- DL manuals

- Wacker Neuson

- Excavators

- ET18

- Operator's Manual

Wacker Neuson ET18 Operator's Manual

Summary of ET18

Page 1

Track excavator et18/20/24 operator’s manual 5200016123 1.3 1113 5 2 0 0 0 1 6 1 2 3 this operator's manual include s t he aem s af et y m anual.

Page 2

Om/service booklet language order no. Spare parts list language order no. Operator's manual us 5200016123 et18 (e12-02) de/en/fr 1000279963 service booklet de 1000146850 et18 (e12-02) de/it/es 1000279982 en 1000148392 et20 (e12-03) de/en/fr 1000281454 fr 1000148394 et20 (e12-03) de/it/es 1000281455 ...

Page 3: Table of Contents

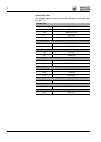

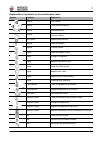

Om et18/20/24 us 1.3 * et18_20_24us1_3ivz.Fm i-1 table of contents ec declaration of conformity (yanmar 3tnv76-snse12) .................................................................. Eg-1 declaration of conformity without ce mark on the type label – except usa and canada (yanmar 3tnv76- snse12)eg...

Page 4

I-2 om et18/20/24 us 1.3 * et18_20_24us1_3ivz.Fm 7 maintenance 7.1 important information on maintenance ................................................................................................. 7-1 7.2 maintenance overview ........................................................................

Page 5

Om et18/20/24 us 1.3 * et18_20_24konf.Fm eg-1 declaration of conformity ec declaration of conformity (yanmar 3tnv76-snse12) ec declaration of conformity according to machine directive 2006/42/ec, appendix ii a manufacturer wacker neuson linz gmbh flughafenstr. 7 a-4063 hörsching product machine desi...

Page 6

Eg-2 om et18/20/24 us 1.3 * et18_20_24konf.Fm declaration of conformity without ce mark on the type label – except usa and canada (yanmar 3tnv76-snse12) declaration of conformity manufacturer wacker neuson linz gmbh flughafenstr. 7 a-4063 hörsching product machine designation: hydraulic excavator ma...

Page 7: Foreword

Om et18/20/24 us 1.3 * et18_20_24v100.Fm 1-1 1 1 foreword 1.1 operator’s manual notices on this operator’s manual this operator’s manual is stored in the compartment under the seat if the machine is equipped with a canopy. If the machine is equipped with a cab, this operator’s manual is stored behin...

Page 8

1-2 om et18/20/24 us 1.3 * et18_20_24v100.Fm 1 explanation of symbols and abbreviations explanation of symbols • identifies a list - identifies a subdivision of a list ➥ description of a result 1. Identifies an activity follow the order of the activity! 2. Continuation of an activity follow the orde...

Page 9

Om et18/20/24 us 1.3 * et18_20_24v100.Fm 1-3 1 abbreviations aux = auxiliary hydraulic circuit b = width ne = nominal width rops = roll over protective structure fops = falling objects protective structure tops = tip over protective structure fgps = front guard protective structure ps = stabilizer b...

Page 10

1-4 om et18/20/24 us 1.3 * et18_20_24v100.Fm 1 conversion table the rounded imperial values are indicated in brackets, for example 1060 cm³ (64.7 in³) . Volume unit 1 cm³ (0.061 in³) 1 m³ (35.31 ft³) 1 ml (0.034 us fl.Oz.) 1 l (0.26 gal) 1 l/min (0.26 gal/min) unit of length 1 mm (0.039 in) 1 m (3.2...

Page 11: 1.2

Om et18/20/24 us 1.3 * et18_20_24v100.Fm 1-5 1 1.2 warranty and liability exemption from warranty and liability warranty warranty claims can be made only if the conditions of warranty have been observed. They are included in the general conditions of sales and delivery for new machines and spare par...

Page 12

1-6 om et18/20/24 us 1.3 * et18_20_24v100.Fm 1 notes:.

Page 13: Safety Information

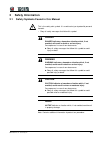

Om et18/20/24 us 1.3 * sicherheit(us).Fm 2-1 2 safety information 2.1 safety symbols found in this manual this is the safety alert symbol. It is used to alert you to potential personal hazards. • obey all safety messages that follow this symbol. Danger danger indicates a hazardous situation which, i...

Page 14: 2.2

2-2 om et18/20/24 us 1.3 * sicherheit(us).Fm information information identifies an instruction that, when followed, provides for a more efficient and economical use of the machine . Environment failure to observe the instructions identified by this symbol can result in damage to the environment. The...

Page 15: 2.4

Om et18/20/24 us 1.3 * sicherheit(us).Fm 2-3 2.4 preparing to use the machine conditions for use • the machine has been designed and built in accordance with state-of- the-art standards and recognized safety regulations. Nevertheless, its use can constitute a risk to the operator or to third parties...

Page 16

2-4 om et18/20/24 us 1.3 * sicherheit(us).Fm modifications and spare parts • never make any modifications, additions or conversions to the machine and its superstructures (for example, cab, etc.), or the machine’s attachments, without the approval of wacker neuson! Such modifications may affect safe...

Page 17

Om et18/20/24 us 1.3 * sicherheit(us).Fm 2-5 • the lifting gear must be checked regularly by a technician, at least once a year. • replace damaged lifting gear immediately. • fasten lifting gear and slings avoiding danger (rotating parts, crushing or shearing) for the person securing the load. Furth...

Page 18: 2.5

2-6 om et18/20/24 us 1.3 * sicherheit(us).Fm 2.5 operator and technician qualifications and basic responsibili- ties operator/machine owner responsibility • only allow trained and experienced individuals to travel, maintain, or repair the machine. Never let unauthorized or underaged persons operate ...

Page 19

Om et18/20/24 us 1.3 * sicherheit(us).Fm 2-7 • careful and prudent working is the best way to avoid accidents!Keep the machine clean. This reduces fire hazard (such as from combustible materials like rags), and reduces the injury hazard or operational accidents that can be caused by dirt build-up on...

Page 20

2-8 om et18/20/24 us 1.3 * sicherheit(us).Fm danger zone awareness • the danger zone is the area in which persons are in danger due to the movements of the machine, work equipment, additional equipment, or material. • the danger zone also includes the area affected by falling material, equipment or ...

Page 21: 2.7

Om et18/20/24 us 1.3 * sicherheit(us).Fm 2-9 • check the machine before entering the cab to operate the machine for visible damage and defects. Report any changes, including changes in the machine’s function and response, to your supervisor immediately! • if the machine is functioning unpredictably,...

Page 22: 2.8

2-10 om et18/20/24 us 1.3 * sicherheit(us).Fm • machine travel with a raised load must be done very carefully on a level surface moving very slowly to avoid sudden motion that can cause swinging or oscillating motion of the load. • the person(s) attaching the load to the excavator shall approach onl...

Page 23: 2.9

Om et18/20/24 us 1.3 * sicherheit(us).Fm 2-11 • prior to fitting attachments to the stick (the mobile extension of the boom), secure the control lever of the hydraulic control unit against unintentional movement. Raise the left arm rest to avoid unintentional activation for the iso/sae operating mod...

Page 24

2-12 om et18/20/24 us 1.3 * sicherheit(us).Fm • observe the specific safety instructions in the maintenance section of this operator’s manual. • always keep a safe distance from all rotating and moving parts, for example, fan blades, v-belt drives, pto shaft drives, fans, etc. • before starting work...

Page 25

Om et18/20/24 us 1.3 * sicherheit(us).Fm 2-13 • wear a safety harness when performing elevated maintenance on or with the machine. Keep all handles, steps, handrails, platforms, landings, and ladders free from dirt, snow and ice. • always use specially designed or otherwise safety-oriented ladders a...

Page 26

2-14 om et18/20/24 us 1.3 * sicherheit(us).Fm • starting the machine with a battery jumper cable can be hazardous if performed improperly. Observe the safety instructions regarding the battery. • before taking up work on machine parts hazardous for life and limb (bruising, cutting), always ensure sa...

Page 27

Om et18/20/24 us 1.3 * sicherheit(us).Fm 2-15 hydraulics • check all lines, hoses, and threaded couplers and fittings regularly for leaks and obvious damage. Repair any damage and leaks immedi- ately. Splashed oil can cause injury and fire! • in accordance with the operator's manual/instructions for...

Page 28

2-16 om et18/20/24 us 1.3 * sicherheit(us).Fm 2.11 safety guidelines while using internal combustion engines warning internal combustion engines present special hazards during operation and fueling. Failure to follow the warnings and safety guidelines could result in severe injury or death. ► read a...

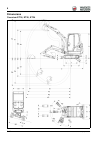

Page 29: Introduction

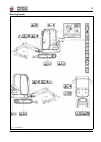

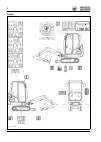

Om et18/20/24 us 1.3 * et18_20_24e300.Fm 3-1 3 3 introduction 3.1 machine overview fig. 3: machine overview position designation 1. Working light on boom 2. Roof lights (option) 3. Lifting eye 4. Rotating beacon (option) 5. Door arrester 6. Engine cover 7. Fuel tank filler inlet 8. Side cover 9. Exh...

Page 30: 3.2

3-2 om et18/20/24 us 1.3 * et18_20_24e300.Fm 3 overview of model designations and trade names 3.2 brief description of the machine the machine model et18/et 20/et24 is a self-propelled work machine. Get informed on and follow the legal regulations of your country. This machine is a versatile and pow...

Page 31

Om et18/20/24 us 1.3 * et18_20_24e300.Fm 3-3 3 cab/canopy the cab/canopy have been specially designed for protection in case of an accident. • rops/tops tested canopy (open version). • rops/tops tested cab (closed version/option). • protective fops structure (option) for cab/canopy; protective struc...

Page 32: 3.3

3-4 om et18/20/24 us 1.3 * et18_20_24e300.Fm 3 3.3 notices and regulations on use designated use • the machine is intended for: - moving earth, gravel or rubble, for hammer operation as well as for - working only with the attachments mentioned in chapter fields of application and use of attachments ...

Page 33

Om et18/20/24 us 1.3 * et18_20_24e300.Fm 3-5 3 fields of application and use of attachments notice in order to avoid damage to the machine, only the attachments listed below have been certified for installation on the machine. ► contact a wacker neuson service center if you wish to use other attachm...

Page 34

3-6 om et18/20/24 us 1.3 * et18_20_24e300.Fm 3 backhoe bucket 300 mm (12 in) 32 kg (71 lbs) 0.027 m 3 (0.95 ft 3 ) et 18 34 kg (75 lbs) 0.028 m 3 (0.99 ft 3 ) et 18 easy lock quickhitch 42 kg (93 lbs) 0.037m 3 (1.31 ft 3 ) et 20 37 kg (82 lbs) 0.036 m 3 (1.27 ft 3 ) et 20 easy lock quickhitch 40.3 k...

Page 35

Om et18/20/24 us 1.3 * et18_20_24e300.Fm 3-7 3 backhoe bucket 600 mm (24 in) 63 kg (139 lbs) 0.053 m 3 (1.87 ft 3 ) et 18 53 kg (117 lbs) 0.055 m 3 (1.94 ft 3 ) et 18 easy lock quickhitch 61 kg (134 lbs) 0.077 m 3 (2.72 ft 3 ) et 20 59 kg (130 lbs) 0.072 m 3 (2.54 ft 3 ) et 20 easy lock quickhitch 6...

Page 36: 3.4

3-8 om et18/20/24 us 1.3 * et18_20_24e300.Fm 3 3.4 labels warning accident hazard! Replace missing or damaged labels immediately. Can result in severe injury or death. ► check warning and information labels regularly whether they are missing or damaged. ► never remove warning and information labels....

Page 37

Om et18/20/24 us 1.3 * et18_20_24e300.Fm 3-9 3 cab number (canopy) the type label is located behind the seat. Cab number (cab) the type label is located under the left-hand window. Engine number the type label is located on the valve cover (engine). Hydraulic quickhitch the serial number is located ...

Page 38

3-10 om et18/20/24 us 1.3 * et18_20_24e300.Fm 3 powertilt with hydraulic quickhitch the serial number of the powertilt is stamped in the housing near the hydraulic connections. The serial number of the hydraulic quickhitch is located on the type label. The type label is located on the rear side of t...

Page 39

Om et18/20/24 us 1.3 * et18_20_24e300.Fm 3-11 3 warning labels fig. 13: warning labels (cab) (canopy).

Page 40

3-12 om et18/20/24 us 1.3 * et18_20_24e300.Fm 3 the following states signs and symbols that do not contain explanatory text and that are not explained in the following chapters. Meaning severe or fatal injury hazard. Stay clear of suspended loads and/or of the danger zone of the machine during opera...

Page 41

Om et18/20/24 us 1.3 * et18_20_24e300.Fm 3-13 3 meaning hand crushing hazard. 1. Always use the handles to open and close the front window. 2. Always lock the front window with both locks. Position on the front window. Meaning accumulator is under high pressure. Always read the operator’s manual bef...

Page 42

3-14 om et18/20/24 us 1.3 * et18_20_24e300.Fm 3 meaning read the operator’s manual before starting the machine. Always fasten the seat belt during operation. When leaving the machine crushing hazard. Crushing hazard. Keep a safe distance from the boom. Possible serious damage to the machine. When tr...

Page 43

Om et18/20/24 us 1.3 * et18_20_24e300.Fm 3-15 3 meaning read the operator’s manual before starting the machine. Injury hazard due to rotating parts. • open the engine cover only at engine standstill. Burn hazard due to hot engine parts. Position on the engine cover. Meaning burn hazard due to hot pa...

Page 44

3-16 om et18/20/24 us 1.3 * et18_20_24e300.Fm 3 labels fig. 28: labels.

Page 45

Om et18/20/24 us 1.3 * et18_20_24e300.Fm 3-17 3 meaning only use diesel fuel with a sulphur content below 15 mg/kg. Position next to the fuel tank filler inlet. Meaning (option) the tank contains biodegradable hydraulic oil. This label is notched on the side depending on the biodegradable hydraulic ...

Page 46

3-18 om et18/20/24 us 1.3 * et18_20_24e300.Fm 3 meaning indicates the interval at a which lubrication point must be lubricated. Lubrication points/grease nipples marked green mean: lubrication every 50 hours or once a week. Lubrication points/grease nipples marked blue mean: lubrication every 10 hou...

Page 47

Om et18/20/24 us 1.3 * et18_20_24e300.Fm 3-19 3 meaning (option) check before starting the machine the operating pattern that has been chosen. Label shows the lever position in which the iso or sae controls are selected. Position at the left under the seat. Meaning (option) indicates the control ope...

Page 48

3-20 om et18/20/24 us 1.3 * et18_20_24e300.Fm 3 meaning (et 18/et 20) this label describes the functions of the pedals and control levers (operating pattern a – iso controls (europe) and operating pattern a). Check before starting the machine the operating pattern that has been chosen. – see “iso/sa...

Page 49

Om et18/20/24 us 1.3 * et18_20_24e300.Fm 3-21 3 meaning (et 24) this label describes the functions of the pedals and control levers (operating pattern a – iso controls (europe) and operating pattern a). Check before starting the machine the operating pattern that has been chosen. – see “iso/sae chan...

Page 50

3-22 om et18/20/24 us 1.3 * et18_20_24e300.Fm 3 meaning indication of maintenance intervals. Position on the roof window on right-hand side in traveling direction. Meaning this label describes the functions of the hydraulic quickhitch. Position canopy: inside on the roof. Cab: at the upper edge of t...

Page 51: Putting Into Operation

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-1 4 4 putting into operation 4.1 cab/control stand safety instructions regarding entry and exit caution accident hazard when entering or exiting! Entering or exiting incorrectly can cause injuries. ► keep the mandatory climbing aids clean. ► use the mandato...

Page 52

4-2 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 information do not use the bar on the door when entering or exiting the cab on the right-hand side. Locking and unlocking the door opening the door from the outside: pull handle a outward. Locking the door: 1. Turn the key in door lock b to the right (r...

Page 53

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-3 4 releasing the door arrester pull button a to release the door out of the arrester. Opening the door to a gap notice the door can be damaged. ► bear in mind the larger width of the machine if the door is opened to a gap. ► close the doors when traveling ...

Page 54

4-4 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 opening/closing the front window caution crushing hazard when opening and closing the front window! Injury hazard due to crushing of parts of body. ► stay clear (extremities, clothing) of the window channel. ► open and close the front window with both h...

Page 55

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-5 4 2. Release levers a and let them engage in both locks c . Closing the front window 1. Press levers a on the left and right, and pull the front window downward with both handles b . 2. Press levers a on either side and engage them in the lock. Fig. 60: o...

Page 56

4-6 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 opening the lower front window 1. Press levers a on the left and right, and pull the front window upward with both handles b . 2. Let levers a engage in both locks c . Closing the lower front window 1. Keep levers a pressed on the left and right, and pu...

Page 57

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-7 4 opening the whole front window 1. Press levers a on the left and right, and pull the lower front window upward with both handles b . 2. Let levers a engage in both locks c . 3. Keep levers a pressed on the left and right, and pull the entire front windo...

Page 58

4-8 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 closing the whole front window 1. Press levers a on the left and right, and pull the front window downward with both handles b . 2. Press levers b on either side and let them engage on either side. 3. Keep levers a pressed on the left and right, and pul...

Page 59

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-9 4 opening the front window to a gap (ventilation position) open 1. Press levers a on either side and pull the front window to the inside. 2. Release levers a and let them engage in both locks b . Close 1. Press levers a on either side. 2. Press the front ...

Page 60

4-10 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 opening/closing the side window open press lever d and let the window engage in the required recess. Close press lever d and close with handle e . Open press lever d and let the window engage in the required recess. Close press lever d and close with h...

Page 61

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-11 4 emergency exit warning injury hazard during emergency exit! Can result in severe injury or death. ► stop the engine. ► only use the windows for exiting the cab if the access (cab door) is obstructed or if it cannot be opened. ► if possible, ask for hel...

Page 62

4-12 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 seat adjustment warning accident hazard due to distraction when adjusting the seat! Can result in severe injury or death. ► adjust the seat only when the machine is at a standstill. Weight adjustment 1. Sit down on the seat. 2. Adjust the weight with r...

Page 63

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-13 4 seat belt adjustment danger personal injury hazard! Do not travel or operate with the seat belt unbuckled. Causes severe injury or death. ► fasten and adjust your seat belt before starting machine travel or operating the machine. ► do not twist the sea...

Page 64

4-14 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 longer/shorter seat belt adjustment longer seat belt adjustment hold buckle latch a at a right angle to the seat belt and pull the seat belt to the required length. Shorter seat belt adjustment pull the free end of the seat belt and shorten it to the r...

Page 65

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-15 4 adjusting the retracting seat belt (option) danger personal injury hazard! Do not travel or operate with the seat belt unbuckled. Causes severe injury or death. ► fasten and adjust your seat belt before starting machine travel or operating the machine....

Page 66

4-16 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 adjusting the rearview mirrors (option) warning injury hazard to persons in the danger zone! Persons in the danger zone are possibly not seen and can be injuried when reversing the machine. ► adjust the existing visual aids (rearview mirrors, for examp...

Page 67

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-17 4 adjusting the mirrors adjust the mirrors in order to: • ensure sufficient visibility from the seat onto the travel area and job site. • ensure maximum visibility to the rear. • ensure visibility of the rear left edge of the machine in the left-hand mir...

Page 68

4-18 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 control lever base raise the left-hand control lever base 4 after stopping the engine. Left-hand control lever base raised: • all hydraulic functions are locked. • the upper carriage is secured against rotation. (the swivel unit brake is enabled.) • th...

Page 69

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-19 4 fire extinguisher a fire extinguisher is not available, neither as standard nor optional equipment. A fire extinguisher according to din-en 3 must be installed by a wacker neuson service center. A bracket for the fire extinguisher must be fastened on t...

Page 70

4-20 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 protective structures protective structures are additional elements that protect the operator against hazard. These elements can be installed later on or as standard equipment. Danger accident hazard due to modified cab and protective structures! Cause...

Page 71

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-21 4 protective fops structure/small screen – level i (option) danger crushing hazard! Falling objects. Causes severe injury or death. ► install a protective fops structure in areas with risk of falling objects. ► machine operation is prohibited without a p...

Page 72

4-22 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 5. Mounting point for cab/canopy: b 6. Tighten screws d (m12/10.9) and lock nuts on the left and right to 110 nm (87 ft.Lbs). 7. Install the mirrors in both positions c . Assembly (black screen) 1. Stop and park the machine. Stop the engine. See “prepa...

Page 73

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-23 4 protective front guard structure with integrated fops/level i respectively (option) danger piercing/penetration hazard by objects from the front or above! Causes severe injury or death. ► a protective front guard structure with integrated fops must be ...

Page 74

4-24 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 6. Mounting point for cab/canopy: b (upper) /d (lower) 7. Tighten screws f (m12/10.9) and lock nuts on the left and right to 110 nm (87 ft.Lbs). 8. Install the mirrors in both positions e . Fig. 96: lower mounting point f fig. 97: upper mounting point ...

Page 75

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-25 4 shatter protection (option) danger piercing/penetration hazard by objects from the front! Causes severe injury or death. ► a shatter protection must be installed on a canopy version if an attachment (a hammer, for example) causes fragments to fly aroun...

Page 76

4-26 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 work area height of work area a : 120 cm (47 in). Figures 99 and 100 refer to machine operation with a wacker neuson hydraulic hammer. Information machine operation with another attachment can modify the height of the work area. Installing/removing the...

Page 77

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-27 4 document storage bin canopy the compartment under the seat is used for storing the operator’s manual. A document box on the headliner is available as an option. Cab (option) the compartment behind the seat is used for storing the operator’s manual. A d...

Page 78

4-28 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 socket a 12 v socket is located at the front left of the machine chassis. Swiveling console limit (option) limits the left-hand limit stop of the swiveling console for attachments with a max. Width of 800 mm (31 in) and prevents the attachment from dam...

Page 79: 4.2

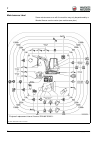

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-29 4 4.2 control element overview this chapter describes the controls, and contains information on the function and handling of the indicator lights and controls in the cab. The pages stated in the table refer to the description of the controls..

Page 80

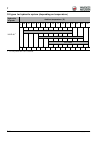

4-30 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 cab 2 1 3 4 6 12 24 7 8 9 10 11 15 17 20 14 19 22 18 21 4 6 5 23 13 25 fig. 107: control element overview – proportional controls fig. 107: control element overview 16.

Page 81

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-31 4 designation see page 1. Travel pedals/travel levers 5-14 2. Boom swivel/auxiliary hydraulics pedal (aux i) 5-29 , 5-27 3. Foot-operated pushbutton switch for hydraulic quickhitch (option) 5-35 4. Control lever base 4-18 5. Horn 5-9 6. Control levers 5-...

Page 82

4-32 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 display element and switches fig. 108: display element and switches switch panel on left-hand control lever base right-hand switch panel (cab) 27 28 26 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 switch panel (canopy) 42 43 45 44 maximum assignment sh...

Page 83

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-33 4 designation see page 26. High speed (2nd speed) 5-1 27. Fuel level indicator 4-36 28. Coolant temperature 4-36 29. Charge indicator light 4-35 30. Engine oil pressure 4-35 31. Preheating 4-35 32. Safe load indicator light 4-35 33. Engine temperature 4-...

Page 84: 4.3

4-34 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 4.3 indicator lights and warning lights (overview) display element the display element provides information on problems and defects. After switching on the starter, the indicator lights are checked during the first 2 seconds. During this time the curre...

Page 85

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-35 4 symbol designation high speed (2nd speed) illuminates with high speed enabled. Charge indicator light this indicator light illuminates if the electrical system has a malfunction. The battery is no longer or insufficiently charged. Note: this indicator ...

Page 86

4-36 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 fuel level indicator indicates the remaining amount of fuel in the tank. Refuel immediately if the segments reach the red range. Coolant temperature indicates the current coolant temperature of the engine. The indicator light illuminates if the segment...

Page 87: 4.4

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-37 4 4.4 preparatory work information before putting the machine into operation before putting the machine into operation, perform a visual check to ensure that: - there are no leaks, - no parts are damaged or loose, - there are neither persons nor objects,...

Page 88

4-38 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 check lists the checklists below are intended to assist you in checking and monitoring the machine before, during and after operation. These checklists cannot claim to be exhaustive. If the answer to one of the following questions is no, first rectify ...

Page 89

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-39 4 operation checklist after starting the engine and during operation, check and observe the following points: parking checklist check and observe the following points when parking the machine: no. Question page ✔ 1. Anyone in the danger zone of the machi...

Page 90

4-40 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 putting the machine into operation for the first time and running-in period before putting the machine into operation for the first time, check it visually for exterior damage due to transport, and check whether the equipment supplied with the machine ...

Page 91: 4.5

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-41 4 4.5 starting and stopping the engine preparations for starting the engine set the throttle to the medium position if the engine is cold. The starter cannot be actuated if the engine is already running (start repeat interlock). Do not run the starter fo...

Page 92

4-42 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 starting the engine notice in order to avoid damage to the starter: ► do not start the engine again immediately after stopping it. ► wait at least 10 seconds after stopping the engine. Notice actuating the preheating system too long can damage the preh...

Page 93

Om et18/20/24 us 1.3 * et18_20_24i400.Fm 4-43 4 jump-starting the engine warning explosion hazard in case of incorrect handling of the battery! Can result in severe injury or death. ► never jump start the engine if the battery is frozen. Dispose of a frozen battery. ► in order to avoid electrical sh...

Page 94

4-44 om et18/20/24 us 1.3 * et18_20_24i400.Fm 4 low-load operation notice the running performance of the engine can be negatively affected if it runs at idling speed or high speed and at less than 20 % of the load. ► run the engine in regular operation at loads of over 20 %. Possible consequences of...

Page 95: Operation

Om et18/20/24 us 1.3 * et18_20_24b500.Fm 5-1 5 5 operation 5.1 steering system see “travel levers and travel pedals” 5.2 accelerator actuation manual throttle speed can be set continuously with throttle 18 . • position a : maximum engine speed • position b : idling speed high speed the machine has t...

Page 96: 5.3

5-2 om et18/20/24 us 1.3 * et18_20_24b500.Fm 5 automatic engine speed setting (option) the switch is located on the right-hand switch panel. Diesel engine speed is automatically reduced to idling after 5 seconds if no hydraulic functions are performed and if the automatic engine speed setting is ena...

Page 97: 5.4

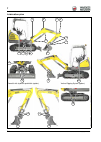

Om et18/20/24 us 1.3 * et18_20_24b500.Fm 5-3 5 5.4 travel operation travel position • position the machine as shown. • position the boom at the center and raise it about 20 to 30 mm (8 – 12 in) off the ground. Information during machine travel, raise the stabilizer blade sufficiently high off the gr...

Page 98

5-4 om et18/20/24 us 1.3 * et18_20_24b500.Fm 5 traveling on slopes warning accident hazard due to tipping over or slipping of the machine on slopes! Can result in severe injury or death. ► travel on slopes only on firm and level ground. ► travel on slopes only with the telescopic travel gear extende...

Page 99

Om et18/20/24 us 1.3 * et18_20_24b500.Fm 5-5 5 preparations for traveling on slopes always travel straight ahead on slopes. When changing position, do not exceed a maximum gradient angle of 15° and a maximum lateral angle of inclination of 10°. Information traveling diagonally on slopes is prohibite...

Page 100

5-6 om et18/20/24 us 1.3 * et18_20_24b500.Fm 5 lateral angle of inclination do not exceed a maximum lateral angle of inclination of 10°. On lateral inclinations over 10°, pile up material to create a level surface that can be used as a platform for the machine. Fig. 123: lateral angle of inclination...

Page 101

Om et18/20/24 us 1.3 * et18_20_24b500.Fm 5-7 5 parking the machine warning accident hazard if the machine tips over or rolls away after parking it! Can result in severe injury or death. ► lower the boom and the stabilizer blade to the ground. ► secure the machine accordingly (chocks, for example). 1...

Page 102: 5.5

5-8 om et18/20/24 us 1.3 * et18_20_24b500.Fm 5 5.5 differential lock no 5.6 lights/signalling system working lights the switch is located on the left-hand control lever base. Warning accident hazard! Motorists can be blinded by bright lights on the job site. Can result in severe injury or death. ► s...

Page 103

Om et18/20/24 us 1.3 * et18_20_24b500.Fm 5-9 5 interior light switched on: press the switch to the left. Switched off: press the switch to the center position or to the right. Horn press button 5 on the right-hand control lever to actuate the horn. Rotating beacon (option) the switch is located on t...

Page 104: 5.7

5-10 om et18/20/24 us 1.3 * et18_20_24b500.Fm 5 traveling signal (option) a traveling signal sounds as soon as at least one of the tracks moves. Danger accident hazard when traveling forward/backward. Crushing hazard causing death or severe injury. ► do not allow anyone to stay in the danger zone. ►...

Page 105: 5.8

Om et18/20/24 us 1.3 * et18_20_24b500.Fm 5-11 5 5.8 heating, ventilation and air conditioning system ventilation/heating (option) the switch is located on the right-hand switch panel. Adjust the nozzles so that the required temperature can be reached. Air the cab from time to time. Information if th...

Page 106: 5.9

5-12 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 5.9 work hydraulics overview of pedals and control levers (operating pattern a) symbol designation symbol designation left-hand track (forward) right-hand track (forward) left-hand track (reverse) right-hand track (reverse) extend stick swivel upper ca...

Page 107

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-13 5 overview of pedals and control levers (operating pattern b) symbol designation symbol designation left-hand track (forward) right-hand track (forward) left-hand track (reverse) right-hand track (reverse) extend stick swivel upper carriage to the right ...

Page 108

5-14 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 travel levers/travel pedals caution accident hazard! The machine moves in the opposite direction if the upper carriage is rotated by 180° and the travel levers/travel pedals are actuated. Injury hazard due to operating error of machine. ► slowly and ca...

Page 109

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-15 5 rotating the upper carriage warning accident hazard! Upper carriage can rotate a little bit farther. Can result in severe injury or death. ► until the hydraulic fluid reaches operating temperature, the upper carriage can rotate farther than expected af...

Page 110

5-16 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 hydraulic swivel unit brake: the upper carriage’s rotation is sufficiently braked by moving the left-hand control lever back to initial position. Moving the control lever in the opposite direction (counteraction) brakes the upper carriage with maximum ...

Page 111

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-17 5 stabilizer blade warning accident hazard due to unintentional actuation! Can result in severe injury or death. ► raise the control lever base. ► lower the stabilizer blade to the ground once machine operation is over. ► ensure that no one is in the dan...

Page 112

5-18 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 information only perform machine operation with an extended telescopic travel gear (option). Lower the stabilizer blade and turn out the extensions (option). Changing the width of the stabilizer blade (option) notice possible machine damage when travel...

Page 113

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-19 5 increasing the width of the stabilizer blade 1. Raise the stabilizer blade to about 1 – 2 cm (about 0.39 – 0.79 in). 2. Pull out pins a on either side. 3. Turn out the stabilizer blade extensions b on either side. 4. Insert pins a on either side. Fig. ...

Page 114

5-20 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 telescopic travel gear (option) warning crushing hazard due to tipping over of the machine. Can result in severe injury or death. ► only perform machine operation with an extended telescopic travel gear. ► traveling with a retracted telescopic travel g...

Page 115

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-21 5 the lever is located at the left under the seat. 1. Set the lever to position b . 2. Raise the machine evenly and horizontally by means of the boom and the stabilizer blade. 3. The telescopic travel gear is controlled via lever 8 . Information only per...

Page 116

5-22 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 proportional controls (option) the proportional controls make it possible to adjust the movement speed of the attachment. Moving the control lever slowly causes the attachment to move slowly. This control mode offers proportional operation of the auxil...

Page 117

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-23 5 hammer operation (option) information regarding hammer operation use the canopy version only with a shatter protection during hammer operation. – see chapter “ shatter protection (option)” on page 4-25 warning piercing/penetration hazard due to flying ...

Page 118

5-24 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 notice if several sizes of hydraulic hammers are available for the machine when using the powertilt unit: ► always use the smallest possible hydraulic hammer. ► contact your dealer for information on the correct equipment. Hammer operation notice in or...

Page 119

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-25 5 hammer pedal – aux i (option) 1. Switch over to hammer operation. The ball-type cock is located on the right in traveling direction on the upper carriage. 2. The auxiliary hydraulics is enabled when the machine is started. ➥ pressing button a changes o...

Page 120

5-26 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 proportionally controlled hammer pedal – aux i (option) 1. Switch over to hammer operation. The ball-type cock is located on the right in traveling direction on the upper carriage. Information set the full oil flow (max) with the rotary switch on the r...

Page 121

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-27 5 additional control circuit – aux i (option) 1. Changeover to the dual-circuit function. The ball-type cock is located on the right in traveling direction on the upper carriage. 2. The auxiliary hydraulics is enabled when the machine is started. ➥ press...

Page 122

5-28 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 proportionally controlled additional control circuit – aux i (option) 1. Changeover to the dual-circuit function. The ball-type cock is located on the right in traveling direction on the upper carriage. 2. Turn the rotary switch on the left-hand contro...

Page 123

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-29 5 swiveling the boom press and hold button a on the left-hand control lever base. Swiveling the boom to the right: press pedal 2 forward. Swiveling the boom to the left: press pedal 2 backward. Swiveling the boom (proportionally controlled) swiveling the...

Page 124

5-30 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 lifting gear applications danger crushing hazard due to tipping over of machine. Causes severe crushing or injury resulting in death. ► observe chapter safety/safety instructions regarding lifting gear applications . ► the authorized lift capacity spec...

Page 125

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-31 5 – see chapter “ safe load indicator (option)” on page 5-50 fig. 168: safe load indicator light 32.

Page 126

5-32 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 additional control circuits 3rd control circuit – aux ii (option) turn the rotary switch on the left-hand control lever base to the required position. Operating the additional control circuit oil flow to left-hand line: push slide switch 23 on the left...

Page 127

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-33 5 powertilt – aux ii (option) warning crushing hazard due to rotating movements of the powertilt unit! Can result in severe injury or death. ► do not allow anyone to stay in the danger zone. Information for more information, see easy lock/powertilt with ...

Page 128

5-34 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 rotating the powertilt unit to the left: push slide switch 23 on the left-hand control lever to the left. Rotating the powertilt unit to the right: push slide switch 23 on the left-hand control lever to the right. Fig. 173: rotating the powertilt unit ...

Page 129

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-35 5 hydraulic quickhitch – easy lock (option) • before putting this feature into operation, specific training must be performed by authorized technical personnel and must be understood by the operator. • for safety reasons, the quickhitch must be operated ...

Page 130

5-36 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 2. Press and hold foot-operated pushbutton switch 3 . 3. Pull and hold stabilizer-blade lever 8 as far as it will go. ➥ the quickhitch opens. ➥ the quickhitch is fully open if check pin k (red) is extended. 4. The stabilizer-blade lever can be released...

Page 131

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-37 5 ➥ the check pin k must be fully retracted. Setting down an attachment warning crushing hazard due to uncontrolled movements of the attachment! Can result in severe injury or death. ► do not allow anyone to stay in the danger zone. ► lower the attachmen...

Page 132

5-38 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 ➥ the quickhitch is fully open if check pin k (red) is extended. 5. Release the stabilizer-blade lever. 6. Retract the bucket hydraulic cylinder. 7. Set down the attachment. 8. Raise the boom. 9. Release foot-operated pushbutton switch 3 . 10.Pull and ...

Page 133

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-39 5 connecting and disconnecting hydraulic couplings 1. Stop and park the machine. See “preparing lubrication”. 2. Position the boom straight ahead at the center of the machine. 3. Lower the stabilizer blade to the ground. 4. Turn the starting key to posit...

Page 134: 5.10 Attachments

5-40 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 5.10 attachments picking up warning injury hazard! Fluid escaping under high pressure can damage the skin and eyes! Can result in severe injury or death. ► do not allow anyone to stay in the danger zone. ► before connecting or removing hydraulic lines ...

Page 135

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-41 5 setting down warning crushing hazard due to uncontrolled movements of the attachment! Can result in severe injury or death. ► ensure that no one is in the danger zone. ► lower the attachment to level and firm ground ensuring stability. Re-equipping the...

Page 136

5-42 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 releasing the pressure in the work hydraulics releasing pressure 1. Stop the machine on firm, level and horizontal ground. 2. Lower the attachment completely to the ground. 3. Lower the stabilizer blade to the ground. 4. Stop the engine. 5. Turn the st...

Page 137

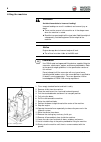

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-43 5 retrofitting a bucket removing 1. Lower the bucket to level ground with the flat side facing downward. 2. Stop and park the machine. Stop the engine. See “preparing lubrication”. 3. Remove linch pins a . 4. First remove pin b , and then pin c . Careful...

Page 138: 5.11 Work Operation

5-44 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 5.11 work operation inadmissible work procedures working with swivel force • do not use the swivel force of the upper carriage to tear down walls or to create level surfaces. • never ram the attachment into the ground when swiveling the upper carriage....

Page 139

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-45 5 avoid tipping the machine and then releasing the boom hydrau- lics to break up material or compact the work. • never use the dead weight of the machine for work. • use only the hydraulic force of the hydraulic cylinders. Fully lowering the stabilizer b...

Page 140

5-46 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 general notices regarding work operation travel operation traveling over obstacles (rocks, tree stumps etc.) can put a heavy load on the travel gear and cause damage. Avoid traveling over obstacles if possible. If it cannot be avoided, lower the boom t...

Page 141

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-47 5 working with the standard bucket the following section describes work operations with the machine equipped with the standard bucket (backhoe bucket 400 mm/16 in). The standard bucket is mainly used for earth-moving applications, namely for digging, loo...

Page 142

5-48 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 loading material • loading material on trucks is easier and more efficient if: - the machine is positioned at the rear end of the truck. - the loading platform of the truck is loaded by starting at the rear end. - work is performed with the smallest po...

Page 143: 5.12 Emergency Lowering

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-49 5 5.12 emergency lowering danger crushing hazard during boom lowering! Causes severe crushing or injury resulting in death. ► do not allow anyone to stay in the danger zone. Information lower the boom immediately after stopping the engine. A load retaini...

Page 144

5-50 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 5.13 additional equipment/options safe load indicator (option) the safe load indicator gives the operator optical and acoustic warnings when the values of the stability table are exceeded. Danger crushing hazard due to tipping over of the machine! A ti...

Page 145

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-51 5 switching on the safe load indicator the safe load indicator switch is located on the left-hand control lever base. 1.Press switch 38 on the instrument panel down. ➥ indicator light 32 in the display element is used for monitoring. ➥ as soon as the adm...

Page 146

5-52 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 hydraulic hose burst valve caution burn hazard due to hot hydraulic oil! Hot hydraulic oil can burn the skin. ► move the control levers to neutral position if a hydraulic hose bursts. Stabilizer blade hydraulic cylinder if a hydraulic hose bursts on th...

Page 147

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-53 5 travel interlock a = operator’s key (blue key) for starting the machine. Scope of delivery includes 2 keys. B = master key (red key) information store the master key in a safe place. It is only used for coding new keys. All coded keys are deleted if th...

Page 148

5-54 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 tilting the upper carriage (vertical digging system) (option) danger crushing hazard due to tipping over of the machine! Severe crushing hazard causing death or severe injury. ► on a slope, position the machine so that the upper carriage is tilted towa...

Page 149

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-55 5 notice crushing hazard due to tipping over of the machine. Damage to machine due to open doors and covers. ► perform smooth and slow movements with the machine. ► all doors and covers must be closed when tilting the machine. ► tilt the machine only on ...

Page 150

5-56 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 shovel bucket operation with some restrictions, wacker neuson backhoe buckets can also be used for shovel bucket operation. Notice do not tilt the bucket fully back in shovel bucket operation, otherwise the bucket base can touch and damage the stick. T...

Page 151

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-57 5 5.14 decommissioning and putting the machine back into operation the specified measures refer to decommissioning and putting the machine back into operation after more than 30 days. Decommissioning the machine temporarily store the machine indoors if p...

Page 152

5-58 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 putting the machine back into operation information if the machine was decommissioned over a longer period of time without performing the steps specified above, contact a wacker neuson service center before putting the machine back into operation. 1. R...

Page 153

Om et18/20/24 us 1.3 * et18_20_24b510.Fm 5-59 5 5.15 final decommissioning of machine disposal all fluids, lubricants, material, etc., used on the machine are subject to specific regulations regarding collection and disposal. Dispose of different materials and consumables separately and in an enviro...

Page 154

5-60 om et18/20/24 us 1.3 * et18_20_24b510.Fm 5 notes:.

Page 155: Transport

Om et18/20/24 us 1.3 * et18_20_24t600.Fm 6-1 6 6 transport 6.1 towing the machine information regarding towing warning accident hazard due to incorrect towing! Can result in severe injury or death. ► the machine may only be towed using suitable towing equipment (towing bar or cable) in connection wi...

Page 156

6-2 om et18/20/24 us 1.3 * et18_20_24t600.Fm 6 1. Ensure that the machine can be towed safely. 2. Use towing eye hook a of the machine for towing. 3. Use towing eye hook a only for towing. 4. Secure shackle b with the shackle pin and a lock pin. 5. Install towing equipment of adequate size on the sh...

Page 157: 6.2

Om et18/20/24 us 1.3 * et18_20_24t600.Fm 6-3 6 6.2 loading the machine information regarding loading warning accident hazard due to incorrect loading! Incorrect loading can result in accidents and severe injury or death. ► ensure that no one is in the danger zone. ► read the transport weight off the...

Page 158

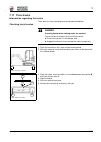

6-4 om et18/20/24 us 1.3 * et18_20_24t600.Fm 6 lifting the machine warning accident hazard due to incorrect loading! Incorrect loading can result in accidents and severe injury or death. ► there must be no one in the machine or in the danger zone when the machine is raised. ► read the transport weig...

Page 159

Om et18/20/24 us 1.3 * et18_20_24t600.Fm 6-5 6 17.Wait until the machine does not swing any more. 18.If the balance and the condition and position of the slings is correct, slowly raise the machine to the required height and load it. Mandatory length l1 of slings: length dimension l1 minimum 1300 mm...

Page 160: 6.3

6-6 om et18/20/24 us 1.3 * et18_20_24t600.Fm 6 6.3 transporting the machine information regarding transport the swivel unit brake is enabled if: • the control lever base is raised. • the starter is turned to position 0 or the engine is stopped. This secures the upper carriage against rotation. Tying...

Page 161

Om et18/20/24 us 1.3 * et18_20_24t600.Fm 6-7 6 fig. 221: tie-down points on either side outside on the travel gear a.

Page 162

6-8 om et18/20/24 us 1.3 * et18_20_24t600.Fm 6.

Page 163: Maintenance

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-1 7 7 maintenance 7.1 important information on maintenance responsibilities and prerequisites the working order and the service life of machines are heavily dependent on maintenance. Daily and weekly service and maintenance on or with the machine must be pe...

Page 164: 7.2

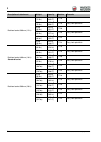

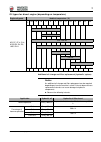

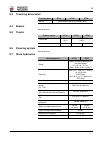

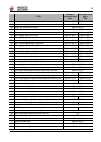

7-2 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 7.2 maintenance overview maintenance plan daily maintenance (operator) inspection work (check the following engine/machine fluids, check the oil levels after a test run and add oil if necessary) page check the engine/machine fluids (engine oil, engine c...

Page 165

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-3 7 information check the antifreeze at temperatures below 4 °c (39 °f). Check the load hook, joint rod, lifting eyes 7-52 check the hydraulic quickhitch (easy lock) for damage -- check powertilt for damage -- weekly maintenance (every 50 service hours) (op...

Page 166

7-4 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 once at 50 service hours (wacker neuson service center) engine oil replacement (yanmar 3tnv76-snse12/3tnv80f-ssns1) -- engine oil filter replacement (yanmar 3tnv76-snse12/3tnv80f-ssns1) -- hydraulic oil filter insert replacement -- drive gearbox oil rep...

Page 167

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-5 7 information maintenance with the note wacker neuson service center must only be performed by the trained and qualified personnel of a wacker neuson service center . Information the maintenance meter starts at 500.0 hours. It counts down to 0.0 hours. A ...

Page 168

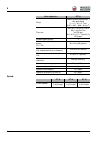

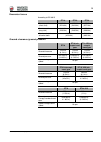

7-6 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 lubrication plan powertilt with hydraulic quickhitch (option) 1 1 2 2 3 4 5 7 6 9 vertical digging system (option) 8 12 12 13 13 14 14 15 11 10 11.

Page 169

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-7 7 green means: lubrication every 50 hours or once a week. Blue means: lubrication every 10 hours or daily. 16 18 17 position lubrication point interval quantity 1. Boom daily 2 2. Stick hydraulic cylinder daily 2 3. Bucket hydraulic cylinder daily 2 4. Bo...

Page 170

7-8 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 maintenance label some maintenance on or with the machine may only be performed by a wacker neuson service center (see maintenance plan). Fig. 222: maintenance label overview *engine oil replacement interval yanmar 3tnv80f-ssns1: *.

Page 171

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-9 7 explanation of symbols on the maintenance label symbol assembly explanation general visual check general visual check of machine general lubrication points general clean the radiator fins, water separator and fresh-air fil- ter of the heating fuel syste...

Page 172: 7.3

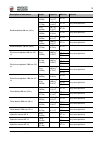

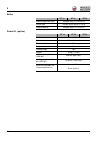

7-10 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 7.3 fluids and lubricants fluids and lubricants unit engine/machine fluid specification season/temper- ature capacities 1 1. The capacities indicated are approximate values; the oil level check alone is relevant for the correct oil level. Capacities in...

Page 173

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-11 7 oil types for diesel engine (depending on temperature) additional oil change and filter replacement (hydraulic system) notice an additional oil change and filter replacement can be required depending on how the machine is used. Failure to observe these...

Page 174

7-12 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 oil types for hydraulic system (depending on temperature) hydraulics oil grade ambient temperature (°c) hvlp 46 1 1. According to din 51524 section 3, iso-vg 46. ° c -20 -15 -10 -5 0 5 10 15 20 25 30 35 40 50 iso vg32 iso vg46 iso vg68 °f -4 5 14 23 32...

Page 175

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-13 7 information regarding operation with biodegradable oil • use only the biodegradable oils that have been tested and approved by wacker neuson. Contact a wacker neuson dealer for the use of other products that have not been recommended. In addition, ask ...

Page 176: 7.4

7-14 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 7.4 maintenance accesses engine cover warning burn hazard due to hot engine parts! Can result in severe injury or death. ► stop the engine and allow it to cool down at least 10 minutes. Warning injury hazard due to rotating parts! Rotating parts can re...

Page 177

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-15 7 left-hand cover opening: 1. Stop and park the machine. Stop the engine. See “preparing lubrication”. 2. Open the engine cover. 3. Pull out lock a . ➥ the side cover is folded sideways. 4. To unlock bow clip b , press and hold it downward. 5. Push side ...

Page 178

7-16 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 2. Press bow clip b downward and hitch it. 3. Position lock d opposite notch b . 4. Press side cover c toward the machine with both hands until it engages with an audible click. 5. Close the engine cover. Right-hand cover opening: 1. Stop and park the ...

Page 179

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-17 7 removing/installing the cab/canopy danger accident hazard when traveling without cab/canopy! Causes severe injury or death. ► traveling with a removed cab/canopy is only allowed for traveling very short distances. ► fastening the seat belt is prohibite...

Page 180

7-18 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 4. Remove the rear roof lights (option). 5. Install shackle a and tighten the screw to 45 nm (33.2 ft.Lbs). 6. Install the lifting gear at the points on the cab provided for lifting the machine. The required length l1 is 1000 mm (39.4 in). 7. Apply ten...

Page 181

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-19 7 10.Raise the floor mat on either side. 11.Remove screws d on either side in the leg-room area. 12. Canopy: remove screws e on either side. 13. Cab (option): remove screws e on either side. 14.Raise the cab as follows: - raise the control lever base. - ...

Page 182: 7.5

7-20 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 7.5 cleaning and maintenance on or with the machine information regarding cleaning and maintenance on or with the machine cleaning the machine is divided into 3 separate areas: • inside the cab. • exterior of the machine. • engine compartment. The wron...

Page 183

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-21 7 use of solvents notice do not clean rubber and electrical parts with solvents. ► do not use solvents, benzine or other aggressive chemicals. Cleaning inside the cab notice never use high-pressure cleaners, steam jets or high-pressure water to clean ins...

Page 184

7-22 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 notice when cleaning the engine with a water or steam jet, the humidity penetrating the electronics causes it to fail and leads to engine damage! ► the engine must be cold. ► do not point the water jet directly at any of the electric sensors such as te...

Page 185: 7.6

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-23 7 7.6 lubrication work preparing lubrication 1. Stop the machine on firm, level and horizontal ground. 2. Position the boom straight ahead at the center of the machine. 3. Lower the boom and the stabilizer blade to the ground. 4. Stop the engine. 5. Oper...

Page 186

7-24 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 live ring (ball bearing) danger crushing hazard. Do not tilt or rotate the upper carriage during lubrication! Severe crushing hazard causing death or severe injury! ► park the machine as shown in fig. 240 . ► do not rotate the upper carriage. ► do not ...

Page 187

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-25 7 control lever base caution crushing hazard in the area of the moving parts of the control lever base! Injury hazard due to crushing of parts of body! ► keep extremities and clothing clear of the window channel. 1. Stop and park the machine. Stop the en...

Page 188: 7.7

7-26 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 7.7 fuel system information regarding the fuel system information fill up the tank with the correct fuel type at the end of each working day to prevent the formation of condensation water in the fuel tank. Do not fill the tank completey so the fuel can...

Page 189

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-27 7 warning fire hazard when handling fuel! Can result in severe burns or death. ► never perform work on the fuel system in the vicinity of open flames or sparks. ► do not smoke. ► keep the maintenance area clean. ► do not refuel in closed rooms. Filler in...

Page 190

7-28 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 bleeding the fuel system bleed the fuel system in the following cases: • after removing and fitting the fuel filter, prefilter or the fuel lines back on again • after running the fuel tank empty • if the machine is put into operation after having been ...

Page 191

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-29 7 checking the water separator water separator empty the water separator if the red indicator ring a rises to position b . Fuel filter empty the fuel filter if the fuel/water mixture rises to position c . Emptying the water separator warning explosion ha...

Page 192

7-30 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 1. Stop and park the machine. Stop the engine. See “preparing lubrication”. 2. Prepare a suitable container for collecting the fuel/water mixture. 3. Open the engine cover. 4. Turn ball-type cock d to the off mark. ➥ fuel supply is interrupted. 5. Unsc...

Page 193

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-31 7 information the fuel system can be bled automatically even if the engine is at operating temperature – see chapter “ bleeding the fuel system” on page 7-28. 1. Stop and park the machine. Stop the engine. See “preparing lubrication”. 2. Open the engine ...

Page 194: 7.8

7-32 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 7.8 engine lubrication system information regarding the engine lubrication system information check the oil level once a day. We recommend checking it before starting the engine. After stopping a warm engine, wait at least 5 minutes before checking. No...

Page 195

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-33 7 adding engine oil 1. Stop and park the machine. Stop the engine. See “preparing lubrication”. 2. Open the engine cover. 3. Clean the area around the oil filler cap with a lint-free cloth. 4. Open filler cap b . 5. Raise oil dipstick a slightly to allow...

Page 196: 7.9

7-34 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 7.9 cooling system information regarding the cooling system the oil/water radiator is located behind the right-hand cover, on the right side of the engine. It cools the diesel engine, and the hydraulic oil of the travel and work hydraulics. Notice in o...

Page 197

Om et18/20/24 us 1.3 * et18_20_24w700.Fm 7-35 7 adding coolant warning burn hazard! The engine coolant is under pressure at high temperature! Causes severe injury or death. ► wear protective gloves and eye protection. ► stop the engine and allow it to cool down at least 10 minutes. ► carefully open ...

Page 198

7-36 om et18/20/24 us 1.3 * et18_20_24w700.Fm 7 cleaning the radiator caution burn hazard when performing maintenance on the radiator! Can cause injuries. ► stop the engine and allow it to cool down at least 10 minutes. ► wear protective gloves and eye protection. Notice dirt on the radiator fins re...

Page 199: 7.10 Air Filter

Om et18/20/24 us 1.3 * et18_20_24w710.Fm 7-37 7 7.10 air filter information regarding the air filter • store filters in their original packaging and in a dry place. • check air filter attachments, air intake hoses and the air filter element for damage, and immediately repair or replace them if neces...

Page 200

7-38 om et18/20/24 us 1.3 * et18_20_24w710.Fm 7 replacing the air filter notice air filter elements degrade prematurely when in service in acidic air for longer periods of time. ► this risk is present, for example, in acid production facilities, steel and aluminium mills, chemical plants and other n...

Page 201

Om et18/20/24 us 1.3 * et18_20_24w710.Fm 7-39 7 checking the air intake notice in order to avoid engine damage when crossing fords: ► always keep the opening of the engine air intake a above the water. ► check once a day for cleanliness before putting the machine into operation. 1. Stop and park the...

Page 202: 7.11 V-Belt

7-40 om et18/20/24 us 1.3 * et18_20_24w710.Fm 7 7.11 v-belt checking v-belt condition and tension warning injury hazard due to rotating parts! Rotating parts can result in severe injury or death. ► stop the engine before opening the engine cover. ► only check the v-belt when the engine is stopped. N...

Page 203: 7.12 Hydraulic System

Om et18/20/24 us 1.3 * et18_20_24w710.Fm 7-41 7 7.12 hydraulic system information regarding the hydraulic system warning burn hazard when performing maintenance on or with the machine on a hot engine and hydraulic system. Can result in severe injury or death. ► wait at least 10 minutes after stoppin...

Page 204

7-42 om et18/20/24 us 1.3 * et18_20_24w710.Fm 7 checking the hydraulic oil level 1. Place the machine on firm, level and horizontal ground. 2. Position the boom straight ahead at the center of the machine (see figure). 3. Lower the boom and the stabilizer blade to the ground. 4. Stop the engine. 5. ...

Page 205

Om et18/20/24 us 1.3 * et18_20_24w710.Fm 7-43 7 checking the hydraulic system for leaks notice leaks and damaged pressure lines must be immediately repaired or replaced by a wacker neuson service center. This not only increases the operating safety of the machine but also helps to protect the enviro...

Page 206

7-44 om et18/20/24 us 1.3 * et18_20_24w710.Fm 7 checking the condition and age of hydraulic hoses notice leaks and damaged pressure lines must be immediately repaired or replaced by a wacker neuson service center. This not only increases the operating safety of the machine but also helps to protect ...

Page 207: 7.13 Electrical System

Om et18/20/24 us 1.3 * et18_20_24w710.Fm 7-45 7 7.13 electrical system information regarding the electrical system maintenance and repair work on the electrical system may be performed only by trained technical personnel and/or wacker neuson service centers. • malfunctioning components of the electr...

Page 208

7-46 om et18/20/24 us 1.3 * et18_20_24w710.Fm 7 fuses and relays • blown fuses indicate overloading or short circuits. Have the electrical system checked by a wacker neuson service center. • only use fuses with the specified load capacity (amperage). – see chapter “ relays” on page 9-5 – see chapter...

Page 209

Om et18/20/24 us 1.3 * et18_20_24w710.Fm 7-47 7 7.14 heating, ventilation and air conditioning system checking/replacing the fresh-air filter the fresh-air filter is located under the seat. Check it every 50 service hours if it is used in a dusty environment and clean it with compressed air or a mil...

Page 210: 7.15 Washer System

7-48 om et18/20/24 us 1.3 * et18_20_24w710.Fm 7 4. Install the filter. 5. Tighten cover b 7.15 washer system information regarding the washer system only use glass cleaner (with antifreeze if necessary) for refilling. Checking the fluid level and adding fluid the tank filler inlet is located in the ...

Page 211: 7.17 Tires/tracks

Om et18/20/24 us 1.3 * et18_20_24w710.Fm 7-49 7 7.17 tires/tracks information regarding the tracks track wear can vary according to work and ground conditions. Checking track tension danger crushing hazard when working under the machine! Causes severe crushing or injury resulting in death. ► ensure ...

Page 212

7-50 om et18/20/24 us 1.3 * et18_20_24w710.Fm 7 7. Adjust the correct track tension if the play between the track roller and the track is not 20 – 25 mm (0.8 – 1 in). Correcting track tension danger projectile hazard! High grease pressure in the hydraulic cylinder. Causes severe injury or death! ► o...

Page 213

Om et18/20/24 us 1.3 * et18_20_24w710.Fm 7-51 7 tightening the tracks 1. Place the machine on firm, level and horizontal ground. 2. Raise the machine evenly and horizontally by means of the boom and the stabilizer blade. 3. Stop the engine. 4. Operate the control lever repeatedly to release the pres...

Page 214: 7.19 Maintenance of Options

7-52 om et18/20/24 us 1.3 * et18_20_24w710.Fm 7 7.18 maintenance of attachments information regarding maintenance of attachments correct maintenance and service is absolutely necessary for smooth and continuous operation, and for an increased service life of the attachments. Please observe the lubri...

Page 215

Om et18/20/24 us 1.3 * et18_20_24w710.Fm 7-53 7 notes:.

Page 216

7-54 om et18/20/24 us 1.3 * et18_20_24w710.Fm 7.

Page 217: Troubleshooting

Om et18/20/24 us 1.3 * et18_20_24b800.Fm 8-1 8 8 troubleshooting notice contact a wacker neuson dealer or customer service in case of malfunctions or signs that are not listed in the following tables or that persist after maintenance on or with the machine has been performed correctly. 8.1 diesel en...

Page 218: 8.6

8-2 om et18/20/24 us 1.3 * et18_20_24b800.Fm 8 8.6 malfunctions of attachments powertilt unit malfunction/sign possible cause remedy see powertilt does not maintain its posi- tion internal release valve activated repeat the work operation with less load. If this problem persists, contact a wacker ne...

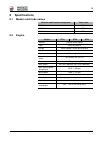

Page 219: Specifications

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-1 9 9 specifications 9.1 models and trade names 9.2 engine machine model/machine designation trade name e12-02 et18 e12-03 et20 e12-04 et24 engine et18 et20 et24 product yanmar diesel engine type 3tnv76-snse12 design water-cooled 4 stroke diesel engine numb...

Page 220

9-2 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 information the machine has about 17 % less output at altitudes over 800 m (2625 ft) above see level. However, this does not affect excavator operation (yanmar 3tnv80f-ssns1). Engine et18 et20 et24 product yanmar diesel engine type 3tnv80f-ssns1 design ...

Page 221: 9.3

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-3 9 9.3 traveling drive/axles 9.4 brakes see travel lever 9.5 tracks 9.6 steering system see travel lever 9.7 work hydraulics traveling drive et18 et20 et24 version axial-piston motor with planetary drive rubber tracks et18 et20 et24 track width 230 mm (9 i...

Page 222

9-4 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 speed work hydraulics et 24 pump double variable displacement + twin gear pump 11 + 11 + 8.2 + 2.7 cm³ (0.67 + 0.67 + 0.50 + 0.16 in 3 ) flow rate 26.1 (p1) + 26.1 (p2) + 19.4 (p3) + 6.4 (p4) l/min at 2375 rpm (6.9 + 6.9 + 5.1 + 1.7 gal/min at 2375 rpm)...

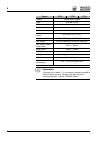

Page 223: 9.8

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-5 9 9.8 electrical system electrical components fuses the fuses are located behind the left-hand cover. Relays the relays are located behind the left-hand cover. Et 18/et 20/et 24 alternator 12 v 55 a starter 12 v 1.1 kw (1.5 hp) battery 12 v 44 ah fig. 275...

Page 224

9-6 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 bulbs powertilt (option) et 18 et 20 et 24 working lights/roof lights halogen lamp 12 v 55 w h3 interior light festoon lamp 10x38 12 v/5 w rotating beacon halogen lamp 12 v-55 w h1 et 18 et 20 et 24 model size 4.5 piston stroke 240 cm³ (14.6 in³) requir...

Page 225: 9.9

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-7 9 9.9 tightening torques general tightening torques property class 8.8 10.9 12.9 8.8 10.9 screw dimen- sions screws according to din 912, din 931, din 933 etc. Screws according to din 7984 nm (ft.Lbs.) nm (ft.Lbs.) nm (ft.Lbs.) nm (ft.Lbs.) nm (ft.Lbs.) m...

Page 226: 9.10 Coolant

9-8 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 9.10 coolant compound table 9.11 noise emissions information measurements performed on asphalted surface. Outside temperature 1 1. Use the 1:1 concentration for warm outside temperatures, too, to ensure protection against corrosion, cavitation and depos...

Page 227: 9.12 Vibration

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-9 9 9.12 vibration vibration values indicated in m/s². Directive 2002/44/ec of european parliament and coucil on minimum health and safety requirements regarding exposure of workers to risks arising from physical agents (vibration). Indications on hand-arm ...

Page 228

9-10 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 directives on reduction of vibration values in earth moving machines: • perform correct adjustments and maintenance on or with the machine. • avoid jerky movements during machine operation. • keep slopes in a perfect condition. Whole-body vibration can...

Page 229

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-11 9 the harmonized data comply with measurements made by international institutes, organizations and manufacturers. This publication offers information on the calculation of whole-body vibrations for operators of earth moving machines. This method is based...

Page 230: 9.13 Weight

9-12 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 9.13 weight machine weight information the actual machine weight depends on the selected options and must be read off the type label. Add the weight of all subsequently installed equipment to the weight of the machine. Weight indications can vary by +/...

Page 231

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-13 9 excavator forces according to iso 6015 ground clearance/ground pressure et 18 et 20 et 24 max. Tearout force (short stick) 11.2 kn (2518 lbf) 12.5 kn (2810 lbf) 15 kn (3372 lbf) max. Tearout force (long stick) 9.8 kn (2203 lbf) 11.1 kn (2495 lbf) 13.3 ...

Page 232: 9.14 Payload/stability

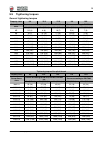

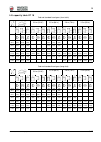

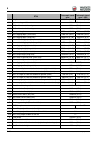

9-14 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 9.14 payload/stability safety instructions – lift capacity table the values of the lift capacity table apply to normal operation (for example excavating, etc.) (the values of the stability table apply to lifting gear applications). Danger crushing haza...

Page 233

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-15 9 legend symbolic representat designation explanation a reach from live ring center b load hook height max authorized lift capacity with horizontal boom with the stabilizer blade in traveling direction with or without the stabilizer blade, 90° to traveli...

Page 234

9-16 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 all table values are specified in kg (lbs) under the following conditions: • upper carriage not tilted. • machine placed on firm, level and horizontal ground. • no bucket or other attachment (hammer etc.) installed. The machine’s lift capacity is restr...

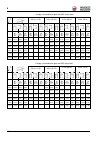

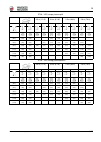

Page 235

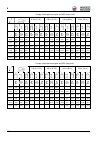

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-17 9 lift capacity table et 18 cab and standard travel gear (short stick) cab and standard travel gear (long stick) 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 1.5 m (59 in) 2.5 m (98 in) 382 (842) 290 (639) 249 (549) - - - 366 (807) 318 (701) 274 (604) - - ...

Page 236

9-18 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 cab and telescopic travel gear (short stick) cab and telescopic travel gear (long stick) 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 1.5 m (59 in) 2.5 m (98 in) 382 (842) 382 (842) 313 (690) - - - 366 (807) 366 (807) 344 (758) - - - - - - 2.0 m (79 in) ...

Page 237

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-19 9 cab, telescopic travel gear and vds (short stick) cab, telescopic travel gear and vds (long stick) 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 1.5 m (59 in) 2.5 m (98 in) 381 (840) 381 (840) 282 (622) - - - 362 (798) 362 (798) 328 (723) - - - - - - 2.0 ...

Page 238

9-20 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 canopy and standard travel gear (short stick) canopy and standard travel gear (long stick) 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 1.5 m (59 in) 2.5 m (98 in) 382 (842) 268 (591) 227 (500) - - - 366 (807) 294 (648) 251 (553) - - - - - - 2.0 m (79 in...

Page 239

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-21 9 canopy and telescopic travel gear (short stick) canopy and telescopic travel gear (long stick) 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 1.5 m (59 in) 2.5 m (98 in) 382 (842) 382 (842) 289 (637) - - - 366 (807) 366 (807) 317 (699) - - - - - - 2.0 m (7...

Page 240

9-22 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 canopy, telescopic travel gear and vds (short stick) canopy, telescopic travel gear and vds (long stick) 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 1.5 m (59 in) 2.5 m (98 in) 381 (840) 381 (840) 256 (564) - - - 362 (798) 362 (798) 298 (657) - - - - - ...

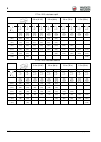

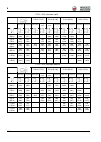

Page 241

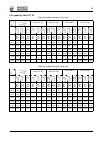

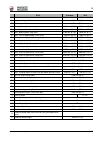

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-23 9 lift capacity tables et 20 cab and telescopic travel gear (short stick) cab and telescopic travel gear (long stick) 3.5 m (11'-6") 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 2.5 m (98 in) 382 (842) 355 (783) 322 (710) - - - - - - 385 (849) 349 (769) 31...

Page 242

9-24 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 cab, telescopic travel gear and vds (short stick) cab, telescopic travel gear and vds (long stick) 3.5 m (11'-6") 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 2.5 m (98 in) 380 (838) 351 (774) 274 (604) - - - 378 (833) 358 (789) 280 (617) 356 (785) 356 (...

Page 243

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-25 9 canopy and telescopic travel gear (short stick) canopy and telescopic travel gear (long stick) 3.5 m (11'-6") 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 2.5 m (98 in) 382 (842) 329 (725) 298 (657) - - - - - - 385 (849) 323 (712) 292 (644) 355 (783) 355...

Page 244

9-26 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 canopy, telescopic travel gear and vds (short stick) canopy, telescopic travel gear and vds (long stick) 3.5 m (11'-6") 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 2.5 m (98 in) 380 (838) 326 (719) 248 (547) - - - 378 (833) 332 (732) 253 (558) 356 (785)...

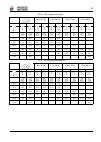

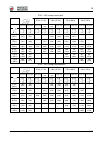

Page 245

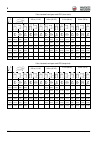

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-27 9 lift capacity table et 24 cab and standard travel gear (short stick) cab and standard travel gear (long stick) 3.5 m (11'-6") 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 2.5 m (98 in) 552 (1217) 440 (970) 356 (785) - - - 547 (1206) 449 (990) 364 (802) 5...

Page 246

9-28 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 cab, standard travel gear and vds (short stick) cab, standard travel gear and vds (long stick) 3.5 m (11'-6") 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 2.5 m (98 in) 552 (1217) 430 (948) 344 (758) - - - 547 (1206) 440 (970) 352 (776) 513 (1131) 513 (1...

Page 247

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-29 9 canopy and standard travel gear (short stick) canopy and standard travel gear (long stick) 3.5 m (11'-6") 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 2.5 m (98 in) 552 (1217) 412 (908) 352 (776) - - - 547 (1206) 421 (928) 333 (734) 513 (1131) 513 (1131)...

Page 248

9-30 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 canopy, standard travel gear and vds (short stick) canopy, standard travel gear and vds (long stick) 3.5 m (11'-6") 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 2.5 m (98 in) 552 (1217) 403 (888) 313 (690) - - - 547 (1206) 412 (908) 321 (708) 513 (1131) ...

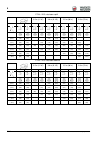

Page 249

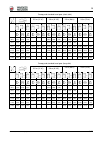

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-31 9 lift capacity tables vds (upper carriage tilted) boom uphill (15° slope) boom downhill (15° slope) symbolic representation symbolic representation designation explanation a reach from live ring center b load hook height max authorized lift capacity wit...

Page 250

9-32 om et18/20/24 us 1.3 * et18_20_24t900.Fm 9 et18 – vds, cab, boom uphill et18 – vds, cab, boom downhill 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 1.5 m (59 in) short stick long stick short stick long stick short stick long stick short stick long stick short stick long stick 2.5 m (98 in) 382 (8...

Page 251

Om et18/20/24 us 1.3 * et18_20_24t900.Fm 9-33 9 et18 – vds, canopy, boom uphill et18 – vds, canopy, boom downhill 3.0 m (9'-10") 2.5 m (98 in) 2.0 m (79 in) 1.5 m (59 in) short stick long stick short stick long stick short stick long stick short stick long stick short stick long stick 2.5 m (98 in) ...

Page 252