- DL manuals

- Wacker Neuson

- Water Pump

- PDI 3

- Repair Manual

Wacker Neuson PDI 3 Repair Manual

Summary of PDI 3

Page 1

Www.Wackergroup.Com pump pdt 2 pdi 2 pdt 3 pdi 3 repair manual 0163153en 001 0606 0 1 6 3 1 5 3 e n.

Page 3: Pd Repair

Pd repair foreword wc_tx000591gb.Fm i operating / parts information you must be familiar with the operation of this machine before you attempt to troubleshoot or repair it. Basic operating and maintenance procedures are described in the operator’s manual supplied with the machine. Keep a copy of the...

Page 4: Foreword

Foreword pd repair wc_tx000591gb.Fm ii california proposition 65 warning: engine exhaust, some of its constituents, and certain vehicle components, contain or emit chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. Laws pertaining to spark arrest...

Page 5: Pd 2/3

Pd 2/3 table of contents wc_br0163153001entoc.Fm 1 1. Safety information 3 1.1 operating safety .................................................................................. 4 1.2 operator safety while using internal combustion engines .................. 5 1.3 service safety ......................

Page 6: Table Of Contents

Table of contents pd 2/3 wc_br0163153001entoc.Fm 2 4.5 cleaning sediment cup—machines with honda engines ..................25 4.6 carburetor adjustment—machines with honda engines ....................25 4.7 servicing air cleaner—machines with honda engines .......................26 4.8 servicing air...

Page 7: Pd 2/3

Pd 2/3 safety information wc_si000176gb.Fm 3 1. Safety information this manual contains danger, warning, caution, and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is used to alert ...

Page 8: Safety Information

Safety information pd 2/3 wc_si000176gb.Fm 4 1.1 operating safety internal combustion engines present special hazards during operation and fueling. Read and follow the warning instructions in the engine owner’s manual and the safety guidelines below. Failure to follow the warnings and safety guideli...

Page 9: Pd 2/3

Pd 2/3 safety information wc_si000176gb.Fm 5 1.2 operator safety while using internal combustion engines poorly maintained equipment can become a safety hazard! In order for the equipment to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are neces...

Page 10: Safety Information

Safety information pd 2/3 wc_si000176gb.Fm 6 1.4 label locations do not operate without safety guards. Read and understand instruction book. Nicht ohne schutzvorrichtung betreiben. Bedienungsanweisung genau durchlesen. No opere sin los dispositivos de seguridad. Lea y entienda primero las instruccio...

Page 11: Pd 2/3

Pd 2/3 safety information wc_si000176gb.Fm 7 1.5 safety labels wacker machines use international pictorial labels where needed. These labels are described below: label meaning danger! Engines emit carbon monoxide; operate only in well-ventilated area. Read the operator’s manual. No sparks, flames, o...

Page 12: Safety Information

Safety information pd 2/3 wc_si000176gb.Fm 8 caution! Lifting point guaranteed sound power level in db(a) label meaning.

Page 13: Pd 2/3

Pd 2/3 safety information wc_si000176gb.Fm 9.

Page 14: Technical Data

Technical data pd wc_td000178gb.Fm 10 2. Technical data 2.1 engine—machines with honda engines item number: pdt/pdi 2a 0007610, 0007611 0007624, 0007625 pdt/pdi 3a 0007614, 0007615, 0007616, 0007628, 0007629, 0009407 engine engine make honda engine model gx 120 k1 qx rated power kw (hp) 3.0 (4.0) sp...

Page 15: Technical Data

Pd technical data wc_td000178gb.Fm 11 2.2 pump—machines with honda engines 2.3 sound measurements—machines with honda engines the required sound specification, paragraph 1.7.4.F of 89/392/eec machinery directive, is: • the guaranteed sound power level (l wa ) = 96 db(a). • the sound pressure level a...

Page 16: Technical Data

Technical data pd wc_td000178gb.Fm 12 2.4 dimensions—machines with honda engines mm (in.) w c _ g r 0 0 1 0 6 2 p d t 2 a / 3 a p d i 2 a / 3 a p d t 2 a - 6 3 5 ( 2 5 ) p d t 3 a - 7 5 0 ( 2 9 . 5 ) p d t 2 a - 1 0 1 5 ( 4 0 ) p d t 3 a - 1 0 1 5 ( 4 0 ) p d i 2 a - 4 4 5 ( 1 7 . 5 ) p d i 3 a - 4 ...

Page 17: Technical Data

Pd technical data wc_td000178gb.Fm 13 2.5 engine—machines with wacker engines item number: pdi/pdt 2 0009489, 0009494 pdi/pdt 3 0009491, 0009492, 0009495 engine engine make wacker engine model wm 130 displacement cm 3 (in 3 ) 126 (7.7) engine speed rpm 2800 max. Operating power kw (hp) 3.2 (4.3) spa...

Page 18: Technical Data

Technical data pd wc_td000178gb.Fm 14 2.6 pump—machines with wacker engines 2.7 sound measurements—machines with wacker engines the required sound specification, paragraph 1.7.4.F of 89/392/eec machinery directive, is: • the guaranteed sound power level (l wa ) = 96 db(a). • the sound pressure level...

Page 19: Pd 2A/3A

Pd 2a/3a operation wc_tx000592gb.Fm 15 3. Operation 3.1 application this pump is intended for removing clean water or water containing a large amount of debris and suspended solids. The model pd 2a can pump water containing solids up to 30 mm (1.25 in.) diameter. The model pd 3a can pump water conta...

Page 20: Operation

Operation pd 2a/3a wc_tx000592gb.Fm 16 3.3 priming pump see graphic: wc_gr001064 diaphragm pumps are self priming and seldom need to have water added to them before starting. However, if the pump has not been used for several weeks and the rubber valves inside it are dry, adding water through the su...

Page 21: Pd 2A/3A

Pd 2a/3a operation wc_tx000592gb.Fm 17 3.5 to start—machines with honda engines see graphic: wc_gr000014 3.5.1 open fuel valve by moving lever to the right (a1). Note: if engine is cold, move choke lever to close position (b1). If engine is hot, set choke to open position (b2). 3.5.2 turn engine swi...

Page 22: Operation

Operation pd 2a/3a wc_tx000592gb.Fm 18 3.7 to start—machines with wacker engines see graphic: wc_gr000655 3.7.1 open fuel valve by moving lever down (a1). Note: if engine is cold, move choke lever to close position (d2). If engine is hot, set choke to open position (d1). 3.7.2 turn engine switch to ...

Page 23: Pd 2A/3A

Pd 2a/3a operation wc_tx000592gb.Fm 19 3.9 operation run engine at full speed while operating pump. Pump should begin pumping water within a minute depending on length of suction hose and height of pump above water. Longer hoses will require more time. If pump does not prime, check for loose fitting...

Page 24: Operation

Operation pd 2a/3a wc_tx000592gb.Fm 20 3.11 hoses and clamps see graphic: wc_gr001065 suction hose suction hoses (a) must be rigid enough not to collapse when pump is operating. Discharge hose discharge hoses (b) are usually thin-walled collapsible hoses. Rigid hoses similar to those used as suction...

Page 25: Pd 2A/3A

Pd 2a/3a operation wc_tx000592gb.Fm 21.

Page 26: Maintenance

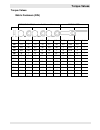

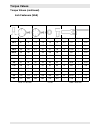

Maintenance pd wc_tx000593gb.Fm 22 4. Maintenance 4.1 periodic maintenance schedule the chart below lists basic machine and engine maintenance. Refer to the engine manufacturer’s operator’s manual for additional information on engine maintenance. Daily before starting after first 20 hrs. Every 2 wee...

Page 27: Maintenance

Pd maintenance wc_tx000593gb.Fm 23 4.2 changing engine oil—machines with honda engines see graphic: wc_gr000022 4.2.1 drain the oil while the engine is still warm. 4.2.2 remove the oil filler plug (a) and the drain plug (b) to drain the oil. Note: in the interests of environmental protection, place ...

Page 28: Maintenance

Maintenance pd wc_tx000593gb.Fm 24 4.3 changing engine oil—machines with wacker engines see graphic: wc_gr000087 4.3.1 drain oil while engine is still warm. Note: in the interests of environmental protection, place a plastic sheet and a container under the machine to collect any liquid which drains ...

Page 29: Maintenance

Pd maintenance wc_tx000593gb.Fm 25 4.5 cleaning sediment cup—machines with honda engines see graphic: wc_gr000029 4.5.1 turn the fuel valve off. 4.5.2 remove the sediment cup (a) and the o-ring (b). 4.5.3 wash both thoroughly in a nonflammable solvent. Dry and reinstall them. 4.5.4 turn the fuel val...

Page 30: Maintenance

Maintenance pd wc_tx000593gb.Fm 26 4.7 servicing air cleaner—machines with honda engines see graphic: wc_gr000025 the engine is equipped with a dual element air cleaner. Service air cleaner frequently to prevent carburetor malfunction. Caution: never run engine without air cleaner. Severe engine dam...

Page 31: Maintenance

Pd maintenance wc_tx000593gb.Fm 27 4.8 servicing air cleaner—machines with wacker engines see graphic: wc_gr000656 never use gasoline or other types of low flash point solvents for cleaning the air cleaner. A fire or explosion could result. Caution: never run engine without air cleaner. Severe engin...

Page 32: Maintenance

Maintenance pd wc_tx000593gb.Fm 28 4.9 spark plug see graphic: wc_gr000028 clean or replace the spark plug as needed to ensure proper operation. Refer to the engine owner’s manual. The muffler becomes very hot during operation and remains hot for a while after stopping the engine. Do not touch the m...

Page 33: Maintenance

Pd maintenance wc_tx000593gb.Fm 29 4.10 gear case see graphic: wc_gr003450 check the oil level in the gear case once a week or every 25 hours of operation. Remove oil level plug (h). Check that oil level is even with plug opening. If oil level is low, add oil through the top fill plug opening (g). D...

Page 34: Maintenance

Maintenance pd wc_tx000593gb.Fm 30 4.11 lubricating connecting rod bearing see graphic: wc_gr003451 grease connecting rod bearing once a week or every 25 hours of operation. Use a hand operated grease gun. Add grease through grease fitting located behind access hole (j) provided on front cover. 4.12...

Page 35: Maintenance

Pd maintenance wc_tx000593gb.Fm 31 4.13 storage if pump is being stored for more than 30 days: never open priming plug, discharge plug, or cover when pump is hot. 4.13.1 remove discharge plug from pump casing and drain out any water left in the housing after pump has cooled. 4.13.2 remove pump cover...

Page 36: Maintenance

Maintenance pd wc_tx000593gb.Fm 32 4.14 troubleshooting problem / symptom reason / remedy engine does not start. • engine problem. See engine manufacturer’s service manual for troubleshooting and repair. • engine oil level too low. Add oil to engine. • pump housing filled with dirt and debris. Disas...

Page 37: Pd Repair

Pd repair disassembly/assembly procedures wc_tx000590gb.Fm 33 5. Disassembly/assembly procedures 5.1 tools because all possible problems encountered while repairing the machine cannot be anticipated, it is up to the mechanic to use common sense and good judgement in tool selection. The use of any sp...

Page 38: Pd Repair

Disassembly/assembly procedures pd repair wc_tx000590gb.Fm 34 5.4 replacing the flapper valve see graphic: wc_gr003452 there are flapper valves located on both the inlet and the outlet sides of the pump. The procedure for replacing either flapper valve is the same. Removal: 5.4.1 turn off the engine...

Page 39: Pd Repair

Pd repair disassembly/assembly procedures wc_tx000590gb.Fm 35 wc_gr003452 a b c h d d e f f g g e h.

Page 40: Pd Repair

Disassembly/assembly procedures pd repair wc_tx000590gb.Fm 36 5.5 replacing the diaphragm see graphic: wc_gr003453 removal: 5.5.1 turn off the engine. 5.5.2 remove the connecting rod cover (a). 5.5.3 with the stop switch in the off position, slowly pull the starter rope until the crank arm (b) is in...

Page 41: Pd Repair

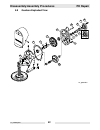

Pd repair disassembly/assembly procedures wc_tx000590gb.Fm 37 wc_gr003453 a c b d e h h f g h a b c d e.

Page 42: Pd Repair

Disassembly/assembly procedures pd repair wc_tx000590gb.Fm 38 5.6 replacing the connecting rod and bearing see graphic: wc_gr003459 this procedure requires an arbor or similar type press. Removal: 5.6.1 turn off the engine. 5.6.2 remove the connecting rod and diaphragm assembly. See section replacin...

Page 43: Pd Repair

Pd repair disassembly/assembly procedures wc_tx000590gb.Fm 39 wc_gr003459 a a c e c g e d f b b d.

Page 44: Pd Repair

Disassembly/assembly procedures pd repair wc_tx000590gb.Fm 40 5.7 replacing the engine see graphic: wc_gr003459 removal: 5.7.1 turn off the engine. 5.7.2 remove the drain plug (a) and drain the oil from the gearbox. 5.7.3 remove the screws (f) and lock washers that secure the engine adapter (b) to t...

Page 45: Pd Repair

Pd repair disassembly/assembly procedures wc_tx000590gb.Fm 41 wc_gr003460 a c f b e d a g g.

Page 46: Pd Repair

Disassembly/assembly procedures pd repair wc_tx000590gb.Fm 42 5.8 gearbox exploded view wc_gr003462 a g c d f e b j n k l m h i.

Page 47: Pd Repair

Pd repair disassembly/assembly procedures wc_tx000590gb.Fm 43 5.9 gearbox components ref. Description ref. Description a screw h seal b screw i needle bearing c gearbox cover j woodruff key d screw k internal gear e engine adapter l external gear f pinion gear m seal g retaining ring n gasket.

Page 48: Pd Repair

Disassembly/assembly procedures pd repair wc_tx000590gb.Fm 44 5.10 gearbox disassembly see graphic: wc_gr003461 and wc_gr003462 this procedure requires an arbor or similar type press. Disassembly: 5.10.1 remove the engine and drain the oil from the gearbox. See section replacing the engine. 5.10.2 r...

Page 49: Pd Repair

Pd repair disassembly/assembly procedures wc_tx000590gb.Fm 45 wc_gr003461 a c d e b b f h j k l m i n.

Page 50: Pd Repair

Disassembly/assembly procedures pd repair wc_tx000590gb.Fm 46 5.11 gearbox reassembly see graphic: wc_gr003462 and wc_gr003463 this procedure requires an arbor or similar type press. Reassembly: 5.11.1 lightly coat the seal (m) with grease and place it into the gearbox housing. 5.11.2 assemble the i...

Page 51: Pd Repair

Pd repair disassembly/assembly procedures wc_tx000590gb.Fm 47 wc_gr003463 a c d e b f h k k l m i n.

Page 52: Pd Repair

Disassembly/assembly procedures pd repair wc_tx000590gb.Fm 48 5.12 testing see graphic: wc_gr003464 and wc_gr003465 this procedure requires a vacuum gauge (pn 28755) and a tachometer. 5.12.1 check that the mounting hardware for the diaphragm and the valves is tight. 5.12.2 if the valves are dry, run...

Page 53: Pd Repair

Pd repair disassembly/assembly procedures wc_tx000590gb.Fm 49 wc_gr003465 wc_gr003464.

Page 54: Pd Repair

Disassembly/assembly procedures pd repair wc_tx000590gb.Fm 50

Page 55: Threadlockers and Sealants

Threadlockers and sealants threadlockers and sealants threadlocking adhesives and sealants are specified throughout this manual by a notation of “s” plus a number (s#) and should be used where indicated. Threadlocking compounds normally break down at temperatures above 175°c (350°f). If a screw or b...

Page 56: Threadlockers and Sealants

Threadlockers and sealants threadlockers and sealants (continued) threadlocking adhesives and sealants are specified throughout this manual by a notation of “s” plus a number (s#) and should be used where indicated. Threadlocking compounds normally break down at temperatures above 175°c (350°f). If ...

Page 57: Torque Values

Torque values torque values metric fasteners (din) torque values (based on bolt size and hardness) wrench size size nm ft.Lb. Nm ft.Lb. Nm ft.Lb. Metric inch metric inch m3 1.2 *11 1.6 *14 2.1 *19 5.5 7/32 2.5 – m4 2.9 *26 4.1 *36 4.9 *43 7 9/32 3 – m5 6.0 *53 8.5 6 10 7 8 5/16 4 – m6 10 7 14 10 17 ...

Page 58: Torque Values

Torque values torque values (continued) inch fasteners (sae) size nm ft.Lb. Nm ft.Lb. Nm ft.Lb. Metric inch metric inch no.4 0.7 *6 1.0 *14 1.4 *12 5.5 1/4 – 3/32 no.6 1.4 *12 1.9 *17 2.4 *21 8 5/16 – 7/64 no.8 2.5 *22 3.5 *31 4.7 *42 9 11/32 – 9/64 no.10 3.6 *32 5.1 *45 6.8 *60 – 3/8 – 5/32 1/4 8.1...

Page 60

Wacker construction equipment ag · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02 - 0 · fax: +49 - (0)89-3 54 02-3 90 wacker corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker asia pacific operations...