- DL manuals

- Wacker Neuson

- Portable Generator

- G 85

- Repair Manual

Wacker Neuson G 85 Repair Manual

Summary of G 85

Page 1

Repair manual mobile generator g 85 0171726en 004 0809 0 1 7 1 7 2 6 e n.

Page 2

Copyright notice © copyright 2009 by wacker neuson corporation. All rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permission from wack...

Page 3: Mobile Generator Repair

Mobile generator repair foreword 3 operating / parts information you must be familiar with the operation of this machine before you attempt to troubleshoot or repair it. Basic operating and maintenance procedures are described in the operator’s manual supplied with the machine. Keep a copy of the op...

Page 4: Foreword

Foreword mobile generator repair 4 california proposition 65 warning: diesel engine exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. Laws pertaining to spark arre...

Page 5: Mg Repair

Mg repair table of contents 5 1 safety information 9 1.1 operating safety ................................................................................ 10 1.2 service safety .................................................................................... 12 1.3 operator safety while using int...

Page 6: Table of Contents

Table of contents mg repair wc_br0171726en_004toc.Fm 6 5 ecm/sensor troubleshooting 44 5.1 checking power to the ecm ...............................................................44 5.2 checking outgoing power from the ecm ..........................................47 5.3 checking temperature sender...

Page 7: Mg Repair

Mg repair table of contents 7 8.7 checking the avr sensing wires ...................................................... 75 8.8 flashing the generator (checking the excitation system) .................. 76 8.9 checking stator windings at the lugs ............................................... 77 8.1...

Page 8: Table of Contents

Table of contents mg repair wc_br0171726en_004toc.Fm 8.

Page 9: G 85

G 85 safety information wc_si000356gb.Fm 9 1 safety information this manual contains danger, warning, caution, notice, and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is used to a...

Page 10: Safety Information

Safety information g 85 wc_si000356gb.Fm 10 1.1 operating safety familiarity and proper training are required for the safe operation of the machine. Machines operated improperly or by untrained personnel can be hazardous. Read the operating instructions contained in this manual and the engine manual...

Page 11: G 85

G 85 safety information wc_si000356gb.Fm 11 1.1.17 always keep the area immediately surrounding and underneath the machine clean, neat, and free of debris and combustible materials. Make sure that the area overhead is clear of debris that could fall onto or into the machine or exhaust compartment. 1...

Page 12: Safety Information

Safety information g 85 wc_si000356gb.Fm 12 1.2 service safety a poorly maintained machine can become a safety hazard! In order for the machine to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. 1.2.1 never perform even routine servi...

Page 13: G 85

G 85 safety information wc_si000356gb.Fm 13 1.2.11 always remain aware of moving parts and keep hands, feet, and loose clothing away from the moving parts of the machine. 1.2.12 always replace all guards, fasten doors, and make sure all safety devices operate properly after making repairs or servici...

Page 14: Safety Information

Safety information g 85 wc_si000356gb.Fm 14 1.4 towing safety towing a large trailer requires special care. Both the trailer and vehicle must be in good condition and securely fastened to each other to reduce the possibility of an accident. 1.4.1 always check that the hitch and coupling on the vehic...

Page 15: Mobile Generator

Mobile generator theory of operation wc_tx001077gb.Fm 15 2 theory of operation 2.1 basic schematic ref. Component ref. Component a exciter stator winding g automatic voltage regulator (avr) b rotor assembly h main circuit breaker c exciter rotor winding i auxiliary winding d rotating rectifier (diod...

Page 16: Theory of Operation

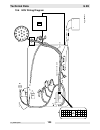

Theory of operation mobile generator wc_tx001077gb.Fm 16 2.2 introduction see graphic: wc_gr003303 a generator set is a transducer, which means it converts energy from one form (heat) into another (electrical). The two main components of a generator set are the prime mover (engine) and the generator...

Page 17: Mobile Generator

Mobile generator theory of operation wc_tx001077gb.Fm 17 wc_gr003303 c a a d e f b c b d e.

Page 18: Theory of Operation

Theory of operation mobile generator wc_tx001077gb.Fm 18 2.3 terminology see graphic: wc_gr003315 to understand the terms “phase”, “leg”, “line-to-line”, and “line-to- neutral”, review the following information. • the main stator (a) consists of three separate groups of windings. These groups of win...

Page 19: Mobile Generator

Mobile generator theory of operation wc_tx001077gb.Fm 19 l1 1 hz wc_gr003315 l2 l3 0˚ 45˚ 9 0˚ 135˚ 180˚ a c e f b 1 rev high wye low wye n l2 t6 t7 t5 t8 t 9 t10 t11 l3 l1 l-l (480v) l-l (208v) t4 t3 t2 t1 n l1 t2 l2 l-n t5 t8 t6 t1 l-n (277v) (120v) t4 l3 t11 t3 45˚ 9 0˚ 135˚ 180˚ 0˚ 225˚ 270˚ 315...

Page 20: Theory of Operation

Theory of operation mobile generator wc_tx001077gb.Fm 20 • since the legs are mechanically 120° apart, as the rotor spins, time elapses between the moment when one leg reaches its largest volt- age potential and the moment when the next leg reaches its largest voltage potential. Thus, no two legs re...

Page 21: Mobile Generator

Mobile generator theory of operation wc_tx001077gb.Fm 21 • wacker neuson generators are designed to accommodate various loads and multiple power factors. Power factor is the relationship between power supplied to the load (referred to as apparent power in kva) and true power (power used by the load ...

Page 22: Mobile Generator

Electrical testing techniques mobile generator 22 wc_tx000699gb.Fm 3 electrical testing techniques 3.1 checking continuity conduct continuity tests when the engine is shut down. When checking continuity, use the ohm setting on your multimeter. Place a lead of the multimeter on one end of the wiring ...

Page 23: Mobile Generator

Mobile generator electrical testing techniques wc_tx000699gb.Fm 23 3.4 probing ecm plugs and pins see graphic: wc_gr002926 to measure the voltage at an ecm pin, attach an appropriate extension (a) to the positive probe on your multimeter. Slide the positive probe into the plug along the wire of the ...

Page 24: Ecm Background Information

Ecm background information mobile generator 24 wc_tx000713gb.Fm 4 ecm background information 4.1 ecm handling precaution see graphic:wc_gr003355 notice : use care when working on or around the ecm. The ecm may be damaged or it may malfunction if it is accidentally hit by your hand or a tool. Do not ...

Page 25: Mobile Generator

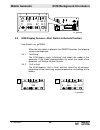

Mobile generator ecm background information wc_tx000713gb.Fm 25 4.2 normal boot-up sequence during the boot-up sequence, the ecm scrolls through several screens before it settles into displaying the run screen. There are two different boot-up sequences depending on size of the generator and options ...

Page 26: Ecm Background Information

Ecm background information mobile generator 26 wc_tx000713gb.Fm g 85 (9305), g 125, g 160 ecm display description start of the boot-up sequence. The ecm display reads “initializing” and shows the model of the generator. If the model displayed does not match the model of the gener- ator, call wacker ...

Page 27: Mobile Generator

Mobile generator ecm background information wc_tx000713gb.Fm 27 the ecm displays the ac configuration as determined by the position of the voltage selector switch (vss). The ecm displays this screen to let the operator know that the alternator protection system has been enabled. The ecm displays the...

Page 28: Ecm Background Information

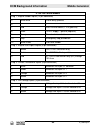

Ecm background information mobile generator 28 wc_tx000713gb.Fm 4.3 display variables and values see graphic: wc_gr002944 • generator variables the values shown in the top line of the ecm display are all variables from the generator side of the machine. They are: (1) voltage (v) (2) phase (Ø) (or le...

Page 29: Mobile Generator

Mobile generator ecm background information wc_tx000713gb.Fm 29 4.4 ecm display screens—start switch in remote position see graphic: wc_gr002943 when the start switch is placed in the remote position, the following screens are displayed. 4.4.1 “initializing” the ecm display reads “initializing” and ...

Page 30: Ecm Background Information

Ecm background information mobile generator 30 wc_tx000713gb.Fm 4.5 additional variables monitored by the ecm holding the toggle switch in the hours/reset position allows the operator to view additional variables monitored by the ecm. It also allows the time-to-service countdown timer to be reset. T...

Page 31: Mobile Generator

Mobile generator ecm background information wc_tx000713gb.Fm 31 g 25, g 50, g 85 (9310) cold weather and custom generators the display shows the status of the oil pressure sender. If the oil pressure sender has failed, the time of the failure will be displayed. The time of the failure will be includ...

Page 32: Ecm Background Information

Ecm background information mobile generator 32 wc_tx000713gb.Fm the display shows the status of the speed sender. If the speed sender has failed, the time of the failure will be dis- played. The time of the failure will be included in the dis- play until the generator has been shut down and remains ...

Page 33: Mobile Generator

Mobile generator ecm background information wc_tx000713gb.Fm 33 the display shows the value of the fault setting for low oil pressure. If the ecm detects that the engine oil pressure is less than 15 psi for longer than 15 seconds, the ecm will shut down the generator. The display shows this screen i...

Page 34: Ecm Background Information

Ecm background information mobile generator 34 wc_tx000713gb.Fm g 85 (9305), g 125, g160 john deere engines with ecu the display shows the status of the battery. When the battery voltage is within its “normal” range, 12 –15v, the ecm displays the voltage value in 1/10v increments on the run screen. ...

Page 35: Mobile Generator

Mobile generator ecm background information wc_tx000713gb.Fm 35 the display shows the present load on the engine. For no load conditions (generator not powering any outside tools or equipment) the display will read 15%. The display shows the percentage of total engine torque being used. The display ...

Page 36: Ecm Background Information

Ecm background information mobile generator 36 wc_tx000713gb.Fm 4.6 voltage display errors see graphic: wc_gr003308 • single-phase display mode when operating in the single-phase 120/240v position, line-to-line voltage will be displayed under p2 (240v). Line-to-neutral voltage (120v) will be display...

Page 37: Mobile Generator

Mobile generator ecm background information wc_tx000713gb.Fm 37 • engine hour switch in locked position another possible display error can occur when starting the machine with the engine hour switch (a) in the down (locked) position. This position is normally used to lock the display onto a single l...

Page 38: Ecm Background Information

Ecm background information mobile generator 38 wc_tx000713gb.Fm 4.7 ecm automatic engine shutdown conditions the engine protection system includes six automatic shutdown conditions: low oil pressure, high coolant temperature, engine underspeed/overspeed, engine overcrank, low fuel. The ecm will also...

Page 39: Mobile Generator

Mobile generator ecm background information wc_tx000713gb.Fm 39 4.8 ecm circuit boards note: your machine’s ecm board may differ slightly from the one pictured. Ref. Description a ac board b engine board c crank relay d fuel relay e preheat relay p1 power and engine sensing p2 power to crank, fuel a...

Page 40: Ecm Background Information

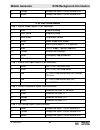

Ecm background information mobile generator 40 wc_tx000713gb.Fm 4.9 control wiring numbering & colors see graphic: wc_gr002924 generator and control wires are marked and color coded to assist in tracing line connections and troubleshooting. The charts below list wire labels and colors followed by a ...

Page 41: Mobile Generator

Mobile generator ecm background information wc_tx000713gb.Fm 41 3 orange voltage line input l3 at volt selector #28 4 yellow voltage line input l2 at volt selector #20 g 50/70/85 control module plug 1: engine sender inputs (12-pin connector) 1 black magnetic pickup 2 clear, shield magnetic pickup 3 ...

Page 42: Ecm Background Information

Ecm background information mobile generator 42 wc_tx000713gb.Fm g 125/160 control module plug 1: engine sender inputs (12-pin connector) 3 white-blue crank delay, preheat 5 - - 7 red run/off/auto switch, +12v (positive) 8 black 12vdc supply, - ground (negative) 9 orange remote start contacts 10 gray...

Page 43: Mobile Generator

Mobile generator ecm background information wc_tx000713gb.Fm 43 4.10 removing and installing the ecm see graphic: wc_gr003316 removal: 4.10.1 remove the nut securing the hour meter switch (a) and the nut securing the start switch (b) to the panel. 4.10.2 disconnect the four harness plugs (e). 4.10.3...

Page 44: Ecm/sensor Troubleshooting

Ecm/sensor troubleshooting mobile generator wc_tx000723gb.Fm 44 5 ecm/sensor troubleshooting 5.1 checking power to the ecm prerequisites fully-charged (12+ volts) battery procedure follow the procedure below to check the fuses. 1. Locate the 10a and 30a fuses near the john deere engine control unit ...

Page 45: Mobile Generator

Mobile generator ecm/sensor troubleshooting wc_tx000723gb.Fm 45 continued from the previous page. 5. Check the voltage between red wire #51 at b+ terminal strip and ground. Is at least 9.8v measured? 6. Check voltage between red wire #49 at start/run switch and ground. Is at least 9.8v measured? 7. ...

Page 46: Ecm/sensor Troubleshooting

Ecm/sensor troubleshooting mobile generator wc_tx000723gb.Fm 46 continued from the previous page. 9. Check the voltage between ecm pin 7 plug 1 (red wire #53) and pin 8 plug 1 (black wire #59). Is at least 9.8v measured? 10.Check the voltage between ecm pin 5 plug 2 (red wire #18) and ground. Is at ...

Page 47: Mobile Generator

Mobile generator ecm/sensor troubleshooting wc_tx000723gb.Fm 47 5.2 checking outgoing power from the ecm prerequisites fully-charged (12+ volts) battery at least 9.8vdc incoing power to ecm on red wires #18 and #53 procedure follow the procedure below to check the outgoing power from the ecm. 1. Ope...

Page 48: Ecm/sensor Troubleshooting

Ecm/sensor troubleshooting mobile generator wc_tx000723gb.Fm 48 5.3 checking temperature sender prerequisites fully-charged battery procedure follow the procedure below to check the ecm and the temperature sender. 1. Open the large hinged panel and locate the temperature sender. 2. Disconnect yellow...

Page 49: Mobile Generator

Mobile generator ecm/sensor troubleshooting wc_tx000723gb.Fm 49 continued from previous page. 10.Reconnect yellow wire #57 to the temperature sender. 11. Start the engine. 12.Measure the voltage between the sender and ground. 13.Find the voltage measured in the chart below. Does the voltage measured...

Page 50: Ecm/sensor Troubleshooting

Ecm/sensor troubleshooting mobile generator wc_tx000723gb.Fm 50 5.4 fuel sender failure and low fuel fault prerequisites fuel in fuel tank procedure follow the procedure below to check the ecm and fuel sender. 1. Open the large hinged panel and locate the fuel sender. 2. Disconnect white/violet (w/v...

Page 51: Mobile Generator

Mobile generator ecm/sensor troubleshooting wc_tx000723gb.Fm 51 5.5 calibrating ecm voltage display prerequisites functioning generator procedure follow the procedure below to calibrate the ecm voltage display. 1. Open the large hinged panel. Remove the “key” (latch) from the lug door and place it i...

Page 52: Ecm/sensor Troubleshooting

Ecm/sensor troubleshooting mobile generator wc_tx000723gb.Fm 52 5.6 calibrating ecm ac amperage display prerequisites functioning generator ammeter 25a or greater load procedure follow the procedure below to calibrate the ecm amperage display. 1. Attach a 25a or greater load to the lugs. 2. Place th...

Page 53: Mobile Generator

Mobile generator ecm/sensor troubleshooting wc_tx000723gb.Fm 53 5.7 calibrating ecm ac frequency display prerequisites functioning generator procedure follow the procedure below to calibrate the ecm ac frequency display. Note: recalibrate only if your unit is off by more than 5 hz. 1. Start the gene...

Page 54: Ecm/sensor Troubleshooting

Ecm/sensor troubleshooting mobile generator wc_tx000723gb.Fm 54 5.8 calibrating ecm dc display prerequisites functioning generator procedure follow the procedure below to calibrate the ecm dc voltage (12v battery) display. 1. Measure the voltage across the machine’s 12v battery using a multimeter. N...

Page 55: Mobile Generator

Mobile generator ecm/sensor troubleshooting wc_tx000723gb.Fm 55 5.9 checking the ecm can bus circuit prerequisites generator shut down ecm turned off procedure follow the procedure below to check the ecm can bus circuit. 1. Open the control panel. 2. Disconnect the can bus connector. 3. Measure the ...

Page 56: Ecm/sensor Troubleshooting

Ecm/sensor troubleshooting mobile generator wc_tx000723gb.Fm 56 5.10 checking the main circuit breaker prerequisites fully-charged battery emergency stop switch in disengaged (out) position. Procedure follow the procedure below to check the main circuit breaker. As a reminder, place a check mark nex...

Page 57: Mobile Generator

Mobile generator ecm/sensor troubleshooting wc_tx000723gb.Fm 57 5.11 ecm plugs and pins 12 11 10 9 8 7 6 5 4 3 2 1 6 5 4 1 2 3 4 3 1 2 8 7 6 5 4 3 2 1 dc plug 1 plug 2 plug 4 wc_gr003988 ac plug 3 ecm plug 1 wires ecm plug 2 wires pin wire description pin wire description 10 gr/61 emergency stop 5 r...

Page 58: Ecm/sensor Troubleshooting

Ecm/sensor troubleshooting mobile generator wc_tx000723gb.Fm 58 notes.

Page 59: Mobile Generator

Mobile generator john deere engines with ecu wc_tx000698gb.Fm 59 6 john deere engines with ecu 6.1 john deere engines with ecu background the tier ii john deere engines with electronic control systems are used on wacker neuson generator models g 85, g 125, and g 160. The electronic control system co...

Page 60: John Deere Engines With Ecu

John deere engines with ecu mobile generator wc_tx000698gb.Fm 60 6.2 locations of engine electrical components wc_gr003343 1 2 5 6 10 16 15 11 13 14 12 3 4 7 8 9.

Page 61: Mobile Generator

Mobile generator john deere engines with ecu wc_tx000698gb.Fm 61 6.3 engine electrical components see graphic: wc_gr003343 ref. Component ref. Component 1 main circuit breaker 9 starter relay 2 engine control module (ecm) 10 oil pressure sensor 3 alternator 11 engine control unit (ecu) 4 slave prehe...

Page 62: G 85

Engine starting troubleshooting g 85 wc_tx000678gb.Fm 62 7 engine starting troubleshooting 7.1 checking the fuses prerequisites fully-charged (12+ volts) battery procedure follow the procedure below to check the fuses. 1. Locate the 10a and 30a fuses near the john deere engine control unit (ecu). 2....

Page 63: G 85

G 85 engine starting troubleshooting wc_tx000678gb.Fm 63 7.2 checking the engine control module (ecm) prerequisites generator shut down procedure follow the procedure below to check the ecm. 1. Open the control panel and locate the ecm. 2. Place the start/run switch in the on position. Does the ecm ...

Page 64: G 85

Engine starting troubleshooting g 85 wc_tx000678gb.Fm 64 7.3 checking the emergency stop switch prerequisites generator shut down battery voltage measuring 11–13vdc procedure follow the procedure below to check the emergency stop switch. 1. Place the emergency stop switch in the de-activated (out) p...

Page 65: G 85

G 85 engine starting troubleshooting wc_tx000678gb.Fm 65 7.4 checking the starter relay prerequisites battery voltage measuring 11–13vdc procedure follow the procedure below to check the starter relay. 1. Locate the starter relay. 2. Check the voltage between the red wire running from the starter to...

Page 66: G 85

Engine starting troubleshooting g 85 wc_tx000678gb.Fm 66 7.5 checking the starter solenoid prerequisites battery voltage measuring 11–13vdc procedure follow the procedure below to check the starter solenoid. 1. Locate the starter and the starter solenoid. 2. Check the connection of the large red wir...

Page 67: G 85

G 85 engine starting troubleshooting wc_tx000678gb.Fm 67 7.6 checking the intake heater relay prerequisites battery voltage measuring 11–13vdc procedure follow the procedure below to check the intake heater relay. 1. Locate the intake heater relay. 2. Check the voltage between terminal 30 (red wire ...

Page 68: G 85

Engine starting troubleshooting g 85 wc_tx000678gb.Fm 68 7.7 checking the main circuit breaker prerequisites fully-charged battery emergency stop switch in disengaged (out) position. Procedure follow the procedure below to check the main circuit breaker. As a reminder, place a check mark next to the...

Page 69: Mobile Generator

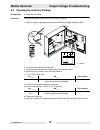

Mobile generator output voltage troubleshooting wc_tx000726gb.Fm 69 8 output voltage troubleshooting 8.1 checking the emergency stop switch prerequisites generator shut down procedure follow the procedure below to check the emergency stop switch. 1. Open the large hinged panel. Remove the "key" (lat...

Page 70: Mobile Generator

Output voltage troubleshooting mobile generator wc_tx000726gb.Fm 70 8.2 checking the lug door switch prerequisites generator shut down procedure follow the procedure below to check the lug door switch. 1. Open the large hinged panel. Remove the "key" (latch) from the lug door and place in the slot o...

Page 71: Mobile Generator

Mobile generator output voltage troubleshooting wc_tx000726gb.Fm 71 8.3 checking the main circuit breaker prerequisites fully-charged battery emergency stop switch in disengaged (out) position. Procedure follow the procedure below to check the main circuit breaker. As a reminder, place a check mark ...

Page 72: Mobile Generator

Output voltage troubleshooting mobile generator wc_tx000726gb.Fm 72 8.4 checking the voltage adjusting rheostat prerequisites generator shut down procedure follow the procedure below to check the voltage adjusting rheostat. 1. Open the control panel and locate the voltage adjusting rheostat. 2. Disc...

Page 73: Mobile Generator

Mobile generator output voltage troubleshooting wc_tx000726gb.Fm 73 8.5 checking the auxiliary winding prerequisites generator shut down procedure follow the procedures below to check the auxiliary winding. 1. Open the large hinged panel and locate the automatic voltage regulator (avr). 2. Disconnec...

Page 74: Mobile Generator

Output voltage troubleshooting mobile generator wc_tx000726gb.Fm 74 8.6 checking the exciter stator prerequisites generator shut down procedure follow the procedure below to check the exciter stator. 1. Open the large hinged panel and locate the automatic voltage regulator (avr). 2. Disconnect the b...

Page 75: Mobile Generator

Mobile generator output voltage troubleshooting wc_tx000726gb.Fm 75 8.7 checking the avr sensing wires prerequisites generator shut down procedure follow the procedure below to check the avr sensing wires. 1. Open the large hinged panel and locate the engine control module (ecm) and the auto- matic ...

Page 76: Mobile Generator

Output voltage troubleshooting mobile generator wc_tx000726gb.Fm 76 8.8 flashing the generator (checking the excitation system) prerequisites source of 12vdc procedure follow the procedure below to flash the generator. 1. Open the large hinged panel and locate the automatic voltage regulator (avr). ...

Page 77: Mobile Generator

Mobile generator output voltage troubleshooting wc_tx000726gb.Fm 77 8.9 checking stator windings at the lugs prerequisites generator shut down two alligator clips each connected to 12 inches of 14-gauge wire procedure follow the procedure below to check the stator windings at the lugs. 1. Place the ...

Page 78: Mobile Generator

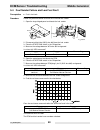

Output voltage troubleshooting mobile generator wc_tx000726gb.Fm 78 8.10 checking the rectifier diodes—thread-in style prerequisites generator shut down procedure follow the procedures below to check the rectifier diodes. 1. Remove the rear baffle from the machine. 2. Remove the cover from the gener...

Page 79: Mobile Generator

Mobile generator output voltage troubleshooting wc_tx000726gb.Fm 79 8.11 checking the rectifier diodes—solder-in style prerequisites generator shut down procedure follow the procedures below to check the rectifier diodes. 1. Remove the rear baffle (a) from the machine. 2. Remove the cover (b) from t...

Page 80: Mobile Generator

Output voltage troubleshooting mobile generator wc_tx000726gb.Fm 80 8.12 checking the main rotor winding prerequisites generator shut down procedure follow the procedure below to check the main rotor winding. 1. Remove the rear baffle from the machine. 2. Remove the cover from the generator. 3. Remo...

Page 81: Mobile Generator

Mobile generator output voltage troubleshooting wc_tx000726gb.Fm 81 8.13 checking the exciter rotor winding prerequisites generator shut down procedure follow the procedure below to check the exciter rotor winding. 1. Remove the rear baffle from the machine. 2. Remove the cover from the generator. 3...

Page 82: Mobile Generator

Output voltage troubleshooting mobile generator wc_tx000726gb.Fm 82 8.14 checking stator windings at the voltage selector switch prerequisites generator shut down procedure 1. Follow the procedure below to check the main stator windings at the generator. 2. Remove the cover from the voltage selector...

Page 83: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 83 9 disassembly/assembly 9.1 tools because all possible problems encountered while repairing the machine cannot be anticipated, it is up to the mechanic to use common sense and good judgement in tool selection. The use of any special tools is r...

Page 84: Disassembly/assembly

Disassembly/assembly mobile generator 84 wc_tx000575gb.Fm 9.5 removing the roof see graphic: wc_gr003320 this procedure requires an appropriate crane capable of lifting 227 kg (500 lbs.). 9.5.1 disconnect the battery. 9.5.2 remove the doors (a) . 9.5.3 remove the front and rear access panels (b and ...

Page 85: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 85 c h b d d e f g a wc_gr003320 a.

Page 86: Disassembly/assembly

Disassembly/assembly mobile generator 86 wc_tx000575gb.Fm 9.6 preparing unit for generator removal see graphic: wc_gr003321 9.6.1 remove the roof. See section removing roof . 9.6.2 remove the screws that secure the air filter assembly and set the air filter assembly off to the side. 9.6.3 remove the...

Page 87: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 87 wc_gr003321 a f e j i h b c d g.

Page 88: Disassembly/assembly

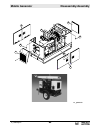

Disassembly/assembly mobile generator 88 wc_tx000575gb.Fm 9.7 replacing the generator see graphic: wc_gr003322 this procedure requires an appropriate crane capable of lifting 365 kg (800 lbs.). Removal: 9.7.1 see section preparing unit for generator removal . 9.7.2 remove the screens (a) from both s...

Page 89: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 89 wc_gr003322 a b c c d d g 25 g 50, g 70, g 85 a g 50, g 70, g 85 g 25.

Page 90: Disassembly/assembly

Disassembly/assembly mobile generator 90 wc_tx000575gb.Fm 9.8 removing the avr prerequisites machine shut down procedure follow the procedure below to remove the automatic voltage regulator (avr). 9.8.1 remove the screws that secure the large access panel (a) and open the large access panel. 9.8.2 m...

Page 91: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 91 9.9 installing the avr prerequisites • machine shut down • multimeter procedure follow the procedure below to install and set the automatic voltage regulator (avr). 9.9.1 check the function of the voltage adjusting rheostat. See section check...

Page 92: Disassembly/assembly

Disassembly/assembly mobile generator 92 wc_tx000575gb.Fm continued from the previous page. 9.9.5 place the voltage selector switch in the 208/120v position. 9.9.6 never adjust the avr voltage pot with the voltage selector switch in any other position. Damage to the generator may occur. 9.9.7 loosen...

Page 93: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 93 continued from the previous page. 9.9.11 check the voltage between lug 1 and lug 2 with a multimeter. 9.9.12 adjust the volt pot of the avr until 250 vac is measured between lug 1 and lug 2.Test the consistency by checking the voltage across ...

Page 94: Disassembly/assembly

Disassembly/assembly mobile generator 94 wc_tx000575gb.Fm continued from the previous page. 9.9.17 check the consistency between the voltage measured at the lugs by the multimeter and that shown on the ecm display. If the ecm display is off by more than 2%, adjust the volt pot on the ecm so that the...

Page 95: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 95 notes.

Page 96: Disassembly/assembly

Disassembly/assembly mobile generator 96 wc_tx000575gb.Fm 9.10 removing the engine see graphic: wc_gr003351 this procedure requires an appropriate crane capable of lifting 1000 kg (2200 lbs.). 9.10.1 remove the roof. See section removing the roof . 9.10.2 remove the generator. See section removing t...

Page 97: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 97 wc_gr003351 a c c e g b d f.

Page 98: Disassembly/assembly

Disassembly/assembly mobile generator 98 wc_tx000575gb.Fm 9.11 installing the engine see graphic: wc_gr003352 this procedure requires an appropriate crane capable of lifting 1000 kg (2200 lbs.). 9.11.1 using as appropriate hoist or crane, lower the engine into the frame. 9.11.2 secure the engine to ...

Page 99: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 99 wc_gr003352 a c c e g b d f.

Page 100: Disassembly/assembly

Disassembly/assembly mobile generator 100 wc_tx000575gb.Fm 9.12 replacing the fuel tank see graphic: wc_gr003350 this procedure requires a crane or hoist capable of lifting 1900 kgs. (2000 lbs.). Removal: 9.12.1 disconnect the fuel hoses and the fuel sender wiring. 9.12.2 remove the screws that secu...

Page 101: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 101 a c b b wc_gr003350

Page 102: Disassembly/assembly

Disassembly/assembly mobile generator 102 wc_tx000575gb.Fm 9.13 replacing the emergency stop switch (older) turn off the generator before replacing the emergency stop switch. Removal: 9.13.1 slide the locking tab (a) to the unlock position and pull the switch off the pushbutton. 9.13.2 label and dis...

Page 103: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 103 wc_gr003286 a b c.

Page 104: Disassembly/assembly

Disassembly/assembly mobile generator 104 wc_tx000575gb.Fm 9.14 replacing the emergency stop switch (newer) see graphic: wc_gr003677 turn off the generator and disconnect the battery before replacing the emergency stop switch. Removal: 9.14.1 slide the locking tab (a) to the unlock position and pull...

Page 105: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 105.

Page 106: Disassembly/assembly

Disassembly/assembly mobile generator 106 wc_tx000575gb.Fm 9.15 replacing the diodes prerequisites • solder (flux core 60-40) • soldering iron ( • heat sink putty or two alligator clips to act as heat sinks • epoxy procedure follow the procedure below to replace the diodes. 9.15.1 remove the rear ac...

Page 107: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 107 continued from the previous page. 9.15.6 add a small amount of epoxy to the diode holder. 9.15.7 insert the diode (e) into the holder. Red marking faces to the right. 9.15.8 cut (f) any excess wire from the new diode. 9.15.9 add heat sinks (...

Page 108: Disassembly/assembly

Disassembly/assembly mobile generator 108 wc_tx000575gb.Fm 9.16 replacing the voltage selector switch (vss) see graphic: wc_gr003284 electric shock hazard. Turn off the generator before replacing the voltage selector switch (vss). Removal: 9.16.1 remove the air filter and the cover of the vss box (a...

Page 109: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 109 wc_gr003284 b a c d e.

Page 110: Disassembly/assembly

Disassembly/assembly mobile generator 110 wc_tx000575gb.Fm 9.17 g 50, g 70, g 85 vss wiring wc_gr003928 t2 t6 t11 l0 n l1 t12 l2 1 5 9 13 17 21 25 3 br 7 11 15 19 23 27 26 22 18 14 10 6 2 28 24 20 16 12 8 4 l3 l2 t10 t7 n t3 or ecm ecm ecm tb* tb** tb ts ts gen gen gen cb gen ts ts lug cb ts t5 gen ...

Page 111: Mobile Generator

Mobile generator disassembly/assembly wc_tx000575gb.Fm 111 notes.

Page 112: Technical Data

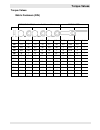

Technical data g 85 wc_td000214gb.Fm 112 10 technical data 10.1 engine data item number: g 85 0009369 0009459 0620003 rev 114 & lower g 85 0620003 rev 115 & above engine engine make / type john deere / 4.5l model 4045tf275 number of cylinders 4 displacement l (in 3 ) 4.5 (274.6) engine speed rpm 180...

Page 113: G 85

G 85 technical data wc_td000214gb.Fm 113 10.2 generator data item number: g 85 0009369 0009459 0620003 generator make/type mecc alte / brushless model eco32-3l/4 generator speed rpm 1800 voltage selector switch 3 position ac voltages available 120/240 zig-zag 120/208 low-wye 277/480 hi-wye frequency...

Page 114: Technical Data

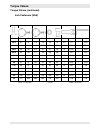

Technical data g 85 wc_td000214gb.Fm 114 10.3 trailer and skid data item number: g 85 0009369 g 85 0009459 0620003 trailer and skid dry weight of skid kg (lbs.) 1580 (3484) 1621 (3574) operating weight of skid kg (lbs.) 1868 (4120) 1909 (4210) trailer weight kg (lbs.) single axle 442 (975) tandem ax...

Page 115: G 85

G 85 technical data wc_td000214gb.Fm 115 10.4 dimensions mm (inches) machine a b c d e f g g 85 965 (38) 1970 (77.5) 1703 (67) 3923 (154.5) 2445 (96.3) 1346 (53) 1475 (58) wc_gr006389 a b d e f g c.

Page 116: Technical Data

Technical data g 85 wc_td000214gb.Fm 116 10.5 engine wiring diagram—john deere with ecu 87 412 050d 422 429 082 050 21 222 2 20 k3 g2 k1 a2 g1 f1 j2 wc_g r004699 john deere ecu ecm j b g a d e f u v a1 a2 a3 b1 b2 b3 c1 c2 c3 d1 d2 d3 e1 e2 e3 f1 f2 f3 g1 g2 g3 h1 h2 h3 j1 j2 j3 k1 k2 k3 si cp cg so...

Page 117: G 85

G 85 technical data wc_td000214gb.Fm 117 engine wiring components—john deere with ecu ref. Description ref. Description 1 plug 1 — engine sender inputs 14 battery 2 plug 2 — engine start/run outputs 15 ecm 10a fuse 3 main circuit breaker (3-phase lugs) 16 starter relay 4 shunt trip coil 17 starter 5...

Page 118: Technical Data

Technical data g 85 wc_td000214gb.Fm 118 87 412 050d 422 429 082 050 21 222 2 20 k3 g2 k1 a2 g1 f1 j2 wc_g r002816 john deere ecu ecm j b g a d e f u v a1 a2 a3 b1 b2 b3 c1 c2 c3 d1 d2 d3 e1 e2 e3 f1 f2 f3 g1 g2 g3 h1 h2 h3 j1 j2 j3 k1 k2 k3 si cp cg so g 23 23 26 24 25 h j b c d e f a 14 14 w a c k...

Page 119: G 85

G 85 technical data wc_td000214gb.Fm 119 engine wiring components—john deere with ecu ref. Description ref. Description 1 plug 1 — engine sender inputs 14 battery 2 plug 2 — engine start/run outputs 15 ecm 10a fuse 3 main circuit breaker (3-phase lugs) 16 starter relay 4 shunt trip coil 17 starter 5...

Page 120: Technical Data

Technical data g 85 wc_td000214gb.Fm 120 10.6 ecu wiring diagram a1 a2 a3 b1 b2 b3 c1 c2 c3 d1 d2 d3 e1 e2 e3 f1 f2 f3 g1 g2 g3 h1 h2 h3 j1 j2 j3 k1 k2 k3 – + john deere ecu 463 418 n/a 050g 012d 002d 914f 429 412 461 914e 428 914d 491 493 467 911 914b 012c betw een a2 and g 022c to k1 447 448 050 0...

Page 121: G 85

G 85 technical data wc_td000214gb.Fm 121 10.7 ecu harness connector see graphic: wc_gr002817 ref. Wire color/# destination ref. Wire color/# destination a1 --- --- f1 green/905 can bus a2 red/012c harness connector (hc) terminal g f2 --- --- a3 orange/493 fuel control solenoid f3 violet/467 oil pres...

Page 122: Technical Data

Technical data g 85 wc_td000214gb.Fm 122 10.8 generator wiring diagram bom rev 0009369 124+ 0009459 133+ 0620003 129+.

Page 123: G 85

G 85 technical data wc_td000214gb.Fm 123 see graphic: wc_gr004692 ref. Description ref. Description 1 lug door (safety interlock) switch 15 voltage selector switch (vss) 2 mechanical lugs 16 generator 3 plug 3 - current transformer inputs 17 automatic voltage regulator (avr) 4 plug 4 - line voltage ...

Page 124: Technical Data

Technical data g 85 wc_td000214gb.Fm 124 wc_g r003296 3 4 13 14 27 28 2 1 4 3 3 2 1 6 5 4 bom rev 0009369 100–123 0009459 100–132 0620003 100–128.

Page 125: G 85

G 85 technical data wc_td000214gb.Fm 125 see graphic: wc_gr003296 ref. Description ref. Description 1 lug door (safety interlock) switch 15 voltage selector switch (vss) 2 mechanical lugs 16 generator 3 plug 3 - current transformer inputs 17 automatic voltage regulator (avr) 4 plug 4 - line voltage ...

Page 126: Threadlockers and Sealants

Threadlockers and sealants threadlockers and sealants threadlocking adhesives and sealants are specified throughout this manual by a notation of “s” plus a number (s#) and should be used where indicated. Threadlocking compounds normally break down at temperatures above 175°c (350°f). If a screw or b...

Page 127: Threadlockers and Sealants

Threadlockers and sealants threadlockers and sealants (continued) threadlocking adhesives and sealants are specified throughout this manual by a notation of “s” plus a number (s#) and should be used where indicated. Threadlocking compounds normally break down at temperatures above 175°c (350°f). If ...

Page 128: Torque Values

Torque values torque values metric fasteners (din) torque values (based on bolt size and hardness) wrench size size nm ft.Lb. Nm ft.Lb. Nm ft.Lb. Metric inch metric inch m3 1.2 *11 1.6 *14 2.1 *19 5.5 7/32 2.5 – m4 2.9 *26 4.1 *36 4.9 *43 7 9/32 3 – m5 6.0 *53 8.5 6 10 7 8 5/16 4 – m6 10 7 14 10 17 ...

Page 129: Torque Values

Torque values torque values (continued) inch fasteners (sae) size nm ft.Lb. Nm ft.Lb. Nm ft.Lb. Metric inch metric inch no.4 0.7 *6 1.0 *14 1.4 *12 5.5 1/4 – 3/32 no.6 1.4 *12 1.9 *17 2.4 *21 8 5/16 – 7/64 no.8 2.5 *22 3.5 *31 4.7 *42 9 11/32 – 9/64 no.10 3.6 *32 5.1 *45 6.8 *60 – 3/8 – 5/32 1/4 8.1...

Page 130

Wacker neuson se · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02-0 · fax: +49 - (0)89-3 54 02-390 wacker neuson corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker neuson limited - room 1701–03 & 171...