- DL manuals

- Wacker Neuson

- Lighting Equipment

- LTN 6L

- Operator's Manual

Wacker Neuson LTN 6L Operator's Manual

Summary of LTN 6L

Page 1

0171883en 007 1110 0 1 7 1 8 8 3 e n operator’s manual light tower ltn 6l 60 hz.

Page 2

Copyright notice © copyright 2010 by wacker neuson corporation. All rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permission from wack...

Page 3: Table of Contents

Wc_bo0171883en_007toc.Fm 3 table of contents ltn 6l foreword 7 1 safety information 9 1.1 signal words used in this manual ....................................................... 9 1.2 machine description and intended use ............................................. 10 1.3 safety guidelines for ope...

Page 4: Table of Contents

4 wc_bo0171883en_007toc.Fm table of contents ltn 6l 4.15 automatic shutdown ...........................................................................47 4.16 operating lights ..................................................................................48 4.17 stopping ............................

Page 5: Table of Contents

Wc_bo0171883en_007toc.Fm 5 table of contents ltn 6l 9 appendix i—assembly instructions 68 9.1 introduction ......................................................................................... 68 10 appendix ii—assembly safety 70 10.1 signal words found in this manual ..............................

Page 6: Table of Contents

6 wc_bo0171883en_007toc.Fm table of contents ltn 6l 13.11 installing the lights ..............................................................................94 13.12 connecting the wiring at the junction box .........................................95 13.13 routing the coil cord ......................

Page 7: Ltn 6L

Ltn 6l foreword wc_tx001571gb.Fm 7 foreword machines covered in this manual machine documentation keep a copy of the operator’s manual with the machine at all times. Use the separate parts book supplied with the machine to order replacement parts. Refer to the separate repair manual for detailed ins...

Page 8: Foreword

Foreword ltn 6l 8 wc_tx001571gb.Fm unapproved parts, attachments, and modifications are those that do not meet the approved criteria. Unapproved parts, attachments, or modifications may have the following conse- quences: serious injury hazards to the operator and persons in the work area permanent d...

Page 9: Ltn 6L

Ltn 6l safety information wc_si000227gb.Fm 9 1 safety information 1.1 signal words used in this manual this manual contains danger, warning, caution, notice, and note signal words which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. Notic...

Page 10: Safety Information

Safety information ltn 6l 10 wc_si000227gb.Fm 1.2 machine description and intended use this machine is a mobile, trailer-mounted light tower. The wacker neuson light tower consists of a trailer with a cabinet containing a diesel engine, a fuel tank, a control panel, and an electric alternator. A tel...

Page 11: Ltn 6L

Ltn 6l safety information wc_si000227gb.Fm 11 • heat, noise, exhaust, and carbon monoxide from the engine • heat from the lights • ultraviolet radiation from the lights • fire hazards from improper refueling techniques • fuel and its fumes • electric shock and arc flash • personal injury from improp...

Page 12: Safety Information

Safety information ltn 6l 12 wc_si000227gb.Fm 1.3.1 do not remove, defeat, deface, or render inoperable any of the safety devices, warnings, or labels on this equipment. If any safety devices, warnings, or labels have been removed, defeated, defaced, or rendered inoperable, do not use this equipment...

Page 13: Ltn 6L

Ltn 6l safety information wc_si000227gb.Fm 13 1.4 operator safety while using internal combustion engines operating safety when running the engine: • keep the area around exhaust pipe free of flammable materials. • check the fuel lines and the fuel tank for leaks and cracks before starting the engin...

Page 14: Safety Information

Safety information ltn 6l 14 wc_si000227gb.Fm 1.5 lamp safety description the lamps provided with your light tower are electric discharge lamps. They are designed for use with metal halide ballasts only, and require time to reach full brightness on initial startup and after a power interruption. The...

Page 15: Ltn 6L

Ltn 6l safety information wc_si000227gb.Fm 15 1.6.1 always replace the safety devices and guards after repairs and maintenance. 1.6.2 before servicing the light tower, make sure the engine start switch is turned to the off position, the circuit breakers are open (off), and the negative terminal on b...

Page 16: Labels

Labels ltn 6l 16 wc_si000381gb.Fm 2 labels 2.1 label locations wc_gr007036 b h d i g p o x j k z q s r t cc bb bb aa aa ee c a e v.

Page 17: Ltn 6L

Ltn 6l labels wc_si000381gb.Fm 17 wc_gr007037 r s u v l h f b n j m d y ff aa aa dd bb gg ee cc bb hh jj.

Page 18: Labels

Labels ltn 6l 18 wc_si000381gb.Fm 2.2 label meanings wacker neuson machines use international pictorial labels where needed. These labels are described below. A warning automatic locking pin. A non-secured, falling tower can cause serious injury or death if a person is hit. To secure tower, verify a...

Page 19: Ltn 6L

Ltn 6l labels wc_si000381gb.Fm 19 d notice lifting point. E warning! Secure tower in transport lock before lifting or towing. A loose swinging tower could cause per- sonal injury or machine damage. F danger! No sparks, flames, or burning objects near machine. Stop the engine before adding fuel. Use ...

Page 20: Labels

Labels ltn 6l 20 wc_si000381gb.Fm h warning! Electric shock and arc flash can cause serious injury or death. Electrical storage device within. Contact a qualified electrician for service or to open electrical box. I warning! Read and understand the supplied operator’s manual before operating the mac...

Page 21: Ltn 6L

Ltn 6l labels wc_si000381gb.Fm 21 m a nameplate listing the model number, item num- ber, revision number, and serial number is attached to each unit. Please record the informa- tion found on this nameplate so it will be available should the nameplate become lost or damaged. When ordering parts or re...

Page 22: Labels

Labels ltn 6l 22 wc_si000381gb.Fm o see operator’s manual for metal halide lamp information and troubleshooting. Before starting engine check levels of: engine oil fuel coolant circuit breakers off start engine engine control panel auto heating preheat light out start, 15 sec. Max. Circuit breakers ...

Page 23: Ltn 6L

Ltn 6l labels wc_si000381gb.Fm 23 p see operator’s manual for metal halide lamp information and troubleshooting. Before starting engine check levels of: engine oil fuel coolant circuit breakers off start engine engine control switch preheat (30 sec.) start, 15 sec. Max. Circuit breakers on shut down...

Page 24: Labels

Labels ltn 6l 24 wc_si000381gb.Fm q manual winch system to raise tower: 1. Release transport lock. 2. Tilt tower using winch. 3. Tilt tower until automatic locking pin snaps into place. To increase height of tower: 4. Raise tower using winch. To aim lights: 5. Rotate tower and tighten knob..

Page 25: Ltn 6L

Ltn 6l labels wc_si000381gb.Fm 25 r manual winch system to lower tower: 1. Turn off all lights and engine. 2. Rotate tower and tighten knob. 3. Lower tower using winch. To tilt tower for transport: 4. Release and hold spring-loaded pin. 5. Tilt tower using winch. To secure tower for transport: 6. In...

Page 26: Labels

Labels ltn 6l 26 wc_si000381gb.Fm s power winch system to raise tower: 1. Release transport lock. 2. Tilt tower using winch. 3. Tilt tower until automatic locking pin snaps into place. To increase height of tower: 4. Raise tower using winch. To aim lights: 5. Rotate tower and tighten knob..

Page 27: Ltn 6L

Ltn 6l labels wc_si000381gb.Fm 27 t power winch system to lower tower: 1. Turn off all lights and engine. 2. Rotate tower and tighten knob. 3. Lower tower using winch. To tilt tower for transport: 4. Release and hold spring-loaded pin. 5. Tilt tower using winch. To secure tower for transport: 6. Ins...

Page 28: Labels

Labels ltn 6l 28 wc_si000381gb.Fm x guaranteed sound power level in db(a). Y read operator’s manual. Use hitch rated from trailer’s “gross vehicle weight rating”. Securely attach trailer to tow vehicle. Attach safety chains using cross pattern. Attach breakdown chain to vehicle. Check trailer lights...

Page 29: Ltn 6L

Ltn 6l labels wc_si000381gb.Fm 29 dd transport position of the jack ee tie-down point. Ff low sulfur fuel or ultra low sulfur fuel only. Gg this machine may be covered by one or more patents. Jj kk danger using a light tower indoors can kill you in minutes. Light tower exhaust contains carbon monoxi...

Page 30: Lifting The Machine

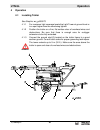

Lifting the machine ltn 6l 30 wc_tx001375gb.Fm 3 lifting the machine 3.1 procedure see graphic: wc_gr005415 3.1.1 check that the tower cradle lock pin (a) is in place and secured with the safety pin. 3.1.2 ensure that the tower is completely nested inside the transport cradle and the pin (b) is secu...

Page 31: Ltn 6L

Ltn 6l operation wc_tx000766gb.Fm 31 4 operation 4.1 locating trailer see graphic: wc_gr005073 4.1.1 for maximum light coverage locate the light tower at ground level or in a spot higher than the area being lighted. 4.1.2 position the trailer on a firm, flat surface clear of overhead wires and obstr...

Page 32: Operation

Operation ltn 6l 32 wc_tx000766gb.Fm 4.2 leveling trailer see graphic: wc_gr005073, wc_gr005074 the trailer must be leveled and the outriggers extended before raising the tower. The outriggers must remain extended while the tower is up. Failure to level the trailer or extend the outriggers will seve...

Page 33: Ltn 6L

Ltn 6l operation wc_tx000766gb.Fm 33 4.3 adjusting lights see graphic: wc_gr005074 each light fixture can be aimed up, down, left or right. Position each fixture by loosening toolless light adjusters (g) and aiming the light up or down. Do not loosen the inside nut (x). Loosening this nut could caus...

Page 34: Operation

Operation ltn 6l 34 wc_tx000766gb.Fm 4.4 preparing trailer for towing or lifting see graphic: wc_gr005073, wc_gr005074 4.4.1 check that the tower cradle lock pin (j) is in place and secured with the safety pin. 4.4.2 ensure that the tower is completely nested inside the transport cradle and the pin ...

Page 35: Ltn 6L

Ltn 6l operation wc_tx000766gb.Fm 35 4.5 raising tower (manual winch system) see graphic: wc_gr005075 never raise the tower or operate the light tower in high winds. Never raise the tower while the engine is running. Do not move the light tower while it is operating. High voltage! Do not use the lig...

Page 36: Operation

Operation ltn 6l 36 wc_tx000766gb.Fm 4.5.4 continue to rotate the winch handle and raise the tower to the vertical position until the vertical tower locking pin (p) locks the tower in place. Be certain the vertical tower locking pin is fully engaged in the locking position before raising the tower. ...

Page 37: Ltn 6L

Ltn 6l operation wc_tx000766gb.Fm 37 o.

Page 38: Operation

Operation ltn 6l 38 wc_tx000766gb.Fm 4.6 lowering tower (manual winch system) see graphic: wc_gr005075 be sure to read and understand the operating instructions before lowering the tower! If for any reason a part of the tower hangs up or a winch cable develops slack before tower is fully lowered, st...

Page 39: Ltn 6L

Ltn 6l operation wc_tx000766gb.Fm 39 4.6.4 pull and hold the tower locking pin (p). Rotate the handle on the tilt winch (o) counterclockwise (“cable out” direction) until the tower spring begins to pivot the tower down. Release the tower locking pin and continue to rotate the handle until the tower ...

Page 40: Operation

Operation ltn 6l 40 wc_tx000766gb.Fm 4.7 raising tower (power winch system) see graphic: wc_gr005076 always observe the tower while raising and lowering the tower. Never raise the tower or operate the light tower in high winds. Never raise the tower while the engine is running. Do not move the light...

Page 41: Ltn 6L

Ltn 6l operation wc_tx000766gb.Fm 41 4.7.5 after the tower is in the vertical position, check the operation of the telescoping winch (q). Turn the telescope rotary switch on the control panel to the up position. Do not attempt to raise the tower if the winch is damaged or not operating properly. Con...

Page 42: Operation

Operation ltn 6l 42 wc_tx000766gb.Fm 4.8 lowering tower (power winch system) see graphic: wc_gr005076 always observe the tower while raising and lowering the tower. Be sure you read and understand the operating instructions before lowering the tower! If for any reason any part of the tower hangs up ...

Page 43: Ltn 6L

Ltn 6l operation wc_tx000766gb.Fm 43 4.8.4 pull and hold the tower locking pin (p). Turn and hold the vertical rotary switch (v) on the control panel in the down position until the tower is resting in the transport cradle. Be sure that the secondary locking pin (t) penetrates all sections of the tow...

Page 44: Operation

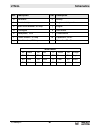

Operation ltn 6l 44 wc_tx000766gb.Fm 4.10 control panels (manual winch system) floodlight control panel engine control panel ref. Description ref. Description a 50 amp circuit breaker k high coolant temperature shutdown b 30 amp lights circuit breaker l alternator indicator c 20 amp gfi circuit brea...

Page 45: Ltn 6L

Ltn 6l operation wc_tx000766gb.Fm 45 4.11 control panels (120/240, manual winch system) floodlight control panel engine control panel ref. Description ref. Description a 25 amp circuit breaker k high coolant temperature shutdown b 30 amp lights circuit breaker l alternator indicator c 20 amp gfi cir...

Page 46: Operation

Operation ltn 6l 46 wc_tx000766gb.Fm 4.12 control panels (power winch system) floodlight control panel engine control panel ref. Description ref. Description a 50 amp circuit breaker l alternator indicator b 30 amp lights circuit breaker m auxiliary light (not used) c 20 amp gfi circuit breaker n gl...

Page 47: Ltn 6L

Ltn 6l operation wc_tx000766gb.Fm 47 4.13 starting see graphic: wc_gr005140, wc_gr006328, wc_gr005141, wc_gr005142 4.13.1 check engine oil, fuel and coolant levels. Note: if fuel tank was drained or run dry it may be necessary to bleed fuel lines. Refer to engine operator’s manual. 4.13.2 check cond...

Page 48: Operation

Operation ltn 6l 48 wc_tx000766gb.Fm 4.16 operating lights see graphic: wc_gr005140, wc_gr006328, wc_gr005141, wc_gr005142 turn on the main circuit breaker (a) first, then turn on each light circuit breaker (b), one at a time. Metal halide floodlights require a warm-up time of 5–15 minutes before th...

Page 49: Ltn 6L

Ltn 6l operation wc_tx000766gb.Fm 49 4.19 receptacle see graphic: wc_gr005140, wc_gr006328, wc_gr005141 the control panel is equipped with a convenience receptacle for running accessories and tools from the generator. Power to this receptacle is available any time the engine is running and the circu...

Page 50: Factory Installed Options

Factory installed options ltn 50 wc_tx001650gb.Fm 5 factory installed options this machine may be equipped with one or more of the following factory-installed options. To verify if any of these options are installed on your machine, contact wacker neuson corporation at 1-800-770-0957. A nameplate li...

Page 51: Ltn

Ltn factory installed options wc_tx001650gb.Fm 51 5.2 battery blanket an electrically powered blanket (a) warms the battery while the machine is not in use. The blanket eliminates engine starting difficulties caused by a cold, frozen, or discharged battery. Plug the cord into a 120v power supply. 5....

Page 52: Maintenance

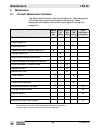

Maintenance ltn 6l 52 wc_tx000767gb.Fm 6 maintenance 6.1 periodic maintenance schedule the table below lists basic machine maintenance. Tasks designated with check marks may be performed by the operator. Tasks designated with square bullet points require special training and equipment. Before each u...

Page 53: Ltn 6L

Ltn 6l maintenance wc_tx000767gb.Fm 53 6.2 installing / removing light fixtures see graphic: wc_gr005376 always turn off light circuit breakers and shut down engine before disconnecting light fixtures or changing lamps. Remove fixtures by disconnecting electrical cords at the junction box (b). Remov...

Page 54: Maintenance

Maintenance ltn 6l 54 wc_tx000767gb.Fm 6.3 replacing / removing lamps prerequisites • engine shut down • light circuit breakers turned off • lamps and fixtures cool to the touch • eye protection and gloves follow the procedures below to remove and install the lamp. Removing the lamp 6.3.1 remove the...

Page 55: Ltn 6L

Ltn 6l maintenance wc_tx000767gb.Fm 55 6.3.2 remove the lens (c) with the gasket (d) attached. 6.3.3 remove the hardware securing one side of the lamp stabilizer (e). Once removed, swing the lamp stabilizer to the side and unscrew the lamp (f). Installing the lamp 6.3.4 screw the lamp in firmly, but...

Page 56: Maintenance

Maintenance ltn 6l 56 wc_tx000767gb.Fm 6.5 air cleaner see graphic: wc_gr000540 replace the air filter cartridge when the indicatormounted on the control panel illuminates. 6.5.1 open air cleaner and remove element. 6.5.2 to clean the filter, lightly tap on a hard surface to eliminate all excess dir...

Page 57: Ltn 6L

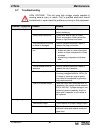

Ltn 6l maintenance wc_tx000767gb.Fm 57 6.7 troubleshooting high voltage! This unit uses high voltage circuits capable of causing serious injury or death. Only a qualified electrician should troubleshoot or repair electrical problems occurring in this equipment. Problem / symptom reason remedy lamp w...

Page 58: Technical Data

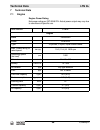

Technical data ltn 6l 58 wc_td000230gb.Fm 7 technical data 7.1 engine engine power rating net power rating per iso 3046 ifn. Actual power output may vary due to conditions of specific use. Item number: ltn 6l engine make lombardini model ldw1003 type 3-cylinder, 4-cycle, liquid-cooled diesel max. Po...

Page 59: Ltn 6L

Ltn 6l technical data wc_td000230gb.Fm 59 7.2 generator 7.3 machine item number: ltn 6l 0620297 0620117 0620550 0620553 0620554 0620561 ltn 6l 0620727 generator frequency hz 60 ± 2 continuous output kw 6.0 output volts/ phase 120, 1Ø 120/240, 1Ø amps a 50 excitation type capacitor / brushless power ...

Page 60: Schematics

Schematics ltn 6l 60 wc_tx000936gb.Fm 8 schematics 8.1 electrical schematic 14 bk/or14 b k /o r 1 bk 8 awg1 b k 8 a w g 8 wh 10 awg8 w h 1 0 a w g 9 wh 10 awg9 w h 1 0 a w g 2 2 4 4 1 1 3 3 gn/yl 12 awgg n /y l 12 a w g control panelc o n t r o l p a n e l ground g r o u n d 12 gn/yl12 g n /y l 12 a...

Page 61: Ltn 6L

Ltn 6l schematics wc_tx000936gb.Fm 61 ref. Description ref. Description a generator h battery b terminal strip i engine control panel c main circuit breaker, 50 amp j engine d floodlights k hour meter e receptacle, 120v l transformers f circuit breaker, 30 amp m capacitors, 24 mf g circuit breaker, ...

Page 62: Schematics

Schematics ltn 6l 62 wc_tx000936gb.Fm 8.2 electrical schematic (120/240) dd dd dd dd mm ll kk mm ll mm ll mm ll bb ee oo gg cc ff ff hh nn aa jj ii bb bb wc_gr006324 14 bk/or1 4 b k /o r 1 bk 10 awg1 b k 1 0 a w g 8 wh 10 awg8 w h 1 0 a w g 9 wh 10 awg9 w h 1 0 a w g 2 2 4 4 3 3 1 gn/yl 12 awg1 g n ...

Page 63: Ltn 6L

Ltn 6l schematics wc_tx000936gb.Fm 63 ref. Description ref. Description a generator i engine control panel b terminal strip j engine c main circuit breaker, 25 amp k hour meter d floodlights l transformers e receptacle, 120v m capacitors, 24 mf f circuit breaker, 30 amp n capacitor, 25 mf g circuit ...

Page 64: Schematics

Schematics ltn 6l 64 wc_tx000936gb.Fm 8.3 trailer wiring ref. Description ref. Description a right stop, turn and tail light d side light, red b left stop, turn and tail light e license plate light c side light, amber wire colors bk black rd red yl yellow or orange gn green tn tan br brown pu purple...

Page 65: Ltn 6L

Ltn 6l schematics wc_tx000936gb.Fm 65 8.4 engine wiring - lombardini ref. Description ref. Description 1 fuel solenoid 7 air filter restriction indicator (normal open type) 2 glow plugs 8 low fuel level switch (not used, normal open type) 3 starter motor 9 low oil pressure switch (normal closed type...

Page 66: Schematics

Schematics ltn 6l 66 wc_tx000936gb.Fm 8.5 control panel wiring ref. Description ref. Description 1 system fuse, 50 amp 4 key switch 2 glow plug load relay 5 l.E.D. Indicator lamp assembly 3 auxiliary terminals (rear view) l b l w/r or b pr r gr w l p br y/g g b w b br y/g r r 86 85 30 87 4 2 7 6 5 1...

Page 67: Ltn 6L

Ltn 6l schematics wc_tx000936gb.Fm 67 8.6 power winch schematic ref. Description ref. Description a engine e telescope switch b battery f tilt winch c 70a blade fuse g telescope winch d tilt switch 6 bk 6 bk 5 rd 5 rd a a c c d d e e g g ff b b -- ++ b1 b1 a1 a1 8 bk 8 bk a2 a2 7 rd 7 rd 1 bk 1 bk b...

Page 68: Ltn

Appendix i—assembly instructions ltn 68 wc_tx001218gb.Fm 9 appendix i—assembly instructions 9.1 introduction scope this manual contains assembly procedures for racked and palletized versions of wacker neuson narrow-body light towers (ltn). There are separate chapters for each version of the machine....

Page 69: Ltn

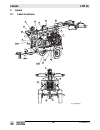

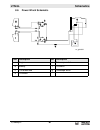

Ltn appendix i—assembly instructions wc_tx001218gb.Fm 69 illustrations d wc_gr006517.

Page 70: Ltn

Appendix ii—assembly safety ltn 70 wc_si000344gb.Fm 10 appendix ii—assembly safety 10.1 signal words found in this manual notice: used without the safety alert symbol, notice indicates a situation which, if not avoided, could result in property damage. Note: a note contains additional information im...

Page 71: Ltn

Ltn appendix ii—assembly safety wc_si000344gb.Fm 71 10.2 lifting safety overview some of the assembly procedures in this manual require the machine to be lifted or supported by slings, chains, hooks, ramps, jacks, or other types of mechanical devices. Follow the guidelines below to avoid personal in...

Page 72: Ltn

Appendix iii—standard pallet assembly ltn 72 wc_tx001214gb.Fm 11 appendix iii—standard pallet assembly scope this set of assembly instructions applies to standard machines shipped on a pallet as shown below. If your machine does not look like the one shown in the illustration, refer to machine ident...

Page 73: Ltn

Ltn appendix iii—standard pallet assembly wc_tx001214gb.Fm 73 11.1 installing the outriggers and outrigger jacks installing the outriggers follow the procedure below to install the two outriggers. (use the same procedure for each side of the light tower.) 1. Locate the locking pin (a) at the outrigg...

Page 74: Ltn

Appendix iii—standard pallet assembly ltn 74 wc_tx001214gb.Fm 11.2 installing the rear jack procedure follow the procedure below to install the rear jack. 1. Locate the 5000 lb.10-inch side crank jack (d). 2. If necessary, remove the locking pin (d4) from the holes in the jack. 3. Fit the socket (d1...

Page 75: Ltn

Ltn appendix iii—standard pallet assembly wc_tx001214gb.Fm 75 11.3 installing the tongue assembly scope installing the tongue assembly consists of installing the tongue and the tongue jack, and connecting the trailer wiring. Installing the tongue follow the procedure below to install the tongue. 1. ...

Page 76: Ltn

Appendix iii—standard pallet assembly ltn 76 wc_tx001214gb.Fm installing the tongue jack follow the procedure below to install the tongue jack. 1. Locate the 2000 lb. 10-inch travel jack (“tongue jack”) (j). 2. If necessary, remove the locking pin (j3) from the holes in the tongue jack. 3. Fit the s...

Page 77: Ltn

Ltn appendix iii—standard pallet assembly wc_tx001214gb.Fm 77 11.4 installing the upper light fixtures materials needed light fixtures (2) hardware bag 6 (tower lights hardware) procedure follow the procedure below to install the upper light fixtures. Install the two upper light fixtures (cc) on the...

Page 78: Ltn

Appendix iii—standard pallet assembly ltn 78 wc_tx001214gb.Fm 11.5 conclusion this completes the assembly procedure for your light tower. Refer to your operator’s manual for instructions on setting up, operating, maintaining, and storing the machine. Notes:.

Page 79: Ltn

Ltn appendix iv—ce pallet assembly wc_tx001215gb.Fm 79 12 appendix iv—ce pallet assembly overview this set of assembly instructions applies to ce machines shipped on a pallet as shown below. A palletized ce machine is intended to be mounted on a trailer that meets local regulations. This manual does...

Page 80: Ltn

Appendix iv—ce pallet assembly ltn 80 wc_tx001215gb.Fm 12.1 installing the side jacks procedure follow the procedure below to attach the two side jacks. (use the same procedure for each side jack.) 1. Locate the two 15-inch travel jacks (c). 2. If necessary, remove the locking pin (c3) from the hole...

Page 81: Ltn

Ltn appendix iv—ce pallet assembly wc_tx001215gb.Fm 81 12.2 installing the rear jack procedure follow the procedure below to install the rear jack. 1. Locate the 5000 lb.10-inch side crank jack (d). 2. If necessary, remove the locking pin (d4) from the holes in the jack. 3. Fit the socket (d1) over ...

Page 82: Ltn

Appendix iv—ce pallet assembly ltn 82 wc_tx001215gb.Fm 12.3 conclusion this completes the assembly procedure for your light tower. Refer to your operator’s manual for instructions on setting up, operating, maintaining, and storing the machine. Notes:.

Page 83: Ltn

Ltn appendix v—standard racked assembly wc_tx001216gb.Fm 83 13 appendix v—standard racked assembly overview this set of assembly instructions applies to standard machines shipped on a container rack as shown below. If your machine does not look like the one shown in the illustration, refer to machin...

Page 84: Ltn

Appendix v—standard racked assembly ltn 84 wc_tx001216gb.Fm tools and materials the following tools and materials are needed: basic hand tools (wrenches, screwdrivers, etc.) torque wrench hardware bags: 1, 2, 3, 4, 5, 6, 8, and fabricated parts 13.1 installing the axle procedure follow the procedure...

Page 85: Ltn

Ltn appendix v—standard racked assembly wc_tx001216gb.Fm 85 13.2 installing the fenders procedure follow the procedure below to install the fenders. 1. Locate the two fenders (w) and hardware bag 2. 2. Align each fender as shown in the illustration. 3. Install each fender on the light tower using (3...

Page 86: Ltn

Appendix v—standard racked assembly ltn 86 wc_tx001216gb.Fm 13.4 installing the outriggers and outrigger jacks installing the outriggers follow the procedure below to install the two outriggers. (use the same procedure for each side of the light tower.) 1. Locate the locking pin (a) at the outrigger...

Page 87: Ltn

Ltn appendix v—standard racked assembly wc_tx001216gb.Fm 87 13.5 installing the rear jack procedure follow the procedure below to install the rear jack. 1. Locate the 5000 lb.10-inch side crank jack (d). 2. If necessary, remove the locking pin (d4) from the holes in the jack. 3. Fit the socket (d1) ...

Page 88: Ltn

Appendix v—standard racked assembly ltn 88 wc_tx001216gb.Fm 13.6 installing the tongue assembly scope installing the tongue assembly consists of installing the tongue and the tongue jack, and connecting the trailer wiring. Installing the tongue follow the procedure below to install the tongue. 1. In...

Page 89: Ltn

Ltn appendix v—standard racked assembly wc_tx001216gb.Fm 89 installing the tongue jack follow the procedure below to install the tongue jack. 1. Locate the 2000 lb. 10-inch travel jack (“tongue jack”) (j). 2. If necessary, remove the locking pin (j3) from the holes in the tongue jack. 3. Fit the soc...

Page 90: Ltn

Appendix v—standard racked assembly ltn 90 wc_tx001216gb.Fm 13.7 installing the tower lock bracket procedure follow the procedure below to install the tower lock bracket. 1. Locate the following in hardware bag 5: (1) tower lock bracket (m) (3) m8 x 20 hex head mounting screws (n) (3) m8 flat washer...

Page 91: Ltn

Ltn appendix v—standard racked assembly wc_tx001216gb.Fm 91 13.8 installing the tower cradle materials needed tower cradle hardware bag 4 (tower cradle hardware) procedure follow the procedure below to assemble the tower cradle (y). 1. Using (4) m10 x 16 serrated flange screws (y1), install the towe...

Page 92: Ltn

Appendix v—standard racked assembly ltn 92 wc_tx001216gb.Fm 13.9 installing the tower materials needed tower assembly hardware bag 8 (tower install assembly) installing the tower follow the procedure below to install the tower. 1. Align the tower assembly (z) on top of the light tower enclosure as s...

Page 93: Ltn

Ltn appendix v—standard racked assembly wc_tx001216gb.Fm 93 13.10 installing the tower pivot cable materials needed tower pivot cable (aa8) hardware bag 8 (tower install assembly) installing the tower follow the procedure below to install the tower pivot cable. 1. One end of the tower pivot cable ha...

Page 94: Ltn

Appendix v—standard racked assembly ltn 94 wc_tx001216gb.Fm 13.11 installing the lights materials needed light fixtures (4) hardware bag 6 (tower lights hardware) procedure follow the procedure below to install the lights. 1. Install the light mount tube (bb) on the tower using (2) m16 x 90 screws (...

Page 95: Ltn

Ltn appendix v—standard racked assembly wc_tx001216gb.Fm 95 13.12 connecting the wiring at the junction box special tools and materials needed coil cord (gg) panduit® crimper ct-100 panduit® crimper ct-1550 hardware bag 6 procedure follow the procedure below to connect the wiring at the junction box...

Page 96: Ltn

Appendix v—standard racked assembly ltn 96 wc_tx001216gb.Fm connecting the wires 6. Refer to the table below and connect the light fixture wires to the coil cord wires. Use the small connectors and panduit wire crimper ct-100. 7. Connect the green wires from the fixture cords and coil cord, along wi...

Page 97: Ltn

Ltn appendix v—standard racked assembly wc_tx001216gb.Fm 97 13.13 routing the coil cord procedure follow the procedure below to route the coil cord. 1. At the base of the tower, wrap the coil cord around the tower twice, creating loops of about 25 cm (10 in.) in diameter. 2. Loosen the connector (cn...

Page 98: Ltn

Appendix v—standard racked assembly ltn 98 wc_tx001216gb.Fm 13.14 wiring the ballasts and terminal strips procedure follow the procedure below to wire the ballasts and terminal strips. 1. Remove the two ballast covers (bc) from the left and right sides of the light tower. 2. Connect the green wire f...

Page 99: Ltn

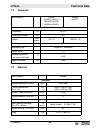

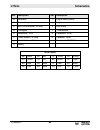

Ltn appendix v—standard racked assembly wc_tx001216gb.Fm 99 terminal strip “a” (right side of machine) terminal strip “b” (left side of machine) position wire description a–f not used g black / yellow from ballasts #1 and #2 h black (#7) from control box i yellows (2) from ballast #1 j yellows (2) f...

Page 100: Ltn

Appendix v—standard racked assembly ltn 100 wc_tx001216gb.Fm 13.15 conclusion this completes the assembly procedure for your light tower. Refer to your operator’s manual for instructions on setting up, operating, maintaining, and storing the machine. Notes:.

Page 101: Ltn Assembly

Ltn assembly appendix vi—ce racked assembly wc_tx001217gb.Fm 101 14 appendix vi—ce racked assembly overview this set of assembly instructions applies to ce machines shipped on a container rack as shown below. If your machine does not look like the one shown in the illustration, refer to machine iden...

Page 102: Ltn Assembly

Appendix vi—ce racked assembly ltn assembly wc_tx001217gb.Fm 102 tools and materials the following tools and materials are needed: basic hand tools (wrenches, screwdrivers, etc.) torque wrench hardware bags: 1, 2, 3, 4, 5, 6, 8, and fabricated parts.

Page 103: Ltn Assembly

Ltn assembly appendix vi—ce racked assembly wc_tx001217gb.Fm 103 14.1 attaching the outriggers and outrigger jacks installing the outriggers follow the procedure below to install the two outriggers. (use the same procedure for each side of the light tower.) 1. Locate the locking pin (a) at the outri...

Page 104: Ltn Assembly

Appendix vi—ce racked assembly ltn assembly wc_tx001217gb.Fm 104 14.2 attaching the rear jack procedure follow the procedure below to install the rear jack. 1. Locate the 5000 lb.10-inch side crank jack (d). 2. If necessary, remove the locking pin (d4) from the holes in the jack. 3. Fit the socket (...

Page 105: Ltn Assembly

Ltn assembly appendix vi—ce racked assembly wc_tx001217gb.Fm 105 14.3 attaching the tower lock bracket procedure follow the procedure below to install the tower lock bracket. 1. Locate the following in hardware bag 5: (1) tower lock bracket (m) (3) m8 x 20 hex head mounting screws (n) (3) m8 flat wa...

Page 106: Ltn Assembly

Appendix vi—ce racked assembly ltn assembly wc_tx001217gb.Fm 106 1. Using (4) m10 x 16 serrated flange screws (y1), install the tower cradle to the light tower upper frame. Torque the screws to 58 nm (42.8 ft.Lbs.) 2. Using (2) m6 x 20 serrated flange screws (y4), install the radiator access cover (...

Page 107: Ltn Assembly

Ltn assembly appendix vi—ce racked assembly wc_tx001217gb.Fm 107 1. Align the tower assembly (z) on top of the light tower enclosure as shown. 2. Place the tower assembly over the tower lock pin (y8) and secure it with the hitch pin. This will help to keep the tower in alignment for the next step. 3...

Page 108: Ltn Assembly

Appendix vi—ce racked assembly ltn assembly wc_tx001217gb.Fm 108 14.6 installing the tower pivot cable materials needed tower pivot cable (aa8) hardware bag 8 (tower install assembly) installing the tower follow the procedure below to install the tower pivot cable. 1. One end of the tower pivot cabl...

Page 109: Ltn Assembly

Ltn assembly appendix vi—ce racked assembly wc_tx001217gb.Fm 109 14.7 attaching the light mount bracket and light bar materials needed light mount bracket (hh) light bar (bb) hardware bag 6 (tower lights hardware) procedure follow the procedure below to attach the light mount bracket and light bar t...

Page 110: Ltn Assembly

Appendix vi—ce racked assembly ltn assembly wc_tx001217gb.Fm 110 14.8 attaching the lights materials needed light fixtures (4) hardware bag 6 (tower lights hardware) procedure follow the procedure below to attach the lights to the tower. Attach the four light fixtures (cc) to the light bar as follow...

Page 111: Ltn Assembly

Ltn assembly appendix vi—ce racked assembly wc_tx001217gb.Fm 111 14.9 wiring the junction box special tools and materials needed coil cord (gg) panduit® crimper ct-100 panduit® crimper ct-1550 hardware bag 6 procedure follow the procedure below to connect the wiring at the junction box. Installing t...

Page 112: Ltn Assembly

Appendix vi—ce racked assembly ltn assembly wc_tx001217gb.Fm 112 connecting the wires 6. Refer to the table below and connect the light fixture wires to the coil cord wires. Use the small connectors and panduit wire crimper ct-100. 7. Connect the green wires from the fixture cords and coil cord, alo...

Page 113: Ltn Assembly

Ltn assembly appendix vi—ce racked assembly wc_tx001217gb.Fm 113 14.10 routing the coil cord procedure follow the procedure below to route the coil cord. 1. At the base of the tower, wrap the coil cord around the tower twice, creating loops of about 25 cm (10 in.) in diameter. 2. Loosen the connecto...

Page 114: Ltn Assembly

Appendix vi—ce racked assembly ltn assembly wc_tx001217gb.Fm 114 14.11 wiring the ballasts and terminal strips procedure follow the procedure below to wire the ballasts and terminal strips. 1. Remove the two ballast covers (bc) from the left and right sides of the light tower. 2. Connect the green w...

Page 115: Ltn Assembly

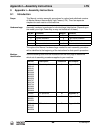

Ltn assembly appendix vi—ce racked assembly wc_tx001217gb.Fm 115 terminal strip “a” (right side of machine) terminal strip “b” (left side of machine) position wire description a–f not used g black / yellow from ballasts #1 and #2 h black (#7) from control box i yellows (2) from ballast #1 j yellows ...

Page 116: Ltn Assembly

Appendix vi—ce racked assembly ltn assembly wc_tx001217gb.Fm 116 result this completes the assembly procedure for your light tower. Refer to your operator’s manual for instructions on setting up, operating, maintaining, and storing the machine..

Page 118

Wacker neuson se · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02-0 · fax: +49 - (0)89-3 54 02-390 wacker neuson corporation · n92w15000 anthony ave. · menomonee falls, wi 53051 · tel. : (262) 255-0500 · fax: (262) 255-0550 ·tel. : (800) 770-0957 wacker neuson limited - room 1701–03 & ...