- DL manuals

- Wacker Neuson

- Heater

- HI 400 HD D

- Operator's Manual

Wacker Neuson HI 400 HD D Operator's Manual

Summary of HI 400 HD D

Page 1

0192824 001 1110 0 1 9 2 8 2 4 operator’s manual indirect-fired air heaters hi 400 hd d hi 400 hd g.

Page 2

Copyright notice © copyright 2010 by wacker neuson corporation. All rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permission from wack...

Page 3: Foreword

Foreword ghi_tx001460gb.Fm 3 foreword this heater is designed and approved for use as a construction heater in accordance with standard ansi z83.7–csga 2.14. Check with your local fire safety authority if you have questions about applications. Other standards govern the use of fuel gases and heat pr...

Page 4: Foreword

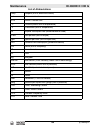

Foreword 4 ghi_tx001460gb.Fm machines covered by this manual this manual covers machines with the following item numbers: machine documentation keep a copy of the operator’s manual with the machine at all times. Use the separate parts book supplied with the machine to order replacement parts. If you...

Page 5: Hi 400Hd D / Hd G

Hi 400hd d / hd g table of contents wc_bo0182003en_001toc.Fm 5 foreword 3 1 safety information 7 1.1 signal words used in this manual ....................................................... 7 1.2 machine description and intended use ............................................... 8 1.3 operating saf...

Page 6: Table of Contents

Table of contents hi 400hd d / hd g 6 wc_bo0182003en_001toc.Fm 4.21 starting the machine (d models) .........................................................39 4.22 starting the machine (g models) .........................................................40 4.23 stopping ................................

Page 7: Hi 400Hd D / Hd G

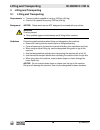

Hi 400hd d / hd g safety information ghi_si000468gb.Fm 7 1 safety information 1.1 signal words used in this manual this manual contains danger, warning, caution, notice, and note signal words which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper se...

Page 8: Safety Information

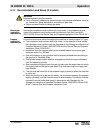

Safety information hi 400hd d / hd g 8 ghi_si000468gb.Fm 1.2 machine description and intended use machine description the hi heater is an indirect-fired air heater. Depending on the model, the machine operates either on diesel fuel (oil) or natural gas / liquid propane (lp). The machine consists of ...

Page 9: Hi 400Hd D / Hd G

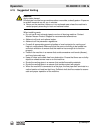

Hi 400hd d / hd g safety information ghi_si000468gb.Fm 9 1.3 operating safety operator training before operating the machine: read and understand the operating instructions contained in all manuals delivered with the machine. Familiarize yourself with the location and proper use of all controls and ...

Page 10: Safety Information

Safety information hi 400hd d / hd g 10 ghi_si000468gb.Fm keep the area immediately surrounding and underneath the machine clean, neat, and free of debris and combustible materials. Keep the area above the machine clear of debris that could fall on the machine. Keep unauthorized personnel, children,...

Page 11: Hi 400Hd D / Hd G

Hi 400hd d / hd g safety information ghi_si000468gb.Fm 11 1.5 safety guidelines for operating combustion burners when using the machine: clean up any spilled fuel immediately. Replace the fuel tank cap after refueling the machine. Refill the fuel tank in a well-ventilated area. Make sure you have pr...

Page 12: Safety Information

Safety information hi 400hd d / hd g 12 ghi_si000468gb.Fm 1.6 service safety personal protective equipment (ppe) wear the following personal protective equipment (ppe) while servicing or maintaining this machine: close-fitting work clothes that do not hinder movement safety glasses with side shields...

Page 13: Hi 400Hd D / Hd G

Hi 400hd d / hd g safety information ghi_si000468gb.Fm 13 accessories, safety devices and modifications when using the machine: use only accessories/attachments that are recommended by wacker neuson corporation. When using the machine: never operate the machine if any safety devices or guards are mi...

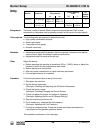

Page 14: Labels

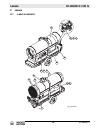

Labels hi 400hd d / hd g 14 ghi_si000469gb.Fm 2 labels 2.1 label locations ghi_gr007391 a c h f (4) o j b e r p k m d g q k.

Page 15: Hi 400Hd D / Hd G

Hi 400hd d / hd g labels ghi_si000469gb.Fm 15 2.2 label meanings a warning! Hot surface! B warning entanglement hazard. Rotating machinery. Do not reach inside machine when engine is running. C notice lifting point. D warning! Electric shock hazard. Disconnect power before servicing. Read operator’s...

Page 16: Labels

Labels hi 400hd d / hd g 16 ghi_si000469gb.Fm g danger using a heater indoors can kill you in minutes. Heater exhaust contains carbon monoxide. This is a poison you cannot see or smell. During indoor operation, vent exhaust gas outdoors. Refer to operator's manual. H caution hot while in operation. ...

Page 17: Hi 400Hd D / Hd G

Hi 400hd d / hd g labels ghi_si000469gb.Fm 17 n warning licensed gas technician required. Natural gas / liquid propane burner setup and installation, fuel supply connection, test firing, and burner adjustment must be performed by a licensed professional gas technician and must conform to the require...

Page 18: Lifting and Transporting

Lifting and transporting hi 400hd d / hd g 18 ghi_tx001461gb.Fm 3 lifting and transporting 3.1 lifting and transporting requirements transport vehicle capable of carrying 1000 lbs (454 kg) crane or lift capable of carrying 1000 lbs (454 kg) background notice: these machines are not designed to be to...

Page 19: Hi 400Hd D / Hd G

Hi 400hd d / hd g operation ghi_tx001462gb.Fm 19 4 operation 4.1 preparing the machine for first use preparing for first use to prepare your machine for first use: 1. Make sure all loose packaging materials have been removed from the machine. 2. Check the machine and its components for damage. If th...

Page 20: Operation

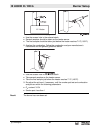

Operation hi 400hd d / hd g 20 ghi_tx001462gb.Fm 4.3 installing the front duct adapter overview the front duct adapter provided with your machine is shipped loose and must be installed before operating the machine. The thermostat probe must also be installed on the inside of the duct adapter during ...

Page 21: Hi 400Hd D / Hd G

Hi 400hd d / hd g operation ghi_tx001462gb.Fm 21 4.4 installing the rear duct adapter (optional) overview the optional rear duct adapter is shipped loose and must be installed before operating the machine. Procedure follow the procedure below to install the rear duct adapter. 1. Loosen, but do not r...

Page 22: Operation

Operation hi 400hd d / hd g 22 ghi_tx001462gb.Fm 4.5 control / component locations machine components a ref description ref description a exhaust flue f air inlet and fan guard b control panel g access panel c manual transport handle h fuel filter (d units) d fuel fill location (d units only) i gas ...

Page 23: Hi 400Hd D / Hd G

Hi 400hd d / hd g operation ghi_tx001462gb.Fm 23 4.6 adjusting the handle height overview your machine is equipped with a manual transport handle. The handle height can be adjusted to suit the operator’s preference. Procedure follow the procedure below to adjust the handle height. 1. Loosen, but do ...

Page 24: Operation

Operation hi 400hd d / hd g 24 ghi_tx001462gb.Fm 4.7 positioning the machine guidelines observe the following guidelines when positioning the machine for operation. Installer must be familiar with all applicable laws, codes, regulations, or other restrictions regarding installation of indirect-fired...

Page 25: Hi 400Hd D / Hd G

Hi 400hd d / hd g operation ghi_tx001462gb.Fm 25 electrical requirements ensure that the machine is connected to a reliable, consistent source of electric power. The electric power source must be grounded per the requirements below and connected to a freely accessible circuit breaker. Ensure that ex...

Page 26: Operation

Operation hi 400hd d / hd g 26 ghi_tx001462gb.Fm 4.8 control panel—oil burner (d models) control panel components symbols and meanings 0 reset ref description ref description a burner fault lamp and reset button (dual function) d firing mode switch (high-fire or low-fire) b mode switch (on-off-on) s...

Page 27: Hi 400Hd D / Hd G

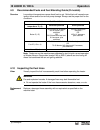

Hi 400hd d / hd g operation ghi_tx001462gb.Fm 27 4.9 recommended fuels and fuel blending guide (d models) overview low ambient temperatures cause diesel fuels to gel. Gelled fuels will cause burner ignition failure and/or burner fuel pump damage. Always use the proper fuel for the conditions. Note: ...

Page 28: Operation

Operation hi 400hd d / hd g 28 ghi_tx001462gb.Fm 4.11 control panel—gas burner (g models) control panel components symbols and meanings 0 reset wc_gr007770 ref description ref description a burner fault lamp and reset button (dual function) d burner indicator b mode switch (on-off-on) see topic star...

Page 29: Hi 400Hd D / Hd G

Hi 400hd d / hd g operation ghi_tx001462gb.Fm 29 4.12 gas installation and setup (g models) natural gas installation requirements natural gas installation must conform with local codes. In the absence of local codes, the installation must conform with the national fuel gas code ansi z223.1/nfpa 54 a...

Page 30: Operation

Operation hi 400hd d / hd g 30 ghi_tx001462gb.Fm 4.13 connecting the gas line (g models) overview the hi 400hd-g heater includes a 3/4” npt inlet (a) on the gas safety valve / pressure regulator body. The gas supply line connects to the inlet. Gas pressures the table below lists the minimum and maxi...

Page 31: Hi 400Hd D / Hd G

Hi 400hd d / hd g operation ghi_tx001462gb.Fm 31 4.14 setting the gas selector valve (g models) overview your machine is configured at the factory to operate on natural gas. The gas selector valve on the gas train allows you to convert the machine from natural gas to lp as job site conditions requir...

Page 32: Operation

Operation hi 400hd d / hd g 32 ghi_tx001462gb.Fm 4.15 suggested venting when installing vents: do not use b-vent exhaust pipes to vent an oil burning machine. Contact wacker neuson product support for recommended alternatives. Adhere to all local and national codes. Adhere to all fire prevention reg...

Page 33: Hi 400Hd D / Hd G

Hi 400hd d / hd g operation ghi_tx001462gb.Fm 33 note: the above venting diagram shows suggested venting layouts only. Consult all appropriate governing bodies or local contractor for venting and fresh air requirements..

Page 34: Operation

Operation hi 400hd d / hd g 34 ghi_tx001462gb.Fm 4.16 installing the heater duct overview optional ducts can be connected to the air outlet. This allows warm air to be evenly distributed throughout the heating area. Notice: when using ducts, observe the static air pressure limits specified in techni...

Page 35: Hi 400Hd D / Hd G

Hi 400hd d / hd g operation ghi_tx001462gb.Fm 35 4.17 installing the remote thermostat or receptacle cap requirements remote thermostat, or thermostat receptacle cap background the control panel includes a receptacle for an optional remote thermostat (b). The receptacle is protected by an attached c...

Page 36: Operation

Operation hi 400hd d / hd g 36 ghi_tx001462gb.Fm 4.18 connecting power to the machine (preheating) requirements power source (115vac) machine properly positioned operation mode switch in the off (0) position ] extension cords restrictions for extension cords: use only 3-wire type extension cords wit...

Page 37: Hi 400Hd D / Hd G

Hi 400hd d / hd g operation ghi_tx001462gb.Fm 37 4.19 starting the machine in extremely cold weather background in temperatures below 32°f (0°c), it may be necessary to preheat the fuel inside the fuel filter canister. The fuel filter canister is equipped with a low-wattage heating element specially...

Page 38: Operation

Operation hi 400hd d / hd g 38 ghi_tx001462gb.Fm 4.20 before starting requirements machine properly positioned power connected to the machine checks before starting the machine, check the following items: result the machine is ready to turn on. Item task fuel sight gauge (if equipped) check that the...

Page 39: Hi 400Hd D / Hd G

Hi 400hd d / hd g operation ghi_tx001462gb.Fm 39 4.21 starting the machine (d models) requirements machine properly positioned power connected pre-starting checks completed procedure to start the machine, follow the procedure below. 1. Select an operation mode. A. Continuous heat mode (i) b. Thermos...

Page 40: Operation

Operation hi 400hd d / hd g 40 ghi_tx001462gb.Fm 4.22 starting the machine (g models) requirements machine properly positioned power connected pre-starting checks completed procedure to start the machine, follow the procedure below. 1. Select an operation mode (b). A. Continuous heat mode (i) b. The...

Page 41: Hi 400Hd D / Hd G

Hi 400hd d / hd g operation ghi_tx001462gb.Fm 41 4.23 stopping procedure follow the procedure below to stop the machine. 1. Turn the operation mode switch to the off (0) position (c). Shutdown sequence the following sequence of events will occur after turning the machine off. 1. The burner will shut...

Page 42: Operation

Operation hi 400hd d / hd g 42 ghi_tx001462gb.Fm 4.25 installing and using the remote thermostat requirements remote thermostat pre-starting checks complete procedure follow the procedure below to install and use the remote thermostat. 1. Remove the thermostat receptacle plug (a) from the control pa...

Page 43: Hi 400Hd D / Hd G

Hi 400hd d / hd g accessories ghi_tx001463gb.Fm 43 5 accessories 5.1 available accessories introduction wacker neuson corporation offers many optional accessories for this machine. These accessories are described below. Contact your local wacker neuson dealer or visit www.Wackerneuson.Com for orderi...

Page 44: Burner Setup

Burner setup hi 400hd d / hd g 44 ghi_tx001464gb.Fm 6 burner setup 6.1 removing the access panel requirements machine shut down and cooled machine properly positioned over overview your machine is equipped with a removable access panel. The access panel must be removed in order to maintain and repai...

Page 45: Hi 400Hd D / Hd G

Hi 400hd d / hd g burner setup ghi_tx001464gb.Fm 45 6.2 removing and installing the burner note: although an oil burning machine (d model) is shown in the photos below, the procedure for removing the burner assembly on a gas burning machine (g model) is similar. Requirements machine shut down and co...

Page 46: Burner Setup

Burner setup hi 400hd d / hd g 46 ghi_tx001464gb.Fm factory settings background the burner consists of several different components and subsystems. Each of these components or subsystems must be operating correctly for the burner to function properly. Tools required the following tools are required ...

Page 47: Hi 400Hd D / Hd G

Hi 400hd d / hd g burner setup ghi_tx001464gb.Fm 47 use the access hole in the exhaust stack. Several samples should be taken as the heater warms. The final sample should be taken just before the heater reaches 71°c (160°f). 8. Analyze the combustion. Follow the combustion analyzer manufacturer’s in...

Page 48: Burner Setup

Burner setup hi 400hd d / hd g 48 ghi_tx001464gb.Fm 6.3 inspecting the oil burner electrodes (d models) requirements machine shut down power disconnected burner cool when to inspect inspect the electrodes on your machine every two weeks or after every 50 hours of operation. The condition of the elec...

Page 49: Hi 400Hd D / Hd G

Hi 400hd d / hd g burner setup ghi_tx001464gb.Fm 49 6.4 checking/changing the burner nozzle (d models) prerequisites machine shut down and cool to the touch machine properly positioned when replace the burner nozzle annually, or if it is damaged. To replace the burner nozzle, carry out the following...

Page 50: Burner Setup

Burner setup hi 400hd d / hd g 50 ghi_tx001464gb.Fm 6.5 adjusting the burner air damper setting requirements machine shut down power disconnected procedure perform the procedure below to check and adjust the burner air damper setting. 1. Shut down the machine and allow it to cool. 2. Disconnect the ...

Page 51: Hi 400Hd D / Hd G

Hi 400hd d / hd g burner setup ghi_tx001464gb.Fm 51 6.6 adjusting the fuel pressure (d models) requirements machine shut down and cool to the touch power disconnected fuel pressure gauge flat-bladed screwdriver background the information below will show you how to check the fuel pressure on your mac...

Page 52: Burner Setup

Burner setup hi 400hd d / hd g 52 ghi_tx001464gb.Fm checking high pressure 7. Set the mode switch to high fire mode (ii). Wait approximately 30 seconds to allow the burner to switch from stage i to stage ii. 8. Verify the high pressure fuel pressure setting. For the correct setting, refer to the tec...

Page 53: Hi 400Hd D / Hd G

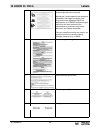

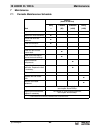

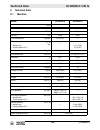

Hi 400hd d / hd g maintenance ghi_tx001465gb.Fm 53 7 maintenance 7.1 periodic maintenance schedule task interval* (hours of service) daily 2 weeks 6 months yearly --- (50) (1000) (1200) inspect the heater. Inspect the hose assembly. Check fuel level and pressure. Clean the machine. Clean the fuel fi...

Page 54: Maintenance

Maintenance hi 400hd d / hd g 54 ghi_tx001465gb.Fm 7.2 changing the fuel heater filter (d models) prerequisites machine shut down burner cool procedure follow the procedure below to change the fuel heater filter. 1. Shut down the machine and allow it to cool. 2. Remove the screw that secures the cov...

Page 55: Hi 400Hd D / Hd G

Hi 400hd d / hd g maintenance ghi_tx001465gb.Fm 55 7.3 inspecting and cleaning the cadmium (cad) cell prerequisites machine shut down and cool to the touch machine properly positioned when inspect and clean the cad cell as needed, or while performing other scheduled maintenance procedures. To inspec...

Page 56: Maintenance

Maintenance hi 400hd d / hd g 56 ghi_tx001465gb.Fm 7.4 cleaning the fan blades and motor prerequisites machine shut down and cool to the touch power source disconnected when clean the fan blades and motors prior to the first seasonal use, every 1200 hours or annually, or as needed. To clean the fan ...

Page 57: Hi 400Hd D / Hd G

Hi 400hd d / hd g maintenance ghi_tx001465gb.Fm 57 7.5 cleaning the interior shell prerequisites machine shut down and cool to the touch power source disconnected when clean the interior shell prior to the first seasonal use, every 1200 hours or annually, or as needed. To clean the interior shell, c...

Page 58: Maintenance

Maintenance hi 400hd d / hd g 58 ghi_tx001465gb.Fm 7.6 inspecting the flame head prerequisites machine shut down and cool to the touch machine properly positioned when inspect the flame head prior to the first seasonal use, during regular maintenance, and as needed. Procedure to inspect the flame he...

Page 59: Hi 400Hd D / Hd G

Hi 400hd d / hd g maintenance ghi_tx001465gb.Fm 59 7.7 inspecting the electrical connections after disconnecting the power cord, check all electrical connections for the following: proper connections. Be sure that all connections are complete and tight. Corrosion. Clean or replace if necessary. Dama...

Page 60: Maintenance

Maintenance hi 400hd d / hd g 60 ghi_tx001465gb.Fm list of abbreviations amp ampere (unit of electrical current) asl above sea level btu british thermal unit °c celsius (metric unit of temperature) °f fahrenheit (unit of temperature) ft 2 square foot/square feet (measurement of area) ft.Lbs. Foot po...

Page 61: Hi 400Hd D / Hd G

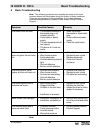

Hi 400hd d / hd g basic troubleshooting ghi_tx001466gb.Fm 61 8 basic troubleshooting note: the following symptoms and remedies are some of the more common issues that have arisen during the history of these machines. These do not represent all the possibilities. If you need advanced troubleshooting ...

Page 62: Technical Data

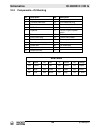

Technical data hi 400hd d / hd g 62 ghi_td000402gb.Fm 9 technical data 9.1 machine model hi 400hd d hi 400hd g units heat input btu/hr 412,682 354,610 heat output btu/hr 341,288 293,617 air flow cfm 3760 3821 fuel consumption l (gal)/hr 11.2 (2.97) — fuel consumption —natural gas —liquid propane (lp...

Page 63: Hi 400Hd D / Hd G

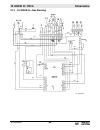

Hi 400hd d / hd g schematics ghi_tx001467gb.Fm 63 10 schematics 10.1 hi 400hd d—oil burning 9 4 10 8 17 23 19 18 6 3 13 20 22 5 12 14 15 1 7 21 5 2 11 1 wh bk bk rd rd rd br bk bk bk bk bu bk wh wh wh bk bk bk bk bk bu rd rd rd rd br br bk bk bk bn bu wh bk wh wh wh wh wh wh wh wh wh wh bu wc_gr0073...

Page 64: Schematics

Schematics hi 400hd d / hd g 64 ghi_tx001467gb.Fm 10.2 components—oil burning no. Description no. Description 1 fuse 13 burner motor 2 overheat thermostat 14 pre-heated filter plug 3 solenoid valve 15 summer/ winter switch 4 cad cell 16 overheat safety thermostat 5 capacitor 17 low fire / high fire ...

Page 65: Hi 400Hd D / Hd G

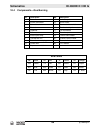

Hi 400hd d / hd g schematics ghi_tx001467gb.Fm 65 10.3 hi 400hd g—gas burning ghi_gr007400 wc_gr007400 15 9 12 10 8 18 19 20 21 3 6 13 16 17 4 1 7 11 5 5 5 2 1 wh wh wh bk bk bk rd bk rd rd rd wh bk bk bk bk bk bk rd rd bn wh wh wh wh wh bk bk bk bk bk wh wh bk bk bk yl/gn wh wh bk bk bk wh bk wh wh.

Page 66: Schematics

Schematics hi 400hd d / hd g 66 ghi_tx001467gb.Fm 10.4 components—gas burning no. Description no. Description 1 fuse 12 ionization probe 2 burner thermostat 13 burner motor 3 solenoid valve 15 summer/ winter switch 4 gas train 16 overheat safety thermostat 5 capacitor 17 fan thermostat 6 fan motor 1...

Page 68

Wacker neuson se · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02-0 · fax: +49 - (0)89-3 54 02-390 wacker neuson corporation · n92w15000 anthony ave. · menomonee falls, wi 53051 · tel. : (262) 255-0500 · fax: (262) 255-0550 ·tel. : (800) 770-0957 wacker neuson limited - room 1701–03 & ...