Wacker Neuson bs65y User Manual

BS65Y

i

This manual provides information and procedures to safely operate and maintain this WACKER model. For your

own safety and protection from injury, carefully read, understand and observe the safety instructions described

in this manual. THE INFORMATION CONTAINED IN THIS MANUAL WAS BASED ON MACHINES IN PRODUCTION

AT THE TIME OF PUBLICATION. WACKER CORPORATION RESERVES THE RIGHT TO CHANGE ANY PORTION

OF THIS INFORMATION WITHOUT NOTICE.

Diese Betriebsanleitung enthält Informationen und Verfahren, um dieses WACKER Gerät sicher zu bedienen und zu

warten. Für Ihre Sicherheit und zur Verhinderung von Verletzungen, diese Betriebsanleitung bitte genau durchlesen

und die Angaben befolgen. DIE HIERIN ENTHALTENEN INFORMATIONEN SIND AKTUELL ZUM ZEITPUNKT DER

VERÖFFENTLICHUNG. ÄNDERUNGSRECHT VORBEHALTEN.

Este manual contiene información y procedimientos que son necesarios para operar y mantener esta máquina

WACKER. Para su propia seguridad y protección, lea por favor este manual cuidadosamente y observe todas las

instrucciones de seguridad descritas en este manual. TODA LA INFORMACION EN ESTE MANUAL SE BASA EN

MAQUINAS EN PRODUCCION VEGENTE A PARTIR DE LA FECHA DE PUBLICACION. TODOS DERECHOS

RESERVADOS POR WACKER CORPORACION.

Ce manuel fournit des informations et des procédures destinées à utiliser et à entretenir en toute sécurité cette machine

WACKER. Pour votre propre sécurité et afin d’éviter tout accident, lisez, comprenez et respectez soigneusement les

consignes de sécurité décrites dans ce manuel. LES INFORMATIONS CONTENUES DANS CE MANUEL SONT

BASEES SUR LES MACHINES EN COURS DE PRODUCTION AU MOMENT DE LA PUBLICATION. WACKER

CORPORATION SE RESERVE LE DROIT DE MODIFIER TOUTE PARTIE DE CES INFORMATIONS SANS

PREAVIS.

This manual is divided into the sections listed below:

Diese Betriebsanleitung ist in folgende Kapitel eingeteilt:

Este manual está compuesto por las siguientes secciones:

Ce manuel contient les sections suivantes:

Item Number / Artikel-Nummer / Número de referencia / Numéro de référence :

0007567, 0007566

Operation

(English)

Betrieb

(Deutsch)

Operación

(Español)

Opération

(Français)

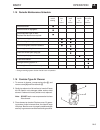

Machine Parts / Maschinenteile / Repuestos de la máquina / Pièces de la machine

1A

1B

1C

1D

2

Engine exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to the State of

California to cause cancer and birth defects or other

reproductive harm.

!

WARNING

1040SD71