- DL manuals

- Wacker Neuson

- Power Tool

- BPU 4045

- Operator's Manual

Wacker Neuson BPU 4045 Operator's Manual

Summary of BPU 4045

Page 1

Operator´s manual vibrating plate bpu 4045, 5545.

Page 2

Manufacturer wacker neuson produktion gmbh & co. Kg preußenstraße 41 80809 münchen www.Wackerneuson.Com tel.: +49-(0)89-354 02-0 fax: +49-(0)89-354 02-390 translation of the original operator's manual in german.

Page 3

5100010141ivz.Fm 3 foreword ............................................................................................................................ 4 introduction ........................................................................................................................ 5 safety .....

Page 4

1 foreword bbip 1 foreword 7klvrshudwruvpdqxdofrqwdlqvlqirupdwlrqdqgsurfhgxuhviruwkhvdihrshud wlrqdqgpdlqwhqdqfhri\rxu:dfnhu1hxvrqpdfklqh,qwkhlqwhuhvwri\rxu rzqvdihw\dqgwrsuhyhqwdfflghqwv\rxvkrxogfduhixoo\uhdgwkurxjkwkhvdihw\ lqirupdwlrqidploldul]h\rxuvhoizlwklwdqgrevhuyhlwdwdoowlphv 7klvrshudwruvpd...

Page 5

2 introduction bbip 2 introduction 2.1 use of the manual 7klvpdqxdolvfrqvlghuhgdvsduwriwkhpdfklqhdqgpxvwehnhswlqdvdih sodfhwkurxjkrxwwkhhqwluholihf\foh7klvpdqxdopxvwehkdqghgryhuwrhyhu\ vxevhtxhqwrzqhuruxvhuriwkhpdfklqh 2.2 storing the manual 7klvpdqxdolvsduwriwkhpdfklqhdqgpxvwehvwruhglqwkhlpphgldwhy...

Page 6

2 introduction bbip 2.5 target group note: 3huvrqvzrunlqjzlwkwklvpdfklqhpxvwuhfhlyhuhjxoduwudlqlqjderxwwkh ulvnvdqgkd]dugvriwklvpdfklqh this operator's manual is aimed at the following persons: operatives: 7khvhshuvrqvduhlqwurgxfhgwrwkhpdfklqhdqglqiruphgderxwsrwhqwldokd] dugvdulvlqjiurplpsurshuehkdy...

Page 7

2 introduction bbip 2.6 symbol explanation 7klvpdqxdofrqwdlqvsurplqhqwvdihw\lqirupdwlrquhodwlqjwrfdwhjru\w\shv danger, warning, caution dqg note. %hiruhfrpphqflqjdq\zrunrqruzlwkwklvpdfklqhqrwhvdqgvdihw\lqirupd wlrqpxvwehuhdgdqgxqghuvwrrg$ooqrwhvdqgvdihw\lqirupdwlrqfrqwdlqhglq wklvpdqxdopxvwdovrehvkd...

Page 8

2 introduction bbip 2.7 wacker neuson representative 'hshqglqjrq\rxufrxqwu\wkh:dfnhu1hxvrquhsuhvhqwdwlyhlvd:dfnhu 1hxvrqvhuylfhd:dfnhu1hxvrqdiiloldwhrud:dfnhu1hxvrqghdohu 2qwkh,qwhuqhwdw zzzzdfnhuqhxvrqfrp 7khdgguhvvriwkhpdqxidfwxuhulvorfdwhgdwwkhehjlqqlqjriwklvpdqxdo 2.8 limitation of liability :df...

Page 9

2 introduction bbip 2.9 identification of the machine nameplate data 7khqdphsodwholvwvlqirupdwlrqwkdwxqltxho\lghqwlilhvwklvpdfklqh7klvlqiru pdwlrqlvqhhghgwrrughuvsduhsduwvdqgzkhquhtxhvwlqjdgglwlrqdowhfkqlfdo lqirupdwlrq x (qwhughwdlovrqwkhpdfklqhlqwkhiroorzlqjwdeoh item designation your information ...

Page 10

Bpu 2 safety 2 safety 2.1 principle state of the art this machine has been constructed with state-of-the-art technology according to the recognized rules of safety. Nevertheless, when used improperly, dangers to the life and limb of the operator or to third persons or damage to the machine or other ...

Page 11

2 safety bpu requirements for operation the ability to operate the machine safely requires: proper transport, storage and setup. Careful operation. Careful service and maintenance. Operation operate the machine only as intended and only when in proper working condi- tion. Operate the machine in a sa...

Page 12

Bpu 2 safety exclusion of liability wacker neuson will refuse to accept liability for injuries to persons or for damage to materials in the following cases: structural modifications. Improper use. Failure to comply with this operator's manual. Improper handling. Using of spare parts which are not fr...

Page 13

2 safety bpu checking for signs of damage inspect the machine when it is switched off for any signs of damage at least once per work shift. Do not operate the machine if there is visible damage or defects. Have any damage or defects eliminated immediately. 2.2 qualification of the operating personne...

Page 14

Bpu 2 safety 2.3 protective gear work clothing clothing should be appropriate, i.E. Should be close-fitting but not restrict your movement. When on construction sites, do not wear long hair loosely, loose clothing or jew- elry including rings. These objects can easily get caught or be drawn in by mo...

Page 15

2 safety bpu 1 lifting when lifting the machine, observe the following instructions: designate a skilled person to guide you for the lifting procedure. You must be able to see or hear this person. Use only suitable and certified hoisting gear, lifting tackle and load-bearing equipment with sufficien...

Page 16

Bpu 2 safety 1 work environment familiarize yourself with your work environment before you start work. This in- cludes e.G. The following items: obstacles in the work and traffic area. Load-bearing capacity of the ground. The measures needed to cordon off the construction site from public traffic in...

Page 17

2 safety bpu 1 switching off the machine switch off the engine in the following situations: before breaks. If you are not using the machine. Store the machine in such a way that it cannot tilt, fall or slip. Storage location after operation, allow the machine to cool and then store it in a sealed-of...

Page 18

Bpu 2 safety 1 compacting on slopes the following points must be observed if you plan to compact inclined surfaces (slopes, escarpments): always stand above the machine on a slope. Start at the bottom of a slope (slopes that can be easily managed in an up- ward direction can be safely traveled in a ...

Page 19

2 safety bpu 1 dangers during operation combustion engines can be dangerous, particularly during operation and when refueling. Read and follow all safety instructions. Otherwise there is a risk of personal injury and/or damage to property! Do not start the engine near spilt fuel or if you smell fuel...

Page 20

Bpu 2 safety operation in closed rooms in closed or partially closed rooms such as tunnels, drifts or deep trenches, en- sure sufficient ventilation and extraction by, for example, providing a powerful ex- haust air fan. Danger of poisoning! Do not inhale exhaust fumes. They contain toxic carbon mon...

Page 21

2 safety bpu 2.8 safety during the operation of hydraulic machines hydraulic oil hydraulic oil is harmful to health. Wear safety glasses and safety gloves when handling hydraulic oil. Avoid direct skin contact with hydraulic oil. Remove hydraulic oil from the skin im- mediately with soap and water. ...

Page 22

Bpu 2 safety handling operating fluids safely observe the following points when handling operating fluids, e.G. Fuels, oils, greases, coolants etc.: always wear personal safety clothing. Avoid skin and eye contact with operating fluids. Do not inhale or swallow operating fluids. In particular, avoid...

Page 23

2 safety bpu 2.10 safety and information labels your machine has adhesive labels containing the most important instructions and safety information. Make sure that all the labels are kept legible. Replace any missing or illegible labels. The item numbers for the labels are in the parts book. Item lab...

Page 24

Bpu 2 safety 19 4 if the machine falls, it can cause severe crushing injuries. F do not lift the machine by the guide handle or the center pole. 5 danger of fire. Smoking and open flames are prohibited. 6 warning of hot surface. 7 us machines warning 8 us machines danger item label description 02200...

Page 25: Description

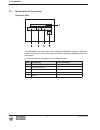

Description t01029gb.Fm 2 5 2. Description 2.1 max. Admissible inclination 2.2 description of function 2.2.1 the vibration required for compaction is produced by the exciter (13) which is firmly joined to the lower mass (5). This exciter (13) is designed as a central vibrator with aligned vibrations...

Page 26: Description

Description t01029gb.Fm 2 6 2.2.2 the drive engine (1) anchored to the upper mass (4) drives the exciter (13). The torque is transmitted by means of a friction connection through the centrifugal clutch (11) and the exciter v-belt (12). 2.2.3 the centrifugal clutch (11) interrupts flow of power to th...

Page 27

Transport to work site/recommendations on compaction t01030gb.Fm 2 7 3. Transport to work site/recommendations on compaction 3.1 transport to work site conditions: to transport the vibration plate, use only suitable lifting equipment with a minimum load-bearing capacity of 400 kg. Always switch off ...

Page 28

Transport to work site/recommendations on compaction t01030gb.Fm 2 8 3.2 recommendations on compaction 3.2.1 ground conditions the max. Compaction depth depends on several factors relating to the ground condition, such as moisture, grain distribution etc, it is therefore not possible to specify exac...

Page 29: Operation

Operation t01031gb.Fm 2 9 4. Operation 4.1 starting 1. Oil level check insert dipstick in oil filler neck, but without screwing in. If oil level is low, fill to the top of the oil filler neck with high grade fuchs titan unic 10w40 mc oil. 2. Dual-air cleander >dual element type check the air cleaner...

Page 30: Operation

Operation t01031gb.Fm 30 4.2 starting the engine once these points have been observed, you can start the engine as follows: 1. Turn the fuel valve to the on position. 2. Move the choke lever to the close position. Take notice: if the engine is warm or the air temperature is high, move the control le...

Page 31: Operation

Operation t01031gb.Fm 31 4.3 handling as the engine warms up, gradually move the choke lever to the open position. Position the throttle lever for the desired engine speed. Oil alert system the oil alert system is designed to prevent engine damage caused by an insufficient amount of oil in the crank...

Page 32: Operation

Operation t01031gb.Fm 32 4.5 stopping the engine to stop the engine in an emergency, turn the engine switch to the off position. Under normal conditions, use the following procedure: 1 move the throttle lever fully to the right. 2 turn the engine switch to the off position. 3 turn the fuel valve to ...

Page 33: Maintenance

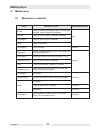

Maintenance t01032gb.Fm 3 3 5. Maintenance 5.1 maintenance schedule parts maintenance jobs maintenance interval air filter check for external damage and tight fit. Check filter cartridge, clean or replace if necessary. Daily fuel tank check tank lid for tight fit, replace if necessary. Drive engine ...

Page 34: Maintenance

Maintenance t01032gb.Fm 3 4 5.2 engine oil 5.2.1 oil change: drain the oil while the engine is still warm to assure rapid and complete draining. 1. Remove the oil filler cap and the drain plug to drain the oil. 2. Install the drain plug, and tighten it securely. 3. Refill with the recommended oil an...

Page 35: Maintenance

Maintenance t01032gb.Fm 3 5 5.4 dual type air filter 5.4.1 remove the wing nut and the air filter cover. Remove the elements and separate them. Carefully check both elements for holes or tears and replace if damaged. 5.4.2 foam element: wash the element in a solution of household detergent and warm ...

Page 36: Maintenance

Maintenance t01032gb.Fm 3 6 3. Measure the plug gap with a feeler gauge. The gap should be 0,7 mm. Correct as necessary by bending the side electrode. 4. Check that the spark plug washer is in good condition, and thread the spark plug in by hand to prevent cross-threading. 5. After the spark plug is...

Page 37: Maintenance

Maintenance t01032gb.Fm 3 7 5.8.1 adjusting the v-belt tension remove belt guard. Loosen nuts situated on the motor v-belt pulley and remove outer v-belt pulley half. Remove necessary number of shims (the removal of one shim is usually suffecient). Install the remo- ved shims on the outside of the v...

Page 38: Maintenance

Maintenance t01032gb.Fm 3 8 5.10 mounting instruction 5.10.1 exciter when disassembling exciter components, always remove eccentric weights first. When assembling, the eccentric weights have to be installed last of all. When installing exciter shafts mind marking of toothed gears. Assembly of excite...

Page 39: Maintenance

Maintenance t01032gb.Fm 3 9 4. Slowly push the control handle (6) in forward direction until hydraulic oil emerges bubblefree at the connection screw. 5. Tighten connecting screw (18), mount apron (17). 6. Replenish hydraulic oil (see technical specifications) as required, then close filler bore (15...

Page 40: Engine

Engine t01033gb.Fm 40 6. Engine 6.1 maschineneinsatz in größeren höhen 6.1.1 air is rarer at greater altitudes and the main jet of the standard carburettor supplies the engine with an extremely rich fuel-air mixture. This, in turn, leads to a loss of engine power and the consequent increase in fuel ...

Page 41: Engine

Engine t01033gb.Fm 41 example: a jet size factor of 85 % should be used for a height of 1500 m (3000 feet). If the equipment is fitted out with a standard main jet # 68, the recommended jet for a height of 1500 m (3000 feet) would be # 65 jet (68 - 3 = 65). For quick reference: the size of the jet i...

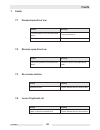

Page 42: Faults

Faults t01034gb.Fm 42 7. Faults 7.1 forward speed too low 7.2 reverse speed too low 7.3 no reverse motion 7.4 loss of hydraulic oil cause remedy to little hydraulic oil in the centre pole head. Top up hydraulic oil. Air in hydraulic control. Bleed system. Cause remedy too much hydraulic oil in centr...

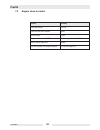

Page 43: Faults

Faults t01034gb.Fm 4 3 7.5 engine does not start cause remedy fuel tank empty. Fuel up. Fuel shut-off valve closed. Open. Air filter dirty. Clean. Engine switch set to "off". Set the engine switch to "on". Recoil starter defective. Repair. Oil alert system has stopped engine. Fill up with engine oil...

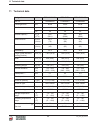

Page 44

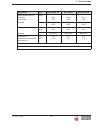

11 technical data bbwgbip 11 technical data designation unit bpu 4045a us bpu 5545a bpu 5545a us ,whpqr &hqwulixjdoirufh n1 9leudwlrqv usp +] 6xuidfhfdsdflw\ p k iw k $gydqfhwudyho pplq iwplq 5hyhuvhwudyho pplq iwplq *udghdelolw\ /hqjwkjxlghkdqgohlq zrunlqjsrvlwlrq pplq :lgwk pplq +hljkw pplq 2shudw...

Page 45

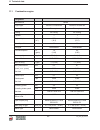

11 technical data bbwgbip 6rxqgsrzhuohyho/ zd 0hdvxuhg *xdudqwhhg g%$ 6wdqgdug (1 (* (1 (* (1 (* 9leudwlrqwrwdoydoxhd ky pv iwv 6wdqgdug (1 (1 (1 8qfhuwdlqw\ri phdvxuhphqwriyleudwlrq wrwdoydoxhd ky pv iwv 'hshqglqjrqwkhfrqglwlrqriwkhvrlo (txlydohqwwrwkhlqvwdoohgsrzhurxwsxwlqdffrugdqfhzlwkwkhgluhfwly...

Page 46

11 technical data bbwgbip 11.1 combustion engine designation 0dqxidfwxuhu +rqgd (qjlqhw\sh *;874$6' *;874$6' &rpexvwlrqphwkrg )rxuf\foh )rxuf\foh &rrolqj $lufrrolqj $lufrrolqj &\olqghu (qjlqhglvsodfhphqw fpñ lqñ 0d[wlowsrvlwlrq r )xhow\sh 2wwrnudiwvwrii 2wwrnudiwvwrii )xhofrqvxpswlrq ok jdok 7dqnfds...

Page 47

3 emission control systems information and warranty operator´s manual 4 3 emission control systems information and warranty the emission control warranty and associated information is valid only for the u.S.A., its territories, and canada. Emission control systems warranty statement see the engine o...

Page 48

4 glossary 4 4 glossary 4.1 use of oxygenated fuels some conventional gasolines are blended with alcohol. These gasolines are col- lectively referred to as oxygenated fuels. If you use an oxygenated fuel, be sure it is unleaded and meets the minimum octane rating requirement. Before using an oxygena...

Page 49: Ec Declaration of Conformity

7udqvodwlrqriwkhruljlqdo'hfodudwlrqri&rqiruplw\ ec declaration of conformity manufacturer :dfnhu1hxvrq 3urgxnwlrq*pe+ &r.*3uhxhqvwudh0qfkhq product conformity assessment procedure $ffruglqjwr(&$sshqgl[9,,,(& notified body 9'(3uixqg=huwlil]lhuxqjvlqvwlwxw*pe+0huldqvwudh2iihqedfk0dlq directives a...

Page 52

Important: for spare parts information, please see your wacker neuson dealer, or visit the wacker neuson website at http://www.Wackerneuson.Com/. Wichtig! Informationen über ersatzteile erhalten sie von ihrem wacker neuson händler oder besuchen sie die wacker neuson website unter http://www.Wackerne...