- DL manuals

- Wacker Neuson

- Tools

- EH 23

- Operation Manual

Wacker Neuson EH 23 Operation Manual

Summary of EH 23

Page 1

5000191541 08 0811 5 0 0 0 1 9 1 5 4 1 operator’s manual electric hammer eh 23, 27 low vib en.

Page 2

Manufacturer wacker neuson produktion gmbh & co. Kg preußenstraße 41 80809 münchen www.Wackerneuson.Com tel.: +49-(0)89-354 02-0 fax: +49-(0)89-354 02-390 translation of the original operator's manual in german 0203373en 08 0811.

Page 3

3 1 foreword .................................................................................................................... 5 2 introduction .............................................................................................................. 6 2.1 means of representation for this ope...

Page 4

4 10 troubleshooting ...................................................................................................... 36 11 disposal ................................................................................................................... 37 11.1 disposal of waste electrical and elec...

Page 5

1 foreword 5 1 foreword this operator's manual contains information and procedures for the safe opera- tion and maintenance of your wacker neuson machine. In the interest of your own safety and to prevent accidents, you should carefully read through the safety information, familiarize yourself with ...

Page 6

2 introduction 6 2 introduction 2.1 means of representation for this operator's manual warning symbols this operator's manual contains safety information of the categories: danger, warning, caution, notice. They should be followed to prevent danger to life and limb of the operator or damage to equip...

Page 7

2 introduction 7 instructions f this symbol indicates there is something for you to do. 1. Numbered instructions indicate that you have to carry out something in a defined sequence. This symbol is used for lists. 2.2 wacker neuson representative depending on your country, your wacker neuson represen...

Page 8

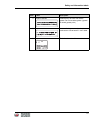

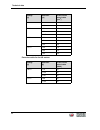

2 introduction 8 2.5 nameplate data the nameplate lists information that uniquely identifies your machine. This information is needed to order spare parts and when requesting additional technical information. F enter the information of your machine into the following table: item designation your inf...

Page 9

Safety 9 3 safety 3.1 principle state of the art this machine has been constructed with state-of-the-art technology according to the recognized rules of safety. Nevertheless, when used improperly, dangers to the life and limb of the operator or to third persons or damage to the machine or other mate...

Page 10

Safety 10 structural modifications never attempt to modify the machine without the written permission of the man- ufacturer. To do so will endanger your safety and the safety of other people! In addition, this will void the warranty and the liability on behalf of the manufacturer. Especially the fol...

Page 11

Safety 11 malfunctions if you detect a malfunction, you must shut down and secure the machine imme- diately. Eliminate the malfunctions that impair safety immediately! Have damaged or defective components replaced immediately! For further information, refer to chapter troubleshooting. Spare parts, a...

Page 12

Safety 12 operator's controls always keep the operator's controls of the machine dry, clean and free of oil or grease. Operating elements such as on/off switch, gas handles etc. May not be locked, manipulated or changed without authorization. Checking for signs of damage inspect the machine when it ...

Page 13

Safety 13 work recommendations please observe the recommendations below: work only if you are in a good physical condition. Work attentively, particularly as you finish. Do not operate the machine when you are tired. Carry out all work calmly, circumspectly and carefully. Never operate the machine u...

Page 14

Safety 14 3.4 transport switching off the machine before you transport the machine, switch it off and pull the plug out of the plug receptacle. Allow the motor to cool down. Transporting the machine secure the machine on the transport device against tilting, falling or slipping. Lifting the machine ...

Page 15

Safety 15 safety in the work area when working with the machine especially pay attention to the following points: electric lines or pipes in work area. Gas lines or water lines in the work area. Material becoming separated, dropping down or ejected. Make sure that you do not put other persons in dan...

Page 16

Safety 16 do not direct towards people do not direct the machine towards people in the vicinity during operation. The tool might be flung out and cause serious injuries. No persons endangered be sure that no persons are endangered by flying or falling materials. Always work very attentively, and ant...

Page 17

Safety 17 safe working with the hammer keep the tool holder closed during operation. Guide the power cable always from the machine to the rear and keep the power cable away from the working range of the machine. 3.7 safety during the operation of electric appliances specific regulations for electric...

Page 18

Safety 18 extension cable the machine may only be operated with undamaged and tested extension ca- bles! Only use extension cables with grounded conductor and correct connection of the grounded conductor to the plug and coupling (only for machines of class rat- ing i, see chapter technical data). On...

Page 19

Safety 19 disconnecting the machine from the electric power supply before carrying out service or maintenance work, pull the plug out of the plug re- ceptacle in order to disconnect the machine from the electric power supply. Cleaning always keep the machine clean and be sure to clean it each time y...

Page 20

Safety and information labels 20 4 safety and information labels your machine has adhesive labels containing the most important instructions and safety information. Make sure that all the labels are kept legible. Replace any missing or illegible labels. The item numbers for the labels are in the par...

Page 21

Safety and information labels 21 4 japan machines grease every 20 hours with lithium grease. Do not use other grease. (grease at central grease point) 5 japan machines in case of using an extension chord, make sure to use at least 2.5 mm² cable. 6 japan machines total vibration value of the accelera...

Page 22

Safety and information labels 22 for the following machines: eh 27: item label description 1 wear personal protective gear to avoid injuries or health hazards: ear protection. Eye protection. Read the operator's manual before start- up. 2 caution. Warning of hot surface. 3 us machines warning. 02191...

Page 23

Scope of delivery 23 5 scope of delivery the scope of delivery includes: machine. Operator's manual. Parts book. General safety instructions..

Page 24

Description 24 6 description 6.1 application use the machine only as intended, see chapter safety, proper use. 6.2 functionality principle the machine is a demolition hammer with a pneumatic percussion system. It is driven by an electric motor. The rotary movement of the electric motor is converted ...

Page 25

Description 25 6.3 components and operator's controls tool holder the tool holder is used to hold the tool. Supplementary handle the supplementary handle simplifies working in a tilted position. Wacker neuson recommends to carry the machine using the supplementary handle. Item designation item desig...

Page 26

Transport 26 7 transport transporting the machine 1. Pull the plug from the plug receptacle. 2. Remove tool. 3. Wind up the power cable. 4. Lift machine with the supplementary handle. 5. Place the machine on or into a suitable transport vehicle. 6. Secure the machine against falling over and down or...

Page 27

Operation 27 8 operation 8.1 prior to starting the machine after unpacking, the machine is ready for operation. Checking the machine f check the machine and all components for damages. Checking the mains f check if mains or power distribution on the construction site have the correct operating volta...

Page 28

Operation 28 8.3 inserting tool 1. Clean tool end. 2. Swivel out handle on the tool holder. 3. Turn the tool into the position which is most suitable for the intended work. 4. Push tool into the tool holder as far as it will go. 5. Press the handle on the tool holder. 6. Check to see if the tool is ...

Page 29

Operation 29 8.4 starting up connecting the machine to the power supply the machine may only be connected to ac single phase, connection values see chapter technical data. 1. If required, connect the machine to a permitted extension cable. Note: see chapter technical data for the permitted lengths a...

Page 30

Operation 30 breaking off material 1. Place the hammer on the material to be broken off. 2. Press the on/off switch. Note: when the on/off switch is pressed, the machine starts to run at full speed immediately. Work tips when working, use the weight of the hammer. Pressing forcefully against the mat...

Page 31

Operation 31 8.5 decomissioning switching off the machine 1. Release on/off switch. 2. Wait until the machine has come to a complete standstill. 3. Set down the machine in such a way that it cannot tilt, fall or slip. 4. Pull the plug from the plug receptacle..

Page 32

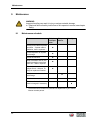

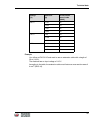

Maintenance 32 9 maintenance 9.1 maintenance schedule warning improper handling can result in injury or serious material damage. F read and follow all safety instructions of this operator's manual, see chapter safety. Task daily be- fore oper- ation every 20 hrs. Monthly check power cable for perfec...

Page 33

Maintenance 33 9.2 maintenance work work in the workshop perform maintenance work in a workshop on a workbench. This has the following benefits: protection of the machine of contamination on the construction site. A level and clean work surface makes work easier. There is a better overview over smal...

Page 34

Maintenance 34 lubricating the machine 1. Remove any dirt around the zerk fitting. 2. Place filled manual grease gun onto the zerk fitting and operate approx. 20 times. Note: only use special lubricants for lubricating, see chapter technical data. 3. Wipe the area around the zerk fitting with a clea...

Page 35

Maintenance 35 checking the tool holder for wear 1. Insert the tool. Note: use a new tool to measure only the wear of the tool holder and not the wear of the tool. 2. Measure the tool play 200 mm from insertion point. Play may not exceed 6 mm. If the play exceeds 6 mm, the tool holder must be replac...

Page 36

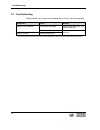

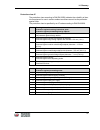

Troubleshooting 36 10 troubleshooting potential faults, their causes and remedies can be found in the following table. Malfunction cause remedy machine not in operation. Power cable interrupted. Check power cable, have it re- placed if defective. * * have these tasks carried out by the service depar...

Page 37

11 disposal 37 11 disposal 11.1 disposal of waste electrical and electronic equipment for customers in eu countries this device is subject to the european directive 2002/96/ec on waste electrical and electronic equipment (weee) and the corresponding national legislation. The weee directive outlines ...

Page 38

Accessories 38 12 accessories there is a wide range of accessories available for the machine. For more information on the individual accessories, visit the following website: www.Wackerneuson.Com. 12.1 truck proper use the truck must only be used for the transport of wacker neuson large hammers and ...

Page 39

Accessories 39 placing hammer on the truck 1. Switch off the machine. 2. Remove tool from the tool holder. 3. Clean the truck's guide rod. 4. Insert hammer with the tool holder on the guide rod and rest on the handles of the truck. 5. Insert tool in tool holder. Caution insufficient stability of the...

Page 40

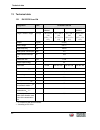

Technical data 40 13 technical data 13.1 eh 23/230 low vib designation unit eh 23/230 low vib item no. 0008914 0008943 0008944 0008941 0008942 0610297 length x width x height mm (ft) 765 x 530 x 210 (2.5 x 1.7 x 0.7) 820 x 530 x 210 (2.7 x 1.7 x 0.7) 765 x 530 x 210 (2.5 x 1.7 x 0.7) 820 x 530 x 210...

Page 41

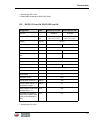

Technical data 41 13.2 eh 23/115 low vib, eh 23/100 low vib *** according to iso 11201 ****determined according to din en iso 5349. Designation unit eh 23/115 low vib eh 23/100 low vib item no. 0008916 0610238 length x width x height mm (ft) 820 x 530 x 210 (2.7 x 1.7 x 0.7) 765 x 530 x 210 (2.5 x 1...

Page 42

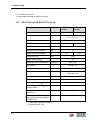

Technical data 42 13.3 eh 27/120 low vib, eh 27/127 low vib *** according to iso 11201 ****determined according to din en iso 5349. Designation unit eh 27/120 low vib eh 27/127 low vib item no. 0610195 0610196 length x width x height mm (ft) 820 x 530 x 210 (2.7 x 1.7 x 0.7) weight kg (lb) 27 (59.5)...

Page 43

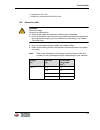

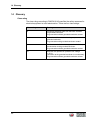

Technical data 43 13.4 extension cable only use permitted extension cables, see chapter safety. Refer to the following table for the required cross-section area of the exten- sion cable: note: refer to the nameplate or the chapter technical data (via the item number) for the type designation and vol...

Page 44

Technical data 44 extension cable for the us market: 115 1~ 2.5 4 230 1~ 1.5 2.5 4 120 1~ 1.5 2.5 4.0 127 1~ 1.5 2.5 4.0 voltage [v] extension [ft] cross-section area of cable [awg] 100 1~ 14 12 10 115 1~ 12 10 voltage [v] extension [m] cross-section area of cable [mm 2 ].

Page 45

Technical data 45 example you utilize an eh 23/115 and want to use an extension cable with a length of 36 m (118 ft). The machine has an input voltage of 115 v. According to the table, the extension cable must feature a cross-section area of 4 mm 2 (awg 10). 230 1~ 16 14 12 10 120 1~ 14 12 10 127 1~...

Page 46

14 glossary 46 14 glossary class rating the class rating according to din en 61140 specifies the safety measures for electrical equipment to avoid electrocution. There are four class ratings: class rating meaning 0 no special protection apart from the basic insulation. No grounded conductor. Plug co...

Page 47

14 glossary 47 protection class ip the protection class according to din en 60529 indicates the suitability of elec- trical equipment for use in certain ambient conditions as well as the protection against risks. The protection class is specified by an ip code according to din en 60529. Code meaning...

Page 48

14 glossary 48.

Page 49

Translation of the original declaration of conformity ec declaration of conformity manufacturer wacker neuson produktion gmbh & co. Kg, preußenstraße 41, 80809 münchen product conformity assessment procedure according to 2000/14/ec, appendix viii, 2005/88/ec. Notified body vde prüf- und zertifizieru...

Page 52

Wacker neuson produktion gmbh & co. Kg, preußenstraße 41, d-80809 münchen, tel.: +49-(0)89-3 54 02-0 fax: +49 - (0)89-3 54 02-390 wacker neuson production americas llc, n92w15000 anthony ave., menomonee falls, wi 53051 tel. : (262) 255-0500 fax: (262) 255-0550 tel.: (800) 770-0957 wacker neuson limi...