- DL manuals

- Wacker Neuson

- Trowels

- CT 36-400E

- Operator's Manual

Wacker Neuson CT 36-400E Operator's Manual

Summary of CT 36-400E

Page 1

Trowel ct 36-400e operator’s manual 0159491en 002 1108 0 1 5 9 4 9 1 e n.

Page 3: Foreword

Foreword wc_tx000001gb electric.Fm 3 foreword this manual provides information and procedures to safely operate and maintain this wacker neuson model. For your own safety and protection from injury, carefully read, understand and observe the safety instructions described in this manual. Keep this ma...

Page 4: Foreword

Foreword wc_tx000001gb electric.Fm 4.

Page 5: Ct 36-400E

Ct 36-400e table of contents 5 foreword 3 1. Safety information 7 1.1 operating safety .................................................................................. 8 1.2 operator safety while using electrical equipment ............................... 9 1.3 service safety .........................

Page 6: Table of Contents

Table of contents ct 36-400e wc_bo0159491en_002toc.Fm 6 3. Maintenance 26 3.1 periodic maintenance schedule ..........................................................26 3.2 trowel lubrication ...............................................................................26 3.3 belt replacement ........

Page 7: Ct 36-400E

Ct 36-400e safety information 7 1. Safety information this manual contains danger, warning, caution, notice and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is used to alert you to...

Page 8: Safety Information

Safety information ct 36-400e 8 1.1 operating safety familiarity and proper training are required for the safe operation of the machine. Machines operated improperly or by untrained personnel can be dangerous. Read the operating instructions contained in both this manual and the engine manual and fa...

Page 9: Ct 36-400E

Ct 36-400e safety information 9 1.2 operator safety while using electrical equipment electrical motors present special hazards during operation! Failure to follow the safety guidelines described below could result in severe injury or death. 1.2.1 never operate machine with damaged or worn electrical...

Page 10: Safety Information

Safety information ct 36-400e 10 1.3 service safety a poorly maintained machine can become a safety hazard! In order for the machine to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. 1.3.1 do not attempt to clean or service machine ...

Page 11: Ct 36-400E

Ct 36-400e safety information 11 1.4 label locations l o 2 l 2 l o o l l 2 l 2 o.

Page 12: Safety Information

Safety information ct 36-400e 12 1.5 safety and information labels wacker neuson machines use international pictorial labels where needed. These labels are described below: label meaning warning! Electric shock hazard. Read operator’s man- ual for instructions. Warning! Always wear hearing and eye p...

Page 13: Ct 36-400E

Ct 36-400e safety information 13 turn motor switch to “on” position. Engage operator present lever. Release operator present lever. Turn motor switch to "off" position. Caution! Read and understand the supplied operator’s manual before operating this machine. Failure to do so increases the risk of i...

Page 14: Safety Information

Safety information ct 36-400e 14 a nameplate listing the model number, item number, revision number, and serial number is attached to each unit. Please record the infor- mation found on this plate so it will be avail- able should the nameplate become lost or damaged. When ordering parts or requestin...

Page 15: Ct 36-400E

Ct 36-400e operation 15 2. Operation 2.1 application this trowel is a modern, high production machine intended for floating and finishing freshly poured concrete slabs. The machine’s good balance, adjustable handle, and easily reached controls add to operator comfort and productivity. An operator pr...

Page 16: Operation

Operation ct 36-400e 16 2.2 installing blades see graphic: wc_gr001097 there are four types of blades available for the trowels. Float pans are large "pizza pan" style blades, which hook on over finish or combination blades and are available for the 36" machines only. Float blades are available for ...

Page 17: Ct 36-400E

Ct 36-400e operation 17 2.3 adjusting handle see graphic: wc_gr002634 2.3.1 straighten the foldable handle and tighten the knob (d) to secure the handle in position. 2.3.2 position the adjustable handle by loosening the knob (c) and adjusting the handle up or down to suit the operator. Tighten the k...

Page 18: Operation

Operation ct 36-400e 18 2.4 installing plugs and power cords see graphic: wc_gr0001177 the trowel comes with a 5-prong plug for connecting to 400v, 3Ø power. To reduce the risk of electric shock, only a certified electrician should install or service power plugs, cords, or electrical boxes. 2.5 conn...

Page 19: Ct 36-400E

Ct 36-400e operation 19 2.6 extension cords when choosing an extension cord, make sure it has adequate wire size for safety. An undersized cord will cause a drop in line voltage resulting in a loss of power and overheating. The table below shows the correct wire size to use depending on cord length....

Page 20: Operation

Operation ct 36-400e 20 2.7 controls see graphic: wc_gr002634 2.8 before starting before starting the trowel, check the following: • condition of the electrical cord • motor box, switch box, and terminal box covers are tight • oil level in gearbox • condition of trowel arms and blades • label locati...

Page 21: Ct 36-400E

Ct 36-400e operation 21 2.9 to start see graphic: wc_gr002634, wc_gr001174 2.9.1 make sure the on/off switch (f) is in the off “0” position. 2.9.2 plug the power cord (e) into a properly sized receptacle. Do not operate the trowel with the operator present lever (safety interlock) disabled. Serious ...

Page 22: Operation

Operation ct 36-400e 22 2.10 to stop see graphic: wc_gr002634, wc_gr001174 2.10.1 release operator present lever (b). 2.10.2 place on/off switch to the “0” (off) position. 2.11 optional weights to install optional weights, place equal number of weights in both front and rear of guard ring in designa...

Page 23: Ct 36-400E

Ct 36-400e operation 23 2.12 pitch adjustment see graphic: wc_gr002613 to adjust blade pitch (angle): a = twist pitch: turn the pitch adjusting knob (a) clockwise to increase pitch and counterclockwise to decrease pitch. For final finishing stages, it is sometimes desirable to add weights to the tro...

Page 24: Operation

Operation ct 36-400e 24 2.13 operation see graphic: wc_gr003239 choose correct blade type and attach blades to trowel arms. Do not mix float or finish blades with combination blades. Note: when operating on soft concrete, do not let trowel stand in one spot too long. Always lift trowel from slab whe...

Page 25: Ct 36-400E

Ct 36-400e operation 25 1 2 wc_gr003239 a b c d.

Page 26: Maintenance

Maintenance ct 36-400e 26 3. Maintenance 3.1 periodic maintenance schedule inspect all electrical cords before each use and have damaged cords replaced or repaired at an authorized service center. Clean trowel after each use by flushing with water to remove concrete splatters. Do not use a high pres...

Page 27: Ct 36-400E

Ct 36-400e maintenance 27 3.3 belt replacement see graphic: wc_gr003538 on new machines or after installing a new belt, check belt tension after the first 20 hours of operation. Check and adjust belt every 100 hours thereafter. To change the belt: 3.3.1 make sure that the trowel is unplugged from an...

Page 28: Maintenance

Maintenance ct 36-400e 28 3.4 lifting see graphic: wc_gr003554 to lift the machine manually: 3.4.1 stop motor and unplug. 3.4.2 obtain a partner and plan the lift. 3.4.3 balance the weight between the partners and lift the machine by the guard ring. To reduce risk of back injury while lifting, keep ...

Page 29: Ct 36-400E

Ct 36-400e maintenance 29 3.5 storage if trowel is being stored for more than 30 days: cover trowel and motor and store in a clean, dry area. 3.6 troubleshooting problem / symptom reason / remedy trowel does not develop full speed. • power supply is not proper voltage. • clean debris from moving par...

Page 30: Maintenance

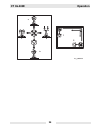

Maintenance ct 36-400e 30 3.7 electrical schematic see graphic: wc_gr001178, wc_gr001179 ref. Description ref. Description a motor b control box 1. Phase-sensing module 6. Contacts from selector switch 2. Transformer 7. Selector switch 3. Operator present lever 8. Motor overload switch (located in m...

Page 31: Ct 36-400E

Ct 36-400e maintenance 31 l1 contacts closed l2 contacts closed r1 contacts closed r2 contacts closed 3-4 3-4 1-2 1-2 5-6 5-6 7-8 7-8 13-14 9-10 13-14 9-10 15-16 11-12 15-16 11-12 21-22 17-18 21-22 17-18 - 19-20 - 19-20 - 23-24 - 23-24.

Page 32: Maintenance

Maintenance ct 36-400e 32 notes.

Page 33: Ct 36-400E

Ct 36-400e technical data 33 4. Technical data 4.1 dimensions and weight dimensions mm (in.) weight kg (lbs.) a 1537 (60-1/2) without float pan 68 (151) b 610 (24) with float pan 74 (163) c 972 (38-1/4) d 940 (37) e 839 (33).

Page 34: Technical Data

Technical data ct 36-400e 34 4.2 motor 4.3 trowel item no. Ct 24-230e 0620377 motor make volt elektrik model vm90l-2 motor output kw (hp) 2.2 (3.0) motor speed rpm 2870 power requirements volts/phase 220 / 1Ø frequency hz 50 operating current amps 5.5 / 7.3 ip rating 55 / 1Ø item no. Ct 36-400e 0009...

Page 35: Ct 36-400E

Ct 36-400e technical data 35 4.4 sound and vibration data the required sound specification, paragraph 1.7.4.F of 89/392/eec machinery directive, is: • the sound pressure level at operator’s location (l pa ) = 85 db(a) • the guaranteed sound power level (l wa ) = 98 db(a) these sound values were dete...

Page 37

Aem_concretepowertrowel.Qxd 7/23/03 6:31 am page 1.

Page 38: Word of Explanation

Safety alert symbol this safety alert symbol means attention is required! The safety alert symbol identifies important safety messages on machines, safety signs, in manuals or elsewhere. When you see this symbol, be alert to the possibility of personal injury or death. Follow the instructions in the...

Page 39: Table of Contents

3 table of contents page word of explanation ................................................................2 foreword........................................................................................4 a word to the user ....................................................................5 fo...

Page 40: A Word to The User

Remember that you are the key to safety. Good safety practices not only protect you but also protect the people around you. It is your responsibility to study this manual and the manufacturer’s manual(s) for your specific machine before operating your machine. Make them a working part of your safety...

Page 41: Prepare For Safe Operation

Learn to be safe • read the operator’s manual. If one has not been provided, get one and study it before operating the equipment. • learn the location and understand the functions of all controls before attempting to operate the equipment. • know the meaning of all identification symbols on the cont...

Page 42: Prepare For Safe Operation

Fire prevention always stop the engine and allow it to cool before refueling. Never refuel – • when engine is running • near open flame or sparks • while smoking • in poorly ventilated areas never overfill fuel tanks or fluid reservoirs. In the event of a fuel spill, do not attempt to start the engi...

Page 43: Start Safely

Start correctly – start safely before starting, check for proper functioning of all operation and shutdown controls. Check all controls to be sure they are in the correct startup position. Know the proper starting procedure for your trowel. Follow the manufacturer’s operational instructions. Walk-be...

Page 44: Work Safely

Safe working procedures danger – carbon monoxide exhaust from the engine contains poisonous carbon monoxide gas that is not easily detected as it is colorless and odorless. Exposure to carbon monoxide can cause loss of consciousness and may lead to death! Do not operate your trowel indoors or in an ...

Page 45: Shut Down Safely

Shut down procedures never disable or disconnect the safety devices! Always close fuel valves when the machine is not being used. Refer to the manufacturer’s manuals for specific shut down procedures. 15 shut down safely trowel.Qxd 11/24/04 10:18 am page 15 precautions • power trowels are heavy and ...

Page 46: Perform Maintenance Safely

Service and maintenance safety poorly maintained equipment can become a safety hazard! In order for your trowel to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. Do not attempt to clean, service, or perform adjustments on the trowel...

Page 47: Perform Maintenance Safely

Fire prevention avoid fire hazards. Always stop the engine and allow it to cool before you refuel the trowel. Do not refuel while smoking or near open flame or sparks. Never overfill fuel tanks or fluid reservoirs. Remove all trash or debris. Make sure oily rags or other flammable materials are not ...

Page 48: Perform Maintenance Safely

Trowel blades and pans • do not attempt to clean, service or perform adjustments on the trowel while it is running. • do not remove while the trowel is hanging overhead. Always support the trowel securely on a flat, level surface before changing blades or pans. • always handle blades and pans carefu...

Page 49: A Final Word to The User

Remember that you are the key to safety. Good safety practices not only protect you but protect the people around you. You have read this safety manual and the manufacturer’s manual(s) for your specific trowel. Make them a working part of your safety program. Keep in mind that this safety manual is ...

Page 50

Aem_concretepowertrowel.Qxd 7/23/03 6:31 am page 1.

Page 51

2008-ce-ct36_48-q.Fm william lahner robert motl vice president of engineering manager, product engineering wacker neuson corporation date / datum / fecha / date ec declaration of conformity ce-konformitÄtserklÄrung declaraciÓn de conformidad de la ce dÉclaration de conformitÉ c.E. Wacker neuson corp...

Page 52

Wacker construction equipment ag · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02 - 0 · fax: +49 - (0)89-3 54 02-3 90 wacker neuson corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker asia pacific ope...