- DL manuals

- Wacker Neuson

- Trowels

- CRT 36-25

- Operator's Manual

Wacker Neuson CRT 36-25 Operator's Manual

Summary of CRT 36-25

Page 1

5200001020 0 3 0 515 5 2 0 0 0 0 1 0 2 0 operator’s manual ride-on trowel crt 36-25 crt 36-26a.

Page 2

Copyright notice © copyright 2015 by wacker neuson production americas llc all rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permissio...

Page 3: Crt 36

Wc_tx001268gb.Fm 3 crt 36 foreword foreword save these instructions—this manual contains important instructions for the machine models below. These instructions have been written expressly by wacker neuson production americas llc and must be followed during installation, operation, and maintenance o...

Page 4: Foreword

Wc_tx001268gb.Fm 4 foreword crt 36 california proposition 65 warning combustion exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. Laws pertaining to spark arrester...

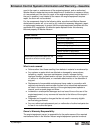

Page 5: Ec Declaration of Conformity

20 1 5-c e- crt3 6-c rt48 -e n. Fm ec declaration of conformity manufacturer wacker neuson production americas llc, n92w15000 anthony avenue, menomonee falls, wisconsin 53051 usa product product product category product function item number crt v36-26a, crt 36-24a, crt 36-25, crt 48-35v, crt 48-35l,...

Page 7: Table of Contents

Table of contents crt 36 wc_bo5200001020_02toc.Fm 7 foreword 3 ec declaration of conformity 5 1 safety information 9 1.1 signal words used in this manual ....................................................... 9 1.2 machine description and intended use ............................................. 1...

Page 8: Table of Contents

Table of contents crt 36 wc_bo5200001020_02toc.Fm 8 4.8 transporting the machine ....................................................................34 4.9 drive belt .............................................................................................35 4.10 battery jump start procedure ......

Page 9: Crt 36

Wc_si000377gb.Fm 9 crt 36 safety information 1 safety information 1.1 signal words used in this manual this manual contains danger, warning, caution, notice, and note signal words which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. Notic...

Page 10: Safety Information

Wc_si000377gb.Fm 10 safety information crt 36 1.2 machine description and intended use this machine is a ride-on concrete finishing trowel. The wacker neuson ride-on trowel consists of a frame onto which are mounted a gasoline or diesel engine, a fuel tank, a water tank, two gearboxes joined by a dr...

Page 11: Crt 36

Wc_si000377gb.Fm 11 crt 36 safety information 1.3 operating safety familiarity and proper training are required for the safe operation of the machine. Machines operated improperly or by untrained personnel can be hazardous. Read the operating instructions contained in this manual and the engine manu...

Page 12: Safety Information

Wc_si000377gb.Fm 12 safety information crt 36 store the machine properly when it is not being used. The machine should be stored in a clean, dry location out of the reach of children. Always operate the machine with all safety devices and guards in place and in working order. 1.4 operator safety whi...

Page 13: Crt 36

Wc_si000377gb.Fm 13 crt 36 safety information 1.5 service safety a poorly maintained machine can become a safety hazard! In order for the machine to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. Service training before servicing or...

Page 14: Safety Information

Wc_si000377gb.Fm 14 safety information crt 36 when replacement parts are required for this machine, use only wacker neuson replacement parts or those parts equivalent to the original in all types of specifications, such as physical dimensions, type, strength, and material. Disconnect the spark plug ...

Page 15: Crt 36

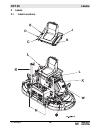

Crt 36 labels wc_si000378gb.Fm 15 2 labels 2.1 label locations c d b j.

Page 16: Labels

Labels crt 36 16 wc_si000378gb.Fm.

Page 17: Crt 36

Crt 36 labels wc_si000378gb.Fm 17 2.2 label meanings a danger asphyxiation hazard. Engines emit carbon monoxide. Do not run the machine indoors or in an enclosed area unless adequate ventilation, through such items as exhaust fans or hoses, is provided. Read the operator’s manual. No sparks, flames,...

Page 18: Labels

Labels crt 36 18 wc_si000378gb.Fm j read and understand the supplied operator’s manual before operating the machine. Failure to do so increases the risk of injury to yourself and others. K pitch control: to increase pitch: rotate the left pitch control clockwise, rotate the right pitch controlcounte...

Page 19: Crt 36

Crt 36 labels wc_si000378gb.Fm 19 p operator’s manual must be stored on machine. Replacement operator’s manual can be ordered through your local wacker neuson distributor. S warning hot surface t warning! Entanglement hazard. Keep hands away from spinning belt and pulley. U emission control informat...

Page 20: Labels

Labels crt 36 20 wc_si000378gb.Fm -- warning remove pan from trowel before lifting machine over- head. Pans can fall and cause death or serious injury if a person is hit. (label is located on top side of float pan.) -- use only glygoyle 460 gear oil in gearbox. -- a nameplate listing the model numbe...

Page 21: Crt 36

Wc_tx000639gb.Fm 21 crt 36 operation 3 operation 3.1 features and controls.

Page 22: Operation

Wc_tx000639gb.Fm 22 operation crt 36 control locations and functions: the ride-on trowel features a seat with an integrated “operator presence” system, which works in conjunction with a throttle mounted switch. This system allows the engine to remain running (idling) with no operator seated in the s...

Page 23: Crt 36

Wc_tx000639gb.Fm 23 crt 36 operation 3.2 position of the operator safe and efficient use of this machine is the operator’s responsibility. Full control of the machine is not possible unless the operator maintains the proper working position at all times. While operating this machine the operator mus...

Page 24: Operation

Wc_tx000639gb.Fm 24 operation crt 36 3.5 break-in period 1. To break in the gearboxes, run the engine at 50% of full throttle for the first 2–4 hours. This will prevent premature wear and extend gear life. Notice: running the engine at full throttle during the break-in period could result in prematu...

Page 25: Crt 36

Wc_tx000639gb.Fm 25 crt 36 operation 3.7 starting before starting the operator must know the location and function of all controls. 1. Push down on the throttle foot pedal, turn the engine keyswitch (o), and hold it until the engine starts. Note: if the engine is cold, pull out the choke control kno...

Page 26: Operation

Wc_tx000639gb.Fm 26 operation crt 36 3.10 steering refer to the illustration for the necessary hand motions to move the trowel in the desired direction, described below. 1 - forward 2 - reverse 3 - rotate clockwise 4 - rotate counter-clockwise 5 - left sideways 6 - right sideways wc_gr000146 1 2 4 3...

Page 27: Crt 36

Wc_tx000639gb.Fm 27 crt 36 operation 3.11 pitch adjustment when changing or setting the pitch (angle) of the trowel blades, slow the machine, set the desired pitch on the left side of the machine, then adjust the right side to match. To increase pitch: rotate the left pitch control (l) clockwise, ro...

Page 28: Maintenance

Wc_tx000640gb.Fm 28 maintenance crt 36 4 maintenance 4.1 maintaining the emission control system for machines sold in north america: normal maintenance, replacement, or repair of emission control devices and systems may be performed by any repair establishment or individual; however, warranty repair...

Page 29: Crt 36

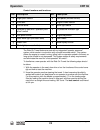

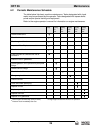

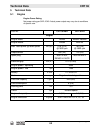

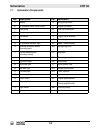

Wc_tx000640gb.Fm 29 crt 36 maintenance 4.2 periodic maintenance schedule the table below lists basic machine maintenance. Tasks designated with check marks may be performed by the operator. Tasks designated with square bullet points require special training and equipment. Refer to the engine operato...

Page 30: Maintenance

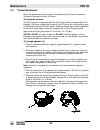

Wc_tx000640gb.Fm 30 maintenance crt 36 4.3 trowel gearboxes check the gearboxes for the correct oil level after every 20 hours of operation. Change the gearbox oil every 300 hours. To check the oil level: each crt gearbox is equipped with two oil fill plugs. Remove one gearbox oil fill plug (b). If ...

Page 31: Crt 36

Wc_tx000640gb.Fm 31 crt 36 maintenance 4.4 control linkage lubrication the drive system, gearbox and pitch posts are equipped with several grease fittings. Grease these fittings once a week, or every 20 hours, to prevent wear. Use a general purpose grease and add one to two shots of grease at each f...

Page 32: Maintenance

Wc_tx000640gb.Fm 32 maintenance crt 36 4.5 control arm adjustment (forward or backward) the control arms should line up evenly. If arms appear out of adjustment, they can be re-adjusted forward or backward as follows: 1. Loosen jam nuts (b). 2. Turn the vertical linkage (a) as follows: extend the li...

Page 33: Crt 36

Wc_tx000640gb.Fm 33 crt 36 maintenance 4.6 right-hand control arm adjustment (right or left) the arms should be set to be perfectly vertical. Should the arms come out of adjustment, adjust as follows: 1. Loosen the jam nuts (d). 2. Drop the horizontal linkage (e) down to clear the bracket. 3. Shorte...

Page 34: Maintenance

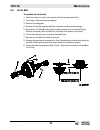

Wc_tx000640gb.Fm 34 maintenance crt 36 4.8 transporting the machine always turn the engine off and remove the key from the machine before moving or transporting machine. To hoist the trowel: attach a sling or chains through the lifting bars (a) on each side of the seat pedestal. Notice: make sure th...

Page 35: Crt 36

Wc_tx000640gb.Fm 35 crt 36 maintenance 4.9 drive belt to replace the drive belt : 1. Place the trowel on a flat, level surface with the blades pitched flat. 2. Turn engine off and disconnect battery. 3. Remove the beltguard. 4. Remove 2 bolts (a), washers (b) and nuts (c) from each bearing flange. 5...

Page 36: Maintenance

Wc_tx000640gb.Fm 36 maintenance crt 36 4.10 battery jump start procedure occasionally, it may be necessary to jump start a weak battery. If jump starting is necessary, the following procedure is recommended to prevent starter damage, battery damage, and personal injuries. Jump starting a battery inc...

Page 37: Crt 36

Wc_tx000640gb.Fm 37 crt 36 maintenance 4.11 spark plug clean or replace spark plug as needed to ensure proper operation. Refer to the engine owner’s manual. Note: refer to the technical data for the recommended spark plug type and the electrode gap setting. The muffler and engine cylinder become ver...

Page 38: Maintenance

Wc_tx000640gb.Fm 38 maintenance crt 36 4.12 air cleaner—crt 36 the engine is equipped with a dual element air cleaner. Service air cleaner frequently to prevent carburetor malfunction. Notice: never run engine without air cleaner. Severe engine damage will occur. Never use gasoline or other types of...

Page 39: Crt 36

Wc_tx000640gb.Fm 39 crt 36 maintenance 4.13 engine oil and filter (honda engine) drain oil while engine is still warm. 1. Remove oil fill cap (a) and drain plug (b) to drain oil. Note: in the interests of environmental protection, place a plastic sheet and a container under the machine to collect an...

Page 40: Maintenance

Wc_tx000640gb.Fm 40 maintenance crt 36 4.14 engine oil and filter (wacker neuson engine) drain the oil while the engine is still warm. To drain oil: 1. Remove the filler cap (a) and drain cap (d). Drain oil into a suitable container. Note: in the interests of environmental protection, place plastic ...

Page 41: Crt 36

Wc_tx000640gb.Fm 41 crt 36 maintenance 4.15 storage when follow the procedures below if the machine is to be stored for more than 30 days. Maintaining the machine to prepare the machine for long-term storage: 1. Drain the fuel tank and the water tank. 2. Change the engine oil. 3. Maintain the engine...

Page 42: Maintenance

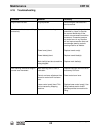

Wc_tx000640gb.Fm 42 maintenance crt 36 4.16 troubleshooting problem reason remedy engine does not start. Engine problem. Consult engine manufacturer’s service manual. Machine out of balance; wobbling excessively. Operator is over-steering. The movement of each gearbox is controlled by “stops” to pro...

Page 43: Crt 36

Wc_tx000640gb.Fm 43 crt 36 maintenance problem reason remedy machine does not move. Drive belt broken. Replace drive belt. Vacuum between bottom of blades and surface of concrete. Change pitch on blades to break suction. Key sheared in the main shaft. Replace damaged key. Trowel noisy. Trowel blades...

Page 44: Technical Data

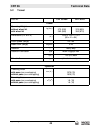

Wc_td000187gb.Fm 44 technical data crt 36 5 technical data 5.1 engine engine power rating net power rating per sae j1349. Actual power output may vary due to conditions of specific use. Part no. Crt 36-26a crt 36-25 engine engine make honda wacker neuson engine model gx690 wm720 max. Rated power @ r...

Page 45: Crt 36

Wc_td000187gb.Fm 45 crt 36 technical data 5.2 trowel part no. Crt 36-26a crt 36-25 trowel operating weight without wheel kit with wheel kit kg (lbs.) 373 (830) 392 (865) 376 (835) 395 (870) dimensions (l x w x h) mm (in.) 2042 x 1041 x 1372 (80 x 41 x 54) rotor speed (range) rpm 25–165 blade pitch (...

Page 46: Technical Data

Wc_td000187gb.Fm 46 technical data crt 36 5.3 sound and vibration specifications the required sound specifications, per annex i, directive 2006/42/ec of the ec- machine regulations, are: the sound pressure level at operator’s location (l pa ): 91.2 db(a) (crt 36-26a), and 91.7 db(a) (crt 36-25). The...

Page 47

Emission control systems information and warranty—gasoline wc_tx001754gb.Fm 47 6 emission control systems information and warranty — gasoline the emission control warranty and associated information is valid only for the u.S.A., its territories, and canada. 6.1 emission control system background inf...

Page 48

Emission control systems information and warranty—gasoline 48 wc_tx001754gb.Fm tampering and altering tampering with or altering the emission control system may increase emissions beyond the legal limit. If evidence of tampering is found, wacker neuson may deny a warranty claim. Among those acts tha...

Page 49

Emission control systems information and warranty—gasoline wc_tx001754gb.Fm 49 used in the repair or maintenance of the engine/equipment, and an authorized wacker neuson dealer/service center determines it is defective or causes a failure of a warranted part, the claim for repair of the engine/equip...

Page 50

Emission control systems information and warranty—gasoline 50 wc_tx001754gb.Fm wacker neuson recommends that all receipts covering maintenance on the engine/equipment be retained, but wacker neuson cannot deny warranty coverage solely for the lack of receipts or for the failure to ensure the perform...

Page 51: Crt 36

Wc_tx001324gb.Fm 51 crt 36 schematics 7 schematics.

Page 52: Schematics

Wc_tx001324gb.Fm 52 schematics crt 36 7.1 schematic components ref. Description ref. Description a battery u spray pump motor b oil pressure switch (dual circuit) v engine connector c fuel pump w fuel cut-off solenoid d fuel pump relay x starter motor e key switch y engine crank solenoid f hour mete...

Page 53

Aem_concretepowertrowel.Qxd 7/23/03 6:31 am page 1.

Page 54: Word of Explanation

Safety alert symbol this safety alert symbol means attention is required! The safety alert symbol identifies important safety messages on machines, safety signs, in manuals or elsewhere. When you see this symbol, be alert to the possibility of personal injury or death. Follow the instructions in the...

Page 55: Table of Contents

3 table of contents page word of explanation ................................................................2 foreword........................................................................................4 a word to the user ....................................................................5 fo...

Page 56: A Word to The User

Remember that you are the key to safety. Good safety practices not only protect you but also protect the people around you. It is your responsibility to study this manual and the manufacturer’s manual(s) for your specific machine before operating your machine. Make them a working part of your safety...

Page 57: Prepare For Safe Operation

Learn to be safe • read the operator’s manual. If one has not been provided, get one and study it before operating the equipment. • learn the location and understand the functions of all controls before attempting to operate the equipment. • know the meaning of all identification symbols on the cont...

Page 58: Prepare For Safe Operation

Fire prevention always stop the engine and allow it to cool before refueling. Never refuel – • when engine is running • near open flame or sparks • while smoking • in poorly ventilated areas never overfill fuel tanks or fluid reservoirs. In the event of a fuel spill, do not attempt to start the engi...

Page 59: Start Safely

Start correctly – start safely before starting, check for proper functioning of all operation and shutdown controls. Check all controls to be sure they are in the correct startup position. Know the proper starting procedure for your trowel. Follow the manufacturer’s operational instructions. Walk-be...

Page 60: Work Safely

Safe working procedures danger – carbon monoxide exhaust from the engine contains poisonous carbon monoxide gas that is not easily detected as it is colorless and odorless. Exposure to carbon monoxide can cause loss of consciousness and may lead to death! Do not operate your trowel indoors or in an ...

Page 61: Shut Down Safely

Shut down procedures never disable or disconnect the safety devices! Always close fuel valves when the machine is not being used. Refer to the manufacturer’s manuals for specific shut down procedures. 15 shut down safely trowel.Qxd 11/24/04 10:18 am page 15 precautions • power trowels are heavy and ...

Page 62: Perform Maintenance Safely

Service and maintenance safety poorly maintained equipment can become a safety hazard! In order for your trowel to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. Do not attempt to clean, service, or perform adjustments on the trowel...

Page 63: Perform Maintenance Safely

Fire prevention avoid fire hazards. Always stop the engine and allow it to cool before you refuel the trowel. Do not refuel while smoking or near open flame or sparks. Never overfill fuel tanks or fluid reservoirs. Remove all trash or debris. Make sure oily rags or other flammable materials are not ...

Page 64: Perform Maintenance Safely

Trowel blades and pans • do not attempt to clean, service or perform adjustments on the trowel while it is running. • do not remove while the trowel is hanging overhead. Always support the trowel securely on a flat, level surface before changing blades or pans. • always handle blades and pans carefu...

Page 65: A Final Word to The User

Remember that you are the key to safety. Good safety practices not only protect you but protect the people around you. You have read this safety manual and the manufacturer’s manual(s) for your specific trowel. Make them a working part of your safety program. Keep in mind that this safety manual is ...

Page 66

Aem_concretepowertrowel.Qxd 7/23/03 6:31 am page 1.

Page 68

Wacker neuson se · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02-0 · fax: +49 - (0)89-3 54 02-390 wacker neuson corporation · n92w15000 anthony ave. · menomonee falls, wi 53051 · tel. : (262) 255-0500 · fax: (262) 255-0550 ·tel. : (800) 770-0957 wacker neuson limited - room 1701–03 & ...