- DL manuals

- Wacker Neuson

- Trowels

- CRT 48-31V-ES

- Operator's Manual

Wacker Neuson CRT 48-31V-ES Operator's Manual

Summary of CRT 48-31V-ES

Page 1

Www.Wackergroup.Com ride-on trowel crt 48-31v-es operator’s manual 0155954en 004 1006 0 1 5 5 9 5 4 e n.

Page 3: Crt 48-31V-Es

Crt 48-31v-es table of contents wc_bo0155954en_004toc.Fm 1 1. Foreword 3 2. Safety information 4 2.1 laws pertaining to spark arresters ...................................................... 4 2.2 operating safety .................................................................................. 5 2...

Page 4: Table of Contents

Table of contents crt 48-31v-es wc_bo0155954en_004toc.Fm 2 5. Maintenance 26 5.1 periodic maintenance schedule ..........................................................26 5.2 trowel gearboxes ...............................................................................27 5.3 switching blade posit...

Page 5

Wc_tx000001gb.Fm 3 california proposition 65 warning: engine exhaust, some of its constituents, and certain vehicle components, contain or emit chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. 1. Foreword this manual provides information and pr...

Page 6: Safety Information

Safety information crt 48-31v-es wc_si000050gb.Fm 4 2. Safety information this manual contains danger, warning, caution, notice and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is ...

Page 7: Crt 48-31V-Es

Crt 48-31v-es safety information wc_si000050gb.Fm 5 2.2 operating safety familiarity and proper training are required for the safe operation of equipment. Equipment operated improperly or by untrained personnel can be dangerous. Read the operating instructions contained in both this manual and the e...

Page 8: Safety Information

Safety information crt 48-31v-es wc_si000050gb.Fm 6 2.3 operator safety while using internal combustion engines internal combustion engines present special hazards during operation and fueling. Read and follow the warning instructions in the engine owner’s manual and the safety guidelines below. Fai...

Page 9: Crt 48-31V-Es

Crt 48-31v-es safety information wc_si000050gb.Fm 7 2.4 service safety poorly maintained equipment can become a safety hazard! In order for the equipment to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. 2.4.1 do not attempt to clea...

Page 10: Safety Information

Safety information crt 48-31v-es wc_si000050gb.Fm 8 2.5 label locations.

Page 11: Crt 48-31V-Es

Crt 48-31v-es safety information wc_si000050gb.Fm 9.

Page 12: Safety Information

Safety information crt 48-31v-es wc_si000050gb.Fm 10 2.6 safety and operating labels wacker machines use international pictorial labels where needed. These labels are described below: label meaning danger! No sparks, flames or burning objects near machine. Caution! Use only clean, filtered gasoline ...

Page 13: Crt 48-31V-Es

Crt 48-31v-es safety information wc_si000050gb.Fm 11 warning! Cutting hazard. Always replace blade guard! Warning! Pressurized contents. Do not open when hot! Warning! Hand injury if caught in moving belt. Always replace beltguard. Caution! Lifting point. Tie-down point. Key switch, engine start: of...

Page 14: Safety Information

Safety information crt 48-31v-es wc_si000050gb.Fm 12 blade pitch control. Turn both controls inward to increase blade pitch. Refer to section pitch adjustment. Operator’s manual must be stored on machine. Replacement operator’s manual can be ordered through your local wacker distributor. Warning! Re...

Page 15: Crt 48-31V-Es

Crt 48-31v-es safety information wc_si000050gb.Fm 13 caution! Disconnect battery before removing cover. Replace cover before using the machine. Caution! Engine oil pressure is low! Stop the engine and check the oil level. Caution! Low voltage! Stop the engine and check the charging system. Caution! ...

Page 16: Technical Data

Technical data crt 48-31v-es wc_td000090gb.Fm 14 3. Technical data 3.1 engine part no. Crt 48-31v-es 0009216 crt 48-31v-es-e 0009482 engine engine make vanguard engine model dm950g rated power kw (hp) 23.1 (31) displacement cm³ (in³) 950 (58) spark plug type champion rc12yc electrode gap mm (in.) 0....

Page 17: Crt 48-31V-Es

Crt 48-31v-es technical data wc_td000090gb.Fm 15 3.2 trowel part no. Crt 48-31v -es 0009216 rev. 118 and lower crt 48-31v -es 0009216 rev. 119 and higher crt 48-31v -es-e 0009482 rev. 118 and lower crt 48-31v -es-e 0009482 rev. 119 and higher trowel operating weight kg (lbs.) 528 (1165) dimensions (...

Page 18: Technical Data

Technical data crt 48-31v-es wc_td000090gb.Fm 16 3.3 sound and vibration specifications the required sound specification, paragraph 1.7.4.F of 89/392/eec machinery directive, is: • the sound pressure level at operator’s location (l pa ) 91 db(a) • the guaranteed sound power level (l wa ) 109 db(a) t...

Page 19: Crt 48-31V-Es

Crt 48-31v-es operation wc_tx000143gb.Fm 17 4. Operation 4.1 description the riding trowel is a modern, high production machine. Finishing rate will vary depending on operator skill and job conditions. The heavy-duty gearboxes are designed to provide exceptional performance, low maintenance, and tro...

Page 20: Operation

Operation crt 48-31v-es wc_tx000143gb.Fm 18 4.2 features and controls the riding trowel features a seat with an integrated “operator presence” system, which works in conjunction with a throttle mounted switch. This system allows the engine to remain running (idling) with no operator seated in the se...

Page 21: Crt 48-31V-Es

Crt 48-31v-es operation wc_tx000143gb.Fm 19 to familiarize a new operator with the riding trowel the following steps should be taken: 4.2.1 with the operator in the seat, show him or her the functions of the joysticks (c) and how to start the machine. 4.2.2 have the operator practice steering the tr...

Page 22: Operation

Operation crt 48-31v-es wc_tx000143gb.Fm 20 4.4 before starting before starting the trowel, check the following: • fuel level • oil level in the engine • condition of the air filter • condition of trowel arms and blades grease the trowel arms daily. 4.5 starting before starting the operator must kno...

Page 23: Crt 48-31V-Es

Crt 48-31v-es operation wc_tx000143gb.Fm 21 4.7 operation to utilize your wacker riding trowel to its fullest capacity, the machine should be driven in the direction that the operator is facing. This will finish the widest possible area, while giving the operator an excellent view of the slab surfac...

Page 24: Operation

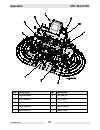

Operation crt 48-31v-es wc_tx000143gb.Fm 22 4.8 steering see graphic: wc_gr000688 refer to the illustration for the necessary hand motions to move the trowel in the desired direction, described below. 1 - forward 2 - reverse 3 - rotate clockwise 4 - rotate counter-clockwise 5 - left sideways 6 - rig...

Page 25: Crt 48-31V-Es

Crt 48-31v-es operation wc_tx000143gb.Fm 23 4.9 status indicator lights see graphic: wc_gr001496 during normal operation, the green status indicator light will remain on. A flashing green light indicates the software is operating in “limp home” mode. This can occur if a load pin is damaged or has an...

Page 26: Operation

Operation crt 48-31v-es wc_tx000143gb.Fm 24 ref. Description ref. Description 1 right actuator 6 left load pin 2 side actuator 7 left joystick 3 left actuator 8 right joystick 4 right load pin 9 control board 5 side load pin 10 status lights.

Page 27: Crt 48-31V-Es

Crt 48-31v-es operation wc_tx000143gb.Fm 25 4.10 pitch adjustment see graphic: wc_gr000147 when changing or setting the pitch (angle) of the trowel blades, slow the machine, set the desired pitch on the left side of the machine, then adjust the right side to match. To increase the pitch, turn the pi...

Page 28: Maintenance

Maintenance crt 48-31v-es wc_tx000144gb.Fm 26 5. Maintenance 5.1 periodic maintenance schedule the chart below lists basic trowel and engine maintenance. Refer to engine manufacturer’s operator’s manual for additional information on engine maintenance. A copy of the engine operator’s manual was supp...

Page 29: Crt 48-31V-Es

Crt 48-31v-es maintenance wc_tx000144gb.Fm 27 5.2 trowel gearboxes see graphic: wc_gr000156 check the gearboxes for the correct oil level after every 20 hours of operation. Change the gearbox oil every 300 hours. To check the oil level: each crt gearbox is equipped with two oil fill plugs. Remove on...

Page 30: Maintenance

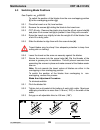

Maintenance crt 48-31v-es wc_tx000144gb.Fm 28 5.3 switching blade positions see graphic: wc_gr000255 to switch the position of the blades from the non-overlapping position (f) to the overlapping position (g): 5.3.1 place the trowel on a flat, level surface. 5.3.2 remove the screws (a) holding the bl...

Page 31: Crt 48-31V-Es

Crt 48-31v-es maintenance wc_tx000144gb.Fm 29 5.4 mounting float pans see graphic: wc_gr000275 certain applications may require the use of float pans. Optional float pans (a) are available, and are used with the machines in the non- overlapping configuration only. To mount float pans: lift trowel of...

Page 32: Maintenance

Maintenance crt 48-31v-es wc_tx000144gb.Fm 30 5.6 drive belt 0009482 revs. 123 and higher see graphic: wc_gr003665 0009216, 0009482 revs. 122 and lower see graphic: wc_gr000152 to replace the drive belt: 5.6.1 place the trowel on a flat, level surface with the blades pitched flat. 5.6.2 disconnect b...

Page 33: Crt 48-31V-Es

Crt 48-31v-es maintenance wc_tx000144gb.Fm 31.

Page 34: Maintenance

Maintenance crt 48-31v-es wc_tx000144gb.Fm 32 5.7 battery jump start procedure occasionally, it may be necessary to jump start a weak battery. If jump starting is necessary, the following procedure is recommended to prevent starter damage, battery damage, and personal injuries. Jump starting a batte...

Page 35: Crt 48-31V-Es

Crt 48-31v-es maintenance wc_tx000144gb.Fm 33 5.8 spark plug clean or replace spark plug as needed to ensure proper operation. Refer to the engine owner’s manual. Recommended plug: champion rc12yc the muffler and engine cylinder become very hot during operation and remain hot for a while after stopp...

Page 36: Maintenance

Maintenance crt 48-31v-es wc_tx000144gb.Fm 34 5.9 air cleaner see graphic: wc_gr000216 to service: 5.9.1 unlock clamps (d) and remove cover (c). 5.9.2 remove cartridge (b) from air cleaner body (a). Clean by gently tapping cartridge. (replace cartridge if very dirty or damaged.) 5.9.3 carefully clea...

Page 37: Crt 48-31V-Es

Crt 48-31v-es maintenance wc_tx000144gb.Fm 35 5.10 engine oil see graphic: wc_gr000217 drain oil while engine is still warm. 5.10.1 remove oil fill cap (a) and drain plug (b) to drain oil. Note: in the interests of environmental protection, place a plastic sheet and a container under the machine to ...

Page 38: Maintenance

Maintenance crt 48-31v-es wc_tx000144gb.Fm 36 5.11 troubleshooting problem reason remedy engine does not start. Operator present switch is not engaged. Sit in operator's seat. Oil alert shutdown feature is activated. Add oil to engine. Engine problem. Oil alert shutdown feature is activated. Machine...

Page 39: Crt 48-31V-Es

Crt 48-31v-es maintenance wc_tx000144gb.Fm 37 machine does not respond correctly to control lever movement. Sheared key. Check all keys in drive system. Loose electrical connector on actuator or joystick. Check all connections. Electronic control board failure. Replace electronic control board. Trow...

Page 40: Maintenance

Maintenance crt 48-31v-es wc_tx000144gb.Fm 38 notes.

Page 41

Aem_concretepowertrowel.Qxd 7/23/03 6:31 am page 1.

Page 42: Word of Explanation

Safety alert symbol this safety alert symbol means attention is required! The safety alert symbol identifies important safety messages on machines, safety signs, in manuals or elsewhere. When you see this symbol, be alert to the possibility of personal injury or death. Follow the instructions in the...

Page 43: Table of Contents

3 table of contents page word of explanation ................................................................2 foreword........................................................................................4 a word to the user ....................................................................5 fo...

Page 44: A Word to The User

Remember that you are the key to safety. Good safety practices not only protect you but also protect the people around you. It is your responsibility to study this manual and the manufacturer’s manual(s) for your specific machine before operating your machine. Make them a working part of your safety...

Page 45: Prepare For Safe Operation

Learn to be safe • read the operator’s manual. If one has not been provided, get one and study it before operating the equipment. • learn the location and understand the functions of all controls before attempting to operate the equipment. • know the meaning of all identification symbols on the cont...

Page 46: Prepare For Safe Operation

Fire prevention always stop the engine and allow it to cool before refueling. Never refuel – • when engine is running • near open flame or sparks • while smoking • in poorly ventilated areas never overfill fuel tanks or fluid reservoirs. In the event of a fuel spill, do not attempt to start the engi...

Page 47: Start Safely

Start correctly – start safely before starting, check for proper functioning of all operation and shutdown controls. Check all controls to be sure they are in the correct startup position. Know the proper starting procedure for your trowel. Follow the manufacturer’s operational instructions. Walk-be...

Page 48: Work Safely

Safe working procedures danger – carbon monoxide exhaust from the engine contains poisonous carbon monoxide gas that is not easily detected as it is colorless and odorless. Exposure to carbon monoxide can cause loss of consciousness and may lead to death! Do not operate your trowel indoors or in an ...

Page 49: Shut Down Safely

Shut down procedures never disable or disconnect the safety devices! Always close fuel valves when the machine is not being used. Refer to the manufacturer’s manuals for specific shut down procedures. 15 shut down safely trowel.Qxd 11/24/04 10:18 am page 15 precautions • power trowels are heavy and ...

Page 50: Perform Maintenance Safely

Service and maintenance safety poorly maintained equipment can become a safety hazard! In order for your trowel to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. Do not attempt to clean, service, or perform adjustments on the trowel...

Page 51: Perform Maintenance Safely

Fire prevention avoid fire hazards. Always stop the engine and allow it to cool before you refuel the trowel. Do not refuel while smoking or near open flame or sparks. Never overfill fuel tanks or fluid reservoirs. Remove all trash or debris. Make sure oily rags or other flammable materials are not ...

Page 52: Perform Maintenance Safely

Trowel blades and pans • do not attempt to clean, service or perform adjustments on the trowel while it is running. • do not remove while the trowel is hanging overhead. Always support the trowel securely on a flat, level surface before changing blades or pans. • always handle blades and pans carefu...

Page 53: A Final Word to The User

Remember that you are the key to safety. Good safety practices not only protect you but protect the people around you. You have read this safety manual and the manufacturer’s manual(s) for your specific trowel. Make them a working part of your safety program. Keep in mind that this safety manual is ...

Page 54

Aem_concretepowertrowel.Qxd 7/23/03 6:31 am page 1.

Page 55

2004-ce-crt36_48-q.Fm william lahner robert motl vice president of engineering manager, product engineering wacker corporation date / datum / fecha / date ec declaration of conformity ce-konformitÄtserklÄrung declaraciÓn de conformidad de la ce dÉclaration de conformitÉ c.E. Wacker corporation, n92 ...

Page 56

Wacker construction equipment ag · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02 - 0 · fax: +49 - (0)89-3 54 02-3 90 wacker corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker asia pacific operations...