- DL manuals

- Wacker Neuson

- Power Tool

- DPU 3050H

- Operator's Manual

Wacker Neuson DPU 3050H Operator's Manual

Summary of DPU 3050H

Page 1

5200001077 05 0811 5 2 0 0 0 0 1 0 7 7 operator’s manual vibratory plate dpu 3050h, dpu 3750hts en.

Page 2

Manufacturer wacker neuson produktion gmbh & co. Kg preußenstraße 41 80809 münchen www.Wackerneuson.Com tel.: +49-(0)89-354 02-0 fax: +49-(0)89-354 02-390 translation of the original operator's manual in german 0217755en 05 0811.

Page 3

3 1 foreword .................................................................................................................... 5 2 introduction ............................................................................................................... 6 2.1 means of representation for this op...

Page 4

4 9 maintenance ............................................................................................................ 36 9.1 maintenance schedule ..................................................................................... 37 9.1.1 one-time maintenance after initial operation...........

Page 5

1 foreword 5 1 foreword this operator's manual contains information and procedures for the safe opera- tion and maintenance of your wacker neuson machine. In the interest of your own safety and to prevent accidents, you should carefully read through the safety information, familiarize yourself with ...

Page 6

2 introduction 6 2 introduction 2.1 means of representation for this operator's manual warning symbols this operator's manual contains safety information of the categories: danger, warning, caution, notice. They should be followed to prevent danger to life and limb of the operator or dam- age to equ...

Page 7

2 introduction 7 instructions f this symbol indicates there is something for you to do. 1. Numbered instructions indicate that you have to carry out something in a defined sequence. This symbol is used for lists. 2.2 wacker neuson representative depending on your country, your wacker neuson represen...

Page 8

2 introduction 8 2.4 identification of the machine nameplate data the nameplate lists information that uniquely identifies your machine. This infor- mation is needed to order spare parts and when requesting additional technical information. F enter the information of your machine into the following ...

Page 9

3 safety 9 3 safety 3.1 principle state of the art this machine has been constructed with state-of-the-art technology according to the recognized rules of safety. Nevertheless, when used improperly, dangers to the life and limb of the operator or to third persons or damage to the machine or other ma...

Page 10

3 safety 10 requirements for operation the ability to operate the machine safely requires: proper transport, storage and setup. Careful operation. Careful service and maintenance. Operation operate the machine only as intended and only when in proper working condi- tion. Operate the machine in a saf...

Page 11

3 safety 11 exclusion of liability wacker neuson will refuse to accept liability for injuries to persons or for damage to materials in the following cases: structural modifications. Improper use. Failure to comply with this operator's manual. Improper handling. Using of spare parts which are not fro...

Page 12

3 safety 12 checking for signs of damage inspect the machine when it is switched off for any signs of damage at least once per work shift. Do not operate the machine if there is visible damage or defects. Have any damage or defects eliminated immediately. 3.2 qualification of the operating personnel...

Page 13

3 safety 13 3.3 protective gear work clothing clothing should be appropriate, i.E. Should be close-fitting but not restrict your movement. When on construction sites, do not wear long hair loosely, loose clothing or jew- elry including rings. These objects can easily get caught or be drawn in by mov...

Page 14

3 safety 14 lifting when lifting the machine, observe the following instructions: designate a skilled person to guide you for the lifting procedure. You must be able to see or hear this person. Use only suitable and certified hoisting gear, lifting tackle and load-bearing equipment with sufficient l...

Page 15

3 safety 15 work environment familiarize yourself with your work environment before you start work. This in- cludes e.G. The following items: obstacles in the work and traffic area. Load-bearing capacity of the ground. The measures needed to cordon off the construction site from public traffic in pa...

Page 16

3 safety 16 switching off the machine switch off the engine in the following situations: before breaks. If you are not using the machine. Store the machine in such a way that it cannot tilt, fall or slip. Storage location after operation, allow the machine to cool and then store it in a sealed-off, ...

Page 17

3 safety 17 avoiding crushing when operating the machine, pay particular attention to avoid being squeezed between the machine and an obstacle. Always look in the direction of travel! Compacting on slopes the following points must be observed if you plan to compact inclined surfaces (slopes, escarpm...

Page 18

3 safety 18 3.7 safety during the operation of combustion engines checking for signs of damage check the engine while switched off for leaks and cracks in the fuel line, tank and fuel cap at least once per work shift. Do not operate the machine if there is visible damage or defects. Have any damage ...

Page 19

3 safety 19 safety precautions when refueling please observe the following safety-relevant instructions when refueling: do not refuel near open flames. Do not smoke. Turn off the engine before refueling and allow it to cool down. Refuel in a well-ventilated environment. Wear fuel-proof protective gl...

Page 20

3 safety 20 3.8 safety during the operation of hydraulic machines hydraulic oil hydraulic oil is harmful to health. Wear safety glasses and safety gloves when handling hydraulic oil. Avoid direct skin contact with hydraulic oil. Remove hydraulic oil from the skin im- mediately with soap and water. M...

Page 21

3 safety 21 working on the battery always take the following safety measures when working with the battery: no fire, sparks, or smoking while working with batteries. Batteries contain corrosive acid. Use acid-proof protective gloves and protec- tive goggles when working with batteries. Avoid short c...

Page 22

3 safety 22 3.10 safety and information labels your machine has adhesive labels containing the most important instructions and safety information. Make sure that all the labels are kept legible. Replace any missing or illegible labels. The item numbers for the labels are in the parts book. Pos. Labe...

Page 23

3 safety 23 4 improper handling can cause serious damage to the engine. F when using the integrated wheels, always turn off the engine. If the engine is running, engine lubrica- tion cannot be ensured in the transport position. There is also a danger that oil may leak out of the engine crankcase bre...

Page 24

4 scope of delivery 24 4 scope of delivery the machine is delivered fully assembled and after unpacking it is ready for op- eration. The scope of delivery includes: machine. Operator's manual. Parts book. Item designation item designation 1 machine 3 parts book 2 operator's manual.

Page 25

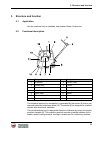

5 structure and function 25 5 structure and function 5.1 application use the machine only as intended, see chapter safety, proper use. 5.2 functional description the vibration required for compaction is generated by the exciter (9) that is per- manently attached to the base plate (10). The exciter (...

Page 26

5 structure and function 26 this procedure is hydraulically controlled with the control handle (3) on the guide handle head (4). The drive motor (13) attached to the upper mass (5) powers the exciter (9). The torque is transferred non-positively by the centrifugal clutch (7) and the exciter v-belt (...

Page 27

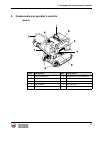

6 components and operator's controls 27 6 components and operator's controls machine item designation item designation 1 central suspension 6 integrated driving mechanism 2 fuel tank 7 guide handle 3 battery 8 control handle 4 recoil starter 9 throttle lever 5 electronic starter.

Page 28

6 components and operator's controls 28 electronic starter (only certain machine types) item designation item designation 1 operation control lamp 3 oil pressure control lamp 2 charging control lamp 4 ignition lock.

Page 29

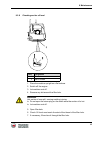

7 transport 29 7 transport warning improper handling can result in injury or serious material damage. F read and follow all safety instructions of this operator's manual, see chapter safety. Warning danger due to the machine falling. If the machine falls, it can cause severe injury such as crushing....

Page 30

7 transport 30 7.1 transporting the machine 1. Place the machine upright on a flat surface. 2. Switch off the engine. 3. Vertically set guide handle head and lock into place. 4. Fasten suitable lifting tackle to the central suspension (2) provided. 5. Lift the machine evenly with the hoist. 6. Caref...

Page 31

8 use and operation 31 8 use and operation 8.1 prior to starting the machine 8.1.1 checks before startup before you start the engine, check the following: fuel level. Motor oil level. Air cleaner. Water separator fuel lines for leaks. External screw connections for tightness. Warning improper handli...

Page 32

8 use and operation 32 8.2 starting up 8.2.1 starting the engine with recoil starter note: do not start the engine until you are sure that it is vertically stable. 1. Set throttle lever to position 1. 2. Slowly pull out the recoil starter until you feel compression. 3. Let the cable rewind from this...

Page 33

8 use and operation 33 8.2.2 starting the engine with electronic starter 1. Set throttle lever to position 1. 2. Insert the key into the ignition lock. 3. Turn key to position ii and release when the engine has started. Note: abort the start attempt after no more than 15 seconds. Note: do not turn t...

Page 34

8 use and operation 34 8.3 operating the machine 8.3.1 operating in the forward and reverse direction f press the control handle in the direction of travel. Note: the forward and reverse speed can be continuously varied. 8.3.2 compacting on a slope compacting on slopes the following points must be o...

Page 35

8 use and operation 35 8.4 decomissioning turning off the engine 1. Set throttle lever to position 0. 2. Press the off switch. Only for machine types with electronic starter: 3. Turn key to position 0. 4. Remove key if necessary. Note: to prevent battery discharge, always remove the key or turn it t...

Page 36

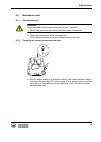

9 maintenance 36 9 maintenance warning improper handling can result in injury or serious material damage. F read and follow all safety instructions of this operator's manual, see chapter safety. Warning injury may be caused by uncontrolled startup and moving parts. F carry out maintenance work only ...

Page 37

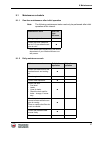

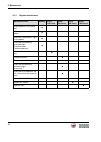

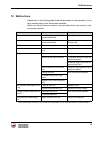

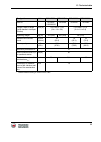

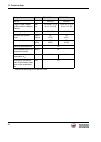

9 maintenance 37 9.1 maintenance schedule 9.1.1 one-time maintenance after initial operation note: the following maintenance tasks need only be performed after initial operation at this interval. 9.1.2 daily maintenance work maintenance work after the first 25 hours change engine oil. Check the valv...

Page 38

9 maintenance 38 9.1.3 regular maintenance maintenance work monthly every 150 hours every 250 hours every 500 hours every 1000 hours check exciter oil - fill if neces- sary. Check hydraulic oil - fill if nec- essary. Check the v-belt tension - tight- en as needed. Check that the fastening screws are...

Page 39

9 maintenance 39 9.2 maintenance work 9.2.1 cleaning machine f clean the machine with water after each use. High pressure washers or chemical agents must not be used. 9.2.2 check the air cleaner maintenance indicator f rev the engine briefly to its maximum speed. If the rubber bellows contract and c...

Page 40

9 maintenance 40 9.2.3 cleaning the air cleaner note: if the motor starts smoking and if the motor output drops at the same time, this indicates that the filter is clogged. 1. Place the machine upright on a flat surface. 2. Switch off the engine. 3. Remove and clean cartridge. Tap lightly against th...

Page 41

9 maintenance 41 9.2.4 checking the water separator 1. Place the machine upright on a flat surface. 2. Switch off the engine. 3. Check whether there is water in the inspection glass of the water separator. 4. If necessary, unscrew drain plug and catch water in a collecting container. If fuel comes o...

Page 42

9 maintenance 42 9.2.5 checking engine oil level 1. Place the machine upright on a flat surface. 2. Switch off the engine. 3. Remove any dirt around the oil level dipstick. 4. Remove the oil level dipstick and wipe it with a clean, lint-free cloth. 5. Screw the oil level dipstick all the way back in...

Page 43

9 maintenance 43 9.2.6 changing the engine oil note: the work area should be covered with a waterproof sheet to protect the floor (protection of the environment). Note: drain the oil while the engine is still hot. This ensures that the oil will be drained quickly and completely. 1. Place the machine...

Page 44

9 maintenance 44 9.2.7 checking / filling hydraulic oil level 1. Place the machine upright on a flat surface. 2. Switch off the engine. 3. Let machine cool off. 4. Vertically set guide handle head and lock into place. 5. Press the control handle in the advance travel position. 6. Remove any dirt aro...

Page 45

9 maintenance 45 9.2.8 checking exciter oil level 1. Place the machine upright on a flat surface. 2. Switch off the engine. 3. Let machine cool off. 4. Remove any dirt around the filler hole. 5. Open filler hole. 6. Check: oil level must reach the start of the thread of the filler hole. 7. If necess...

Page 46

9 maintenance 46 8. Close filler hole and use a torque wrench to tighten it to 100 nm..

Page 47

9 maintenance 47 9.2.9 re-tighten exciter v-belt 1. Place the machine upright on a flat surface. 2. Switch off the engine. 3. Let machine cool off. 4. Remove v-belt protector. 5. Unscrew screws at the engine v-belt disc and remove external v-belt pulley half. 6. Remove the necessary number of washer...

Page 48

9 maintenance 48 11. If necessary retighten the screws..

Page 49

10 malfunctions 49 10 malfunctions please refer to the following table if the machine does not work properly. It con- tains potential faults, their causes and remedies. Notify your wacker neuson contact in case of malfunctions you cannot or may not remedy yourself. Malfunction cause remedy reverse t...

Page 50

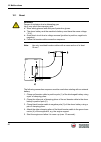

10 malfunctions 50 10.1 boost note: use only insulated booster cables with a cross section of at least 16 mm². The following connection sequence must be used when starting with an external battery: 1. Clamp red booster cable to positive pole (1) of the discharged battery using a pair of clamping pli...

Page 51

10 malfunctions 51 6. Follow these steps in reverse to remove all clamped on cables - first the black and then the red booster cable..

Page 52

11 disposal 52 11 disposal 11.1 disposal of batteries for customers in eu countries this device contains one or more batteries or rechargeable batteries (hereafter referred to as "batteries"). This battery is subject to the european directive 2006/66/ec on (waste) batteries, as well as the correspon...

Page 53

12 accessories 53 12 accessories there is a wide range of accessories available for the machine. For more information on the individual accessories, visit the following website: www.Wackerneuson.Com..

Page 54

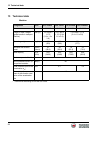

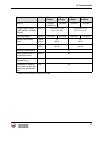

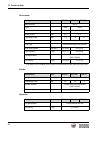

13 technical data 54 13 technical data machine designation unit dpu 2540h dpu 2550h dpu 2560h dpu 2560hts item no. 0610035 0610036 0610037 0610038 length x width x height (guide handle in transport position) mm (ft) 733 x 400 x 1,170 (2.4 x 1.3 x 3.8) 733 x 500 x 1,170 (2.4 x 1.6 x 3.8) 733 x 600 x ...

Page 55

13 technical data 55 designation unit dpu 3050h dpu 3050he dpu 3060h dpu 3060hts item no. 0610039, 5100000310 0610298 0610040 0610042 length x width x height (guide handle in transport position) mm (ft) 733 x 500 x 1,170 (2.4 x 1.6 x 3.8) 733 x 600 x 1,170 (2.4 x 1.9 x 3.8) operating weight kg (lb) ...

Page 56

13 technical data 56 designation unit dpu 3060hets dpu 3070h item no. 0610302 0610041 length x width x height (guide handle in transport position) mm (ft) 733 x 600 x 1,170 (2.4 x 1.9 x 3.8) 733 x 700 x 1,170 (2.4 x 2.3 x 38) operating weight kg (lb) 215 (474) 195 (430) advance and reverse travel m/...

Page 57

13 technical data 57 designation unit dpu 3750hts dpu 3750hets dpu 3760hts dpu 3760hets item no. 0610321, 5100000311 0610322 0610358 0610359 length x width x height (guide handle in transport position) mm (ft) 733 x 500 x 1,170 (2.4 x 1.6 x 3.8) 733 x 600 x 1,170 (2.4 x 1.9 x 3.8) operating weight k...

Page 58

13 technical data 58 drive motor exciter hydraulic designation unit dpu 25.. Dpu 30.. Dpu 37.. Manufacturer hatz type 1b20 1b30 engine displacement cm³ (in³) 243 (14.8) 347 (21.2) rated output* * equivalent to the installed power output in accordance with the directive 2000/14/ec. Kw 3.1 4.2 operati...

Page 59

13 technical data 59 electrical designation unit dpu 3050he, dpu 3060hets, dpu 3750hets, dpu 3760hets battery type special wacker neuson battery for vibration plates, 12 v - 18 ah, maintenance free.

Page 60

13 technical data 60

Page 61

Translation of the original declaration of conformity ec declaration of conformity manufacturer wacker neuson produktion gmbh & co. Kg, preußenstraße 41, 80809 münchen product conformity assessment procedure according to 2000/14/ec, appendix viii, 2005/88/ec. Notified body vde prüf- und zertifizieru...

Page 64

Wacker neuson produktion gmbh & co. Kg, preußenstraße 41, d-80809 münchen, tel.: +49-(0)89-3 54 02-0 fax: +49 - (0)89-3 54 02-390 wacker neuson production americas llc, n92w15000 anthony ave., menomonee falls, wi 53051 tel. : (262) 255-0500 fax: (262) 255-0550 tel.: (800) 770-0957 wacker neuson limi...