler...

Page 24: Www.Jackhammers.Com

5 scope of delivery 24 5 scope of delivery the scope of delivery includes: machine. Operator's manual. Parts book. Www.Jackhammers.Com matw, inc. 800-241-9669.

Page 25: Www.Jackhammers.Com

6 structure and function 25 6 structure and function 6.1 application use the machine only as intended, see chapter safety, proper use. 6.2 functional description principle the machine is a demolition hammer with a pneumatic percussion system. It is driven by a gasoline engine. The rotary movement of...

Page 26: Www.Jackhammers.Com

7 components and operator's controls 26 7 components and operator's controls recoil starter the recoil starter starts the engine. In certain operating situations, e.G. When ramming in posts and grounding rods, it can be advantageous to change the traction direction of the recoil starter, i.E. The po...

Page 27: Www.Jackhammers.Com

7 components and operator's controls 27 gas handle the gas handle has several positions: idle position gas handle in its original position, not pressed. Engine running at idle speed. Percussion system disengaged and does not strike. Working position the machine is pressed against the material when t...

Page 28: Www.Jackhammers.Com

8 transport 28 8 transport performing preparations 1. Switch off the engine. 2. Remove tool. 3. Lean the machine upright against a solid object and secure it to prevent it from toppling over. Wacker neuson recommends to hang the machine on the truck. 4. Let machine cool off. Emptying the fuel system...

Page 29: Www.Jackhammers.Com

9 initial start up 29 9 initial start up rendering the machine functional f place the spark plug cap onto the spark plug. Item designation 1 spark plug cap www.Jackhammers.Com matw, inc. 800-241-9669.

Page 30: Www.Jackhammers.Com

10 use and operation 30 10 use and operation 10.1 prior to starting the machine checking the machine check the following points before beginning work: f damage to the machine and to all components. If the machine is damaged, do not start the machine. Have any damage or defects eliminated immediately...

Page 31: Www.Jackhammers.Com

10 use and operation 31 10.2 adjusting the machine machine with integrated shut-off device – rs (optional) the machine only works when either the plug of the remote cut-off or the shorting plug is plugged in at the connection socket of the integrated shut-off device. Operation with remote cut-off if...

Page 32: Www.Jackhammers.Com

10 use and operation 32 10.3 changing tools general notes you can change the tool without additional tools. Notes on using tools only use tools with the following properties: the tool must be suitable for the tool holder. The tool end must be undamaged. The tool must be sufficiently sharp to avoid i...

Page 33: Www.Jackhammers.Com

10 use and operation 33 removing tool 1. Swivel out handle on the tool holder. 2. Remove tool from the tool holder. 3. Press the handle on the tool holder. 10.4 starting up work tips when working, use the weight of the hammers. Pressing forcefully against the material to be worked on does not improv...

Page 34: Www.Jackhammers.Com

10 use and operation 34 10.4.1 starting the engine note: when starting the engine, move to a position at least 3 m (9.8 ft) from the fueling area. Item designation item designation 1 fuel tap 4 throttle lever 2 fuel pump 5 choke 3 starter rope www.Jackhammers.Com matw, inc. 800-241-9669.

Page 35: Www.Jackhammers.Com

10 use and operation 35 performing preparations 1. Put the machine into an upright position and hold it with one hand. 2. Open the fuel tap. 3. Cold motor: activate choke. Warm engine: deactivate choke. Hot engine: activate choke. 4. Press the fuel pump bellows repeatedly until the bellows is comple...

Page 36: Www.Jackhammers.Com

10 use and operation 36 starting the engine 1. Press down the gas handle (full throttle position). 2. Pull out the starter rope slowly until compression resistance can be felt and then let it slowly roll back in again. 3. Pull the starter rope firmly, but not suddenly (several times if necessary). 4...

Page 37: Www.Jackhammers.Com

10 use and operation 37 10.5 operating the machine processing material 1. Hold the machine firmly with both hands. 2. Place the tool into position on the material. 3. Press down the gas handle. 4. With both hands, press the machine against the material to be processed. Note: press with sufficient st...

Page 38: Www.Jackhammers.Com

10 use and operation 38 10.6 decommissioning switching off the machine 1. Release the gas handle. 2. Keep the off switch pressed until the machine has come to a complete stand- still. 3. Close the fuel tap. 4. Set down the machine in such a way that it cannot tilt, fall or slip. Item designation ite...

Page 39: Www.Jackhammers.Com

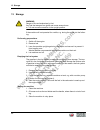

11 maintenance 39 11 maintenance warning improper handling can result in injury or serious material damage. F read and follow all safety instructions of this operator's manual, see chapter safety. Warning danger of poisoning by exhaust fumes. Exhaust fumes contain toxic carbon monoxide that can lead...

Page 40: Www.Jackhammers.Com

11 maintenance 40 11.1 maintenance personnel qualifications qualifications for maintenance work the maintenance work described in this operator's manual may be performed by any responsible user unless otherwise stated. Some maintenance work may only be performed by specially trained personnel or by ...

Page 41: Www.Jackhammers.Com

11 maintenance 41 11.3 maintenance work working in the workshop perform maintenance work in a workshop on a workbench. This has the following benefits: protection of the machine of contamination on the construction site. A level and clean work surface makes work easier. There is a better overview ov...

Page 42: Www.Jackhammers.Com

11 maintenance 42 11.3.2 topping up with fuel performing preparations 1. Switch off the engine. 2. Lean the machine upright against a solid object and secure it to prevent it from toppling over. Wacker neuson recommends to hang the machine on the truck. 3. Let machine cool off. Warning danger of fir...

Page 43: Www.Jackhammers.Com

11 maintenance 43 topping up with fuel 1. Remove any dirt around the fuel cap. 2. Slowly unscrew and remove fuel cap. Note: slowly unscrew the fuel cap so that any overpressure can slowly escape. 3. Use a clean funnel to replenish fuel. See chapter technical data for the fuel specification. See chap...

Page 44: Www.Jackhammers.Com

11 maintenance 44 installing air cleaner cartridge 1. Insert air cleaner cartridge. 2. Replace air cleaner cap. 3. Tighten all nuts of the air cleaner cap securely with a screw wrench. 11.3.4 lubricating the machine 1. Remove any dirt around the zerk fitting. 2. Place filled manual grease gun onto t...

Page 45: Www.Jackhammers.Com

11 maintenance 45 11.3.5 checking/cleaning/replacing spark plug performing preparations 1. Switch off the engine. 2. Let machine cool off. Removing the spark plug 1. Clean around the spark plug thoroughly. 2. Pull off the spark plug cap from the spark plug. Note: do not pull the spark plug cap off t...

Page 46: Www.Jackhammers.Com

11 maintenance 46 installing the spark plug 1. First screw in the spark plug manually then tighten it with a spark plug wrench. Torque 22 nm (16 lbf ft). 2. Place the spark plug cap onto the spark plug. 11.3.6 checking the tool holder for wear 1. Insert the tool. Note: use a new tool to measure only...

Page 47: Www.Jackhammers.Com

12 malfunctions 47 12 malfunctions potential faults, their causes and remedies can be found in the following table. Notify your wacker neuson contact in case of malfunctions you cannot or may not remedy yourself. Malfunction cause remedy engine does not start. Fuel tap is closed. Open the fuel tap. ...

Page 48: Www.Jackhammers.Com

13 storage 48 13 storage if the machine will not operated for a while, e.G. During the winter, do the follow- ing: performing preparations 1. Switch off the engine. 2. Remove tool. 3. Lean the machine upright against a solid object and secure it to prevent it from toppling over. Wacker neuson recomm...

Page 49: Www.Jackhammers.Com

14 accessories 49 14 accessories there is a wide range of accessories available for the machine. For more information on the individual accessories, visit the following website: www.Wackerneuson.Com. 14.1 truck proper use the truck must only be used for the transport of wacker neuson large hammers a...

Page 50: Www.Jackhammers.Com

14 accessories 50 placing hammer on the truck 1. Switch off the machine. 2. Remove tool from the tool holder. 3. Clean the truck's guide rod. 4. Insert hammer with the tool holder on the guide rod and rest on the handles of the truck. 5. Insert tool in the tool holder. Caution insufficient stability...

Page 51: Www.Jackhammers.Com

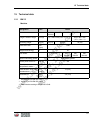

15 technical data 51 15 technical data 15.1 bh 23 machine designation unit bh 23 item no. 0610381 0610410 0610377 0610378 0610379 0610380 length x width x height mm (ft) 777 x 492 x 346 (2.5 x 1.6 x 1.1) 833 x 492 x 346 (2.7 x 1.6 x 1.1) operating weight kg (lb) 23 (51) 24 (53) 25 (55) percussion ra...

Page 52: Www.Jackhammers.Com

15 technical data 52 drive engine designation unit bh 23 manufacturer wacker neuson engine type wm 80 combustion method 2-cycle engine type gasoline engine engine displacement cm³ (in³) 80 (4.9) rated output* * according to din iso 3046-1. Kw 1,6 rated speed min -1 ( rpm) 4,250 idle speed min -1 ( r...

Page 53: Www.Jackhammers.Com

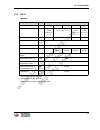

15 technical data 53 15.2 bh 24 machine designation unit bh 24 item no. 0610382 0610384 0610385 0610383 0610386 length x width x height mm (ft) 848 x 492 x 346 (2.8 x 1.6 x 1.1) 905 x 492 x 346 (3.0 x 1.6 x 1.1) 858 x 492 x 346 (2.8 x 1.6 x 1.1) 905 x 492 x 346 (3.0 x 1.6 x 1.1) operating weight kg ...

Page 54: Www.Jackhammers.Com

15 technical data 54 machine designation unit bh 24 low vib item no. 0610388 0610393* * remote cut-off (rs). 0610390 0610391 0610389 0610392 length x width x height mm (ft) 842 x 492 x 346 (2.8 x 1.6 x 1.1) 898 x 492 x 346 (2.9 x 1.6 x 1.1) 852 x 492 x 346 (2.8 x 1.6 x 1.1) 898 x 492 x 346 (2.9 x 1....

Page 55: Www.Jackhammers.Com

15 technical data 55 drive engine designation unit bh 24 bh 24 low vib manufacturer wacker neuson engine type wm 80 combustion method 2-cycle engine type gasoline engine engine displacement cm³ (in³) 80 (4.9) rated output* * according to din iso 3046-1. Kw 1,7 1,6 rated speed min -1 (rpm) 4,100 4,50...

Page 56: Www.Jackhammers.Com

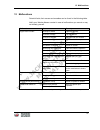

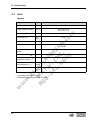

15 technical data 56 15.3 bh 65 machine designation unit bh 65 item no. 0610387 length x width x height mm (ft) 905 x 492 x 346 (3.0 x 1.6 x 1.1) operating weight kg (lb) 26 (57) percussion rate min -1 (rpm) 1,250 single stroke energy j 65 tool holder hex 28x152 special lubricating grease retinax lx...

Page 57: Www.Jackhammers.Com

15 technical data 57 drive engine designation unit bh 65 manufacturer wacker neuson engine type wm 80 combustion method 2-cycle engine type gasoline engine engine displacement cm³ (in³) 80 (4.9) rated output* * according to din iso 3046-1. Kw 1,7 rated speed min -1 (rpm) 4,100 idle speed min -1 (rpm...

Page 58: Www.Jackhammers.Com

15 technical data 58 www.Jackhammers.Com matw, inc. 800-241-9669.

Page 59: Www.Jackhammers.Com

Www.Wackerneuson.Com ec declaration of conformity manufacturer wacker neuson se preußenstraße 41, 80809 münchen product conformity assessment procedure in accordance with 2000/14/ec, appendix viii, 2005/88/ ec guidelines and standards this is to certify that this product meets and complies with the ...

Page 60: Www.Jackhammers.Com

Emission control system information emission control system information source of emissions the combustion process produces carbon monoxide, oxides of nitrogen, and hydrocarbons. Control of hydrocarbons and oxides of nitrogen is very important because, under certain conditions, they react to form ph...

Page 61: Www.Jackhammers.Com

Emission control system information replacement parts the emission control systems on your wacker neuson engine were designed, built, and certified to conform with epa and california emissions regulations. We recommend the use of genuine wacker neuson parts whenever you have maintenance done. These ...

Page 62: Www.Jackhammers.Com

Emission control system information methanol - (methyl or wood alcohol) 5% by volume. You may use gasoline containing up to 5% methanol by volume, as long as it contains cosolvents and corrosion inhibitors to protect the fuel system. Gasoline containing more than 5% methanol by volume may cause star...

Page 63: Www.Jackhammers.Com

Emission control system information owner’s warranty responsibility: as the engine owner, you are responsible for the performance of the required maintenance listed in your owner’s manual. Wacker neuson recommends that you retain all receipts covering maintenance on your engine, but wacker neuson ca...

Page 64: Www.Jackhammers.Com

Emission control system information to obtain warranty service: you must take your wacker neuson product along with proof of original purchase date, at your expense, to any wacker neuson authorized dealer during their normal business hours. Claims for repair or adjustment found to be caused solely b...

Page 65: Www.Jackhammers.Com

Emission control system information systems covered by this warranty parts descriptions fuel metering carburetor assembly exhaust system muffler air induction air filter housing air filter element* ignition flywheel magneto ignition module spark plug cap spark plug* miscellaneous parts tubing, fitti...

Page 66: Www.Jackhammers.Com

Www.Jackhammers.Com matw, inc. 800-241-9669.

Page 67: Www.Jackhammers.Com

Www.Jackhammers.Com matw, inc. 800-241-9669.

Page 68: Www.Jackhammers.Com

Www.Jackhammers.Com matw, inc. 800-241-9669.