- DL manuals

- Wacker Neuson

- Heater

- E3000

- Operator's Manual

Wacker Neuson E3000 Operator's Manual

Summary of E3000

Page 1

Operator’s manual hydronic surface heater e3000 type e3000 document 5000188154 date 1115 version 05 language en 5 0 0 0 1 8 8 1 5 4.

Page 2

Copyright notice © copyright 2015 by wacker neuson production americas llc all rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permissio...

Page 3: E 3000

E 3000 foreword wc_tx002028gb.Fm 3 foreword this heater is designed and approved for use as a construction heater in accordance with standard ansi z83.7–csga 2.14. Check with your local fire safety authority if you have questions about applications. Other standards govern the use of fuel gases and h...

Page 4: Foreword

Foreword wc_tx002028gb.Fm 4 save these instructions—this manual contains important instructions for the machine models below. These instructions have been written expressly by wacker neuson production americas llc and must be followed during installation, operation, and maintenance of the machines. ...

Page 5: Foreword

Foreword wc_tx002028gb.Fm 5 comply with local laws regarding spark arresters, consult the engine distributor or the local health and safety administrator. Manufacturer’s approval this manual contains references to approved parts, attachments, and modifications. The following definitions apply: appro...

Page 6: Foreword

Foreword wc_tx002028gb.Fm 6.

Page 7: Table of Contents

Table of contents e 3000 wc_bo5000188154_05toc.Fm 7 foreword 3 1 safety information 11 1.1 signal words used in this manual ..................................................... 11 1.2 machine description and intended use ............................................. 12 1.3 safety guidelines for ope...

Page 8: Table of Contents

Table of contents e 3000 wc_bo5000188154_05toc.Fm 8 4.12 recommended fuel ............................................................................50 4.13 refueling the machine .........................................................................51 4.14 positioning the machine ..................

Page 9: Table of Contents

Table of contents e 3000 wc_bo5000188154_05toc.Fm 9 6.2 setting up the burner ....................................................................... 109 6.3 setting/checking the electrodes ...................................................... 112 6.4 replacing the burner nozzle ......................

Page 10: Table of Contents

Table of contents e 3000 wc_bo5000188154_05toc.Fm 10 9.2 checking the engine oil ....................................................................156 9.3 changing the engine oil and oil filter ..............................................157 9.4 checking the engine coolant level ...................

Page 11: E 3000

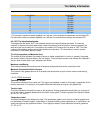

E 3000 safety information wc_si000579gb.Fm 11 1 safety information 1.1 signal words used in this manual this manual contains danger, warning, caution, notice, and note signal words which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. Noti...

Page 12: Safety Information

Safety information e 3000 wc_si000579gb.Fm 12 1.2 machine description and intended use this machine is a hydronic surface heater. The wacker neuson hydronic surface heaters consist of trailer-mounted enclosures that house an optional diesel generator, a hydronic heater, electric motors, fixed pump(s...

Page 13: E 3000

E 3000 safety information wc_si000579gb.Fm 13 fire hazards from improper refueling techniques fuel and its fumes personal injury from improper lifting of the trailer tongue tripping hazards from the hoses to protect yourself and others, make sure you thoroughly read and understand the safety informa...

Page 14: Safety Information

Safety information e 3000 wc_si000579gb.Fm 14 when operating this machine: do not operate a machine in need of repair. Personal protective equipment (ppe) wear the following personal protective equipment (ppe) while operating this machine: close-fitting work clothes that do not hinder movement safet...

Page 15: E 3000

E 3000 safety information wc_si000579gb.Fm 15 1.5 safety guidelines for operating combustion burners when using the machine: clean up any spilled fuel immediately. Replace the fuel tank cap after refueling the machine. Refill the fuel tank in a well-ventilated area. Shut down the generator, if equip...

Page 16: Safety Information

Safety information e 3000 wc_si000579gb.Fm 16 1.6 safety guidelines for operating gensets this machine is built with user safety in mind; however, like any electrical device it can present serious hazards if improperly operated and serviced. Follow instructions carefully. Should questions arise duri...

Page 17: E 3000

E 3000 safety information wc_si000579gb.Fm 17 before operating the genset know how to start, operate, and stop the genset before starting it. Obtain the proper training for operating the genset. Do not allow untrained personnel to operate or service the genset. Check the fuel lines and the fuel tank...

Page 18: Safety Information

Safety information e 3000 wc_si000579gb.Fm 18 1.7 service safety service training before servicing or maintaining the machine: read and understand the instructions contained in all manuals delivered with the machine. Familiarize yourself with the location and proper use of all controls and safety de...

Page 19: E 3000

E 3000 safety information wc_si000579gb.Fm 19 when cleaning the machine: do not clean the machine while it is running. Never use gasoline or other types of fuels or flammable solvents to clean the machine. Fumes from fuels and solvents can become explosive. Personal protective equipment (ppe) wear t...

Page 20: Safety Information

Safety information e 3000 wc_si000579gb.Fm 20 1.8 safety guidelines for towing the machine when towing the machine: do not tow the machine if the towing vehicle’s hitch or the trailer’s coupler are damaged. Do not tow the machine if any of the trailer’s lug nuts are missing. Do not tow the machine i...

Page 21: E 3000

E 3000 safety information wc_si000579gb.Fm 21 1.9 reporting safety defects if you believe your trailer has a defect which could cause a crash or could cause injury or death, you should immediately inform the national highway traffic safety administration (nhtsa) in addition to notifying wacker neuso...

Page 22: Labels

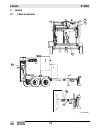

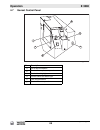

Labels e 3000 wc_si000643gb.Fm 22 2 labels 2.1 label locations 603 wc_gr008850 998 608 626 602 601 999 618.

Page 23: E 3000

E 3000 labels wc_si000643gb.Fm 23 616 625 613 613 602 626 619 995 625 608 616 609 607 612 617 600 613 604 612 618 609 602 611 wc_gr008849.

Page 24: Labels

Labels e 3000 wc_si000643gb.Fm 24 2.2 label meanings ref. Label definition 600 601 turn the handle clockwise to engage the hose reel brake. Turn the handle counterclockwise to release the hose reel brake. 602 warning! Hot surface hazard. Wear safety gloves. Wear eye protection. For machines powered ...

Page 25: E 3000

E 3000 labels wc_si000643gb.Fm 25 603 heat transfer fluid level. This label indicates the minimum and maximum level for the heat transfer fluid. This label is located adjacent to a sight gauge on the heat trans- fer fluid reservoir. 604 warning! Do not engage trailer jack while transporting the mach...

Page 26: Labels

Labels e 3000 wc_si000643gb.Fm 26 608 tie-down location marker. 609 notice! Lift point. Attach lifting device in this location. 611 warning! Hand entanglement hazard. Moving parts can crush and cut. Do not operate with guard removed. 612 caution! Hot surface hazard! Ref. Label definition caution vor...

Page 27: E 3000

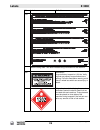

E 3000 labels wc_si000643gb.Fm 27 613 not a step. 616 weight/mass label: this label indicates the total weight of the machine, including the trailer and a full fuel tank. 617 caution this machine uses diesel fuel. 618 danger asphyxiation hazard. Using a hydronic surface heater indoors can kill you i...

Page 28: Labels

Labels e 3000 wc_si000643gb.Fm 28 619 machine rating label: this label indicates rating information for the machine. 625 warning! Lugnuts factory torqued to 110 ft.Lbs. Verify lugnuts are properly torqued before trans- porting. Failure to heed above warning could result in wheel loss which can cause...

Page 29: E 3000

E 3000 labels wc_si000643gb.Fm 29 626 caution! Pressurized contents. Do not open when hot! 995 warning! Never operate in an explosive environment or near flammable vapors, fuels or combusti- bles. Explosion or fire may occur. Risk of severe injury or death. 998 (on trailer) tire and loading informat...

Page 30: Lifting and Transporting

Ghi_tx001160gb.Fm 30 lifting and transporting e 3000 3 lifting and transporting 3.1 lifting the machine requirements properly rated lifting equipment (crane or hoist). See chapter technical data. Machine stopped. See topic stopping the machine. All doors and access covers closed and secured. Procedu...

Page 31: E 3000

Ghi_tx001160gb.Fm 31 e 3000 lifting and transporting 3.2 preparing the machine for transport on a truck or trailer requirements machine stopped. Flatbed truck or trailer capable of supporting the machine’s weight. Chains, hooks, or straps capable of supporting the machine’s weight. Checklist before ...

Page 32: Lifting and Transporting

Ghi_tx001160gb.Fm 32 lifting and transporting e 3000 3.3 transporting the machine on a truck or trailer requirements machine stopped. See topic stopping the machine. All doors and access covers closed and secured. Notice: do not run chains or straps across painted surfaces. Chains or straps may dama...

Page 33: E 3000

Ghi_tx001160gb.Fm 33 e 3000 lifting and transporting continued from the previous page. Secure the machine 5. Install properly rated securing mechanisms (d) such as chains or straps. 6. Install chocks (e) under all four wheels. Result the machine is ready to be transported..

Page 34: Lifting and Transporting

Ghi_tx001160gb.Fm 34 lifting and transporting e 3000 3.4 before towing checklist before towing the machine, check the licensing requirements for trailers in your area. Also check the following items: hitch and coupler check that the towing vehicle and hitch have a rating equal to or greater than t...

Page 35: E 3000

Ghi_tx001160gb.Fm 35 e 3000 lifting and transporting 3.5 towing the machine notice: the towing vehicle must be equipped with a class iii or above hitch. Procedure perform the procedure below when towing the machine. 1. Read and follow the towing safety guidelines. See topic safety guidelines for tow...

Page 36: Lifting and Transporting

Ghi_tx001160gb.Fm 36 lifting and transporting e 3000 3.6 testing the breakaway system (electric brakes) requirements voltmeter battery charger or backup battery (charged) when test the breakaway system: before towing monthly if the machine is not in service procedure perform the following procedure ...

Page 37: E 3000

Ghi_tx001160gb.Fm 37 e 3000 lifting and transporting continued from the previous page. 5. If the brakes did not function, check the voltage of the breakaway battery. To do so: a. Remove the cover of the battery box. B. Remove the wires connected to the breakaway battery (d). C. Measure the voltage. ...

Page 38: Lifting and Transporting

Ghi_tx001160gb.Fm 38 lifting and transporting e 3000 3.7 hazardous materials placards hazardous materials placards the pipeline and hazardous materials safety administration (phmsa) requires that hazardous materials placards be placed on this machine when transporting it unless the fuel tank has bee...

Page 39: E 3000

Ghi_tx001160gb.Fm 39 e 3000 lifting and transporting notes.

Page 40: Operation

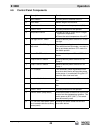

Wc_tx001951gb.Fm 40 operation e 3000 4 operation 4.1 external components wc_gr008851 1 3 7 8 9 4 10 6 2 5 ref. Description ref. Description 1 hitch (ball or pintle) 6 fender 2 tie-down 7 onan genset (option) 3 fuel tank 8 jack stand 4 fuel tank cap 9 tandem axles 5 performance monitoring light 10 li...

Page 41: E 3000

Wc_tx001951gb.Fm 41 e 3000 operation 4.2 internal components 1 this hydronic heater operates at zero (atmospheric) pressure and is not subject to regulations applicable to pressurized “boilers”. Ref. Description ref. Description a hydronic heater 1 h fill valve #3 b burner (oil burning shown) i htf ...

Page 42: Operation

Wc_tx001951gb.Fm 42 operation e 3000 4.3 rear components ref. Description ref. Description a control panel g hose reels and hose b heat transfer fluid (htf) return plumbing h pump pack supply connections c htf supply plumbing i duplex receptacle d hose reel brake t-handle j operator’s manual holder ...

Page 43: E 3000

Wc_tx001951gb.Fm 43 e 3000 operation 4.4 pumps, gauges, and valves pumps and gauges valves ref. Description a left pump b return flow indicator c accessory htf return thermometer d main htf return thermometer e check valves f pump pressure gauge g right pump valve # description 1 pump pack supply an...

Page 44: Operation

Wc_tx001951gb.Fm 44 operation e 3000 4.5 control panel wc_gr008606 1 2 n d e f g h i j k l m a b c o p.

Page 45: E 3000

Wc_tx001951gb.Fm 45 e 3000 operation 4.6 control panel components ref description function a main breaker 1 controls power to electrical circuit 1. B hour meter meters usage of the machine. C main breaker 2 controls power to the pump circuit (20a) d circuit 2 gfci provides protection for the operato...

Page 46: Operation

Wc_tx001951gb.Fm 46 operation e 3000 4.7 genset control panel ref description a oil fill cap and dipstick b coolant recovery access panel c coolant level sightglass d control switch and status light e line circuit breakers f coolant fill access panel f a b c e d wc_gr008140

Page 47: E 3000

Wc_tx001951gb.Fm 47 e 3000 operation 4.8 preparing the machine for first use preparing for first use to prepare your machine for first use: 1. Make sure all loose packaging materials have been removed from the machine. 2. Check the machine and its components for damage. If there is visible damage, d...

Page 48: Operation

Wc_tx001951gb.Fm 48 operation e 3000 4.10 general sequence of operation follow the sequence of operation below. Refer to the specific topic for details. Task when/where see topic 1. Check htf level. Before leaving for the job site. Or, when at the job site before daily operation. 4.11 / 4.15 2. Chec...

Page 49: E 3000

Wc_tx001951gb.Fm 49 e 3000 operation 4.11 checking the htf level when before leaving for the job site, or before beginning operation at the job site prerequisites the machine is level. The machine is cool. Procedure the heat transfer fluid (htf) level must be between the marks on the sightglass (c)....

Page 50: Operation

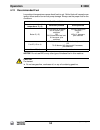

Wc_tx001951gb.Fm 50 operation e 3000 4.12 recommended fuel low ambient temperatures cause diesel fuels to gel. Gelled fuels will cause burner ignition failure and/or burner fuel pump damage. Always use the proper fuel for the conditions. Notice: do not use b20 or any other type of biodiesel fuel in ...

Page 51: E 3000

Wc_tx001951gb.Fm 51 e 3000 operation 4.13 refueling the machine requirements machine shut down machine level with the ground diesel fuel supply procedure perform the procedure below to refuel the machine. Note: on models with generators, it is not necessary to fill the generator’s fuel tank. Both th...

Page 52: Operation

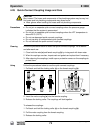

Wc_tx001951gb.Fm 52 operation e 3000 4.14 positioning the machine co alarms because this machine produces carbon monoxide (co), wacker neuson recommends that co alarms be installed in all structures in close proximity to the machine. Co alarms provide an extra measure of protection against this pois...

Page 53: E 3000

Wc_tx001951gb.Fm 53 e 3000 operation continued from the previous page. Procedure perform the following procedure to position the machine. 1. Place the machine near the application area (a) on solid, stable, and level ground. 2. For machines with trailers, install chocks (b) under the wheels. Result ...

Page 54: Operation

Wc_tx001951gb.Fm 54 operation e 3000 4.15 pre-starting checks requirements machine properly positioned power connected to the machine checks before starting the machine, check the following items: fuel system fuel sight gauge valve (a) f check that the fuel sight gauge valve is open. Fuel sight gaug...

Page 55: E 3000

Wc_tx001951gb.Fm 55 e 3000 operation suction valve (#2) f check that suction valve (#2) is open. Htf fill valve (#3) f check that htf fill valve (#3) is closed and locked with the locking pin. Notice: the htf fill valve must remain closed and locked during normal operation. An open htf fill valve wi...

Page 56: Operation

Wc_tx001951gb.Fm 56 operation e 3000 result the machine is ready to have power applied. Hydronic heater (f) f inspect for signs of exhaust leaks. See topic inspecting/ replacing the rope gasket. Genset (g) (if equipped) f check oil level. See topic checking the engine oil. F inspect for signs of fue...

Page 57: E 3000

Wc_tx001951gb.Fm 57 e 3000 operation 4.16 connecting power to the machine prerequisites power source machine properly positioned extension cords restrictions for extension cords: use only 3-wire type extension cords with heavy-duty plugs. The maximum length of extension cord usage per circuit is 30 ...

Page 58: Operation

Wc_tx001951gb.Fm 58 operation e 3000 4.17 starting and stopping the generator background only general starting and stopping procedures for the generator are included in this manual. See the generator manufacturer’s operation manual for detailed procedures. Starting perform the procedure below to sta...

Page 59: E 3000

Wc_tx001951gb.Fm 59 e 3000 operation 4.18 applying power to the machine requirements pre-starting checks have been completed power connected to the machine procedure follow the procedure below to apply power to the machine. 1. Move both circuit breaker switches (a) to the on position. 2. Check that ...

Page 60: Operation

Wc_tx001951gb.Fm 60 operation e 3000 4.19 preheating the htf notice: starting the machine with frozen or partially frozen heat transfer fluid (htf) will permanently damage the pumps. Preheat the htf when ambient air temperature is below -26°c (-15°f). Requirements htf reservoir full machine powered ...

Page 61: E 3000

Wc_tx001951gb.Fm 61 e 3000 operation 4.20 initiating htf flow requirements heat transfer fluid (htf) preheated. See topic preheating the htf. Gloves note: if you are using accessories, see chapter “accessories”. Procedure follow the procedure below to initiate htf flow. 1. Close and lock valve #3. T...

Page 62: Operation

Wc_tx001951gb.Fm 62 operation e 3000 continued from the previous page. 4. Move the left pump on-off switch (d) to the on position. 5. Check the pump pressure gauge (e). The following should occur: during the first minute of operation, the pressure should build to as high as 170 psi. Notice: if the h...

Page 63: E 3000

Wc_tx001951gb.Fm 63 e 3000 operation 4.22 unwinding and positioning the hoses requirements htf preheated if applicable htf flow initiated procedure follow the procedure below to unwind and position the hoses. 1. Rotate the t-handle (a) counter-clockwise to unlock it. : 2. Pull the hose (b) off the r...

Page 64: Operation

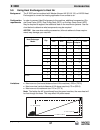

Wc_tx001951gb.Fm 64 operation e 3000 4.23 hose spacing guidelines background when laying hose in the application area, the space between individual lines of hose significantly affects the progress of the application. Although it is impossible to predict the ambient conditions for each job site, wack...

Page 65: E 3000

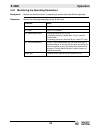

Wc_tx001951gb.Fm 65 e 3000 operation 4.24 monitoring the operating parameters background monitor the machine while it is operating to ensure safe and efficient operation. Parameters monitor the following parameters every 8–24 hours. Parameter notes fuel level add fuel as needed. Htf level add htf as...

Page 66: Operation

Wc_tx001951gb.Fm 66 operation e 3000 4.25 rewinding the hoses requirements all accessories off, if applicable machine turned on procedure perform the procedure below to rewind the hose. Note: turn the pump on. Turning the pump on—to circulate warm htf through the hose—will aid in handling of the hos...

Page 67: E 3000

Wc_tx001951gb.Fm 67 e 3000 operation continued from the previous page. Notice: disengage the clutch before reaching the hose end. Failure to comply may damage the machine. 6. Release the foot pedal to disengage the clutch before reaching the hose end. 7. Manually wind the remainder of the hose onto ...

Page 68: Operation

Wc_tx001951gb.Fm 68 operation e 3000 4.26 shutting down and packing up the machine shutting down perform the procedure below to shut down the machine. 1. Turn off all accessories if applicable. 2. Rewind the hoses. See topic rewinding the hoses. 3. Move the burner on-off switch (a) to the off positi...

Page 69: E 3000

Wc_tx001951gb.Fm 69 e 3000 operation 4.27 resetting a low htf fault requirements genuine wacker neuson heat transfer fluid, or dowfrost hd 50 heat transfer fluid notice: use only factory-recommended heat transfer fluid (htf). Failure to do so may damage the machine. Background the htf reservoir incl...

Page 70: Operation

Wc_tx001951gb.Fm 70 operation e 3000 continued from the previous page. 7. Lift and hold the htf fill switch (b) in the on position (i) and watch the htf reservoir sightglass (c)—release the htf fill switch when the htf level is seen in the htf reservoir sightglass. Notice: do not overfill the htf re...

Page 71: E 3000

Wc_tx001951gb.Fm 71 e 3000 operation continued from the previous page. 10.Move valve #3 to the normal position. 11.Remove the fill hose from the htf container and allow any htf within the hose to drip back into the container. Cap the fill hose if a cap is provided. 12.Move the fill hose to its stora...

Page 72: Operation

Wc_tx001951gb.Fm 72 operation e 3000 4.28 quick-connect coupling usage and care precautions do not join or separate quick-connect couplings when the pressure gauge indicates that the system is pressurized. Do not join or separate quick-connect couplings when the htf temperature is above 48°c (120°f)...

Page 73: E 3000

Wc_tx001951gb.Fm 73 e 3000 operation 4.29 operating states of the beckett burner controller burner states the burner control has several states that it sequences through during normal operation. These operating states are described below. . Standby run ignition carryover state 10 30 operating wc_gr0...

Page 74: Operation

Wc_tx001951gb.Fm 74 operation e 3000 ignition carryover the ignition carryover state starts as soon as the flame is established. During this state: the fuel shut-off valve is open (energized). Pressurized fuel atomizes at the burner nozzle. The atomized fuel is ignited by the electrodes. The electro...

Page 75: E 3000

Wc_tx001951gb.Fm 75 e 3000 operation lockout the lockout state is described below. Recycle the recycle mode is described below. State action or function lockout the burner will enter the lockout state for the following reasons: trial for ignition time has expired without flame being estab- lished. C...

Page 76: Operation

Wc_tx001951gb.Fm 76 operation e 3000 pump prime the pump prime mode is described below. State action or function pump prime during the pump prime mode, the cad cell is disregarded, allowing the technician to prime the pump without having to jumper the cad cell. This mode lasts 4 minutes. During this...

Page 77: E 3000

Wc_tx001951gb.Fm 77 e 3000 operation notes.

Page 78: Accessories

Ghi_tx001162gb.Fm 78 accessories e 3000 5 accessories 5.1 available accessories to increase the machine’s capabilities and capacities, the following wacker neuson accessories are available. Configurations these accessories allow the following application configurations: combining your parent machine...

Page 79: E 3000

Ghi_tx001162gb.Fm 79 e 3000 accessories 5.2 expanding the surface heating capacity background the e 3000 can be combined with wacker neuson hose handling systems (hhs 3002) and dual pump packs (dpp) to increase the surface heating capacity. The typical configurations are shown below; however, this d...

Page 80: Accessories

Ghi_tx001162gb.Fm 80 accessories e 3000 5.3 expanded operation using one hhs 3002 and one dpp requirements machine stopped one hhs 3002 hose handling system one dpp dual pump pack procedure perform the procedure below to expand the machine with one hose handling system (hhs) and one dual pump pack (...

Page 81: E 3000

Ghi_tx001162gb.Fm 81 e 3000 accessories continued from the previous page. Ref description condition #1 pump pack supply valve 1 open after connection #4 right htf supply valve open after connection #5 cross connect valve closed #6 left htf supply valve open after connection #7 pump pack supply valve...

Page 82: Accessories

Ghi_tx001162gb.Fm 82 accessories e 3000 5.4 expanded operation using two hhs 3002 and two dpp requirements machine stopped two hhs 3002 hose handling systems two dpp dual pump packs two 2-1 adapters procedure perform the procedure below to expand the machine with two hose handling systems (hhs) and ...

Page 83: E 3000

Ghi_tx001162gb.Fm 83 e 3000 accessories continued from the previous page. This procedure continues on the next page. Wc_gr008542 g i f n j h b c k l d e m y x.

Page 84: Accessories

Ghi_tx001162gb.Fm 84 accessories e 3000 continued from the previous page. Ref description condition #1 pump pack supply valve 1 open after connection #4 right htf supply valve open after connection #5 cross connect valve closed #6 left htf supply valve open after connection #7 pump pack supply valve...

Page 85: E 3000

Ghi_tx001162gb.Fm 85 e 3000 accessories 5.5 mounting and connecting the auxiliary pump panel prerequisites machine shut down power disconnected background the wacker neuson auxiliary pump panel (app) is an electrical device that communicates with the main machine’s systems to provide protection for ...

Page 86: Accessories

Ghi_tx001162gb.Fm 86 accessories e 3000 continued from the previous page. Electrical connections after mounting, carry out the steps below to complete the electrical connections. 1. Connect the din leader (a) from the main control panel to the corresponding din leader on the app (b). 2. Connect a pr...

Page 87: E 3000

Ghi_tx001162gb.Fm 87 e 3000 accessories 5.6 using heat exchangers to heat air background the e 3000 can be combined with wacker neuson hx 50, hx 100, or hx 200 heat exchangers to convert the heating application from surface to air. Configuration requirements in order to connect heat exchangers to th...

Page 88: Accessories

Ghi_tx001162gb.Fm 88 accessories e 3000 5.7 connecting six hx 50 heat exchangers requirements six hx 50 heat exchangers four 2-1 adapters three 1-2 adapters one single pump pack (spp) auxiliary pump pack (app) (see topic mounting the auxiliary pump panel.) connect adapters perform the procedure belo...

Page 89: E 3000

Ghi_tx001162gb.Fm 89 e 3000 accessories continued from the previous page. Run the machine notice: only start the pumps when the heat exchangers are connected. Starting the pumps when the heat exchangers are not connected will cause excess system pressure which may damage the pumps. 1. Start the e 30...

Page 90: Accessories

Ghi_tx001162gb.Fm 90 accessories e 3000 5.8 connecting five hx 50 heat exchangers requirements machine stopped five hx 50 heat exchangers three 2-1 adapters two 1-2 adapters one single pump pack (spp) auxiliary pump pack (app) (see topic mounting the auxiliary pump panel.) connect adapters perform t...

Page 91: E 3000

Ghi_tx001162gb.Fm 91 e 3000 accessories wc_gr008557 app 2-1 2-1 2-1 1-2 1-2 g i x w v z y a b c d e lr rr rs ls hx 50 hx 50 hx 50 hx 50 hx 50 spp.

Page 92: Accessories

Ghi_tx001162gb.Fm 92 accessories e 3000 5.9 connecting four hx 50 heat exchangers requirements machine stopped four hx 50 heat exchangers two 2-1 adapters two 1-2 adapters connect adapters perform the procedure below to connect the heat exchangers to the machine. 1. Connect a 2-1 adapter (x) to the ...

Page 93: E 3000

Ghi_tx001162gb.Fm 93 e 3000 accessories wc_gr008558 2-1 2-1 1-2 1-2 x v z y a b c d lr rr rs ls hx 50 hx 50 hx 50 hx 50

Page 94: Accessories

Ghi_tx001162gb.Fm 94 accessories e 3000 5.10 connecting three hx 50 heat exchangers requirements machine stopped three hx 50 heat exchangers one 2-1 adapter one1-2 adapter connect adapters perform the procedure below to connect the heat exchangers to the machine. 1. Connect a 2-1 adapter (x) to the ...

Page 95: E 3000

Ghi_tx001162gb.Fm 95 e 3000 accessories wc_gr008559 2-1 1-2 x z a b c lr rr rs ls hx 50 hx 50 hx 50

Page 96: Accessories

Ghi_tx001162gb.Fm 96 accessories e 3000 5.11 connecting two hx 50 heat exchangers requirements machine stopped two hx 50 heat exchangers connect the hx hoses 1. Position the heat exchangers (a and b) within the space to be heated. 2. Connect heat exchanger (a) to left accessory supply (ls). 3. Conne...

Page 97: E 3000

Ghi_tx001162gb.Fm 97 e 3000 accessories wc_gr008560 a b lr rr rs ls hx 50 hx 50

Page 98: Accessories

Ghi_tx001162gb.Fm 98 accessories e 3000 5.12 connecting one hx 50 heat exchanger requirements machine stopped one hx 50 heat exchanger connect the hx hoses 1. Position the heat exchanger (a) within the space to be heated. 2. Connect heat exchanger to left accessory supply (ls). 3. Connect heat excha...

Page 99: E 3000

Ghi_tx001162gb.Fm 99 e 3000 accessories wc_gr008561 a lr ls hx 50

Page 100: Accessories

Ghi_tx001162gb.Fm 100 accessories e 3000 5.13 connecting three hx 100 heat exchangers requirements machine stopped three hx 100 heat exchangers one 2-1 adapter one single pump pack (spp) auxiliary pump pack (app) (see topic mounting the auxiliary pump panel.) connect adapter perform the procedure be...

Page 101: E 3000

Ghi_tx001162gb.Fm 101 e 3000 accessories wc_gr008580 spp hx 100 hx 100 hx 100 d e a b c lr rr y ls rs app 2-1.

Page 102: Accessories

Ghi_tx001162gb.Fm 102 accessories e 3000 5.14 connecting two hx 100 heat exchangers requirements machine stopped two hx 100 heat exchangers connect the hx hoses 1. Position the heat exchangers (a and b) within the space to be heated. 2. Connect heat exchanger (a) to left accessory supply (ls). 3. Co...

Page 103: E 3000

Ghi_tx001162gb.Fm 103 e 3000 accessories wc_gr008582 hx 100 hx 100 a b lr rr ls rs.

Page 104: Accessories

Ghi_tx001162gb.Fm 104 accessories e 3000 5.15 connecting one hx 100 heat exchanger requirements machine stopped one hx 100 heat exchangers connect the hx hoses 1. Position the heat exchanger (a) within the space to be heated. 2. Connect heat exchanger (a) to left accessory supply (ls). 3. Connect he...

Page 105: E 3000

Ghi_tx001162gb.Fm 105 e 3000 accessories wc_gr008583 hx 100 a lr ls.

Page 106: Accessories

Ghi_tx001162gb.Fm 106 accessories e 3000 5.16 connecting two hx 200 heat exchangers requirements machine stopped two hx 200 heat exchangers one 2-1 adapter one dual pump pack (dpp) auxiliary pump pack (app) (see topic mounting the auxiliary pump panel.) connect the hx hoses 1. Position the heat exch...

Page 107: E 3000

Ghi_tx001162gb.Fm 107 e 3000 accessories wc_gr008584 app c e d dpp a b lr ls rr rs 2-1 hx 200 hx 200

Page 108: Accessories

Ghi_tx001162gb.Fm 108 accessories e 3000 5.17 connecting one hx 200 heat exchanger requirements machine stopped one hx 200 heat exchanger connect the hx hoses 1. Position the heat exchangers (a) within the space to be heated. 2. Connect heat exchanger (a) to left accessory supply (ls). 3. Connect he...

Page 109: E 3000

Wc_tx001802gb.Fm 109 e 3000 burner setup—oil 6 burner setup—oil 6.1 factory settings 6.2 setting up the burner background the burner consists of several different components and subsystems. Each of these components or subsystems must be operating correctly for the burner to function properly. Fuel l...

Page 110: Burner Setup—Oil

Wc_tx001802gb.Fm 110 burner setup—oil e 3000 continued from the previous page. When adjust the burner: before operating the machine at elevations 305 m (1,000 ft) above or below the location of the previous adjustments before starting at a new job site after any burner maintenance or repair has been...

Page 111: E 3000

Wc_tx001802gb.Fm 111 e 3000 burner setup—oil continued from the previous page. 9. Analyze the combustion. Follow the combustion analyzer manufacturer’s instructions and the general guidelines below. Use the access hole in the exhaust stack. Take several samples as the heater warms. Take the final sa...

Page 112: Burner Setup—Oil

Wc_tx001802gb.Fm 112 burner setup—oil e 3000 6.3 setting/checking the electrodes requirements power supplies disconnected ruler/measuring device procedure follow the procedure below to check the electrodes. 1. Disconnect the power supplies. 2. Remove the copper fuel line (a) between the fuel pump an...

Page 113: E 3000

Wc_tx001802gb.Fm 113 e 3000 burner setup—oil continued from the previous page. 7. Use the measurements below to properly set the electrodes. 8. Reconnect the preheater wiring. 9. Reinstall the nozzle assembly into the burner. Result the electrodes have now been checked/adjusted. Ref. Description gap...

Page 114: Burner Setup—Oil

Wc_tx001802gb.Fm 114 burner setup—oil e 3000 6.4 replacing the burner nozzle requirements power supplies disconnected machine cool procedure follow the procedure below to replace the burner nozzle. 1. Disconnect the power supplies. 2. Remove the copper fuel line (a) between the fuel pump and the bur...

Page 115: E 3000

Wc_tx001802gb.Fm 115 e 3000 burner setup—oil continued from the previous page. 7. Unscrew the burner nozzle (f) from the burner tube. 8. Install a new burner nozzle. Note: do not use thread sealant on the threads of the nozzle. 9. Reconnect the preheater wiring. 10.Reinstall the nozzle/electrode ass...

Page 116: Burner Setup—Oil

Wc_tx001802gb.Fm 116 burner setup—oil e 3000 6.5 setting the “z” distance prerequisites burner removed from the machine beckett t501 gauge procedure follow the procedure below to set the “z” distance on f220 heads. 1. Remove the burner from the machine. 2. Loosen the knurled nut (b) . 3. Loosen the ...

Page 117: E 3000

Wc_tx001802gb.Fm 117 e 3000 burner setup—oil continued from the previous page. Measuring measuring the “z” distance. A. Place a straight edge over the end of the flame retention head. B. Adjust the nozzle assembly until the distance between the front face of the burner nozzle and the end of the flam...

Page 118: Burner Setup—Oil

Wc_tx001802gb.Fm 118 burner setup—oil e 3000 6.6 adjusting the air settings factory settings air band: 0 air shutter: 6.5 note: these settings are initial settings only. Adjust the air settings as necessary to obtain the proper smoke spot and combustion analysis values. Background there are two part...

Page 119: E 3000

Wc_tx001802gb.Fm 119 e 3000 burner setup—oil 6.7 adjusting the fuel pressure factory setting “f” head: 150 psig (10.0 bar) procedure follow the procedure below to check and adjust the fuel pressure. 1. Shut down the machine. 2. Remove the bleeder valve (a) from the fuel pump. 3. Insert the gauge in ...

Page 120: Burner Setup—Gas

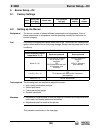

Wc_tx002070gb.Fm 120 burner setup—gas e 3000 7 burner setup—gas 7.1 factory settings make sure you have proper certification or licensing required by the locality, state, or province in which the machine is being installed to connect natural gas or lp. E 3000 ng lp air damper setting 3.8 4.0 combust...

Page 121: E 3000

Wc_tx002070gb.Fm 121 e 3000 burner setup—gas 7.2 restrictions for connecting the gas supply requirements the technician installing the supply gas shall have proper certification or licensing required by the locality, state, or province in which the machine is being installed to connect natural gas o...

Page 122: Burner Setup—Gas

Wc_tx002070gb.Fm 122 burner setup—gas e 3000 7.3 setting up the burner background the burner consists of several different components and subsystems. Each of these components or subsystems must be operating correctly for the burner to function properly. Tools required the following tools are require...

Page 123: E 3000

Wc_tx002070gb.Fm 123 e 3000 burner setup—gas continued from the previous page. 9. Conduct a smoke spot test. Follow the smoke spot tester manufacturer’s instructions and the general guidelines below. Use the access hole in the exhaust outlet. Take several samples as the heater warms. Take the final ...

Page 124: Burner Setup—Gas

Wc_tx002070gb.Fm 124 burner setup—gas e 3000 7.4 removing and installing the combustion head requirements machine shut down burner cool removal perform the procedure below to remove the combustion head. 1. Open the access door and locate the burner. 2. Remove the burner assembly cover (a). 3. Remove...

Page 125: E 3000

Wc_tx002070gb.Fm 125 e 3000 burner setup—gas continued from the previous page. 6. Remove the combustion head (f). Installation perform the procedure below to install the combustion head. 1. Install the combustion head into the burner. Adjust the combustion per topic adjusting the combustion head. 2....

Page 126: Burner Setup—Gas

Wc_tx002070gb.Fm 126 burner setup—gas e 3000 7.5 adjusting the ionization probe and the electrode requirements machine shut down burner cool procedure perform the procedure below to adjust both the ionizaton probe and the electrode. 1. Shut down the machine and allow it to cool. 2. Remove the combus...

Page 127: E 3000

Wc_tx002070gb.Fm 127 e 3000 burner setup—gas 7.6 changing the burner diaphragm requirements machine shut down machine cool correct burner diaphragm: c6 for ng; c3 for lp background the burner can burn either lp or natural gas (ng). The burner comes from the factory set up to burn ng. In order to bur...

Page 128: Burner Setup—Gas

Wc_tx002070gb.Fm 128 burner setup—gas e 3000 7.7 checking and adjusting the air damper (gate) setting requirements machine shut down burner cool procedure follow the procedure below to check the air damper setting. Note: this procedure must be performed at each new job site. The proper setting depen...

Page 129: E 3000

Wc_tx002070gb.Fm 129 e 3000 burner setup—gas 7.8 adjusting the combustion head requirements machine shut down machine cool procedure perform the procedure below to adjust the combustion head. 1. Open the access door and locate the burner. 2. Remove the burner assembly cover (a). 3. Remove nut (c) an...

Page 130: Burner Setup—Gas

Wc_tx002070gb.Fm 130 burner setup—gas e 3000 7.9 checking the supply gas pressure requirements machine shut down supply gas turned off manometer nipple checking pressure perform the procedure below to check and adjust the supply gas pressure. 1. Shut down the machine and allow it to cool. 2. Close t...

Page 131: E 3000

Wc_tx002070gb.Fm 131 e 3000 burner setup—gas continued from the previous page. 7. Check the pressure reading on the manometer. See section technical data for the correct pressure. Adjust the supply gas pressure as needed. 8. After the supply gas pressure has been set, turn off the supply gas. 9. Rem...

Page 132: Burner Setup—Gas

Wc_tx002070gb.Fm 132 burner setup—gas e 3000 7.10 checking and adjusting the burner gas pressure requirements machine shut down adequate supply gas pressure manometer checking pressure follow the procedure below to check and adjust the burner gas pressure. 1. Turn the control knob (a) to the “off” p...

Page 133: E 3000

Wc_tx002070gb.Fm 133 e 3000 burner setup—gas continued from the previous page. Adjusting pressure follow the procedure below to adjust the burner gas pressure at the gas control valve. 1. Remove the cap (e). 2. Turn the screw under the cap to adjust the burner gas pressure: clockwise to increase pre...

Page 134: Maintenance

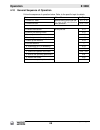

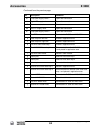

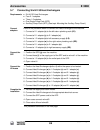

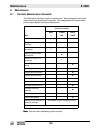

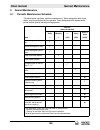

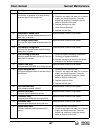

Wc_tx001803gb.Fm 134 maintenance e 3000 8 maintenance 8.1 periodic maintenance schedule the table below lists basic machine maintenance. Tasks designated with check marks may be performed by the operator. Tasks designated with square bullet points require special training and equipment. Note: test t...

Page 135: E 3000

Wc_tx001803gb.Fm 135 e 3000 maintenance 8.2 inspecting the htf system and the fuel system requirements machine shut down burner cool htf system hoses: 1. Rotate the hose reel brake t-handle counterclockwise to release the brake. 2. Unwind all the hose off the reel. Inspect the hose for leaks and/or ...

Page 136: Maintenance

Wc_tx001803gb.Fm 136 maintenance e 3000 8.3 repairing a hose requirements hose nipple two hose ferrules hose crimping tool, wacker neuson part number 5000169002 procedure follow the procedure below to repair a damaged hose. 1. Shut down the machine and allow the heat transfer fluid (htf) to cool. 2....

Page 137: E 3000

Wc_tx001803gb.Fm 137 e 3000 maintenance continued from the previous page. 7. Use a wacker neuson brand hose crimper (e) to crimp both ferrules. 8. Rotate the hose 90 degrees and crimp both ferrules again. The procedure is now complete..

Page 138: Maintenance

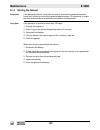

Wc_tx001803gb.Fm 138 maintenance e 3000 8.4 inspecting the electrical components requirements machine shut down and cooled circuit breaker off power disconnected . Inspections inspect the electrical connections and cables on the following items for corrosion, wear, or damage. Repair or replace as ne...

Page 139: E 3000

Wc_tx001803gb.Fm 139 e 3000 maintenance continued from the previous page. Item reference photo hose reel rewind motor (d) light (e) trailer f lights (f) f wiring harness (g) f brake (h) generator (i) (if applicable) low-level shut- down device (j) thermocouple (k).

Page 140: Maintenance

Wc_tx001803gb.Fm 140 maintenance e 3000 8.5 filling the htf reservoir requirements genuine wacker neuson heat transfer fluid, or dowfrost hd 50 heat transfer fluid machine is on a level surface notice: use only factory-recommended heat transfer fluid (htf). Failure to comply may damage the machine. ...

Page 141: E 3000

Wc_tx001803gb.Fm 141 e 3000 maintenance continued from the previous page. 7. Open valve #6 (right hose reel supply valve). 8. Move the right pump switch (b) to the on position and watch the htf reservoir sightglass (c), then move the right pump switch to the off position when the level is between th...

Page 142: Maintenance

Wc_tx001803gb.Fm 142 maintenance e 3000 8.6 cleaning the htf strainer requirements machine shut down source of clean, warm water removal perform the procedure below to clean the htf strainer. Note: in the interests of environmental protection, place a plastic sheet and a container under the machine ...

Page 143: E 3000

Wc_tx001803gb.Fm 143 e 3000 maintenance continued from the previous page. Installation 1. Inspect the strainer gasket (f) and replace it if it is damaged. 2. To ensure strainer gasket (f) placement, install the canister (b) over the strainer basket (c). 3. Install the gasket (d) to the canister. 4. ...

Page 144: Maintenance

Wc_tx001803gb.Fm 144 maintenance e 3000 8.7 replacing the fuel filter requirements machine shut down new fuel filter element and gasket kit removal perform the procedure below to remove the fuel filter element. Note: in the interests of environmental protection, place a plastic sheet and a container...

Page 145: E 3000

Wc_tx001803gb.Fm 145 e 3000 maintenance 8.8 lubricating the hose reel system requirements machine shut down machine cool procedure perform the procedure below to lubricate the hose reel system. 1. Disconnect electric power from the machine. 2. Apply low temperature bearing grease, with several pumps...

Page 146: Maintenance

Wc_tx001803gb.Fm 146 maintenance e 3000 8.9 cleaning the turbulators and the exhaust ducting requirements machine shut down machine cool procedure follow the procedure below to clean/change the turbulator tubes. 1. Allow the machine to cool. 2. Remove the nuts (a) that secure the flue box door (b). ...

Page 147: E 3000

Wc_tx001803gb.Fm 147 e 3000 maintenance continued from the previous page. 7. Vacuum out each burner tube. 8. Remove the exhaust stack (e) (both inner and outer panels). 9. Vacuum out the exhaust ducting (f) and the heater. 10.Reinstall the exhaust stack. 11.Reassemble the machine. Result the procedu...

Page 148: Maintenance

Wc_tx001803gb.Fm 148 maintenance e 3000 8.10 inspecting/replacing the rope gasket requirements machine shut down machine cool integrity inspection follow the procedure below to confirm the integrity of the flue box rope gasket. 1. Allow the machine to cool. 2. Inspect the area around the flue box do...

Page 149: E 3000

Wc_tx001803gb.Fm 149 e 3000 maintenance 8.11 removing the oil burner requirements power supplies disconnected machine cool procedure follow the procedure below to remove the burner. 1. Disconnect the power supplies. 2. Disconnect fuel lines (a) at the quick-connects. 3. Remove the burner controller ...

Page 150: Maintenance

Wc_tx001803gb.Fm 150 maintenance e 3000 8.12 installing the burner requirements power supplies disconnected machine cool procedure follow the procedure below to install the burner. 1. Position the burner inside the machine and secure it to the hydronic heater. 2. Reconnect the wiring from the snap s...

Page 151: E 3000

Wc_tx001803gb.Fm 151 e 3000 maintenance 8.13 storing the machine short-term storage 1. Fill the htf reservoir if it is low. 2. Stop the machine. See topic shutting down and packing up the machine. 3. Remove and store any accessories. 4. Allow the heater to cool sufficiently. 5. Verify that all contr...

Page 152: Maintenance

Wc_tx001803gb.Fm 152 maintenance e 3000 8.14 storing the genset short term if the genset sits idle for more than one month, exercise the genset at least two hours each month by running the genset at approximately 1/2 rate power. A single two-hour exercise period is preferred over several shorter per...

Page 153: E 3000

Wc_tx001803gb.Fm 153 e 3000 maintenance 8.15 preparing the machine for seasonal operation background after removing the machine from long-term storage, it must be prepared for operation. Perform the procedures below before each seasonal use. Before powering up machine perform the procedures below be...

Page 154: Maintenance

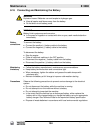

Wc_tx001803gb.Fm 154 maintenance e 3000 8.16 connecting and maintaining the battery battery connections to connect the battery: connect the positive (+) battery cable to the battery. Connect the negative (-) battery cable to the battery. To disconnect the battery: stop the engine. Place all electric...

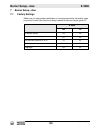

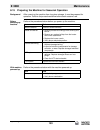

Page 155: Onan Genset

Wc_tx002068gb.Fm 155 onan genset genset maintenance 9 genset maintenance 9.1 periodic maintenance schedule the table below lists basic machine maintenance. Tasks designated with check marks may be performed by the operator. Tasks designated with square bullet points require special training and equi...

Page 156: Genset Maintenance

Wc_tx002068gb.Fm 156 genset maintenance onan genset 9.2 checking the engine oil requirements genset stopped machine level checking perform the procedure below to check the engine oil. 1. Pull the dipstick/plug (a) out of the oil fill opening. 2. Wipe the dipstick/plug clean. 3. Reinsert the dipstick...

Page 157: Onan Genset

Wc_tx002068gb.Fm 157 onan genset genset maintenance 9.3 changing the engine oil and oil filter requirements engine warm new oil filter fresh, clean oil draining oil perform the procedure below to change the oil and oil filter. Note: in the interests of environmental protection, place a plastic sheet...

Page 158: Genset Maintenance

Wc_tx002068gb.Fm 158 genset maintenance onan genset continued from the previous page. 7. Unscrew the oil filter (c) and remove it through the front access opening. 8. Clean the oil filter mounting surface of the engine. Filling 1. Apply a thin coat of clean oil to the gasket of the new oil filter. 2...

Page 159: Onan Genset

Wc_tx002068gb.Fm 159 onan genset genset maintenance 9.4 checking the engine coolant level requirements genset stopped engine cool checking perform the procedure below to check the engine coolant level. 1. Check the engine coolant level through the opening (a) in the panel. When cold, the coolant lev...

Page 160: Genset Maintenance

Wc_tx002068gb.Fm 160 genset maintenance onan genset 9.5 replacing the air filter element requirements engine stopped new air filter element removing perform the procedure below to replace the air filter element. 1. Disconnect the battery. 2. Remove the front access cover (a). 3. Remove the wing nuts...

Page 161: Onan Genset

Wc_tx002068gb.Fm 161 onan genset genset maintenance 9.6 replacing engine fuel filter requirements genset shut down and cool new fuel filter removal perform the procedure below to remove the fuel filter. 1. Close the fuel supply valve. 2. Disconnect the battery. 3. Disconnect the flare nuts that secu...

Page 162: Genset Maintenance

Wc_tx002068gb.Fm 162 genset maintenance onan genset continued from the previous page. 2. Loosely secure the filter and filter bracket (f) to the generator with the two filter bracket mounting screws (e) and reconnect the fuel lines (a and b). Note: take care not to cross-thread the fuel fittings. Th...

Page 163: Onan Genset

Wc_tx002068gb.Fm 163 onan genset genset maintenance 9.7 changing engine coolant requirements genset shut down and cool 50/50 mixture of ethylene glycol and water collection container, 2-liter (1/2-gal) funnel background the genset is filled with a 50/50 mixture of ethylene glycol and water at the fa...

Page 164: Genset Maintenance

Wc_tx002068gb.Fm 164 genset maintenance onan genset continued from the previous page. 5. Remove bottom access cover. 6. Position the collection container under the drain cock (b). 7. Open the drain cock and drain the coolant. Approximately 1.5 l (1.5 qts.) will drain. Cleaning clean and flush the co...

Page 165: Onan Genset

Wc_tx002068gb.Fm 165 onan genset genset maintenance 9.8 genset shut-down codes background the genset controller includes built-in diagnostic capabilities. Through the blinking of the light indicator on the control switch, a genset fault may be diagnosed. After a fault shutdown, the indicator light w...

Page 166: Genset Maintenance

Wc_tx002068gb.Fm 166 genset maintenance onan genset code fault type corrective action 1 high temperature fault first-level fault; engine coolant temperature exceeded 110°c (230°f). 1. Check engine coolant level and add coolant as necessary. 2. Check for and remove any objects blocking the air inlet ...

Page 167: Onan Genset

Wc_tx002068gb.Fm 167 onan genset genset maintenance 22 governor overload fault the duration of operation at or near full-duty cycle was beyond the design limit. 1. Disconnect any extra loads. 2. Check for and repair fuel leaks. Air in the fuel supply can disrupt frequency. Prime the engine fuel syst...

Page 168: Genset Maintenance

Wc_tx002068gb.Fm 168 genset maintenance onan genset 57 over-prime fault prime mode exceeded 3 minutes. 1. Check control switch. Remove anything that may be holding it in the prime position. Code fault type corrective action.

Page 169: E 3000

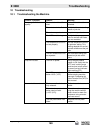

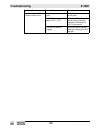

Wc_tx002271gb.Fm 169 e 3000 troubleshooting 10 troubleshooting 10.1 troubleshooting the machine problem / symptom reason remedy thaw progress is below capacity. The insulation is insuffi- cient. Add additional insulation blankets. The moisture is insufficient. Verify that there is standing water on ...

Page 170: Troubleshooting

Wc_tx002271gb.Fm 170 troubleshooting e 3000 pump is noisy and htf flow is below nominal value. The suction valve is not fully open. Verify that the suction valve is fully open. The htf temperature is below -26°c (-15°f). Warm the htf and hoses before starting machine; see topic preheating the htf in...

Page 171: E 3000

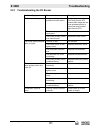

Wc_tx002271gb.Fm 171 e 3000 troubleshooting 10.2 troubleshooting the oil burner problem / symptom reason remedy the burner does not start. Improper switch position or protective function action. Verify that the breaker is on. Verify that the htf level is within range and low level shutdown device is...

Page 172: Troubleshooting

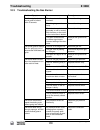

Wc_tx002271gb.Fm 172 troubleshooting e 3000 10.3 troubleshooting the gas burner problem / symptom reason remedy the flame ignites, but the burner goes to lockout within 5 seconds the phase/neutral lines are reversed. Correct the wiring. The wiring to ground is faulty. Correct the wiring. The ionizat...

Page 173: E 3000

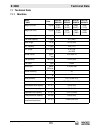

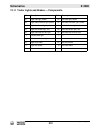

Ghi_td000301gb.Fm 173 e 3000 technical data 11 technical data 11.1 machine model e 3000 units item no. 0620158 item no. 0620219 item no. 0620678 item no. 0620679 weight (no fuel) kg (lb) 2,531 (5,580) 2,769 (6,105) 2,928 (6,457) 3,209 (7,073) weight (full fuel) kg (lb) 3,262 (7,190) 3,500 (7,715) 3,...

Page 174: Technical Data

Ghi_td000301gb.Fm 174 technical data e 3000 11.2 trailer 11.3 dimensions cm (in.) item number model 0620158 e 3000 0620219 e 3000 0620678 e 3000 0620679 e 3000 gawr (gross axle weight rating) kg (lb) 1,588 (3,500) 2,359 (5,200) wheel diameter mm (in.) 356 (14) 381 (15) tire code — 225 75r14 215 75r1...

Page 175: Material Safety Data Sheet

Msds: dowfrost™ hd 50 msds: dowfrost hd 50 product name: dowfrost* hd 50 heat transfer fluid, dyed issue date: 09/24/2010 print date: 18 aug 2011 ®(tm)*trademark of the dow chemical company ("dow") or an affiliated company of dow page 1 of 7 the dow chemical company encourages and expects you to rea...

Page 176

Msds: dowfrost™ hd 50 product name: dowfrost* hd 50 heat transfer fluid, dyed issue date: 09/24/2010 page 2 of 7 inhalation: at room temperature, exposure to vapor is minimal due to low volatility. Mist may cause irritation of upper respiratory tract (nose and throat). Ingestion: very low toxicity i...

Page 177

Msds: dowfrost™ hd 50 product name: dowfrost* hd 50 heat transfer fluid, dyed issue date: 09/24/2010 page 3 of 7 personal precautions: keep unnecessary and unprotected personnel from entering the area. Use appropriate safety equipment. For additional information, refer to section 8, exposure control...

Page 178

Msds: dowfrost™ hd 50 product name: dowfrost* hd 50 heat transfer fluid, dyed issue date: 09/24/2010 page 4 of 7 9. Physical and chemical properties physical state liquid. Color yellow to green odor characteristic odor threshold no test data available flash point - closed cup not applicable, water b...

Page 179

Msds: dowfrost™ hd 50 product name: dowfrost* hd 50 heat transfer fluid, dyed issue date: 09/24/2010 page 5 of 7 eye damage/eye irritation may cause slight temporary eye irritation. Corneal injury is unlikely. Skin corrosion/irritation prolonged contact is essentially nonirritating to skin. Repeated...

Page 180

Msds: dowfrost™ hd 50 product name: dowfrost* hd 50 heat transfer fluid, dyed issue date: 09/24/2010 page 6 of 7 14. Transport information dot non-bulk not regulated dot bulk not regulated imdg not regulated icao/iata not regulated this information is not intended to convey all specific regulatory o...

Page 181

Msds: dowfrost™ hd 50 product name: dowfrost* hd 50 heat transfer fluid, dyed issue date: 09/24/2010 page 7 of 7 all components of this product are on the tsca inventory or are exempt from tsca inventory requirements under 40 cfr 720.30 cepa - domestic substances list (dsl) this product contains one...

Page 182

Msds: dowfrost™ hd 50

Page 183: Fuji Temperature Controller

Wc_tx001673gb.Fm 183 fuji temperature controller fuji temperature controller fuji temperature controller hysteresis (differential) adjusting se l sv pv c1 c2 al 1 al3 al 2 se l sv pv c1 c2 al 1 al3 al 2 se l sv pv c1 c2 al 1 al3 al 2 sel sv pv c1 c2 al 1 al3 al 2 se l sv pv c1 c2 al 1 al3 al 2 se l ...

Page 184: Fuji Temperature Controller

Wc_tx001673gb.Fm 184 fuji temperature controller fuji temperature controller low temperature limit adjusting sel sv pv c1 c2 al 1 al3 al2 sv pv c1 c2 al 1 al3 al 2 se l se l sv pv c1 c2 al 1 al3 al 2 sel sv pv sel sv pv c1 c2 al 1 al 3 al2 se l sv pv sv pv c1 c2 al1 al 3 al 2 sel sv pv c1 c2 al 1 al...

Page 185: Fuji Temperature Controller

Wc_tx001673gb.Fm 185 fuji temperature controller fuji temperature controller high temperature limit adjusting sel sv pv c1 c2 al1 al 3 al 2 sv pv c1 c2 al 1 al 3 al 2 se l sel sv pv c1 c2 al 1 al 3 al2 sel sv pv c1 c2 al 1 al3 al 2 se l sv pv c1 c2 al 1 al 3 al 2 se l sv pv c1 c2 al 1 al 3 al 2 sel ...

Page 186: Fuji Temperature Controller

Wc_tx001673gb.Fm 186 fuji temperature controller.

Page 187

Tire safety information tire safety information introduction to tire safety information federal regulation 49 cfr 575 requires trailer manufacturers to include certain tire information in the owner’s manuals for the trailers they manufacture. This regulation requires that the information be in the e...

Page 188

Tire safety information 1. T ire s afety i nformation this portion of the 8vhu¶v0dqxdofrqwdlqvwluhvdihw\lqirupdwlrqdvuhtxluhge\&)5 section 1.1 contains ³6whsviru'hwhuplqlqj&ruuhfw/rdg/lplw - trailer´. Section 1.2 contains ³6whsviru'hwhuplqlqj&ruuhfw/rdg/lmit ± tow vehicle´. Section 1.3 contains a gl...

Page 189

Tire safety information excessive loads and/or underinflation cause tire overloading and, as a result, abnormal tire flexing occurs. This situation can generate an excessive amount of heat within the tire. Excessive heat may lead to tire failure. It is the air pressure that enables a tire to support...

Page 190

Tire safety information bead the part of the tire that is made of steel wires, wrapped or reinforced by ply cords and that is shaped to fit the rim. Bead separation this is the breakdown of the bond between components in the bead. Bias ply tire a pneumatic tire in which the ply cords that extend to ...

Page 191

Tire safety information intended outboard sidewall the sidewall that contains a white-wall, bears white lettering or bears manufacturer, brand, and/or model name molding that is higher or deeper than the same molding on the other sidewall of the tire or the outward facing sidewall of an asymmetrical...

Page 192

Tire safety information ply a layer of rubber-coated parallel cords. Ply separation a parting of rubber compound between adjacent plies. Pneumatic tire a mechanical device made of rubber, chemicals, fabric and steel or other materials, that, when mounted on an automotive wheel, provides the traction...

Page 193

Tire safety information tread rib a tread section running circumferentially around a tire. Tread separation pulling away of the tread from the tire carcass. Treadwear indicators (twi) the projections within the principal grooves designed to give a visual indication of the degrees of wear of the trea...

Page 194

Tire safety information y p use this information to make tire safety a regular part of your vehicle maintenance routine. Recognize that the time you spend is minimal compared with the inconvenience and safety consequences of a flat tire or other tire failure. 1.5. S afety f irst ±b asic t ire m aint...

Page 195

Tire safety information 1.5.4. S teps for m aintaining p roper t ire p ressure step 1: locate the recommended tire pressure on the vehicle's tire information placard, certification label, or in the owner's manual. Step 2: record the tire pressure of all tires. Step 3: if the tire pressure is too hig...

Page 196

Tire safety information 1.5.9.1. Information on passenger vehicle tires please refer to the diagram below. P the "p" indicates the tire is for passenger vehicles. Next number this three-digit number gives the width in millimeters of the tire from sidewall edge to sidewall edge. In general, the large...

Page 197

Tire safety information letter rating speed rating q 99 mph r 106 mph s 112 mph t 118 mph u 124 mph h 130 mph v 149 mph w 168* mph y 186* mph * for tires with a maximum speed capability over 149 mph, tire manufacturers sometimes use the letters zr. For those with a maximum speed capability over 186 ...

Page 198

Tire safety information g please refer to the following diagram. Tires for light trucks have other markings besides those found on the sidewalls of passenger tires. Lt the "lt" indicates the tire is for light trucks or trailers. St an "st" is an indication the tire is for trailer use only. Max. Load...

Page 199

Tire safety information.

Page 200: Schematics

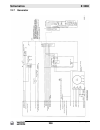

Wc_tx001952gb.Fm 200 schematics e 3000 12 schematics 12.1 composite schematic—machine with oil burner.

Page 201: E 3000

Wc_tx001952gb.Fm 201 e 3000 schematics 12.2 composite schematic—machine with gas burner.

Page 202: Schematics

Wc_tx001952gb.Fm 202 schematics e 3000 12.3 electrical schematic components use the following table of symbols for the schematics found throughout this chapter. Symbol ref description cb1 circuit breaker 1 gfci 1 ground fault circuit interrupt 1 fu1 fuse 1 hose rewind hose rewind on/off switch mtr r...

Page 203: E 3000

Wc_tx001952gb.Fm 203 e 3000 schematics k2 relay normally closed contacts (k2) k2 relay normally open contacts (k2) fu3 fuse 3 low level low-level shut-down device power connection terminals k1 relay coil (k1) k1 relay normally open contacts (k1) k1 relay normally closed contacts (k1) pl1 pilot light...

Page 204: Schematics

Wc_tx001952gb.Fm 204 schematics e 3000 ts1 thermal switch 1 (snap disc) htr1 heater (fuel prewarmer) cad cad cell low level override momentary low-level shut-down device momentary override on/off switch. E-stop emergency stop switch k4 relay coil (k4) k4 relay normally closed contacts (k4) k4 relay ...

Page 205: E 3000

Wc_tx001952gb.Fm 205 e 3000 schematics 12.4 circulation system circuit.

Page 206: Schematics

Wc_tx001952gb.Fm 206 schematics e 3000 12.5 rewind system circuit.

Page 207: E 3000

Wc_tx001952gb.Fm 207 e 3000 schematics 12.6 gas train schematic.

Page 208: Schematics

Wc_tx001952gb.Fm 208 schematics e 3000 12.7 generator.

Page 209: E 3000

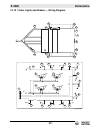

Wc_tx001952gb.Fm 209 e 3000 schematics 12.8 trailer plug — wiring diagram trailer plug the slots on the trailer plug receptacle are each designated for specific components. The designations are as follows. Ref designation wire color a battery (+12v) black b running lights green c left hand turn/stop...

Page 210: Schematics

Wc_tx001952gb.Fm 210 schematics e 3000 12.9 trailer junction box — wiring diagram the wires inside the trailer junction box are designated for specific components. The designations are as follows. Note: the colors used on your vehicle’s plug may vary from those used in the trailer junction box. + – ...

Page 211: E 3000

Wc_tx001952gb.Fm 211 e 3000 schematics 12.10 trailer lights and brakes — wiring diagram wc_gr008465 a 1 a 2 b 1 c 1 b 2 c 2 d 1 k 1 d 2 k 2 f e 1 e 2 g h 1 j i 1 h 2 i 2 r w l br br g a 1 a 2 b 1 b 2 c 1 c 2 d 1 k 1 k 2 d 2 f e 1 e 2 g.

Page 212: Schematics

Wc_tx001952gb.Fm 212 schematics e 3000 12.11 trailer lights and brakes — components ref description ref description a1 right side light, amber a2 left side light, amber b1 right side miniature light, amber b2 left side miniature light, amber c1 right side fender light, amber c2 left side fender ligh...

Page 214

Important: for spare parts information, please see your wacker neuson dealer, or visit the wacker neuson website at http://www.Wackerneuson.Com/. Wichtig! Informationen über ersatzteile erhalten sie von ihrem wacker neuson händler oder besuchen sie die wacker neuson website unter http://www.Wackerne...